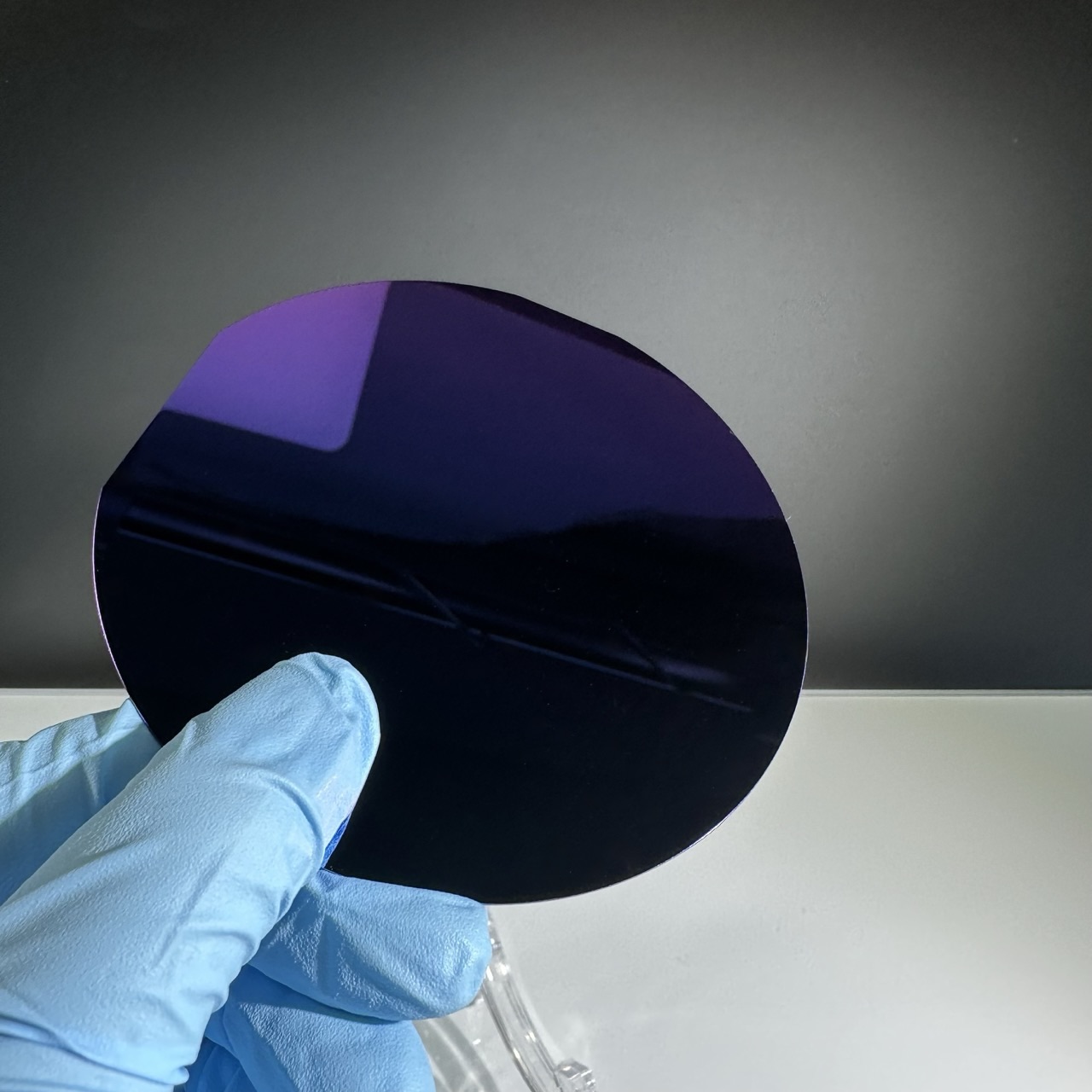

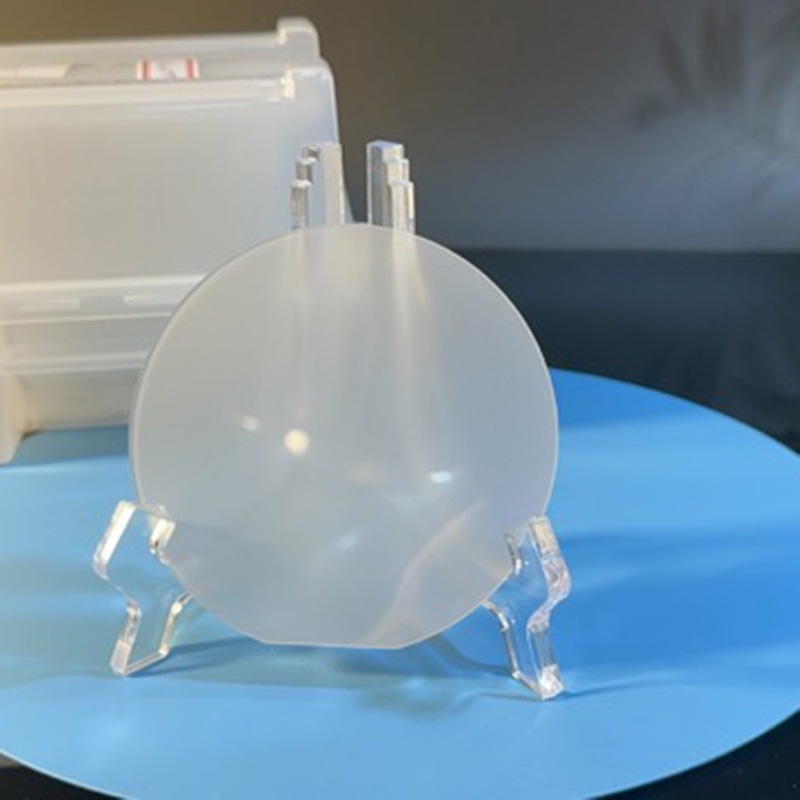

I-Silicon Dioxide wafer i-SiO2 wafer ewugqinsi Ipholishiwe, I-Prime And Test Grade

Ukwethulwa kwebhokisi le-wafer

| Umkhiqizo | Amawafa e-Thermal Oxide (Si+SiO2). |

| Indlela Yokukhiqiza | I-LPCVD |

| Ukupholisha ubuso | I-SSP/DSP |

| Ububanzi | 2inch/3inch/4inch/5inch/6inch |

| Uhlobo | Uhlobo lwe-P / N uhlobo |

| Ukujiya Kwesendlalelo Se-Oxidation | 100nm ~1000nm |

| Ukuqondisa | <100> <111> |

| Ukumelana nogesi | 0.001-25000(Ω•cm) |

| Isicelo | Isetshenziselwa isithwali sesampula se-synchrotron radiation, i-PVD/CVD coating njenge-substrate, isampula yokukhula ye-magnetron sputtering, i-XRD, i-SEM,Amandla e-athomu, i-infrared spectroscopy, i-fluorescence spectroscopy nezinye izingxenye zokuhlola zokuhlaziya, i-molecular beam epitaxial growth substrates, ukuhlaziywa kwe-X-ray kwama-crystalline semiconductors. |

