I-4H-N HPSI SiC wafer 6H-N 6H-P 3C-N SiC Epitaxial wafer ye-MOS noma i-SBD

I-SiC Substrate SiC Epi-wafer Brief

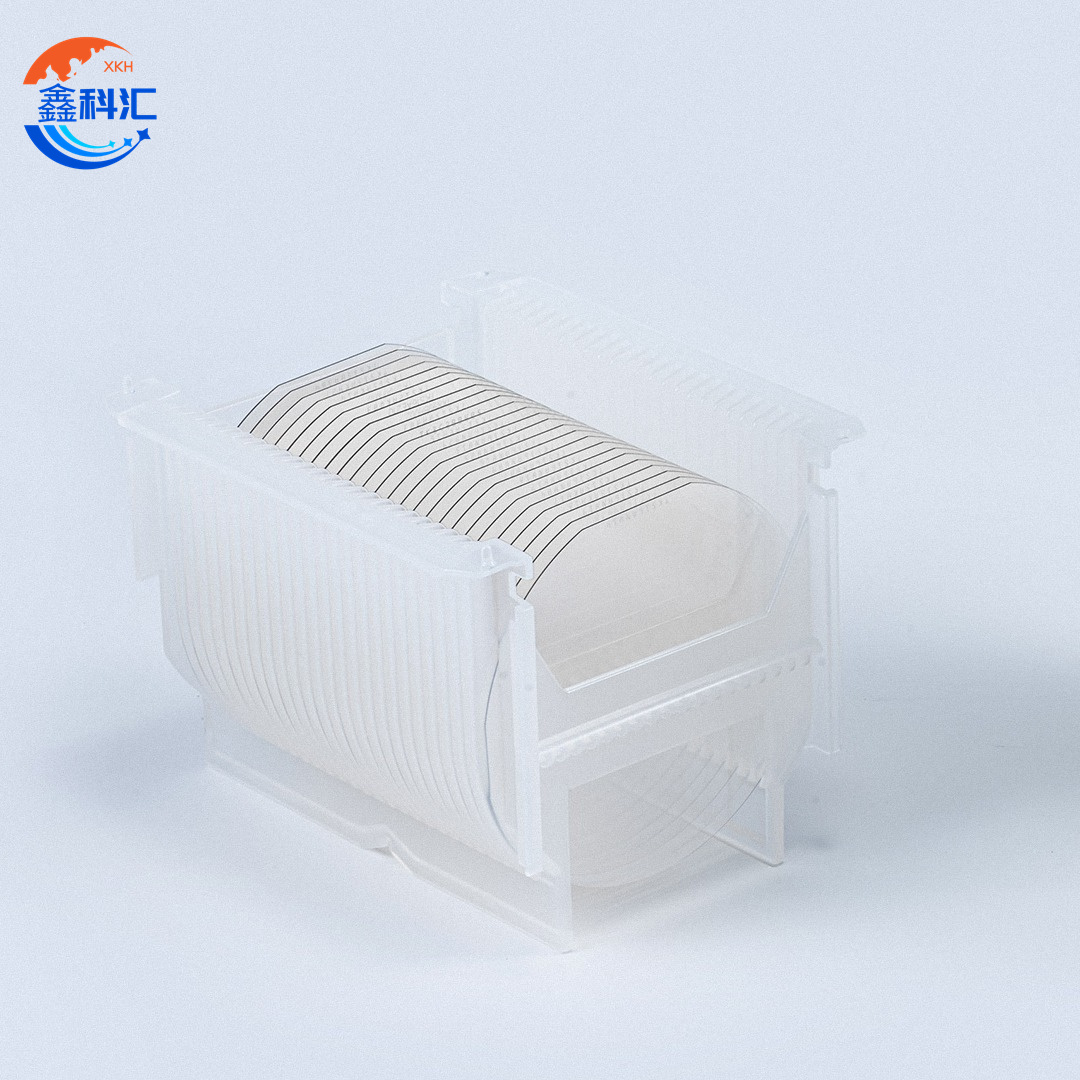

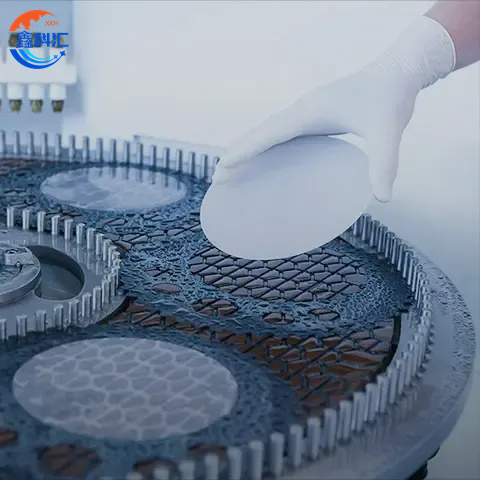

Sinikeza iphothifoliyo egcwele yekhwalithi ephezulu yama-SiC substrates namawafa e-sic kuma-polytypes amaningi kanye namaphrofayili e-doping—okuhlanganisa i-4H-N (n-type conductive), 4H-P (p-type conductive), 4H-HPSI (high-purity semi-insulating), kanye no-6H-P (p-type conductive)—4″ conductive)—kusuka ku-6″ yonke, 6″ yonke, 6″ yonke kuze kufike ku-12 ″. Ngalé kwama-substrates angenalutho, izinsizakalo zethu zokukhulisa i-epi wafer enevalue ziletha ama-wafer e-epitaxial (epi) anogqinsi olulawulwa ngokuqinile (1–20 µm), ukugxila kwe-doping, nokuminyana kokukhubazeka.

Iwafa ngayinye ye-sic kanye ne-epi wafer ihlolwa ngokuqinile emgqeni (ukuminyana kwe-micropipe <0.1 cm⁻², ukuhwaqeka kwendawo engu-Ra <0.2 nm) kanye nezinhlamvu ezigcwele zikagesi (i-CV, imephu yokumelana) ukuze kuqinisekiswe ukufana kwekristalu okukhethekile nokusebenza. Kungakhathaliseki ukuthi isetshenziselwa amamojula kagesi kagesi, ama-amplifiers e-RF anemvamisa ephezulu, noma amadivaysi e-optoelectronic (ama-LED, ama-photodetectors), i-SiC substrate yethu kanye nemigqa yomkhiqizo we-epi wafer iletha ukwethembeka, ukuzinza okushisayo, namandla okuqhekeka adingwa izinhlelo zokusebenza ezinzima zanamuhla.

Izakhiwo kanye nokusetshenziswa kohlobo lwe-SiC Substrate 4H-N

-

4H-N SiC substrate Polytype (Hexagonal) Ukwakheka

I-bandgap ebanzi engu-~3.26 eV iqinisekisa ukusebenza kukagesi okuzinzile kanye nokuqina okushisayo ngaphansi kwezimo zokushisa eziphezulu neziphezulu zenkundla kagesi.

-

I-substrate ye-SiCI-N-Type Doping

Idoping ye-nitrogen elawulwa ngokunembile ikhiqiza ukugxila kwenkampani yenethiwekhi ukusuka ku-1×10¹⁶ ukuya ku-1×10¹⁹ cm⁻³ kanye nokuhamba kwama-electron ezinga lokushisa ekamelweni kufika ku-~900 cm²/V·s, kunciphisa ukulahleka kokusebenza.

