Ama-wafers e-SiC angama-semiconductors enziwe nge-silicon carbide. Le nto yasungulwa ngo-1893 futhi ilungele ukusetshenziswa okuhlukahlukene. Ifaneleka kakhulu i-Schottky diode, i-junction barrier Schottky diode, amaswishi nama-metal-oxide-semiconductor field-effect transistors. Ngenxa yokuqina kwayo okuphezulu, kuyisinqumo esihle kakhulu samandla we-elekthronikhi.

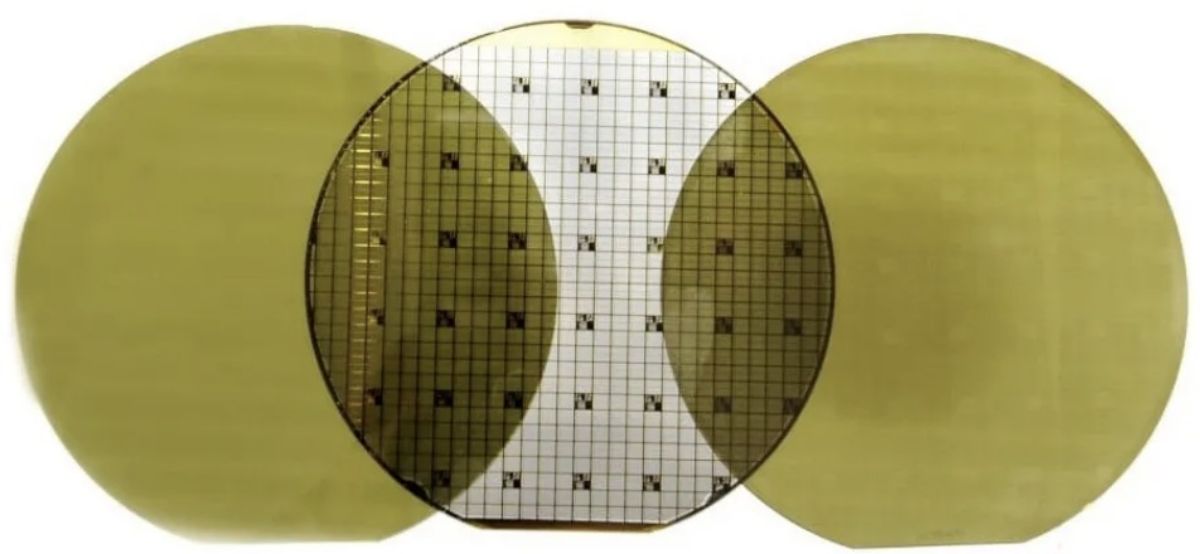

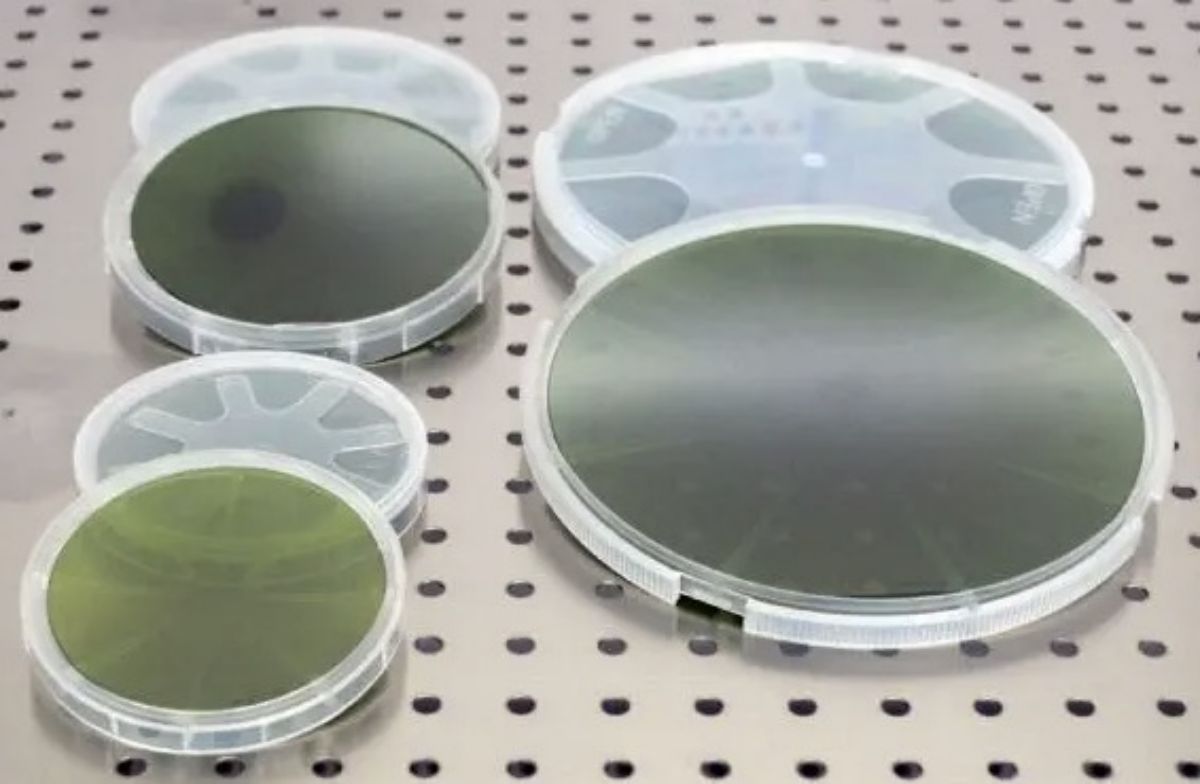