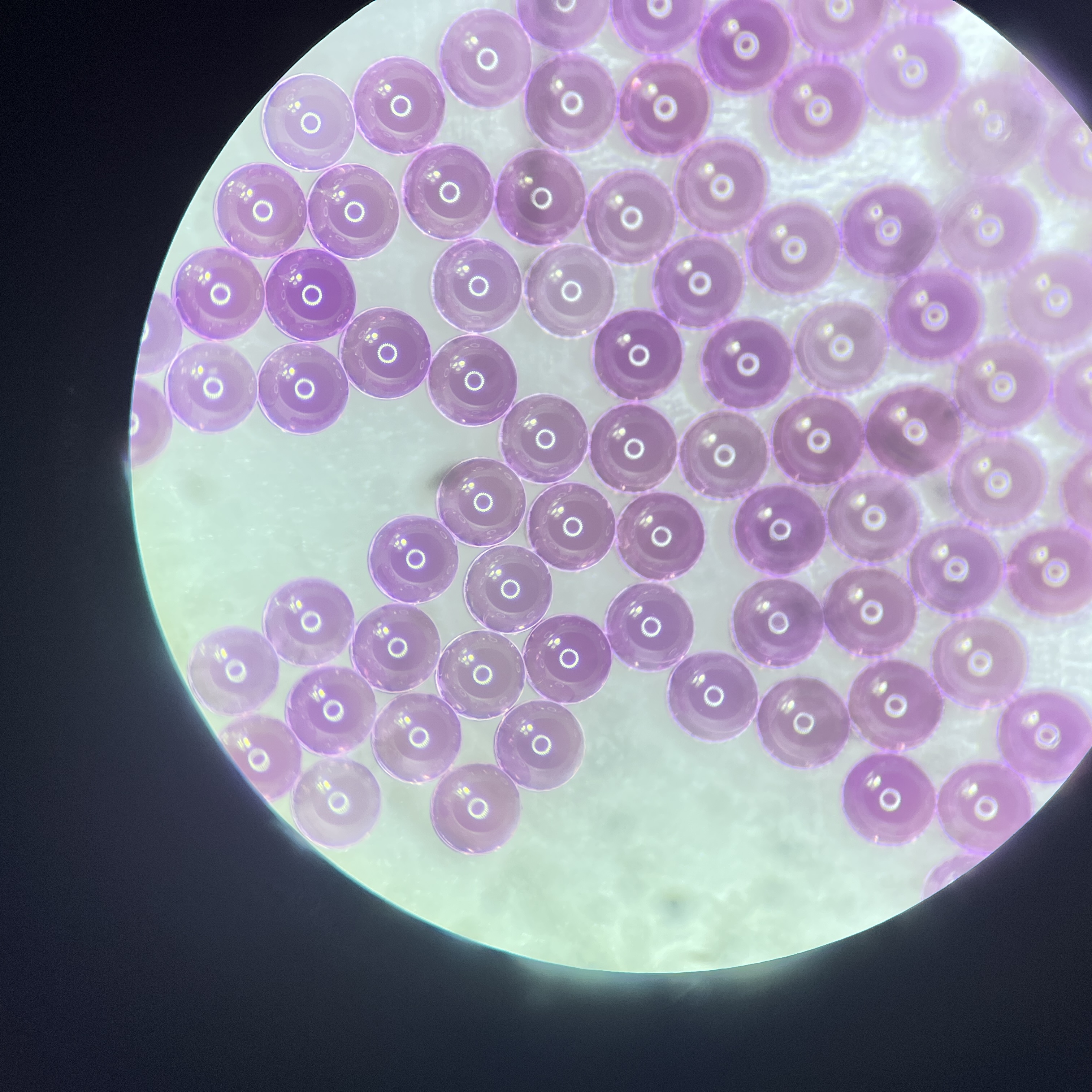

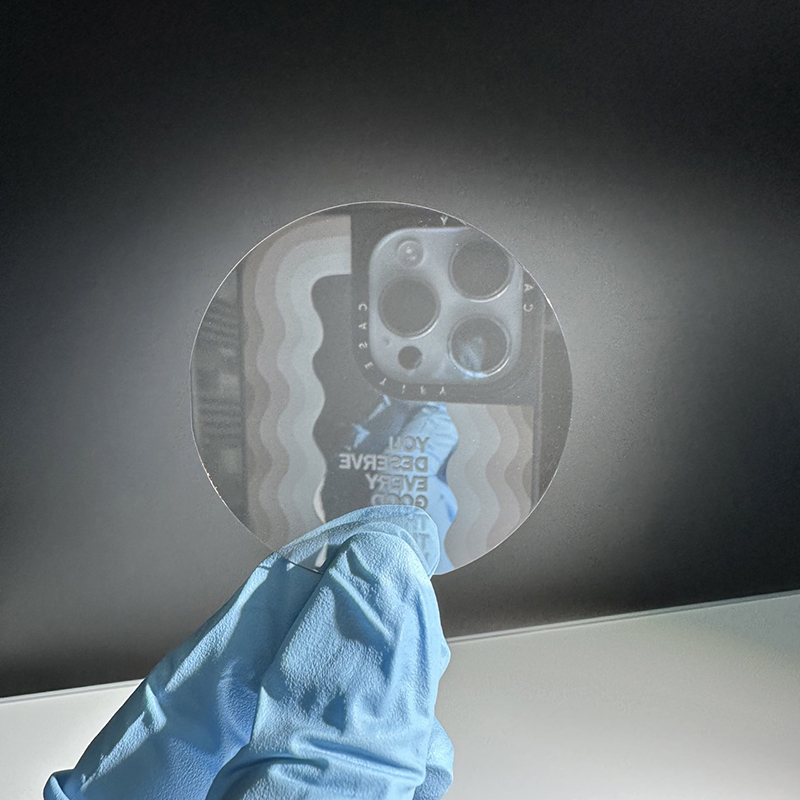

Amawafa e-Silicon oxide amafilimu e-silicon dioxide akhuliswa phezu kwamawafa e-silicon ngokusebenzisa umoya-mpilo noma umhwamuko wamanzi emazingeni okushisa aphezulu (800°C~1150°C) esebenzisa inqubo ye-oxidation eshisayo enemishini yeshubhu yesithando somoya.Ubukhulu benqubo busuka kuma-nanometers angu-50 kuya ku-2 microns, izinga lokushisa lenqubo lifika ku-1100 degrees Celsius, indlela yokukhula ihlukaniswe ngokuthi "i-oksijeni emanzi" kanye "nomoya-mpilo owomile" izinhlobo ezimbili.I-Thermal Oxide iyisendlalelo se-oxide "esikhulile", esinokufana okuphezulu, ukuminyana okungcono namandla e-dielectric ephakeme kunezendlalelo ze-oxide ezifakwe kwi-CVD, okuholela kukhwalithi ephezulu.

I-Oxygen Oxidation Eyomile

I-silicon ihlangana nomoya-mpilo futhi ungqimba lwe-oxide lulokhu luhamba lubheke kungqimba lwe-substrate.I-oxidation eyomile idinga ukwenziwa emazingeni okushisa asuka ku-850 kuya ku-1200°C, namazinga aphansi okukhula, futhi