I-Sapphire Crystal Growth Furnace KY Indlela ye-Kyropoulos ye-Sapphire Wafer kanye Nokukhiqizwa Kwewindi Lokukhanya

Isimiso Sokusebenza

Umgomo oyinhloko wendlela ye-KY uhlanganisa ukuncibilika okuhlanzekile okuphezulu kwe-Al₂O₃ ku-tungsten/molybdenum crucible ku-2050°C. Ikristalu yembewu yehliselwa ekuncibilikeni, kulandelwa ukuhoxiswa okulawulwayo (0.5-10 mm/h) nokujikeleza (0.5-20 rpm) ukuze kuzuzwe ukukhula okuqondile kwamakristalu angama-α-Al₂O₃ owodwa. Izici ezibalulekile zifaka:

• Amakristalu anobukhulu obukhulu (ubukhulu Φ400 mm × 500 mm)

• I-Low-stress Optical-grade sapphire (i-wavefront distortion <λ/8 @ 633 nm)

• Amakristalu ane-Doped (isb, i-Ti³⁰ doping ye-star sapphire)

Izingxenye Zesistimu Eziyinhloko

1. Uhlelo Lokuncibilikisa Lokushisa Okuphezulu

• I-Tungsten-molybdenum composite crucible (ubukhulu. izinga lokushisa 2300°C)

• I-Multi-zone graphite heater (±0.5°C ukulawula izinga lokushisa)

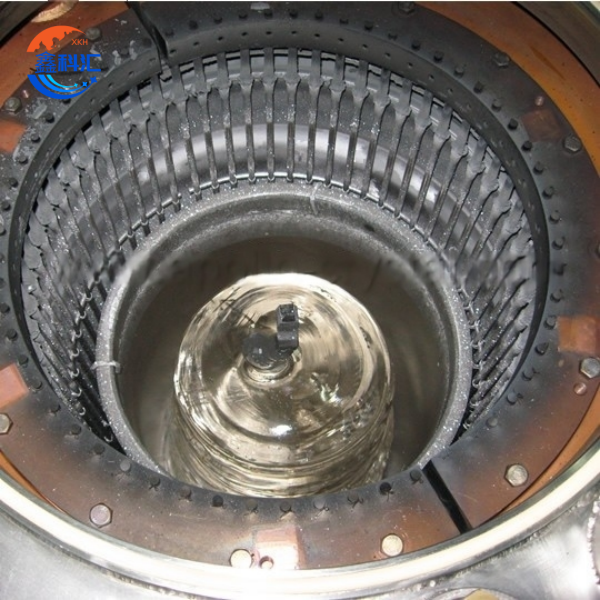

2. I-Crystal Growth System

• Indlela yokudonsa eshayelwa yi-Servo (±0.01 mm ukunemba)

• I-Magnetic fluid rotary seal (0–30 rpm ukulawulwa kwesivinini esingenasinyathelo)

3. I-Thermal Field Control

• Ukulawulwa kwezinga lokushisa okuzimele okuyi-5-zone (1800–2200°C)

• Isivikelo sokushisa esilungisekayo (±2°C/cm igradient)

• I-Vacuum & Atmosphere System

• 10⁻⁴ Pa high vacuum

• Ukulawulwa kwegesi okuxubile kwe-Ar/N₂/H₂

4. Intelligent Monitoring

• Ukuqapha kwe-crystal diameter yesikhathi sangempela se-CCD

• Ukutholwa kwezinga lokuncibilika kwe-Multi-spectral

KY vs. CZ Indlela Ukuqhathanisa

| Ipharamitha | Indlela ye-KY | Indlela ye-CZ |

| Ubukhulu. Usayizi we-Crystal | Φ400 mm | Φ200 mm |

| Izinga Lokukhula | 5–15 mm/h | 20–50 mm/h |

| Defect Density | <100/cm² | 500-1000/cm² |

| Ukusetshenziswa kwamandla | 80–120 kWh/kg | 50–80 kWh/kg |

| Izicelo Ezijwayelekile | Amawindi okukhanya/amawafa amakhulu | Ama-substrates/ubucwebe be-LED |

Izinhlelo zokusebenza ezibalulekile

1. IWindows ye-Optoelectronic

• Amadome e-IR amasosha (ukudluliselwa >85%@3–5 μm)

• Amawindi e-UV laser (amelana nokuminyana kwamandla okungu-200 W/cm²)