-

I-substrate ye-SiCI-Wide Resistivity & Ukufana

Ibanga elitholakalayo lokumelana no-0.01–10 Ω·cm nogqinsi lwe-wafer elingu-350–650 µm nokubekezelela okungu-±5% kukho kokubili i-doping nogqinsi—ilungele ukwenziwa kwedivayisi yamandla aphezulu.

-

I-substrate ye-SiCUkuminyana Kwesici Esiphansi Kakhulu

Ukuminyana kwe-Micropipe <0.1 cm⁻² kanye nokuminyana kwe-basal-plane dislocation < 500 cm⁻², iletha > 99% isivuno sedivayisi nobuqotho obucwebezelayo obuphakeme.

- I-substrate ye-SiCI-Exceptional Thermal Conductivity

I-Thermal conductivity efika ku-~370 W/m·K kusiza ukususwa kokushisa okusebenzayo, kukhulisa ukuthembeka kwedivayisi nokuminyana kwamandla.

-

I-substrate ye-SiCIzinhlelo zokusebenza eziqondisiwe

Ama-SiC MOSFET, ama-Schottky diode, amamojula kagesi namadivayisi e-RF okushayela izimoto zikagesi, ama-solar inverters, amadrayivu ezimboni, amasistimu wokudonsa, nezinye izimakethe zama-electronics ezidinga amandla.

I-6inch 4H-N yohlobo lwe-SiC wafer olucacile | ||

| Impahla | Ibanga le-Zero MPD Production (Ibanga le-Z) | I-Dummy Grade (D Grade) |

| Ibanga | Ibanga le-Zero MPD Production (Ibanga le-Z) | I-Dummy Grade (D Grade) |

| Ububanzi | 149.5 mm - 150.0 mm | 149.5 mm - 150.0 mm |

| Uhlobo lwe-Poly | 4H | 4H |

| Ubukhulu | 350 µm ± 15 µm | 350 µm ± 25 µm |

| I-Wafer Orientation | Ku-axis evaliwe: 4.0° kuya ku-<1120> ± 0.5° | Ku-axis evaliwe: 4.0° kuya ku-<1120> ± 0.5° |

| I-Micropipe Density | ≤ 0.2 cm² | ≤ 15 cm² |

| Ukungazweli | 0.015 - 0.024 Ω·cm | 0.015 - 0.028 Ω·cm |

| Isisekelo se-Flat Orientation | [10-10] ± 50° | [10-10] ± 50° |

| Ubude Befulethi obuyisisekelo | 475 mm ± 2.0 mm | 475 mm ± 2.0 mm |

| Ukukhishwa komkhawulo | 3 mm | 3 mm |

| I-LTV/TIV / Umnsalo / I-Warp | ≤ 2.5 µm / ≤ 6 µm / ≤ 25 µm / ≤ 35 µm | ≤ 5 µm / ≤ 15 µm / ≤ 40 µm / ≤ 60 µm |

| Ubulukhuni | I-Polish Ra ≤ 1 nm | I-Polish Ra ≤ 1 nm |

| CMP Ra | ≤ 0.2 nm | ≤ 0.5 nm |

| I-Edge Cracks By High Intensity Light | Ubude obukhulayo ≤ 20 mm ubude obubodwa ≤ 2 mm | Ubude obukhulayo ≤ 20 mm ubude obubodwa ≤ 2 mm |

| I-Hex Plates Ngokukhanya Okunamandla Okuphezulu | Indawo eqoqiwe ≤ 0.05% | Indawo eqoqiwe ≤ 0.1% |

| Izindawo ze-Polytype Ngokukhanya Okunamandla Okuphezulu | Indawo eqoqiwe ≤ 0.05% | Indawo eqoqiwe ≤ 3% |

| I-Visual Carbon Inclusions | Indawo eqoqiwe ≤ 0.05% | Indawo eqoqiwe ≤ 5% |

| I-Silicon Surface Scratches By High Intensity Light | Ubude obuqongelelwayo ≤ 1 ububanzi bewafa | |

| Ama-Edge Chips Ngokukhanya Okunamandla Okuphezulu | Akukho okuvunyelwe ≥ 0.2 mm ububanzi nokujula | 7 okuvunyelwe, ≤ 1 mm ngakunye |

| Ukukhipha Isikulufu sochungechunge | <500cm³ | <500cm³ |

| I-Silicon Surface Contamination By High Intensity Light | ||

| Ukupakisha | Ikhasethi elinesinkwa esilucwecwana noma Isitsha Esiyisinkwa Esikodwa | Ikhasethi elinesinkwa esilucwecwana noma Isitsha Esiyisinkwa Esikodwa |

8inch 4H-N uhlobo lwe-SiC wafer olucacisiwe | ||

| Impahla | Ibanga le-Zero MPD Production (Ibanga le-Z) | I-Dummy Grade (D Grade) |

| Ibanga | Ibanga le-Zero MPD Production (Ibanga le-Z) | I-Dummy Grade (D Grade) |

| Ububanzi | 199.5 mm - 200.0 mm | 199.5 mm - 200.0 mm |

| Uhlobo lwe-Poly | 4H | 4H |

| Ubukhulu | 500 µm ± 25 µm | 500 µm ± 25 µm |

| I-Wafer Orientation | 4.0° ukuya ku-<110> ± 0.5° | 4.0° ukuya ku-<110> ± 0.5° |

| I-Micropipe Density | ≤ 0.2 cm² | ≤ 5 cm² |

| Ukungazweli | 0.015 - 0.025 Ω·cm | 0.015 - 0.028 Ω·cm |

| Noble Orientation | ||

| Ukukhishwa komkhawulo | 3 mm | 3 mm |

| I-LTV/TIV / Umnsalo / I-Warp | ≤ 5 µm / ≤ 15 µm / ≤ 35 µm / 70 µm | ≤ 5 µm / ≤ 15 µm / ≤ 35 µm / 100 µm |

| Ubulukhuni | I-Polish Ra ≤ 1 nm | I-Polish Ra ≤ 1 nm |

| CMP Ra | ≤ 0.2 nm | ≤ 0.5 nm |

| I-Edge Cracks By High Intensity Light | Ubude obukhulayo ≤ 20 mm ubude obubodwa ≤ 2 mm | Ubude obukhulayo ≤ 20 mm ubude obubodwa ≤ 2 mm |

| I-Hex Plates Ngokukhanya Okunamandla Okuphezulu | Indawo eqoqiwe ≤ 0.05% | Indawo eqoqiwe ≤ 0.1% |

| Izindawo ze-Polytype Ngokukhanya Okunamandla Okuphezulu | Indawo eqoqiwe ≤ 0.05% | Indawo eqoqiwe ≤ 3% |

| I-Visual Carbon Inclusions | Indawo eqoqiwe ≤ 0.05% | Indawo eqoqiwe ≤ 5% |

| I-Silicon Surface Scratches By High Intensity Light | Ubude obuqongelelwayo ≤ 1 ububanzi bewafa | |

| Ama-Edge Chips Ngokukhanya Okunamandla Okuphezulu | Akukho okuvunyelwe ≥ 0.2 mm ububanzi nokujula | 7 okuvunyelwe, ≤ 1 mm ngakunye |

| Ukukhipha Isikulufu sochungechunge | <500cm³ | <500cm³ |

| I-Silicon Surface Contamination By High Intensity Light | ||

| Ukupakisha | Ikhasethi elinesinkwa esilucwecwana noma Isitsha Esiyisinkwa Esikodwa | Ikhasethi elinesinkwa esilucwecwana noma Isitsha Esiyisinkwa Esikodwa |

I-4H-SiC iyinto esebenza kahle kakhulu esetshenziselwa amandla kagesi, amadivaysi e-RF, kanye nezicelo ezishisa kakhulu. I-"4H" ibhekisela esakhiweni sekristalu, esiyi-hexagonal, futhi u-"N" ubonisa uhlobo lwe-doping olusetshenziselwa ukuthuthukisa ukusebenza kwento.

