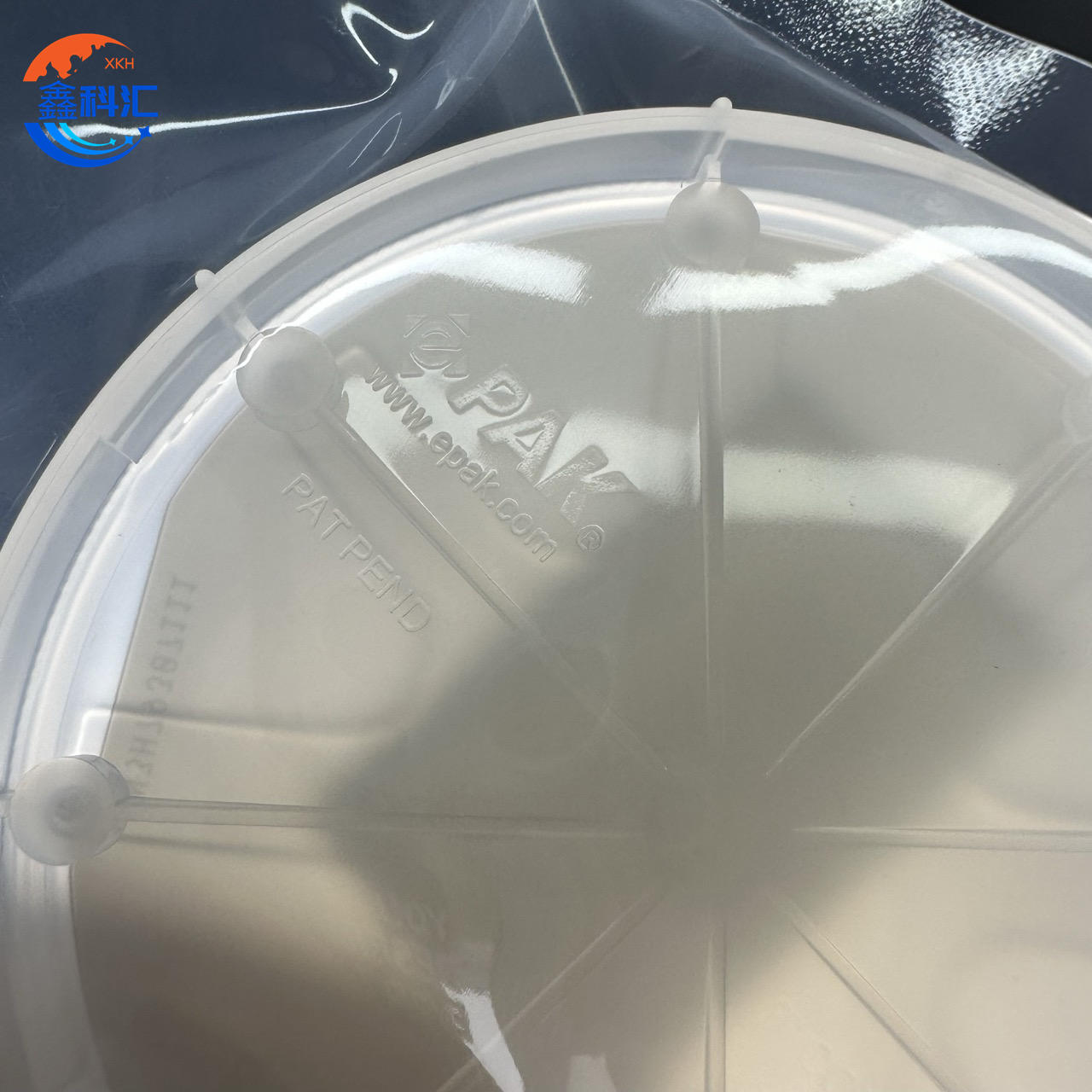

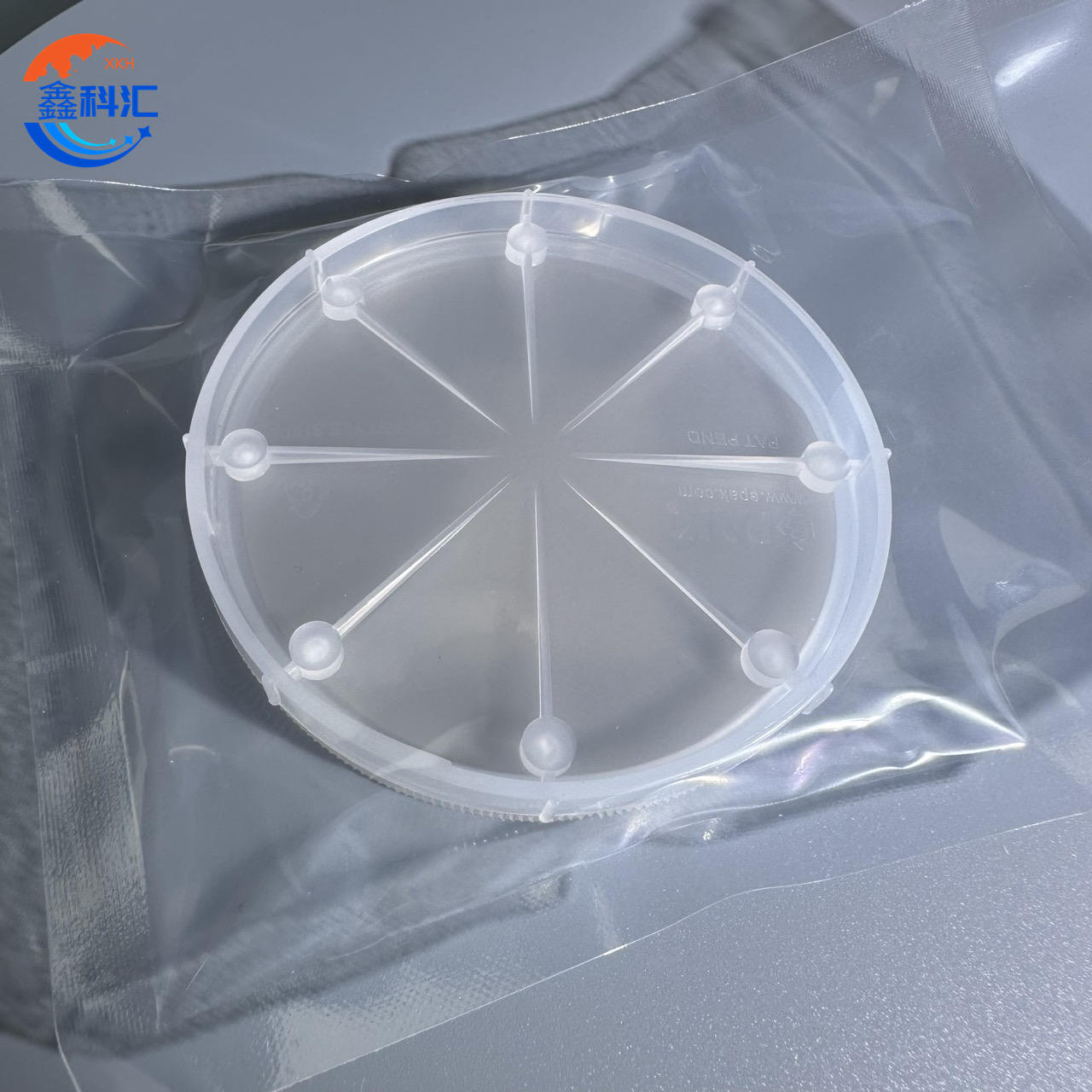

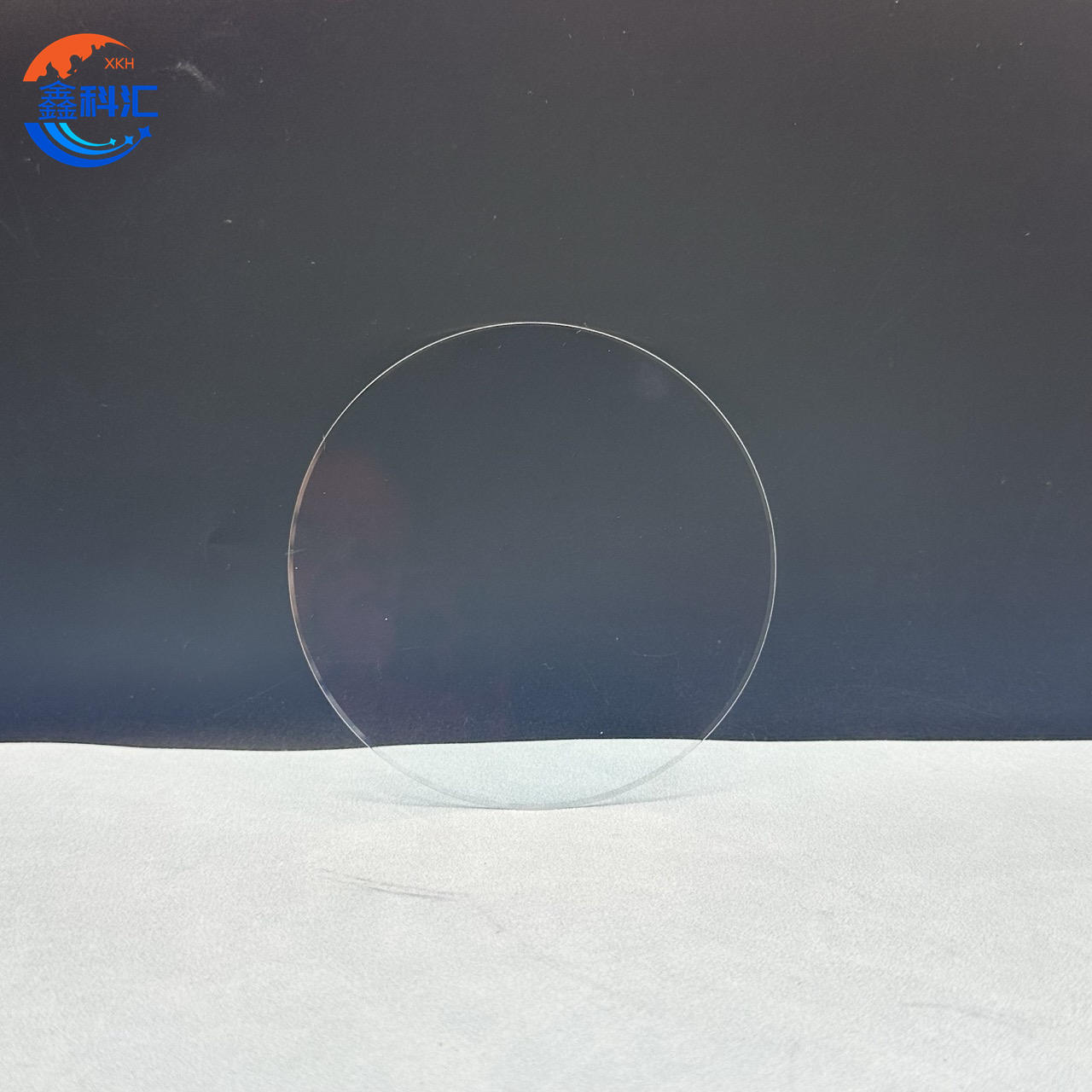

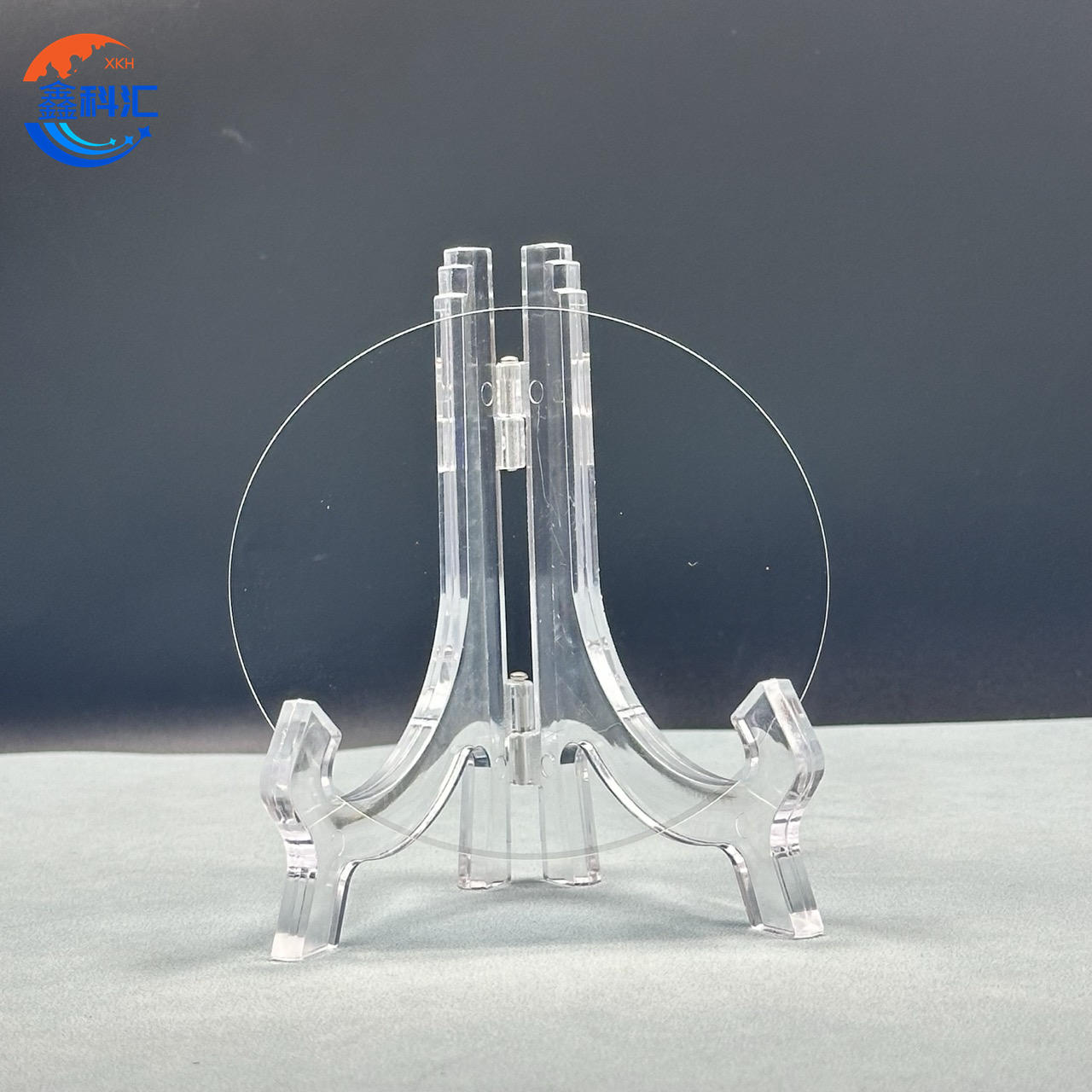

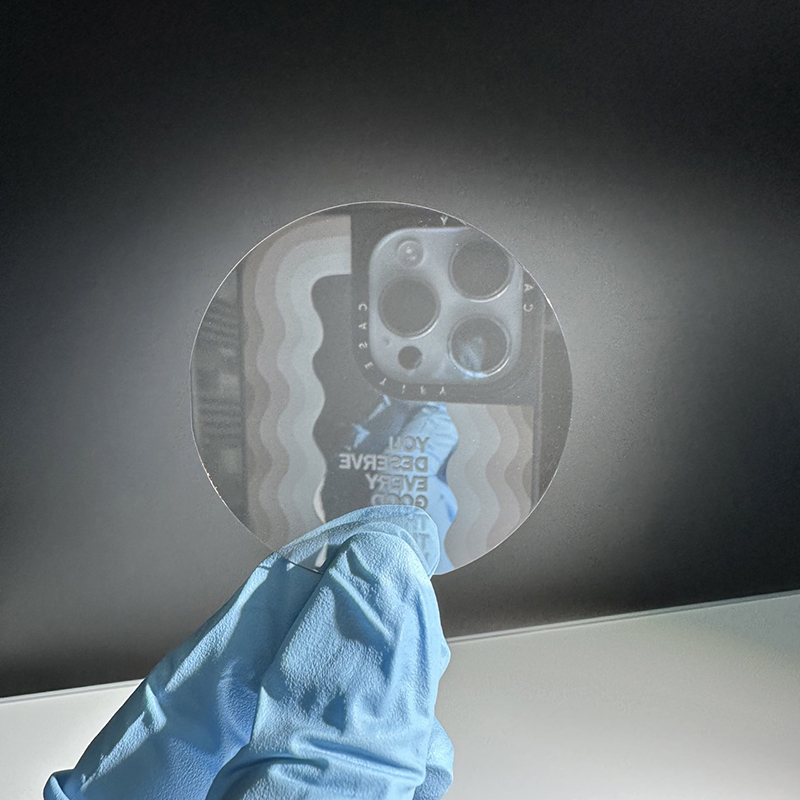

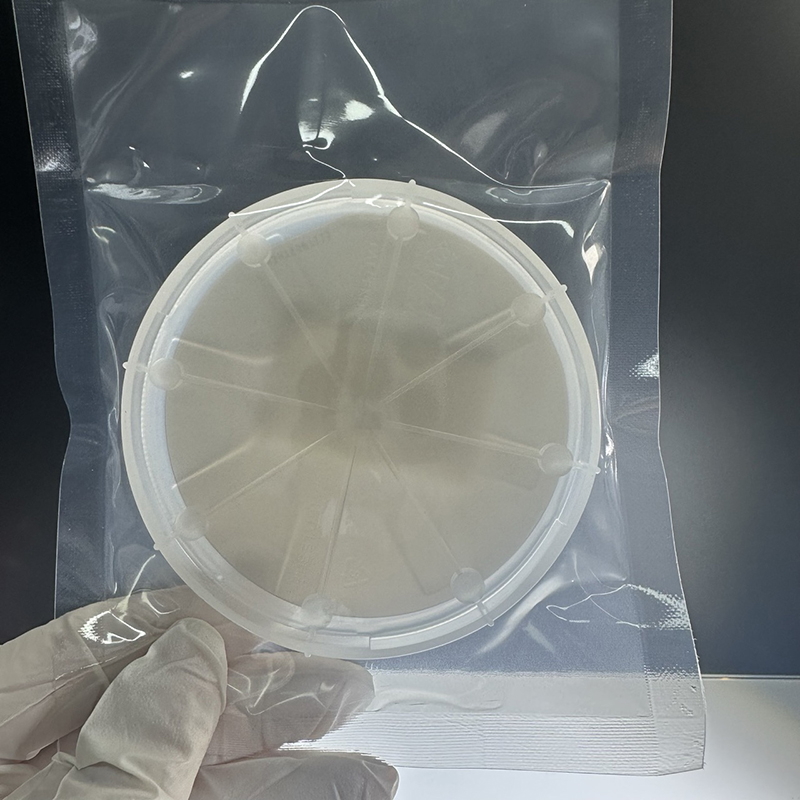