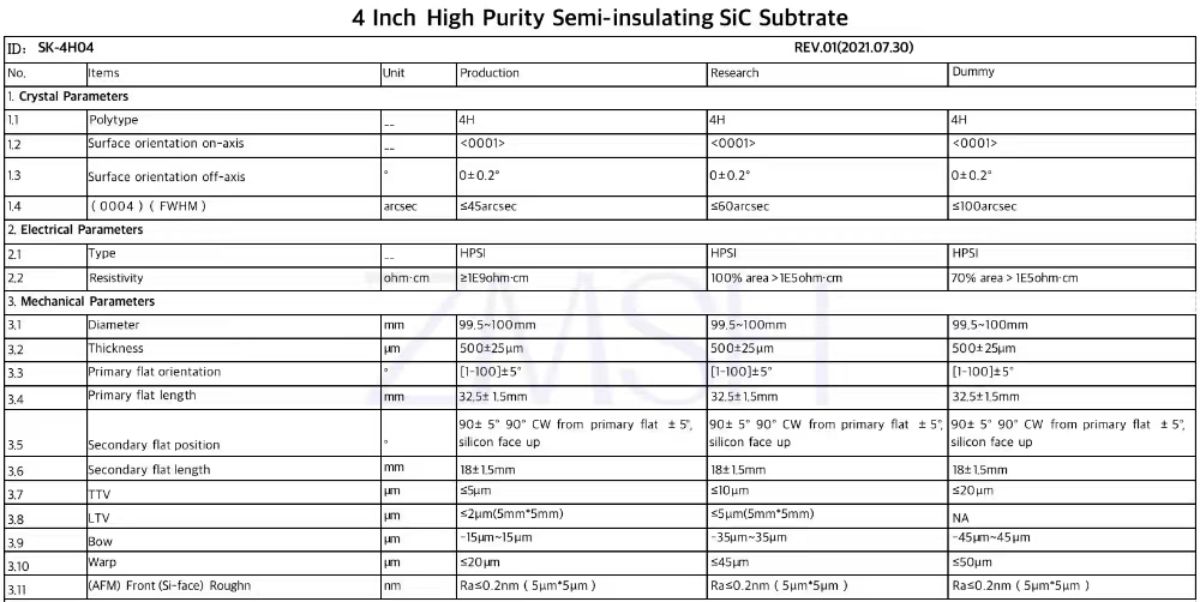

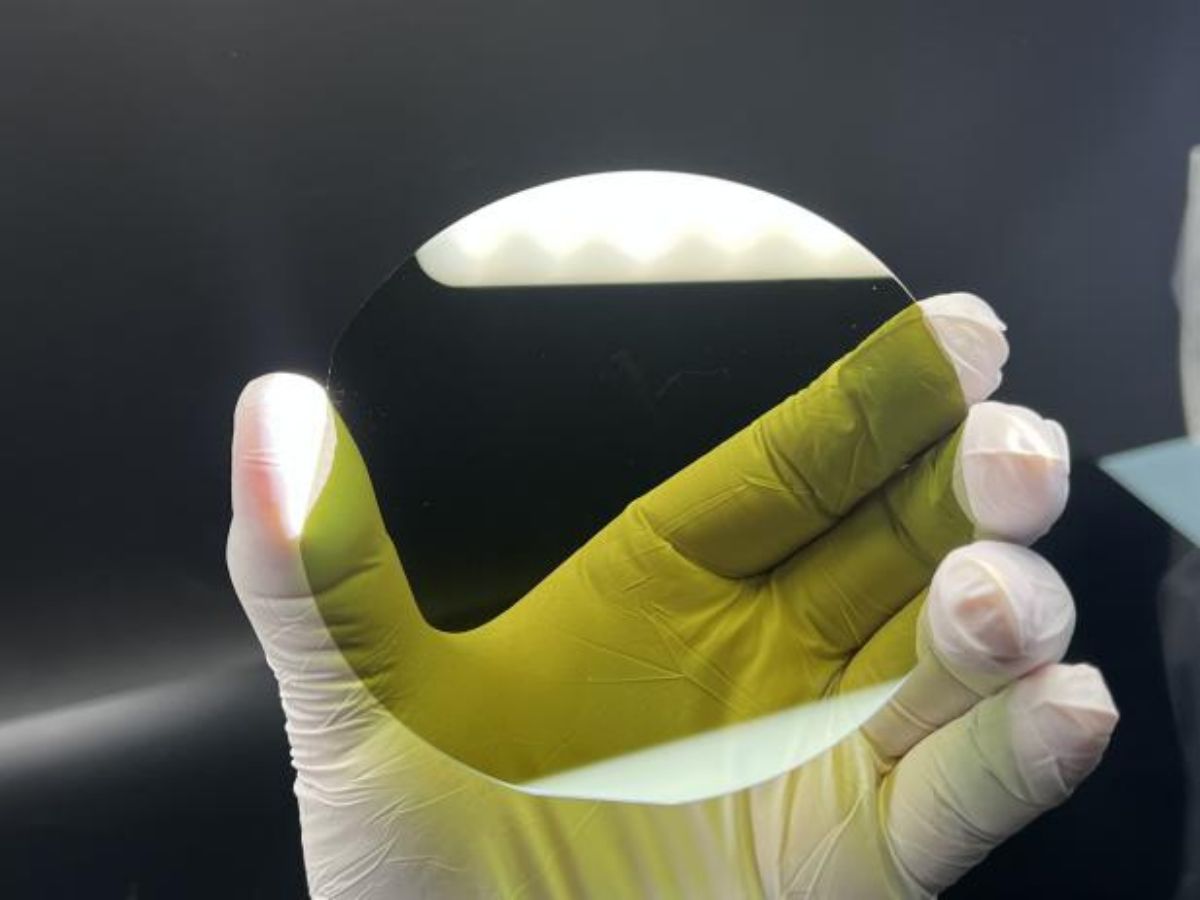

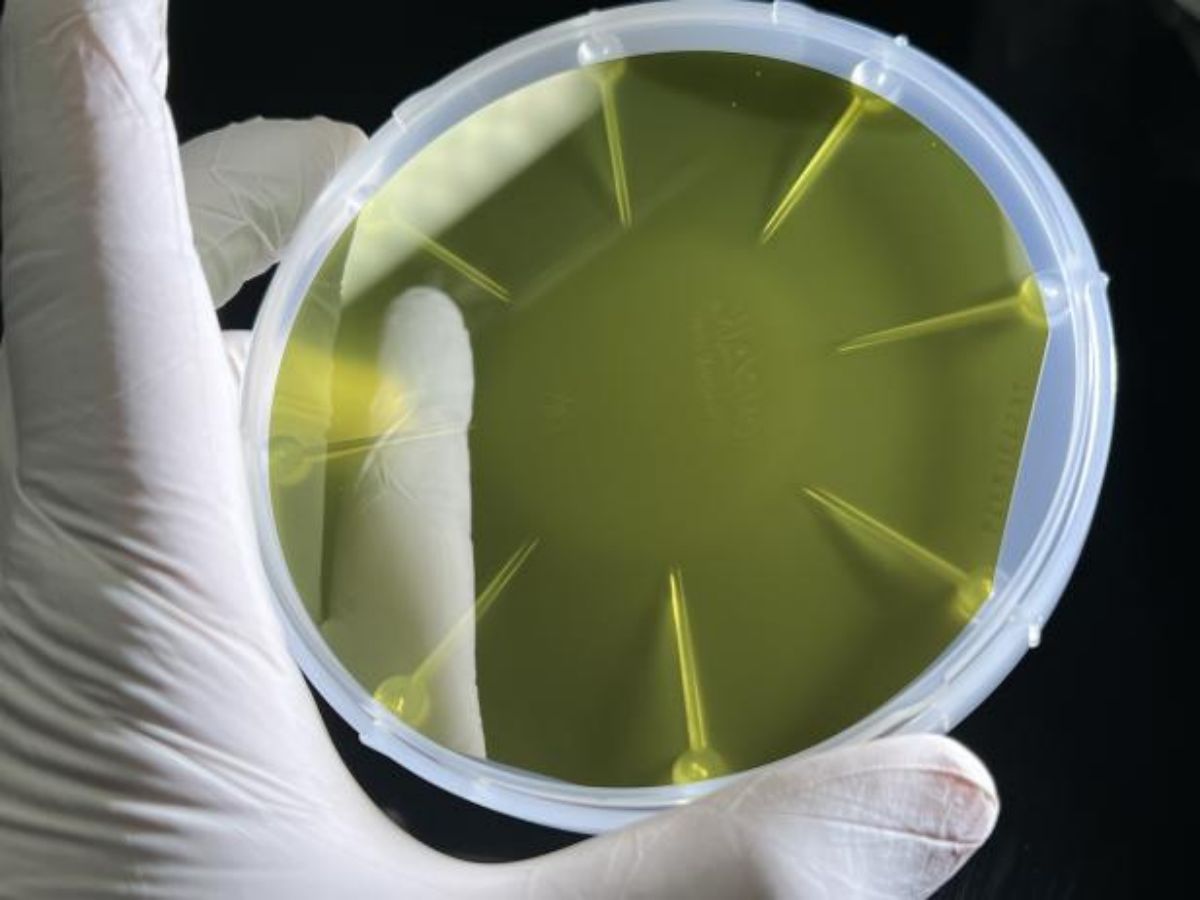

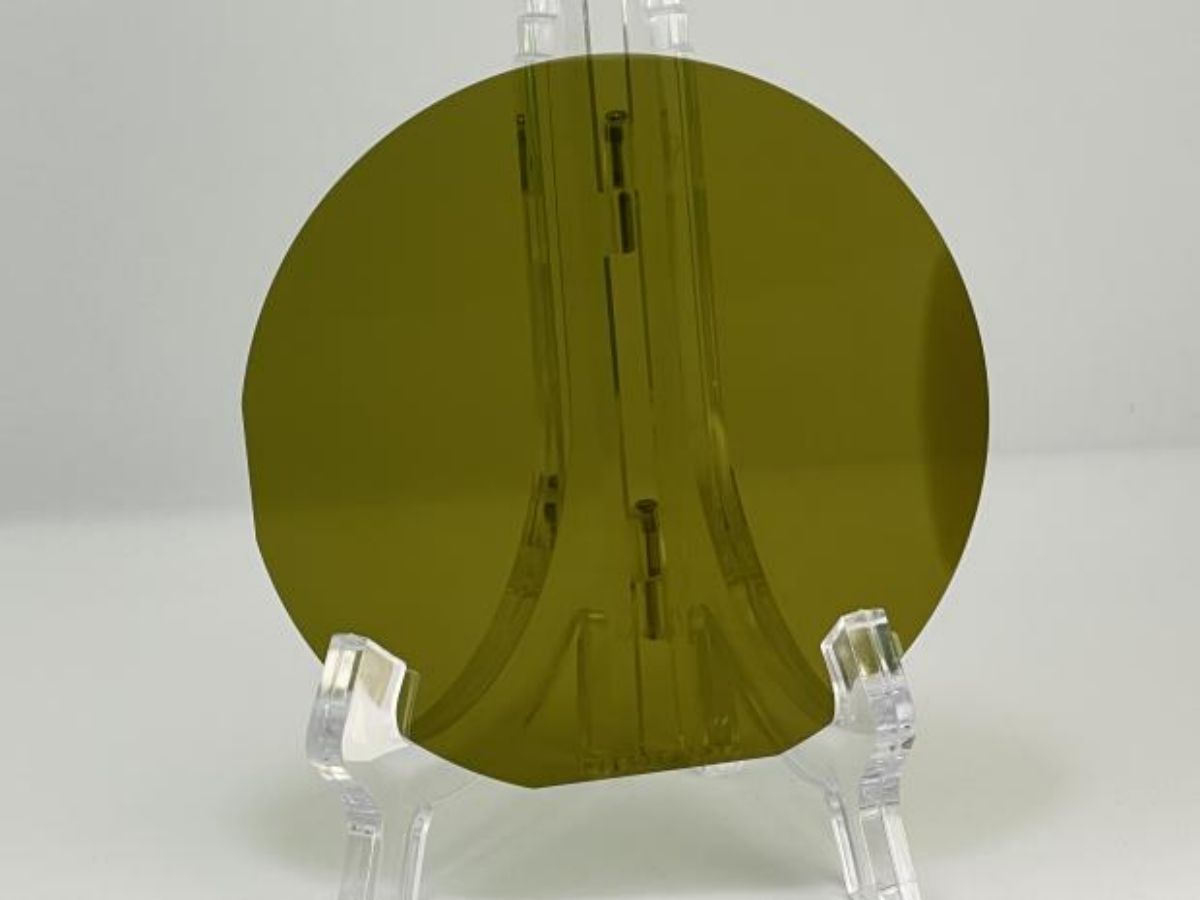

Njengamanje, kunezinhlobo ezimbili eziyinhloko zama-wafers e-SiC. Eyokuqala icwecwe elicwebezelayo, okuyi-wafer eyodwa ye-silicon carbide. Yenziwe ngamakristalu e-SiC ahlanzekile futhi ingaba yi-100mm noma i-150mm ububanzi. Isetshenziswa kumishini kagesi enamandla amakhulu. Uhlobo lwesibili i-epitaxial crystal silicon carbide wafer. Lolu hlobo lwe-wafer lwenziwa ngokungeza ungqimba olulodwa lwamakristalu e-silicon carbide phezulu. Le ndlela idinga ukulawula okunembile kokuqina kwento futhi yaziwa ngokuthi i-N-type epitaxy.