I4H-SiCuhlobo luvame ukusetshenziselwa:

Amandla kagesi:Isetshenziswa kumadivayisi afana nama-diode, ama-MOSFET, nama-IGBT kuma-powertrains emoto kagesi, imishini yezimboni, nezinhlelo zamandla avuselelekayo.

Ubuchwepheshe be-5G:Ngesidingo se-5G sezingxenye zemvamisa ephezulu nezisebenza kahle kakhulu, ikhono le-SiC lokusingatha ama-voltage aphezulu futhi isebenze emazingeni okushisa aphezulu iyenza ilungele izikhulisamandla zamandla esiteshi kanye namadivayisi e-RF.

Amasistimu Amandla Elanga:Izakhiwo zokuphatha amandla ezinhle kakhulu ze-SiC zilungele ama-inverter nama-photovoltaic (amandla elanga) neziguquli.

Izimoto zikagesi (EVs):I-SiC isetshenziswa kakhulu kuma-powertrains e-EV ukuze kuguqulwe amandla asebenza kahle, ukukhiqiza ukushisa okuphansi, kanye nokuminyana kwamandla aphezulu.

Izakhiwo kanye nokusetshenziswa kohlobo lwe-SiC Substrate 4H Semi-Insulating

Izakhiwo:

-

Amasu okulawula ukuminyana angenawo amapayipi: Iqinisekisa ukungabikho kwama-micropipes, ithuthukisa ikhwalithi ye-substrate.

-

Izindlela zokulawula i-Monocrystalline: Iqinisekisa isakhiwo sekristalu esisodwa sezinto ezibonakalayo ezithuthukisiwe.

-

Amasu okulawula okufakiwe: Yehlisa ukuba khona kokungcola noma okufakiwe, iqinisekisa i-substrate emsulwa.

-

Amasu okulawula ukumelana: Ivumela ukulawula okunembayo kokumelana nogesi, okubalulekile ekusebenzeni kwedivayisi.

-

Ukulawula ukungcola nezindlela zokulawula: Ilawula futhi ikhawulele ukwethulwa kokungcola ukuze kugcinwe ubuqotho be-substrate.

-

Izindlela zokulawula ububanzi besinyathelo se-substrate: Inikeza ukulawula okunembile phezu kobubanzi besinyathelo, iqinisekisa ukuvumelana kuyo yonke i-substrate

6Intshi 4H-semi SiC substrate ukucaciswa | ||

| Impahla | Ibanga le-Zero MPD Production (Ibanga le-Z) | I-Dummy Grade (D Grade) |

| Ububanzi (mm) | 145 mm - 150 mm | 145 mm - 150 mm |

| Uhlobo lwe-Poly | 4H | 4H |

| Ubukhulu (um) | 500 ± 15 | 500 ± 25 |

| I-Wafer Orientation | Ku-eksisi: ±0.0001° | Ku-eksisi: ±0.05° |

| I-Micropipe Density | ≤ 15 cm-2 | ≤ 15 cm-2 |

| Ukungazweli (Ωcm) | ≥ 10E3 | ≥ 10E3 |

| Isisekelo se-Flat Orientation | (0-10)° ± 5.0° | (10-10)° ± 5.0° |

| Ubude Befulethi obuyisisekelo | Inothi | Inothi |

| Ukukhishwa komphetho (mm) | ≤ 2.5 µm / ≤ 15 µm | ≤ 5.5 µm / ≤ 35 µm |

| LTV / Isitsha / Warp | ≤3 µm | ≤3 µm |

| Ubulukhuni | I-Polish Ra ≤ 1.5 µm | I-Polish Ra ≤ 1.5 µm |

| Ama-Edge Chips Ngokukhanya Okunamandla Okuphezulu | ≤ 20 µm | ≤ 60 µm |

| Amapuleti Okushisa Ngokukhanya Okunamandla Okuphezulu | Okunqwabelanayo ≤ 0.05% | Okunqwabelanayo ≤ 3% |

| Izindawo ze-Polytype Ngokukhanya Okunamandla Okuphezulu | I-Visual Carbon Inclusions ≤ 0.05% | Okunqwabelanayo ≤ 3% |

| I-Silicon Surface Scratches By High Intensity Light | ≤ 0.05% | Okunqwabelanayo ≤ 4% |

| Ama-Edge Chips Ngokukhanya Okumandla Okuphezulu (Usayizi) | Akuvunyelwe > 02 mm Ububanzi Nokujula | Akuvunyelwe > 02 mm Ububanzi Nokujula |

| I-Aiding Screw Dilation | ≤ 500 µm | ≤ 500 µm |

| I-Silicon Surface Contamination By High Intensity Light | ≤ 1 x 10^5 | ≤ 1 x 10^5 |

| Ukupakisha | I-Multi-wafer Cassette noma Isiqukathi Esiyisicwecwana Esisodwa | I-Multi-wafer Cassette noma Isiqukathi Esiyisicwecwana Esisodwa |

4-Intshi 4H-Semi Insulating SiC Substrate Specification

| Ipharamitha | Ibanga le-Zero MPD Production (Ibanga le-Z) | I-Dummy Grade (D Grade) |

|---|---|---|

| Izakhiwo Zomzimba | ||

| Ububanzi | 99.5 mm – 100.0 mm | 99.5 mm – 100.0 mm |

| Uhlobo lwe-Poly | 4H | 4H |

| Ubukhulu | 500 μm ± 15 μm | 500 μm ± 25 μm |

| I-Wafer Orientation | Ku-eksisi: <600h > 0.5° | Ku-eksisi: <000h > 0.5° |

| Izakhiwo zikagesi | ||

| I-Micropipe Density (MPD) | ≤1 cm⁻² | ≤15 cm⁻² |

| Ukungazweli | ≥150 Ω·cm | ≥1.5 Ω·cm |

| Ukubekezelelana kweJomethrikhi | ||

| Isisekelo se-Flat Orientation | (0x10) ± 5.0° | (0x10) ± 5.0° |

| Ubude Befulethi obuyisisekelo | 52.5 mm ± 2.0 mm | 52.5 mm ± 2.0 mm |

| Ubude Befulethi besibili | 18.0 mm ± 2.0 mm | 18.0 mm ± 2.0 mm |

| I-Flat Orientation yesibili | 90° CW kusuka kuPrime flat ± 5.0° (Sibheke phezulu) | 90° CW kusuka kuPrime flat ± 5.0° (Sibheke phezulu) |

| Ukukhishwa komkhawulo | 3 mm | 3 mm |

| LTV / TTV / Bow / Warp | ≤2.5 μm / ≤5 μm / ≤15 μm / ≤30 μm | ≤10 μm / ≤15 μm / ≤25 μm / ≤40 μm |