3 inch High Purity (Akulungisiwe) I-Silicon Carbide Wafers semi-Insulating Sic Substrates (HPSl)

Izakhiwo

1. Izakhiwo zePhysical and Structural

● Uhlobo Lwezinto Ezibalulekile: Ukuhlanzeka Okuphezulu (Akususiwe) I-Silicon Carbide (SiC)

● Ububanzi: 3 amayintshi (76.2 mm)

● Ubukhulu: 0.33-0.5 mm, ukwenziwa ngendlela oyifisayo ngokusekelwe ezimfuneko zohlelo lokusebenza.

● I-Crystal Structure: I-4H-SiC i-polytype ene-hexagonal lattice, eyaziwa ngokuhamba okuphezulu kwe-electron kanye nokuzinza kwe-thermal.

●Umumo:

oStandard: [0001] (C-plane), ilungele uhla olubanzi lwezinhlelo zokusebenza.

Ongakukhetha: I-off-eksisi (4° noma 8° tilt) ukuze kuthuthukiswe ukukhula kwe-epitaxial kwezingqimba zedivayisi.

●Ukucaba: Ukuhlukahluka kokuqina okuphelele (TTV) ●Ikhwalithi yobuso:

o polished to oLow-defect density (<10/cm² ukuminyana kwamapayipi). 2. Izakhiwo Zikagesi ●Ukumelana: >109^99 Ω·cm, kugcinwa ukuqedwa kwama-dopant wamabomu.

● Amandla e-Dielectric: Ukubekezela kwe-voltage ephezulu nokulahlekelwa okuncane kwe-dielectric, ilungele izinhlelo zokusebenza zamandla aphezulu.

●I-Thermal Conductivity: 3.5-4.9 W/cm·K, inika amandla ukulahlwa kokushisa okusebenzayo kumadivayisi asebenza kahle kakhulu.

