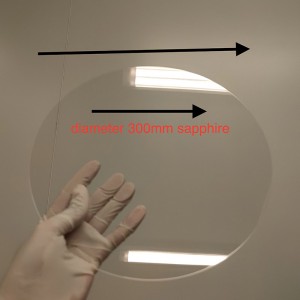

I-Dia300x1.0mmt Ukuqina kweSapphire Wafer C-Plane SSP/DSP

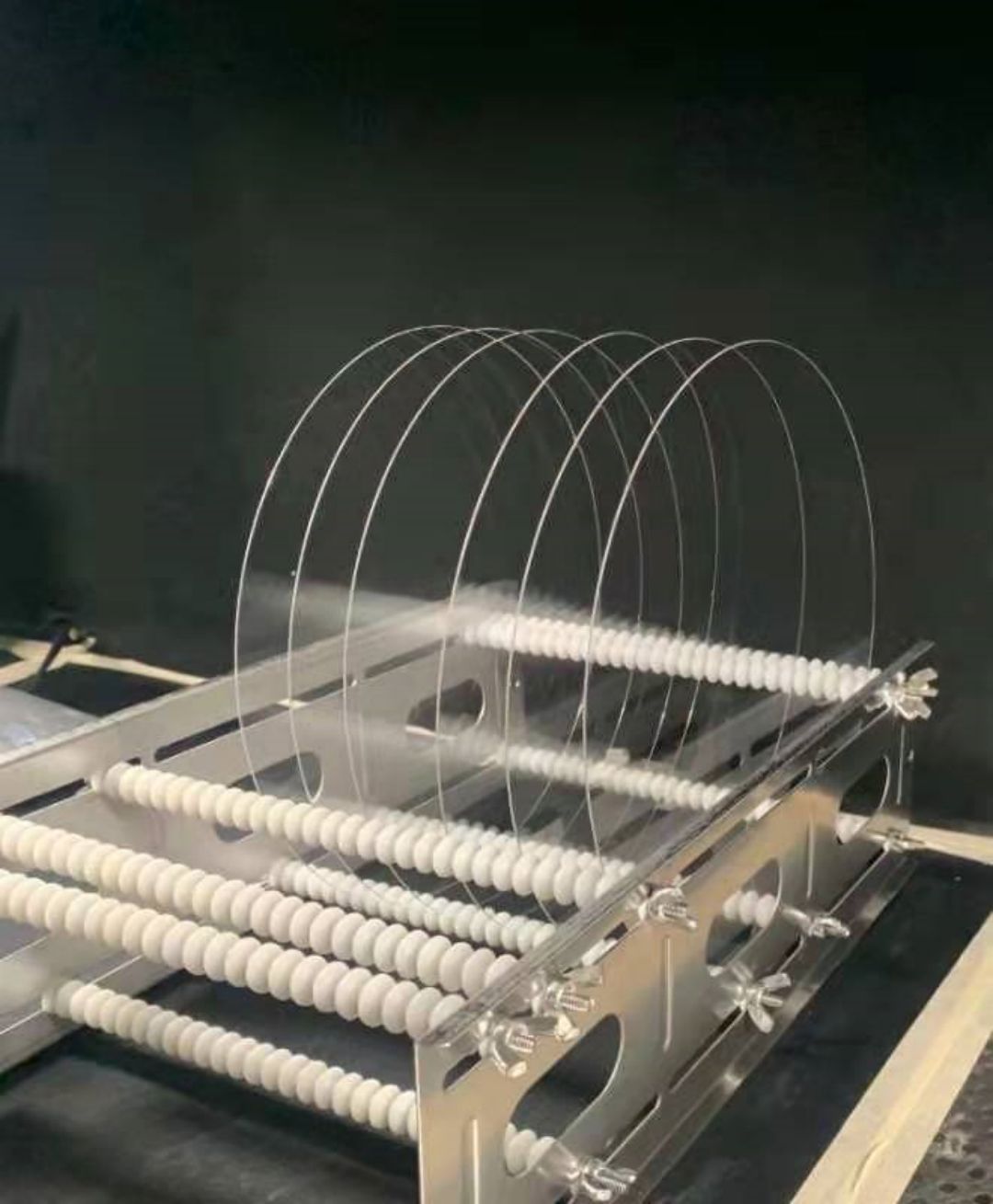

Ukwethulwa kwebhokisi le-wafer

| I-Crystal Materials | 99,999% ye-Al2O3,I-High Purity, i-Monocrystalline, i-Al2O3 | |||

| Ikhwalithi ye-Crystal | Okufakiwe, ama-block marks, amawele, Umbala, amabhamuza amancane kanye nezikhungo zokuhlakazeka azikho | |||

| Ububanzi | 2intshi | 3inch | 4intshi | 6inch ~ 12inch |

| 50.8± 0.1mm | 76.2±0.2mm | 100±0.3mm | Ngokuhambisana nezinhlinzeko zokukhiqiza okujwayelekile | |

| Ubukhulu | 430±15µm | 550±15µm | 650±20µm | Kungenziwa egcizelele ikhasimende |

| Ukuqondisa | I-C- indiza (0001) eya ku-M-indiza (1-100) noma i-A-plane(1 1-2 0) 0.2±0.1° /0.3±0.1°, i-R-plane (1-1 0 2), i-A-plane (1 1-2 0), indiza ye-M(1-1 0 0), Noma yikuphi ukuma , Noma iyiphi i-engeli | |||

| Ubude obuyisicaba obuyisisekelo | 16.0±1mm | 22.0±1.0mm | 32.5±1.5 mm | Ngokuhambisana nezinhlinzeko zokukhiqiza okujwayelekile |