| Ikhwalithi Yobuso | ||

| I-Surface Roughness (Polish Ra) | ≤1 nm | ≤1 nm |

| I-Surface Roughness (CMP Ra) | ≤0.2 nm | ≤0.2 nm |

| Ama-Edge Cracks (Ukukhanya Okumandla Kakhulu) | Akuvunyelwe | Ubude obuqongelelwayo ≥10 mm, ukuqhekeka okukodwa ≤2 mm |

| I-Hexagonal Plate Defects | ≤0.05% indawo eqongelelwe | ≤0.1% indawo eqongelelwe |

| Izindawo zokufakwa kwe-Polytype | Akuvunyelwe | ≤1% indawo eqongelelwe |

| I-Visual Carbon Inclusions | ≤0.05% indawo eqongelelwe | ≤1% indawo eqongelelwe |

| I-Silicon Surface Scratches | Akuvunyelwe | ≤1 ubude obuyi-wafer obuhlanganisiwe ubude |

| Ama-Edge Chips | Akukho okuvunyelwe (≥0.2 mm ububanzi/ukushona) | ≤5 ama-chips (ngalinye ≤1 mm) |

| I-Silicon Surface Ukungcola | Akucacisiwe | Akucacisiwe |

| Ukupakisha | ||

| Ukupakisha | Ikhasethi le-wafer eningi noma isiqukathi se-wafer esisodwa | Multi-wafer cassette noma |

Isicelo:

II-SiC 4H Semi-Insulating substrateszisetshenziswa ngokuyinhloko kumadivayisi kagesi anamandla aphezulu kanye nemvamisa ephezulu, ikakhulukazi kuma-Inkambu ye-RF. Lawa ma-substrates abalulekile ezinhlelweni ezahlukahlukene kubandakanyaamasistimu okuxhumana nge-microwave, i-radar yohlu olunezigaba, futhiimitshina kagesi engenantambo. I-thermal conductivity ephezulu kanye nezici zikagesi ezinhle kakhulu zibenza bafaneleke ekusetshenzisweni okudingayo kugesi wamandla kanye nezinhlelo zokuxhumana.

Izakhiwo zohlobo lwe-SiC epi wafer 4H-N kanye nohlelo lokusebenza

I-SiC 4H-N Uhlobo lwe-Epi Wafer Properties kanye nezicelo

Izakhiwo ze-SiC 4H-N Uhlobo lwe-Epi Wafer:

Ukwakhiwa Kwezinto:

I-SiC (Silicon Carbide): Yaziwa ngobulukhuni bayo obuvelele, izinga eliphezulu le-thermal conductivity, kanye nezakhiwo zikagesi ezinhle kakhulu, i-SiC ilungele izinto zikagesi ezisebenza kahle kakhulu.

I-4H-SiC Polytype: I-polytype ye-4H-SiC yaziwa ngokusebenza kwayo okuphezulu nokuzinza ezinhlelweni ze-elekthronikhi.

I-N-Type Doping: I-N-type doping (i-doped ne-nitrogen) inikeza ukuhamba kahle kwe-electron, okwenza i-SiC ifanelekele ukusetshenziswa kwe-high-frequency kanye namandla aphezulu.

High Thermal Conductivity:

Ama-wafers e-SiC ane-conductivity ephakeme kakhulu ye-thermal, ngokuvamile esukela120–200 W/m·K, okubavumela ukuthi baphathe ngempumelelo ukushisa kumadivayisi anamandla amakhulu njengama-transistors nama-diode.

I-Bandgap ebanzi:

Nge-bandgap ye3.26 eV, I-4H-SiC ingasebenza ngama-voltage aphezulu, amaza, namazinga okushisa uma kuqhathaniswa namadivayisi asekelwe ku-silicon, okwenza kube kuhle ekusebenzeni okuphezulu, izinhlelo zokusebenza ezisebenza kahle.

Izakhiwo zikagesi:

Ukuhamba kwe-electron ephezulu ye-SiC kanye nokusebenza kwayo kuyenza ilungeleamandla kagesi, enikeza isivinini sokushintsha okusheshayo kanye nomthamo ophezulu wamanje kanye nomthamo we-voltage, okuphumela ezinhlelweni zokuphatha amandla ezisebenza kahle kakhulu.

Ukumelana Nemishini Namakhemikhali:

I-SiC ingenye yezinto eziqinile, isibili ngemuva kwedayimane, futhi imelana kakhulu ne-oxidation nokugqwala, iyenza iqine ezindaweni ezinokhahlo.

Izicelo ze-SiC 4H-N Uhlobo lwe-Epi Wafer:

Amandla kagesi:

I-SiC 4H-N yohlobo lwe-epi wafers isetshenziswa kabanzi kuamandla MOSFETs, I-IGBTs, futhiama-diodeokweukuguqulwa kwamandlaezinhlelweni ezifanaama-solar inverters, izimoto zikagesi, futhiizinhlelo zokugcina amandla, enikeza ukusebenza okuthuthukisiwe nokusebenza kahle kwamandla.

Izimoto zikagesi (EVs):

In ama-powertrains emoto kagesi, izilawuli zezimoto, futhiiziteshi zokushaja, Amawafa e-SiC asiza ukufeza ukusebenza kahle kwebhethri okungcono, ukushaja okusheshayo, nokusebenza kwamandla okuthuthukisiwe kukonke ngenxa yekhono lawo lokuphatha amandla aphezulu namazinga okushisa.

Amasistimu Amandla Avuselelekayo:

Ama-Solar Inverters: Ama-wafers e-SiC asetshenziswa kuizinhlelo zamandla elangangokuguqula amandla e-DC asuka kumaphaneli elanga abe yi-AC, okwandisa ukusebenza kahle kohlelo lonke nokusebenza.

Izinjini Zomoya: Ubuchwepheshe be-SiC busetshenziswa kuamasistimu okulawula i-turbine yomoya, ukuthuthukisa ukukhiqizwa kwamandla nokusebenza kahle kokuguqulwa.

I-Aerospace nokuvikela:

Ama-wafers e-SiC alungele ukusetshenziswa kuwoi-aerospace electronicsfuthiizicelo zempi, kuhlanganiseizinhlelo ze-radarfuthisatellite electronics, lapho ukumelana nemisebe ephezulu nokuzinza kokushisa kubalulekile.