3. Izakhiwo ezishisayo nezemishini

● I-Wide Bandgap: 3.26 eV, ukusebenza okusekelayo ngaphansi kwamandla kagesi aphezulu, izinga lokushisa eliphezulu, nezimo zemisebe ephezulu.

● Ukuqina: Isikali se-Mohs 9, siqinisekisa ukuqina ngokumelene nokugqokwa kwemishini ngesikhathi sokucubungula.

● I-Thermal Expansion Coefficient: 4.2×10−6/K4.2 \izikhathi ezingu-10^{-6}/\text{K}4.2×10−6/K, iqinisekisa ukuzinza kwe-dimensional ngaphansi kokuhlukahluka kwezinga lokushisa.

| Ipharamitha | Ibanga Lokukhiqiza | IBanga Lokucwaninga | Dummy Grade | Iyunithi |

| Ibanga | Ibanga Lokukhiqiza | IBanga Lokucwaninga | Dummy Grade | |

| Ububanzi | 76.2 ± 0.5 | 76.2 ± 0.5 | 76.2 ± 0.5 | mm |

| Ubukhulu | 500 ± 25 | 500 ± 25 | 500 ± 25 | µm |

| I-Wafer Orientation | Ku-eksisi: <0001> ± 0.5° | Ku-eksisi: <0001> ± 2.0° | Ku-eksisi: <0001> ± 2.0° | iziqu |

| I-Micropipe Density (MPD) | ≤1 | ≤ 5 | ≤ 10 | cm−2^-2−2 |

| Ukungazweli Kagesi | ≥ 1E10 | ≥ 1E5 | ≥ 1E5 | Ω·cm |

| I-Dopant | Kuhlehlisiwe | Kuhlehlisiwe | Kuhlehlisiwe | |

| Isisekelo se-Flat Orientation | {1-100} ± 5.0° | {1-100} ± 5.0° | {1-100} ± 5.0° | iziqu |

| Ubude Befulethi obuyisisekelo | 32.5 ± 3.0 | 32.5 ± 3.0 | 32.5 ± 3.0 | mm |

| Ubude Befulethi besibili | 18.0 ± 2.0 | 18.0 ± 2.0 | 18.0 ± 2.0 | mm |

| I-Flat Orientation yesibili | 90° CW kusukela efulethini lokuqala ± 5.0° | 90° CW kusukela efulethini lokuqala ± 5.0° | 90° CW kusukela efulethini lokuqala ± 5.0° | iziqu |

| Ukukhishwa komkhawulo | 3 | 3 | 3 | mm |

| LTV/TTV/Bow/Warp | 3/10 / ±30/40 | 3/10 / ±30/40 | 5/15 / ±40/45 | µm |

| Ukuqina Kobuso | Ubuso beSi: CMP, C-face: Bupholishiwe | Ubuso beSi: CMP, C-face: Bupholishiwe | Ubuso beSi: CMP, C-face: Bupholishiwe | |

| Imifantu (High-Intensity Light) | Lutho | Lutho | Lutho | |

| I-Hex Plates (Ukukhanya Okunamandla Kakhulu) | Lutho | Lutho | Indawo eqoqiwe 10% | % |

| Izindawo ze-Polytype (Ukukhanya Okunamandla Kakhulu) | Indawo ehlanganisiwe 5% | Indawo eqoqiwe 20% | Indawo eqoqiwe 30% | % |

| Ukuklwebheka (Ukukhanya Okumandla Kakhulu) | ≤ 5 imihuzuko, ubude obukhulayo ≤ 150 | ≤ 10 imihuzuko, ubude obuningi ≤ 200 | ≤ 10 imihuzuko, ubude obuningi ≤ 200 | mm |

| I-Edge Chipping | Lutho ≥ 0.5 mm ububanzi/ukushona | 2 okuvunyelwe ≤ 1 mm ububanzi/ukushona | 5 okuvunyelwe ≤ 5 mm ububanzi/ukushona | mm |

| Ukungcoliswa kobuso | Lutho | Lutho | Lutho |

Izinhlelo zokusebenza

1. Amandla kagesi

I-bandgap ebanzi kanye ne-thermal conductivity ephezulu yama-substrates e-HPSI SiC awenza alungele amadivayisi kagesi asebenza ezimeni ezimbi kakhulu, njenge:

●Amadivayisi Anamandla Aphezulu: Kufaka ama-MOSFET, ama-IGBT, nama-Schottky Barrier Diode (SBDs) okuguqulwa kwamandla okusebenzayo.