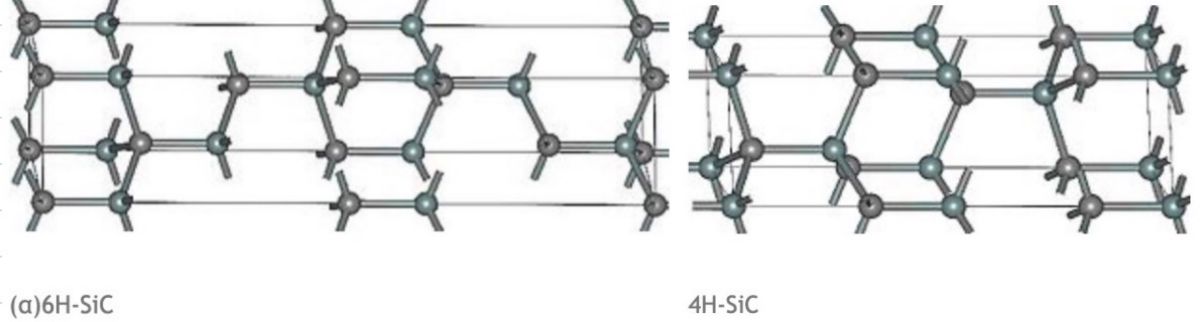

Uhlobo olulandelayo i-beta silicon carbide. I-Beta SiC ikhiqizwa emazingeni okushisa angaphezu kuka-1700 degrees Celsius. I-Alpha carbides yizona ezivame kakhulu futhi zinesakhiwo sekristalu esiyi-hexagonal esifana ne-wurtzite. Ifomu le-beta lifana nedayimane futhi lisetshenziswa kwezinye izinhlelo zokusebenza. Bekulokhu kuyisinqumo sokuqala semikhiqizo yamandla emoto kagesi eqediwe kancane. Abahlinzeki abambalwa beqembu lesithathu le-silicon carbide wafer bayasebenza njengamanje kule nto entsha.

Ama-wafer e-ZMSH SiC athandwa kakhulu ngezinto zokwakha ze-semiconductor. Kuyinto yekhwalithi ephezulu ye-semiconductor elungele izinhlelo zokusebenza eziningi. Ama-wafers e-silicon carbide e-ZMSH ayinto ewusizo kakhulu kumadivaysi kagesi ahlukahlukene. I-ZMSH ihlinzeka ngezinhlobonhlobo zamawafa e-SiC aphezulu kanye nama-substrates. Atholakala ngohlobo lwe-N kanye namafomu afakwe i-semi-insulated.

2---Silicon Carbide: Ibheke enkathini entsha yama-wafers

Izakhiwo zomzimba kanye nezici ze-silicon carbide

I-Silicon carbide inesakhiwo esikhethekile sekristalu, isebenzisa isakhiwo esine-hexagonal esiseduze esifana nedayimane. Lesi sakhiwo senza i-silicon carbide ibe ne-conductivity enhle kakhulu yokushisa kanye nokumelana nokushisa okuphezulu. Uma kuqhathaniswa nezinto ze-silicon zendabuko, i-silicon carbide inobubanzi begebe elikhulu lebhendi, ehlinzeka ngesikhala esiphezulu se-electron band, okuholela ekuhambeni okuphezulu kwama-electron kanye nokuvuza okuphansi kwamanje. Ngaphezu kwalokho, i-silicon carbide nayo inesivinini esiphezulu sokukhukhuleka kwe-electron kanye ne-resistivity ephansi yezinto ngokwazo, enikeza ukusebenza okungcono kwezicelo zamandla aphezulu.

Amacala okufaka isicelo kanye namathemba we-silicon carbide wafers

Izinhlelo zokusebenza ze-Power electronics

I-Silicon carbide wafer inethuba elibanzi lesicelo emkhakheni we-electronics power. Ngenxa yokuhamba kwawo okuphezulu kwama-electron kanye nokuhamba kahle kwe-thermal, ama-wafers e-SIC angasetshenziswa ukwenza amadivaysi okushintsha amandla amakhulu, njengamamojula wamandla wezimoto zikagesi kanye nama-solar inverters. Ukuzinza okuphezulu kwezinga lokushisa kwe-silicon carbide wafers kwenza lawa madivaysi asebenze ezindaweni zokushisa okuphezulu, anikeze ukusebenza kahle okukhulu nokuthembeka.

Izinhlelo zokusebenza ze-Optoelectronic

Emkhakheni wamadivayisi we-optoelectronic, ama-wafers e-silicon carbide akhombisa izinzuzo zawo ezihlukile. Izinto ze-Silicon carbide zinezici zegebe elibanzi, eliyenza ikwazi ukuzuza amandla aphezulu e-photonon nokulahlekelwa ukukhanya okuphansi kumadivayisi we-optoelectronic. Ama-wafers e-silicon carbide angasetshenziswa ukulungisa amadivaysi okuxhumana anesivinini esikhulu, ama-photodetectors nama-lasers. I-thermal conductivity yayo enhle kakhulu kanye nokuminyana kwe-crystal ephansi kuyenza ilungele ukulungiswa kwemishini ye-optoelectronic yekhwalithi ephezulu.