Izicelo Zezinga Lokushisa Eziphezulu Nezinga eliphezulu:

Ama-wafers e-SiC ahamba phambiliama-electronics anezinga lokushisa eliphezulu, esetshenziswa kuizinjini zezindiza, umkhumbi-mkhathi, futhiizinhlelo zokushisa zezimboni, njengoba begcina ukusebenza ezimweni zokushisa okukhulu. Ukwengeza, i-bandgap yabo ebanzi ivumela ukusetshenziswa ngaphakathiizicelo high-frequencynjengeImishini ye-RFfuthimicrowave ukuxhumana.

| 6-intshi N-uhlobo lwe-epit axial ukucaciswa | |||

| Ipharamitha | iyunithi | Z-MOS | |

| Uhlobo | I-Condutivity / I-Dopant | - | N-uhlobo / Nitrojeni |

| Isendlalelo se-Buffer | Buffer Layer Ukuqina | um | 1 |

| Ukubekezelela Ukuqina Kwengqimba ye-Buffer | % | ±20% | |

| I-Buffer Layer Concentration | cm-3 | 1.00E+18 | |

| I-Buffer Layer Concentration Tolerance | % | ±20% | |

| 1st Isendlalelo se-Epi | I-Epi Layer Thickness | um | 11.5 |

| I-Epi Layer Thickness Uniformity | % | ±4% | |

| Ukubekezelela Ukuqina Kwezendlalelo ze-Epi((Spec- Ubukhulu , Ubuncane)/Isicaciso) | % | ±5% | |

| I-Epi Layer Concentration | cm-3 | 1E 15~ 1E 18 | |

| I-Epi Layer Concentration Tolerance | % | 6% | |

| I-Epi Layer Concentration Uniformity (σ /okusho) | % | ≤5% | |

| I-Epi Layer Concentration Uniformity <(ubuningi-min)/(ubuningi+min> | % | ≤ 10% | |

| I-Epitaixal Wafer Shape | Khothama | um | ≤±20 |

| I-WARP | um | ≤30 | |

| I-TTV | um | ≤ 10 | |

| I-LTV | um | ≤2 | |

| Izimpawu Ezijwayelekile | Ubude bemihuzuko | mm | ≤30mm |

| Ama-Edge Chips | - | AKUKHO | |

| Incazelo yamaphutha | ≥97% (Ikalwe ngo-2*2, Amaphutha okubulala ahlanganisa: Amaphutha afaka phakathi Umbhobho/Imigodi emikhulu, Isanqante, Unxantathu | ||

| Ukungcoliswa kwensimbi | ama-athomu/cm² | df ngi ≤5E10 ama-athomu/cm2 (Al, Cr, Fe, Ni, Cu, Zn, Hg,Na,K,Ti,Ca &Mn) | |

| Iphakheji | Ukupakisha imininingwane | ama-pcs/ibhokisi | i-multi-wafer cassette noma isiqukathi esisodwa se-wafer |

| 8-intshi N-uhlobo lwe-epitaxial yokucacisa | |||

| Ipharamitha | iyunithi | Z-MOS | |

| Uhlobo | I-Condutivity / I-Dopant | - | N-uhlobo / Nitrojeni |

| Isendlalelo sebhafa | Buffer Layer Ukuqina | um | 1 |

| Ukubekezelela Ukuqina Kwengqimba ye-Buffer | % | ±20% | |

| I-Buffer Layer Concentration | cm-3 | 1.00E+18 | |

| I-Buffer Layer Concentration Tolerance | % | ±20% | |

| 1st Isendlalelo se-Epi | I-Epi Layers Ukuqina Okumaphakathi | um | 8-12 |

| I-Epi Layers Thickness Uniformity (σ/mean) | % | ≤2.0 | |

| Ukubekezelela Ukuqina Kwezendlalelo ze-Epi((Spec -Max, Min)/Spec) | % | ±6 | |

| I-Epi Layers Net Average Doping | cm-3 | 8E+15 ~2E+16 | |

| I-Epi Layers Net Doping Uniformity (σ/mean) | % | ≤5 | |

| I-Epi Layers Net DopingTolerance ((Spec -Max, | % | ± 10.0 | |

| I-Epitaixal Wafer Shape | Mi)/S) I-Wap | um | ≤50.0 |

| Khothama | um | ± 30.0 | |

| I-TTV | um | ≤ 10.0 | |

| I-LTV | um | ≤4.0 (10mm×10mm) | |

| Okujwayelekile Izici | Ukuklwebheka | - | Ubude obuqongelelayo≤ 1/2 Wafer diameter |

| Ama-Edge Chips | - | ≤2 chips, Irediyasi ngayinye≤1.5mm | |

| Surface Metals Ukungcola | ama-athomu/cm2 | ≤5E10 ama-athomu/cm2 (Al, Cr, Fe, Ni, Cu, Zn, Hg,Na,K,Ti,Ca &Mn) | |

| Ukuhlola Isici | % | ≥ 96.0 (Amaphutha angu-2X2 ahlanganisa i-Micropipe / Imigodi emikhulu, Isanqante, ukukhubazeka kukanxantathu, ukuwa, Linear/IGSF-s, BPD) | |

| Surface Metals Ukungcola | ama-athomu/cm2 | ≤5E10 ama-athomu/cm2 (Al, Cr, Fe, Ni, Cu, Zn, Hg,Na,K,Ti,Ca &Mn) | |

| Iphakheji | Ukupakisha imininingwane | - | i-multi-wafer cassette noma isiqukathi esisodwa se-wafer |

I-Q&A ye-SiC wafer

Q1: Yiziphi izinzuzo ezibalulekile zokusebenzisa amawafa e-SiC ngaphezu kwamawafa e-silicon endabuko kugesi wamandla?

A1:

Ama-wafer e-SiC anikeza izinzuzo ezibalulekile ezimbalwa ngaphezu kwamawafa e-silicon (Si) endabuko kuma-electronics amandla, okuhlanganisa:

Ukusebenza Okuphakeme: I-SiC ine-bandgap ebanzi (3.26 eV) uma iqhathaniswa ne-silicon (1.1 eV), evumela amadivayisi ukuthi asebenze ngama-voltage aphezulu, amaza, namazinga okushisa. Lokhu kuholela ekulahlekeni kwamandla okuphansi kanye nokusebenza kahle okuphezulu ezinhlelweni zokuguqula amandla.

High Thermal Conductivity: I-SiC's conductivity ye-thermal iphakeme kakhulu kune-silicon, ivumela ukuchithwa okungcono kokushisa ezinhlelweni zokusebenza zamandla aphezulu, okuthuthukisa ukuthembeka nokuphila kwamadivayisi kagesi.

Amandla kagesi aphezulu kanye nokubamba kwamanje: Amadivayisi e-SiC angakwazi ukuphatha amandla kagesi aphezulu kanye namazinga amanje, awenze afanelekele izinhlelo zokusebenza zamandla aphezulu njengezimoto zikagesi, izinhlelo zamandla avuselelekayo, namadrayivu ezimoto ezimboni.

Isivinini Sokushintsha Okusheshayo: Amadivayisi e-SiC anamandla okushintsha ngokushesha, anomthelela ekwehliseni ukulahleka kwamandla kanye nosayizi wesistimu, okuwenza alungele izinhlelo zokusebenza zamafrikhwensi aphezulu.

Q2: Yiziphi izinhlelo zokusebenza eziyinhloko zama-wafers e-SiC embonini yezimoto?

A2:

Embonini yezimoto, ama-wafers e-SiC asetshenziswa ngokuyinhloko ku:

Imoto Kagesi (EV) Powertrains: Izingxenye ezisekelwe ku-SiC ezifanaama-invertersfuthiamandla MOSFETsngcono ukusebenza kahle kanye nokusebenza kwezitimela zemoto kagesi ngokunika amandla isivinini sokushintsha ngokushesha kanye nokuminyana kwamandla aphezulu. Lokhu kuholela empilweni yebhethri ende kanye nokusebenza okungcono kwemoto sekukonke.

Amashaja Asebhodini: Amadivayisi e-SiC asiza ukuthuthukisa ukusebenza kahle kwezinhlelo zokushaja ezisebhodini ngokunika amandla izikhathi zokushaja ezisheshayo kanye nokuphathwa okungcono kwe-thermal, okubalulekile kuma-EV ukuze asekele iziteshi zokushaja ezinamandla amakhulu.

