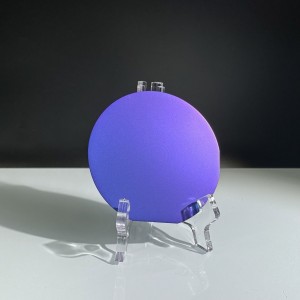

I-SiO2 Thin Film Thermal Oxide Silicon wafer 4inch 6inch 8inch 12inch

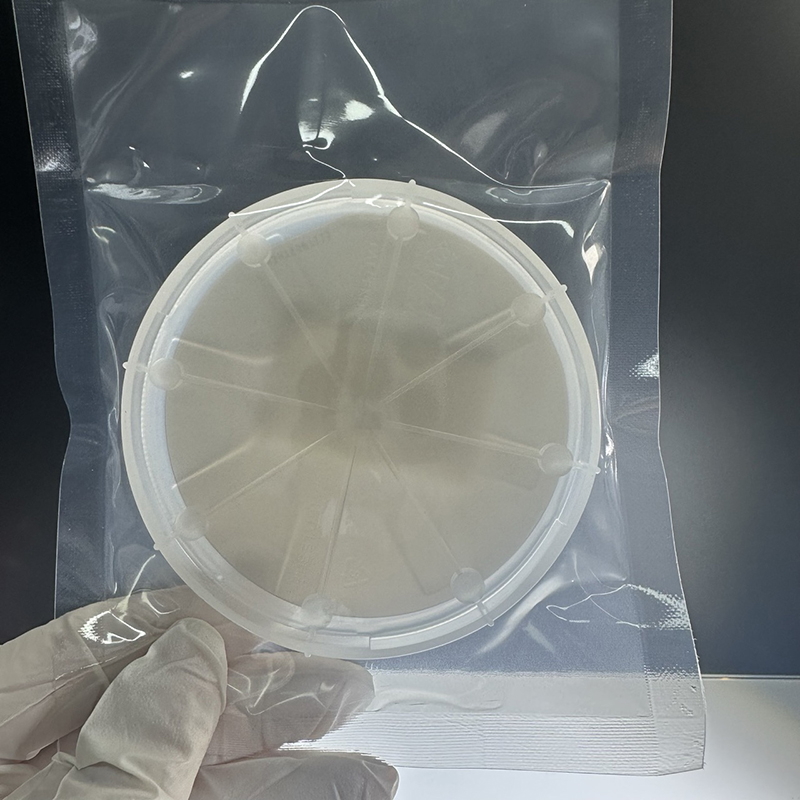

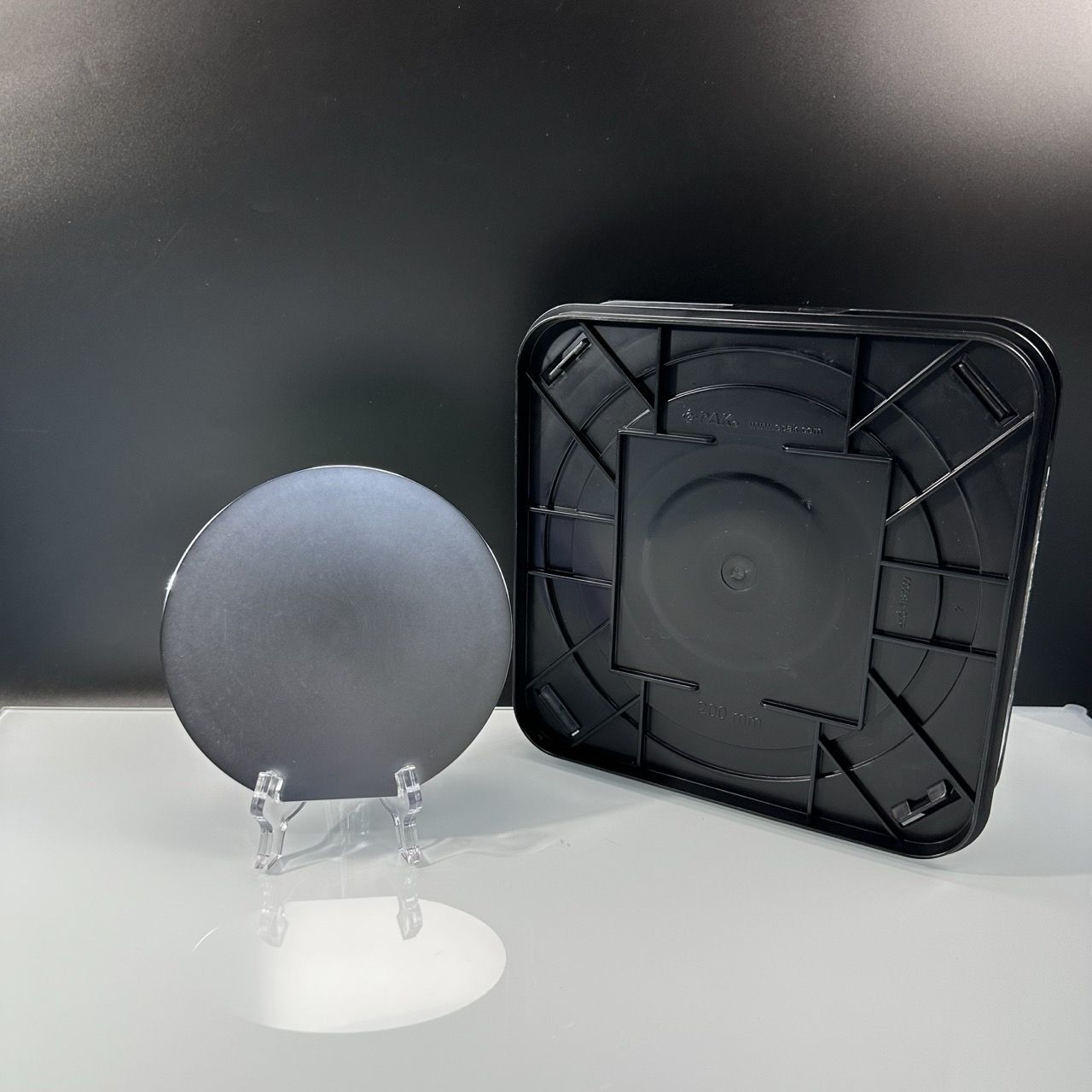

Ukwethulwa kwebhokisi le-wafer

Inqubo eyinhloko yokukhiqiza amawafa e-silicon oxidized ngokuvamile ahlanganisa izinyathelo ezilandelayo: ukukhula kwe-silicon ye-monocrystalline, ukusika kube ama-wafers, ukupholisha, ukuhlanzwa kanye ne-oxidation.

Ukukhula kwe-silicon ye-Monocrystalline: Okokuqala, i-silicon ye-monocrystalline ikhuliswa emazingeni okushisa aphezulu ngezindlela ezifana nendlela ye-Czochralski noma indlela ye-Float-zone.Le ndlela ivumela ukulungiswa kwamakristalu e-silicon eyodwa ngokuhlanzeka okuphezulu nobuqotho be-lattice.

I-Dicing: I-silicon ekhulile ye-monocrystalline ivamise ukuba yisilinda futhi idinga ukusikwa ibe ama-wafer amancane azosetshenziswa njenge-wafer substrate.Ukusika ngokuvamile kwenziwa ngomsiki wedayimane.

Ukupholisha: Ingaphezulu lewafa elisikiwe lingase lingalingani futhi lidinga ukupholisha ngamakhemikhali ukuze kutholwe indawo ebushelelezi.

Ukuhlanza: Iwafa epholishiwe iyahlanzwa ukuze kukhishwe ukungcola nothuli.