● Amasistimu Amandla Avuselelekayo: Njengeziguquli zelanga nezilawuli ze-turbine yomoya.

●Izimoto zikagesi (EVs): Isetshenziswa kuma-inverter, amashaja, namasistimu e-powertrain ukuthuthukisa ukusebenza kahle nokunciphisa usayizi.

2. Izicelo ze-RF neMicrowave

Ukumelana okuphezulu nokulahleka kwe-dielectric okuphansi kwamawafa e-HPSI kubalulekile kuma-radio-frequency (RF) namasistimu we-microwave, okuhlanganisa:

● Ingqalasizinda Yezokuxhumana: Iziteshi eziyisisekelo zamanethiwekhi e-5G nokuxhumana ngesathelayithi.

● I-Aerospace kanye Nokuvikela: Amasistimu e-radar, ama-antenna ahlelwe ngezigaba, nezingxenye ze-avionics.

3. I-Optoelectronics

Ukungafihli kanye ne-bandgap ebanzi ye-4H-SiC kunika amandla ukusetshenziswa kwayo kumadivayisi we-optoelectronic, afana nalokhu:

● Ama-Photodetectors e-UV: Okokuqapha imvelo kanye nokuxilongwa kwezokwelapha.

●Ama-LED Anamandla Aphezulu: Asekela amasistimu okukhanyisa esimo esiqinile.

● Ama-Laser Diodes: Okwezicelo zezimboni nezokwelapha.

4. Ucwaningo Nentuthuko

Ama-substrates e-HPSI SiC asetshenziswa kabanzi kumalebhu e-R&D ezemfundo nawezimboni ukuze kuhlolwe izakhiwo zempahla ethuthukisiwe nokwakhiwa kwemishini, okuhlanganisa:

●I-Epitaxial Layer Growth: Izifundo zokunciphisa isici nokuthuthukisa isendlalelo.

●Izifundo Zokuhamba Kwenkampani Yenethiwekhi: Ukuphenywa kwezinto zokuhamba nge-electron nezimbobo ezintweni ezihlanzeke kakhulu.

● I-Prototyping: Ukuthuthukiswa kokuqala kwamadivayisi amanoveli namasekhethi.

Izinzuzo

Ikhwalithi Ephakeme:

Ukuhlanzeka okuphezulu kanye nokuminyana kwesici esiphansi kunikeza inkundla enokwethenjelwa yezinhlelo zokusebenza ezithuthukile.

Ukuqina Kokushisa:

Izakhiwo ezinhle kakhulu zokukhipha ukushisa zivumela amadivaysi ukuthi asebenze kahle ngaphansi kwamandla aphezulu kanye nezimo zokushisa.

Ukuhambisana Okubanzi:

Imikhombandlela etholakalayo nezinketho zokujiya ngokwezifiso ziqinisekisa ukuguquguquka kwezidingo zedivayisi ezahlukahlukene.

Ukuqina:

Ukuqina okungavamile nokuzinza kwesakhiwo kunciphisa ukuguga nokuguqulwa ngesikhathi sokucubungula nokusebenza.

Ukuhlukahluka:

Ifanele izimboni eziningi, kusukela kumandla avuselelekayo ukuya emkhathini kanye nezokuxhumana.

Isiphetho

Iwafa ye-High Purity Semi-Insulating Silicon Carbide engu-3-intshi imelela isiqongo sobuchwepheshe be-substrate kumadivayisi anamandla amakhulu, ama-high-frequency, nawe-optoelectronic. Inhlanganisela yayo yezinto ezinhle kakhulu ezishisayo, zikagesi, nemishini iqinisekisa ukusebenza okuthembekile ezindaweni eziyinselele. Kusukela kuma-electronics amandla namasistimu e-RF kuya ku-optoelectronics kanye ne-R&D ethuthukisiwe, lawa ma-substrates e-HPSI ahlinzeka ngesisekelo sezinto ezintsha zakusasa.

Ukuze uthole ulwazi olwengeziwe noma ukufaka i-oda, sicela usithinte. Ithimba lethu lobuchwepheshe liyatholakala ukuze likunikeze isiqondiso nezinketho zokwenza ngokwezifiso ezihambisana nezidingo zakho.

Umdwebo onemininingwane