Amasistimu Okuphatha Ibhethri (BMS): Ubuchwepheshe be-SiC buthuthukisa ukusebenza kahle kweamasistimu okuphatha ibhethri, okuvumela ukulawulwa okungcono kwamandla kagesi, ukuphatha amandla aphezulu, nempilo yebhethri ende.

Iziguquli ze-DC-DC: Ama-wafers e-SiC asetshenziswa kuIziguquli ze-DC-DCukuguqula amandla e-DC aphezulu abe amandla kagesi aphansi e-DC ngendlela ephumelela kakhudlwana, okubalulekile ezimotweni zikagesi ukuze zilawule amandla asuka ebhethrini aye ezingxenyeni ezihlukahlukene zemoto.

Ukusebenza okuphezulu kwe-SiC ku-high-voltage, izinga lokushisa eliphezulu, kanye nezinhlelo zokusebenza ezisebenza kahle kakhulu kukwenza kubaluleke ekushintsheni kwemboni yezimoto ukuya ekuhambeni kukagesi.

I-6inch 4H-N yohlobo lwe-SiC wafer olucacile | ||

| Impahla | Ibanga le-Zero MPD Production (Ibanga le-Z) | I-Dummy Grade (D Grade) |

| Ibanga | Ibanga le-Zero MPD Production (Ibanga le-Z) | I-Dummy Grade (D Grade) |

| Ububanzi | 149.5 mm – 150.0 mm | 149.5 mm – 150.0 mm |

| Uhlobo lwe-Poly | 4H | 4H |

| Ubukhulu | 350 µm ± 15 µm | 350 µm ± 25 µm |

| I-Wafer Orientation | Ku-axis evaliwe: 4.0° kuya ku-<1120> ± 0.5° | Ku-axis evaliwe: 4.0° kuya ku-<1120> ± 0.5° |

| I-Micropipe Density | ≤ 0.2 cm² | ≤ 15 cm² |

| Ukungazweli | 0.015 – 0.024 Ω·cm | 0.015 – 0.028 Ω·cm |

| Isisekelo se-Flat Orientation | [10-10] ± 50° | [10-10] ± 50° |

| Ubude Befulethi obuyisisekelo | 475 mm ± 2.0 mm | 475 mm ± 2.0 mm |

| Ukukhishwa komkhawulo | 3 mm | 3 mm |

| I-LTV/TIV / Umnsalo / I-Warp | ≤ 2.5 µm / ≤ 6 µm / ≤ 25 µm / ≤ 35 µm | ≤ 5 µm / ≤ 15 µm / ≤ 40 µm / ≤ 60 µm |

| Ubulukhuni | I-Polish Ra ≤ 1 nm | I-Polish Ra ≤ 1 nm |

| CMP Ra | ≤ 0.2 nm | ≤ 0.5 nm |

| I-Edge Cracks By High Intensity Light | Ubude obukhulayo ≤ 20 mm ubude obubodwa ≤ 2 mm | Ubude obukhulayo ≤ 20 mm ubude obubodwa ≤ 2 mm |

| I-Hex Plates Ngokukhanya Okunamandla Okuphezulu | Indawo eqoqiwe ≤ 0.05% | Indawo eqoqiwe ≤ 0.1% |

| Izindawo ze-Polytype Ngokukhanya Okunamandla Okuphezulu | Indawo eqoqiwe ≤ 0.05% | Indawo eqoqiwe ≤ 3% |

| I-Visual Carbon Inclusions | Indawo eqoqiwe ≤ 0.05% | Indawo eqoqiwe ≤ 5% |

| I-Silicon Surface Scratches By High Intensity Light | Ubude obuqongelelwayo ≤ 1 ububanzi bewafa | |

| Ama-Edge Chips Ngokukhanya Okunamandla Okuphezulu | Akukho okuvunyelwe ≥ 0.2 mm ububanzi nokujula | 7 okuvunyelwe, ≤ 1 mm ngakunye |

| Ukukhipha Isikulufu sochungechunge | <500cm³ | <500cm³ |

| I-Silicon Surface Contamination By High Intensity Light | ||

| Ukupakisha | Ikhasethi elinesinkwa esilucwecwana noma Isitsha Esiyisinkwa Esikodwa | Ikhasethi elinesinkwa esilucwecwana noma Isitsha Esiyisinkwa Esikodwa |

8inch 4H-N uhlobo lwe-SiC wafer olucacisiwe | ||

| Impahla | Ibanga le-Zero MPD Production (Ibanga le-Z) | I-Dummy Grade (D Grade) |

| Ibanga | Ibanga le-Zero MPD Production (Ibanga le-Z) | I-Dummy Grade (D Grade) |

| Ububanzi | 199.5 mm – 200.0 mm | 199.5 mm – 200.0 mm |

| Uhlobo lwe-Poly | 4H | 4H |

| Ubukhulu | 500 µm ± 25 µm | 500 µm ± 25 µm |

| I-Wafer Orientation | 4.0° ukuya ku-<110> ± 0.5° | 4.0° ukuya ku-<110> ± 0.5° |

| I-Micropipe Density | ≤ 0.2 cm² | ≤ 5 cm² |

| Ukungazweli | 0.015 – 0.025 Ω·cm | 0.015 – 0.028 Ω·cm |

| Noble Orientation | ||

| Ukukhishwa komkhawulo | 3 mm | 3 mm |

| I-LTV/TIV / Umnsalo / I-Warp | ≤ 5 µm / ≤ 15 µm / ≤ 35 µm / 70 µm | ≤ 5 µm / ≤ 15 µm / ≤ 35 µm / 100 µm |

| Ubulukhuni | I-Polish Ra ≤ 1 nm | I-Polish Ra ≤ 1 nm |

| CMP Ra | ≤ 0.2 nm | ≤ 0.5 nm |

| I-Edge Cracks By High Intensity Light | Ubude obukhulayo ≤ 20 mm ubude obubodwa ≤ 2 mm | Ubude obukhulayo ≤ 20 mm ubude obubodwa ≤ 2 mm |

| I-Hex Plates Ngokukhanya Okunamandla Okuphezulu | Indawo eqoqiwe ≤ 0.05% | Indawo eqoqiwe ≤ 0.1% |

| Izindawo ze-Polytype Ngokukhanya Okunamandla Okuphezulu | Indawo eqoqiwe ≤ 0.05% | Indawo eqoqiwe ≤ 3% |

| I-Visual Carbon Inclusions | Indawo eqoqiwe ≤ 0.05% | Indawo eqoqiwe ≤ 5% |

| I-Silicon Surface Scratches By High Intensity Light | Ubude obuqongelelwayo ≤ 1 ububanzi bewafa | |

| Ama-Edge Chips Ngokukhanya Okunamandla Okuphezulu | Akukho okuvunyelwe ≥ 0.2 mm ububanzi nokujula | 7 okuvunyelwe, ≤ 1 mm ngakunye |

| Ukukhipha Isikulufu sochungechunge | <500cm³ | <500cm³ |

| I-Silicon Surface Contamination By High Intensity Light | ||

| Ukupakisha | Ikhasethi elinesinkwa esilucwecwana noma Isitsha Esiyisinkwa Esikodwa | Ikhasethi elinesinkwa esilucwecwana noma Isitsha Esiyisinkwa Esikodwa |