I-Oxidizing: Okokugcina, ama-wafer e-silicon afakwa esithandweni sokushisa okuphezulu ukuze kusetshenziswe i-oxidizing ukuze kwakheke ungqimba oluvikelayo lwe-silicon dioxide ukuze luthuthukise izakhiwo zalo zikagesi namandla omshini, kanye nokusebenza njengongqimba oluvikelayo kumasekethe ahlanganisiwe.

Ukusetshenziswa okuyinhloko kwama-silicon wafers ane-oxidized kufaka phakathi ukwenziwa kwamasekhethi ahlanganisiwe, ukwakhiwa kwamaseli elanga, kanye nokwakhiwa kwamanye amadivaysi kagesi.Ama-wafers we-silicon oxide asetshenziswa kakhulu emkhakheni wezinto zokwakha ze-semiconductor ngenxa yezakhiwo zabo ezinhle kakhulu zemishini, ukuzinza kwe-dimensional kanye namakhemikhali, amandla okusebenza emazingeni okushisa aphezulu kanye nokucindezela okuphezulu, kanye nezakhiwo ezinhle zokuvikela kanye ne-optical.

Izinzuzo zayo zihlanganisa isakhiwo sekristalu esiphelele, ukwakheka kwamakhemikhali ahlanzekile, ubukhulu obunembile, izici ezinhle zemishini, njll. Lezi zici zenza ama-wafer e-silicon oxide afaneleke ikakhulukazi ukwakhiwa kwamasekethe ahlanganisiwe asebenza kahle kanye namanye amadivaysi e-microelectronic.