I-Outlook

Ngokukhula kwesidingo samadivaysi e-elekthronikhi asebenza kahle kakhulu, amawafa e-silicon carbide anekusasa elithembisayo njengempahla enezakhiwo ezinhle kakhulu namandla okusebenza abanzi. Ngokuthuthuka okuqhubekayo kobuchwepheshe bokulungiselela kanye nokwehliswa kwezindleko, ukusetshenziswa kwezentengiselwano kwama-silicon carbide wafers kuzothuthukiswa. Kulindeleke ukuthi eminyakeni embalwa ezayo, ama-wafers e-silicon carbide azongena kancane kancane emakethe futhi abe yisinqumo esijwayelekile samandla aphezulu, imvamisa ephezulu kanye nezicelo zokushisa okuphezulu.

3---Ukuhlaziywa okujulile kwemakethe ye-SiC wafer kanye nezitayela zobuchwepheshe

Ukuhlaziywa okujulile kwabashayeli bemakethe ye-silicon carbide (SiC).

Ukukhula kwemakethe ye-silicon carbide (SiC) kuthonywa izici ezimbalwa ezibalulekile, futhi ukuhlaziya okujulile komthelela walezi zici emakethe kubalulekile. Nazi ezinye zezindlela eziyinhloko zemakethe:

Ukonga amandla nokuvikelwa kwemvelo: Ukusebenza okuphezulu nezici zokusetshenziswa kwamandla okuphansi kwezinto ze-silicon carbide ziyenza idume emkhakheni wokonga amandla nokuvikelwa kwemvelo. Isidingo sezimoto zikagesi, ama-solar inverters namanye amadivaysi okuguqula amandla kuqhuba ukukhula kwemakethe kwama-silicon carbide wafers njengoba kusiza ukunciphisa ukumosheka kwamandla.

Izinhlelo zokusebenza ze-Power Electronics: I-silicon carbide ihamba phambili ezinhlelweni zikagesi zikagesi futhi ingasetshenziswa kuma-electronics wamandla ngaphansi kwengcindezi ephezulu kanye nezimo zokushisa eziphezulu. Ngokuthandwa kwamandla avuselelekayo kanye nokugqugquzelwa kokushintshwa kwamandla kagesi, isidingo sama-silicon carbide wafers emakethe ye-electronics power siyaqhubeka nokukhula.

I-SiC wafers yesikhathi esizayo yokuthuthukiswa kobuchwepheshe bokukhiqiza ukuhlaziya okuningiliziwe

Ukukhiqizwa ngobuningi nokwehliswa kwezindleko: Ukwenziwa kwe-future SiC wafer kuzogxila kakhulu ekukhiqizweni ngobuningi nasekunciphiseni izindleko. Lokhu kubandakanya amasu okukhula athuthukisiwe afana ne-chemical vapor deposition (CVD) kanye ne-physical vapor deposition (PVD) ukuze kwandiswe ukukhiqiza nokunciphisa izindleko zokukhiqiza. Ukwengeza, ukwamukelwa kwezinqubo zokukhiqiza ezihlakaniphile nezizenzekelayo kulindeleke ukuthi kuthuthukiswe ukusebenza kahle.

Usayizi omusha wamawafa nesakhiwo: Usayizi nesakhiwo samawafa e-SiC kungase kushintshe esikhathini esizayo ukuze kuhlangatshezwane nezidingo zezinhlelo zokusebenza ezahlukene. Lokhu kungase kuhlanganise amawafa amakhulu amakhulu, izakhiwo ezihlukene, noma amawafa amaningi ukuze kunikeze ukuguquguquka okwengeziwe komklamo kanye nezinketho zokusebenza.

Ukusebenza Kahle Kwezamandla Nokukhiqiza Okuluhlaza: Ukukhiqizwa kwamawafa e-SiC esikhathini esizayo kuzogcizelela kakhulu ukusebenza kahle kwamandla kanye nokukhiqizwa okuluhlaza. Izimboni ezinikezwa amandla avuselelekayo, izinto eziluhlaza, ukugaywa kabusha kwemfucuza kanye nezinqubo zokukhiqiza ikhabhoni ephansi zizoba izitayela zokukhiqiza.

Isikhathi sokuthumela: Jan-19-2024