ingasetshenziselwa ukukhula kwesango elivikelwe i-MOS.I-oxidation eyomile ikhethwa kune-oxidation emanzi uma ikhwalithi ephezulu, ungqimba lwe-silicon oxide oluncane kakhulu ludingeka.Umthamo we-oxidation owomile: 15nm ~ 300nm.

2. I-Oxidation Emanzi

Le ndlela isebenzisa umhwamuko wamanzi ukwenza ungqimba lwe-oxide ngokufaka ithubhu yesithando somlilo ngaphansi kwezimo zokushisa eziphakeme.Ukuminyana kwe-oksijini oxidation emanzi kubi kancane kune-oksijini eyomile, kodwa uma kuqhathaniswa ne-oksijini eyomile inzuzo yayo ukuthi inezinga eliphezulu lokukhula, elifanele ukukhula kwefilimu engaphezu kuka-500nm.Umthamo we-oxidation omanzi: 500nm ~ 2µm.

Ishubhu ye-AEMD ye-atmospheric pressure oxidation furnace tube iyishubhu yesithando somlilo esivundlile saseCzech, esibonakala ngokuzinza kwenqubo ephezulu, ukufana kwefilimu okuhle nokulawula izinhlayiyana eziphakeme.Ishubhu le-silicon oxide furnace lingacubungula ama-wafer angama-50 ngeshubhu ngalinye, anokufana okuhle kakhulu kwe-intra- kanye ne-inter-wafers.

Umdwebo onemininingwane