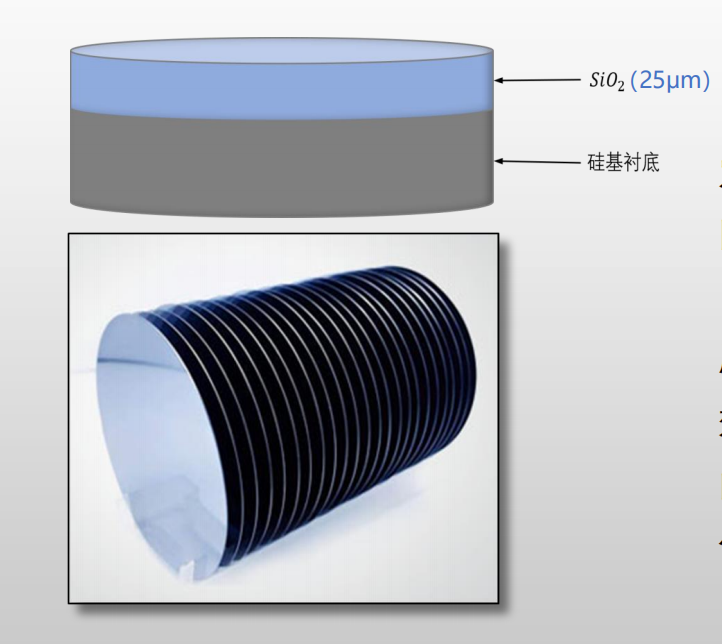

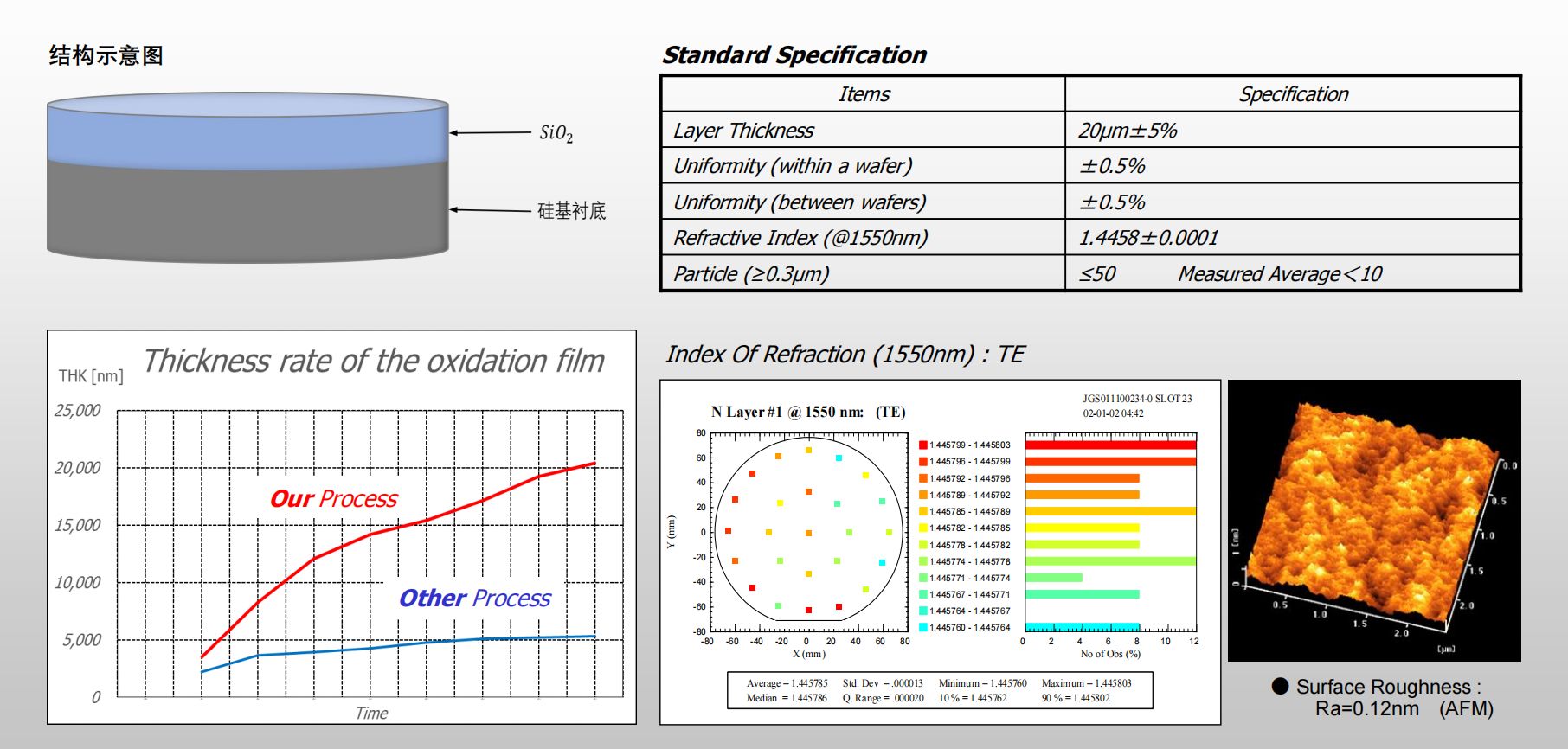

Umdwebo onemininingwane