| I-Primary Orientation | I-A-plane (1 1-2 0 ) ± 0.2° | |||

| I-TTV | ≤10µm | ≤15µm | ≤20µm | ≤30µm |

| I-LTV | ≤10µm | ≤15µm | ≤20µm | ≤30µm |

| I-TIR | ≤10µm | ≤15µm | ≤20µm | ≤30µm |

| KHOTHAMA | ≤10µm | ≤15µm | ≤20µm | ≤30µm |

| I-Wap | ≤10µm | ≤15µm | ≤20µm | ≤30µm |

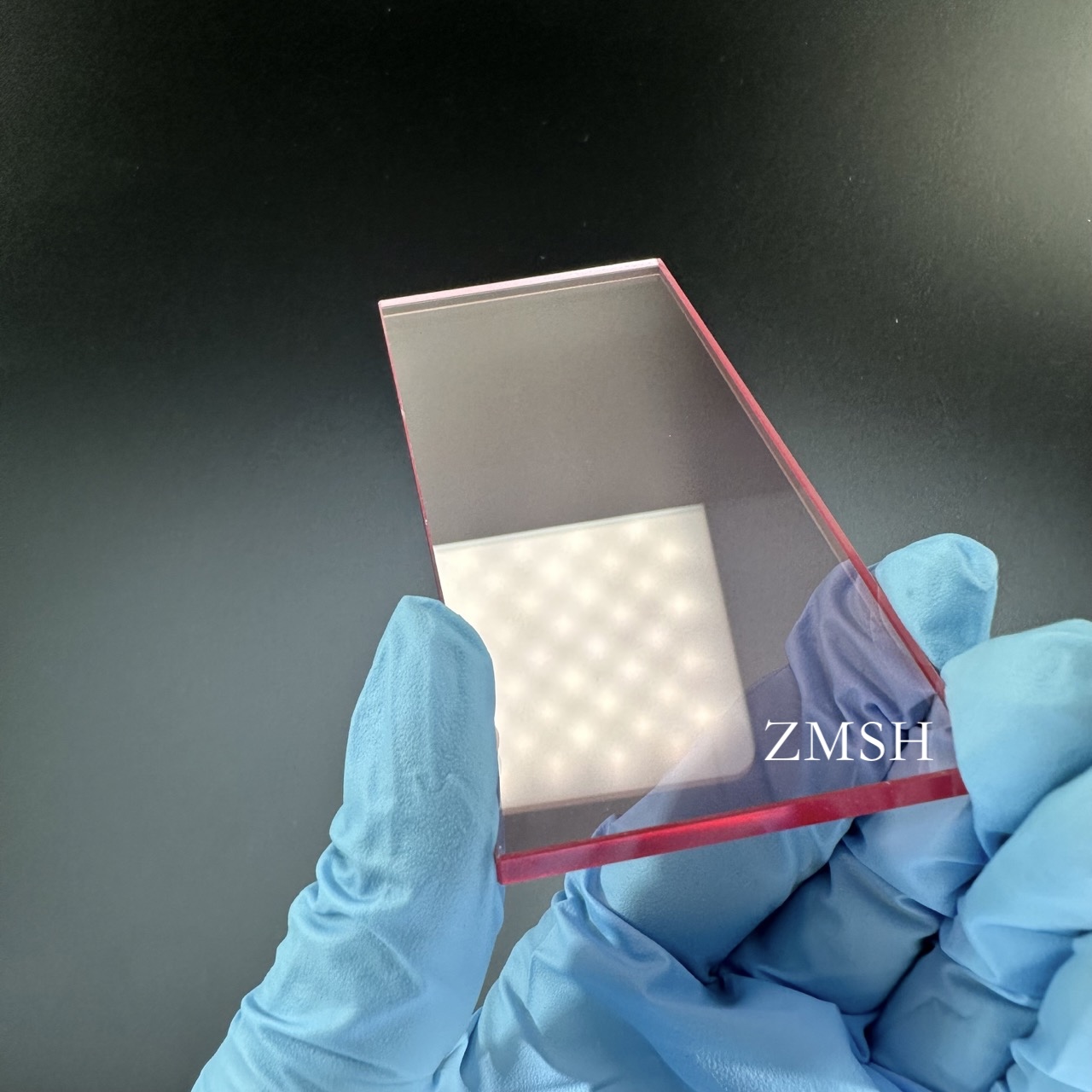

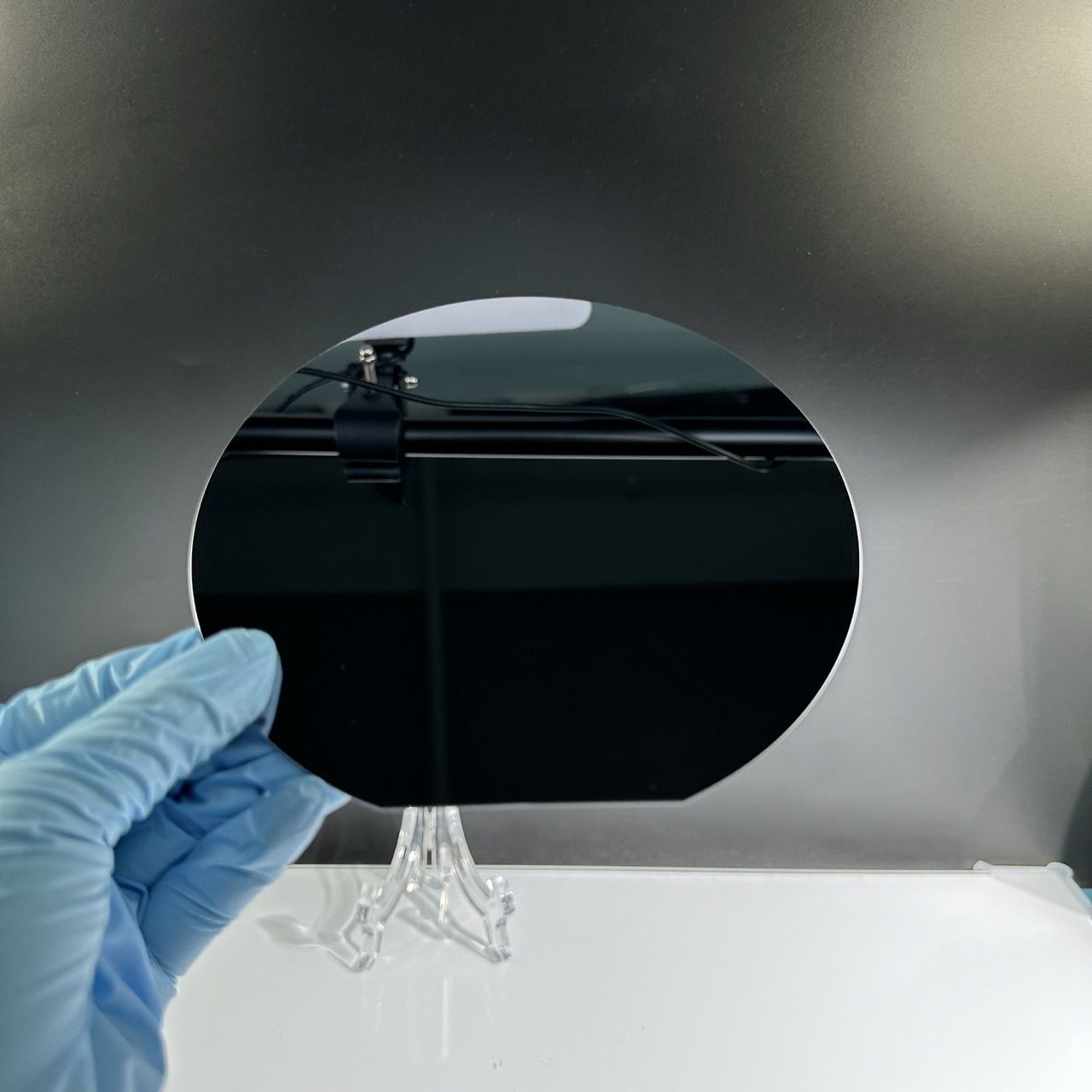

| Indawo Engaphambili | I-Epi-Polished (Ra< 0.2nm) | |||