6Intshi 4H-semi SiC substrate ukucaciswa | ||

| Impahla | Ibanga le-Zero MPD Production (Ibanga le-Z) | I-Dummy Grade (D Grade) |

| Ububanzi (mm) | 145 mm - 150 mm | 145 mm - 150 mm |

| Uhlobo lwe-Poly | 4H | 4H |

| Ubukhulu (um) | 500 ± 15 | 500 ± 25 |

| I-Wafer Orientation | Ku-eksisi: ±0.0001° | Ku-eksisi: ±0.05° |

| I-Micropipe Density | ≤ 15 cm-2 | ≤ 15 cm-2 |

| Ukungazweli (Ωcm) | ≥ 10E3 | ≥ 10E3 |

| Isisekelo se-Flat Orientation | (0-10)° ± 5.0° | (10-10)° ± 5.0° |

| Ubude Befulethi obuyisisekelo | Inothi | Inothi |

| Ukukhishwa komphetho (mm) | ≤ 2.5 µm / ≤ 15 µm | ≤ 5.5 µm / ≤ 35 µm |

| LTV / Isitsha / Warp | ≤3 µm | ≤3 µm |

| Ubulukhuni | I-Polish Ra ≤ 1.5 µm | I-Polish Ra ≤ 1.5 µm |

| Ama-Edge Chips Ngokukhanya Okunamandla Okuphezulu | ≤ 20 µm | ≤ 60 µm |

| Amapuleti Okushisa Ngokukhanya Okunamandla Okuphezulu | Okunqwabelanayo ≤ 0.05% | Okunqwabelanayo ≤ 3% |

| Izindawo ze-Polytype Ngokukhanya Okunamandla Okuphezulu | I-Visual Carbon Inclusions ≤ 0.05% | Okunqwabelanayo ≤ 3% |

| I-Silicon Surface Scratches By High Intensity Light | ≤ 0.05% | Okunqwabelanayo ≤ 4% |

| Ama-Edge Chips Ngokukhanya Okumandla Okuphezulu (Usayizi) | Akuvunyelwe > 02 mm Ububanzi Nokujula | Akuvunyelwe > 02 mm Ububanzi Nokujula |

| I-Aiding Screw Dilation | ≤ 500 µm | ≤ 500 µm |

| I-Silicon Surface Contamination By High Intensity Light | ≤ 1 x 10^5 | ≤ 1 x 10^5 |

| Ukupakisha | I-Multi-wafer Cassette noma Isiqukathi Esiyisicwecwana Esisodwa | I-Multi-wafer Cassette noma Isiqukathi Esiyisicwecwana Esisodwa |

4-Intshi 4H-Semi Insulating SiC Substrate Specification

| Ipharamitha | Ibanga le-Zero MPD Production (Ibanga le-Z) | I-Dummy Grade (D Grade) |

|---|---|---|

| Izakhiwo Zomzimba | ||

| Ububanzi | 99.5 mm – 100.0 mm | 99.5 mm – 100.0 mm |

| Uhlobo lwe-Poly | 4H | 4H |

| Ubukhulu | 500 μm ± 15 μm | 500 μm ± 25 μm |

| I-Wafer Orientation | Ku-eksisi: <600h > 0.5° | Ku-eksisi: <000h > 0.5° |

| Izakhiwo zikagesi | ||

| I-Micropipe Density (MPD) | ≤1 cm⁻² | ≤15 cm⁻² |

| Ukungazweli | ≥150 Ω·cm | ≥1.5 Ω·cm |

| Ukubekezelelana kweJomethrikhi | ||

| Isisekelo se-Flat Orientation | (0×10) ± 5.0° | (0×10) ± 5.0° |

| Ubude Befulethi obuyisisekelo | 52.5 mm ± 2.0 mm | 52.5 mm ± 2.0 mm |

| Ubude Befulethi besibili | 18.0 mm ± 2.0 mm | 18.0 mm ± 2.0 mm |

| I-Flat Orientation yesibili | 90° CW kusuka kuPrime flat ± 5.0° (Sibheke phezulu) | 90° CW kusuka kuPrime flat ± 5.0° (Sibheke phezulu) |

| Ukukhishwa komkhawulo | 3 mm | 3 mm |

| LTV / TTV / Bow / Warp | ≤2.5 μm / ≤5 μm / ≤15 μm / ≤30 μm | ≤10 μm / ≤15 μm / ≤25 μm / ≤40 μm |

| Ikhwalithi Yobuso | ||

| I-Surface Roughness (Polish Ra) | ≤1 nm | ≤1 nm |

| I-Surface Roughness (CMP Ra) | ≤0.2 nm | ≤0.2 nm |

| Ama-Edge Cracks (Ukukhanya Okumandla Kakhulu) | Akuvunyelwe | Ubude obuqongelelwayo ≥10 mm, ukuqhekeka okukodwa ≤2 mm |

| I-Hexagonal Plate Defects | ≤0.05% indawo eqongelelwe | ≤0.1% indawo eqongelelwe |

| Izindawo zokufakwa kwe-Polytype | Akuvunyelwe | ≤1% indawo eqongelelwe |

| I-Visual Carbon Inclusions | ≤0.05% indawo eqongelelwe | ≤1% indawo eqongelelwe |

| I-Silicon Surface Scratches | Akuvunyelwe | ≤1 ubude obuyi-wafer obuhlanganisiwe ubude |

| Ama-Edge Chips | Akukho okuvunyelwe (≥0.2 mm ububanzi/ukushona) | ≤5 ama-chips (ngalinye ≤1 mm) |

| I-Silicon Surface Ukungcola | Akucacisiwe | Akucacisiwe |

| Ukupakisha | ||

| Ukupakisha | Ikhasethi le-wafer eningi noma isiqukathi se-wafer esisodwa | Multi-wafer cassette noma |

| 6-intshi N-uhlobo lwe-epit axial ukucaciswa | |||

| Ipharamitha | iyunithi | Z-MOS | |

| Uhlobo | I-Condutivity / I-Dopant | - | N-uhlobo / Nitrojeni |

| Isendlalelo se-Buffer | Buffer Layer Ukuqina | um | 1 |

| Ukubekezelela Ukuqina Kwengqimba ye-Buffer | % | ±20% | |

| I-Buffer Layer Concentration | cm-3 | 1.00E+18 | |

| I-Buffer Layer Concentration Tolerance | % | ±20% | |

| 1st Isendlalelo se-Epi | I-Epi Layer Thickness | um | 11.5 |

| I-Epi Layer Thickness Uniformity | % | ±4% | |

| Ukubekezelela Ukuqina Kwezendlalelo ze-Epi((Spec- Ubukhulu , Ubuncane)/Isicaciso) | % | ±5% | |

| I-Epi Layer Concentration | cm-3 | 1E 15~ 1E 18 | |

| I-Epi Layer Concentration Tolerance | % | 6% | |

| I-Epi Layer Concentration Uniformity (σ /okusho) | % | ≤5% | |

| I-Epi Layer Concentration Uniformity <(ubuningi-min)/(ubuningi+min> | % | ≤ 10% | |