*Umnsalo: Ukuchezuka kwephoyinti elimaphakathi lendawo emaphakathi yewafa yamahhala, engaboshiwe ukusuka endizeni eyireferensi, lapho indiza eyinkomba ichazwa khona amakhona amathathu kanxantathu olinganayo.

*I-Warp: Umehluko phakathi kobukhulu nobuncane bebanga lendawo emaphakathi yewafa yamahhala, engaboshiwe ukusuka endizeni eyireferensi echazwe ngenhla.

Imikhiqizo yekhwalithi ephezulu namasevisi wamadivayisi e-semiconductor esizukulwane esilandelayo kanye nokukhula kwe-epitaxial:

Izinga eliphakeme lokucaba (i-TTV elawulwayo, umnsalo, i-warp njll.)

Ukuhlanzwa kwekhwalithi ephezulu (ukungcoliswa kwezinhlayiyana eziphansi, ukungcoliswa kwensimbi ephansi)

I-substrate drilling, i-grooving, ukusika, nokupholisha ngemuva

Ukunamathiselwa kwedatha njengokuhlanzeka nokuma kwe-substrate (kuyakhetheka)

Uma unesidingo sama-sapphire substrates, sicela ukhululeke ukuxhumana:

imeyili:eric@xkh-semitech.com+86 158 0194 2596 /doris@xkh-semitech.com+86 187 0175 6522

Sizobuyela kuwe ngokushesha!

Umdwebo onemininingwane