| I-Epitaixal Wafer Shape | Khothama | um | ≤±20 |

| I-WARP | um | ≤30 | |

| I-TTV | um | ≤ 10 | |

| I-LTV | um | ≤2 | |

| Izimpawu Ezijwayelekile | Ubude bemihuzuko | mm | ≤30mm |

| Ama-Edge Chips | - | AKUKHO | |

| Incazelo yamaphutha | ≥97% (Ikalwe ngo-2*2, Amaphutha okubulala ahlanganisa: Amaphutha afaka phakathi Umbhobho/Imigodi emikhulu, Isanqante, Unxantathu | ||

| Ukungcoliswa kwensimbi | ama-athomu/cm² | df ngi ≤5E10 ama-athomu/cm2 (Al, Cr, Fe, Ni, Cu, Zn, Hg,Na,K,Ti,Ca &Mn) | |

| Iphakheji | Ukupakisha imininingwane | ama-pcs/ibhokisi | i-multi-wafer cassette noma isiqukathi esisodwa se-wafer |

| 8-intshi N-uhlobo lwe-epitaxial yokucacisa | |||

| Ipharamitha | iyunithi | Z-MOS | |

| Uhlobo | I-Condutivity / I-Dopant | - | N-uhlobo / Nitrojeni |

| Isendlalelo sebhafa | Buffer Layer Ukuqina | um | 1 |

| Ukubekezelela Ukuqina Kwengqimba ye-Buffer | % | ±20% | |

| I-Buffer Layer Concentration | cm-3 | 1.00E+18 | |

| I-Buffer Layer Concentration Tolerance | % | ±20% | |

| 1st Isendlalelo se-Epi | I-Epi Layers Ukuqina Okumaphakathi | um | 8-12 |

| I-Epi Layers Thickness Uniformity (σ/mean) | % | ≤2.0 | |

| Ukubekezelela Ukuqina Kwezendlalelo ze-Epi((Spec -Max, Min)/Spec) | % | ±6 | |

| I-Epi Layers Net Average Doping | cm-3 | 8E+15 ~2E+16 | |

| I-Epi Layers Net Doping Uniformity (σ/mean) | % | ≤5 | |

| I-Epi Layers Net DopingTolerance ((Spec -Max, | % | ± 10.0 | |

| I-Epitaixal Wafer Shape | Mi)/S) I-Wap | um | ≤50.0 |

| Khothama | um | ± 30.0 | |

| I-TTV | um | ≤ 10.0 | |

| I-LTV | um | ≤4.0 (10mm×10mm) | |

| Okujwayelekile Izici | Ukuklwebheka | - | Ubude obuqongelelayo≤ 1/2 Wafer diameter |

| Ama-Edge Chips | - | ≤2 chips, Irediyasi ngayinye≤1.5mm | |

| Surface Metals Ukungcola | ama-athomu/cm2 | ≤5E10 ama-athomu/cm2 (Al, Cr, Fe, Ni, Cu, Zn, Hg,Na,K,Ti,Ca &Mn) | |

| Ukuhlola Isici | % | ≥ 96.0 (Amaphutha angu-2X2 ahlanganisa i-Micropipe / Imigodi emikhulu, Isanqante, ukukhubazeka kukanxantathu, ukuwa, Linear/IGSF-s, BPD) | |

| Surface Metals Ukungcola | ama-athomu/cm2 | ≤5E10 ama-athomu/cm2 (Al, Cr, Fe, Ni, Cu, Zn, Hg,Na,K,Ti,Ca &Mn) | |

| Iphakheji | Ukupakisha imininingwane | - | i-multi-wafer cassette noma isiqukathi esisodwa se-wafer |

Q1: Yiziphi izinzuzo ezibalulekile zokusebenzisa amawafa e-SiC ngaphezu kwamawafa e-silicon endabuko kugesi wamandla?

A1:

Ama-wafer e-SiC anikeza izinzuzo ezibalulekile ezimbalwa ngaphezu kwamawafa e-silicon (Si) endabuko kuma-electronics amandla, okuhlanganisa:

Ukusebenza Okuphakeme: I-SiC ine-bandgap ebanzi (3.26 eV) uma iqhathaniswa ne-silicon (1.1 eV), evumela amadivayisi ukuthi asebenze ngama-voltage aphezulu, amaza, namazinga okushisa. Lokhu kuholela ekulahlekeni kwamandla okuphansi kanye nokusebenza kahle okuphezulu ezinhlelweni zokuguqula amandla.

High Thermal Conductivity: I-SiC's conductivity ye-thermal iphakeme kakhulu kune-silicon, ivumela ukuchithwa okungcono kokushisa ezinhlelweni zokusebenza zamandla aphezulu, okuthuthukisa ukuthembeka nokuphila kwamadivayisi kagesi.

Amandla kagesi aphezulu kanye nokubamba kwamanje: Amadivayisi e-SiC angakwazi ukuphatha amandla kagesi aphezulu kanye namazinga amanje, awenze afanelekele izinhlelo zokusebenza zamandla aphezulu njengezimoto zikagesi, izinhlelo zamandla avuselelekayo, namadrayivu ezimoto ezimboni.

Isivinini Sokushintsha Okusheshayo: Amadivayisi e-SiC anamandla okushintsha ngokushesha, anomthelela ekwehliseni ukulahleka kwamandla kanye nosayizi wesistimu, okuwenza alungele izinhlelo zokusebenza zamafrikhwensi aphezulu.

Q2: Yiziphi izinhlelo zokusebenza eziyinhloko zama-wafers e-SiC embonini yezimoto?

A2:

Embonini yezimoto, ama-wafers e-SiC asetshenziswa ngokuyinhloko ku:

Imoto Kagesi (EV) Powertrains: Izingxenye ezisekelwe ku-SiC ezifanaama-invertersfuthiamandla MOSFETsngcono ukusebenza kahle kanye nokusebenza kwezitimela zemoto kagesi ngokunika amandla isivinini sokushintsha ngokushesha kanye nokuminyana kwamandla aphezulu. Lokhu kuholela empilweni yebhethri ende kanye nokusebenza okungcono kwemoto sekukonke.

Amashaja Asebhodini: Amadivayisi e-SiC asiza ukuthuthukisa ukusebenza kahle kwezinhlelo zokushaja ezisebhodini ngokunika amandla izikhathi zokushaja ezisheshayo kanye nokuphathwa okungcono kwe-thermal, okubalulekile kuma-EV ukuze asekele iziteshi zokushaja ezinamandla amakhulu.

Amasistimu Okuphatha Ibhethri (BMS): Ubuchwepheshe be-SiC buthuthukisa ukusebenza kahle kweamasistimu okuphatha ibhethri, okuvumela ukulawulwa okungcono kwamandla kagesi, ukuphatha amandla aphezulu, nempilo yebhethri ende.

Iziguquli ze-DC-DC: Ama-wafers e-SiC asetshenziswa kuIziguquli ze-DC-DCukuguqula amandla e-DC aphezulu abe amandla kagesi aphansi e-DC ngendlela ephumelela kakhudlwana, okubalulekile ezimotweni zikagesi ukuze zilawule amandla asuka ebhethrini aye ezingxenyeni ezihlukahlukene zemoto.

Ukusebenza okuphezulu kwe-SiC ku-high-voltage, izinga lokushisa eliphezulu, kanye nezinhlelo zokusebenza ezisebenza kahle kakhulu kukwenza kubaluleke ekushintsheni kwemboni yezimoto ukuya ekuhambeni kukagesi.