2. Ama-Semiconductor Substrates

• Ama-wafers e-GaN epitaxial (2–8 amayintshi, TTV <10 μm)

• Ama-substrates e-SOI (ubukhulu bobuso obungu-<0.2 nm)

3. I-Consumer Electronics

• Ingilazi yekhava yekhamera ye-smartphone (Mohs hardness 9)

• Izibonisi ze-Smartwatch (ukuthuthukiswa kokumelana nokuklwebheka okungu-10×)

4. Izinto Ezikhethekile

• I-High-purity IR Optics (i-coefficient yokumuncwa <10⁻³ cm⁻¹)

• Amawindi okubuka i-nuclear reactor (ukubekezelela imisebe: 10¹⁶ n/cm²)

Izinzuzo ze-Kyropoulos (KY) Izisetshenziswa ze-Sapphire Crystal Growth

I-Kyropoulos (KY) imishini yokukhulisa ikristalu yesafire esekelwe endleleni ihlinzeka ngezinzuzo zobuchwepheshe ezingenakuqhathaniswa, iyibeka njengesixazululo esisezingeni eliphezulu sokukhiqizwa kwezimboni. Izinzuzo ezibalulekile zifaka:

1. Ikhono elikhulu le-Direyimu

2. Ukuminyana Kokukhubazeka Okuphansi Kakhulu: Ifinyelela ukuminyana kokugudluzwa<100/cm² ngedizayini yenkambu eshisayo elungiselelwe kanye nokulawula okunembayo kwegradient, iqinisekisa ubuqotho obuphakeme bekristalu kumadivayisi e-optoelectronic.

3. Ukusebenza Kokubonwa Kwekhwalithi Ephezulu: Iletha ukudluliselwa >85%kuyo yonke indawo ebonakalayo ku-infrared spectra (400–5500 nm), okubalulekile kumawindi e-UV laser kanye ne-infrared optics.

4. Okuzenzakalela Okuthuthukile: Ifaka phakathi izindlela zokudonsa ezishayelwa yi-servo (ukunemba okungu-±0.01 mm) nezigxivizo ezijikelezayo zikazibuthe (0–30 rpm controlless stepless), ukunciphisa ukungenelela komuntu nokuthuthukisa ukungaguquguquki.

5. Izinketho Ze-Doping Eziguqukayo: Isekela ukwenza ngendlela oyifisayo ngama-dopants afana ne-Cr³⁰ (yeruby) kanye ne-Ti³⁰ (yenkanyezi yesafire), ihlinzekela izimakethe ze-niche ku-optoelectronics nobucwebe.

6. I-Energy Efficiency: Ukufakwa kwe-thermal okuthuthukisiwe (i-tungsten-molybdenum crucible) kunciphisa ukusetshenziswa kwamandla ukuya ku-80–120 kWh/kg, kuqhudelana nezinye izindlela zokukhula.

7. Ukukhiqiza Okuthuthukile: Ithola ukukhishwa kwanyanga zonke kwamawafa angu-5,000+ anezikhathi zomjikelezo osheshayo (izinsuku ezingu-8–10 zamakristalu angu-30–40 kg), okugunyazwe ukufakwa komhlaba wonke okungaphezu kuka-200.

.

8. Ukuqina Kwebanga Lezempi: Ihlanganisa imiklamo engavimbeli imisebe nezinto ezikwazi ukumelana nokushisa (zimelana nokungu-10¹⁶ n/cm²), okubalulekile kwi-aerospace nezinhlelo zokusebenza zenuzi.

Lezi zinto ezintsha ziqinisa indlela ye-KY njengezinga legolide lokukhiqiza amakristalu esafire asebenza kahle kakhulu, ukushayela intuthuko kwezokuxhumana kwe-5G, i-quantum computing, nobuchwepheshe bokuvikela.

Izinsizakalo ze-XKH

I-XKH ihlinzeka ngezixazululo ezibanzi ze-turnkey zamasistimu okukhula kwekristalu yesafire, okuhlanganisa ukufakwa, ukuthuthukiswa kwenqubo, nokuqeqeshwa kwabasebenzi ukuze kuqinisekiswe ukuhlanganiswa kokusebenza okungenazihibe. Siletha amarisiphu okukhula aqinisekiswe ngaphambilini (50+) enzelwe izidingo ezihlukene zezimboni, sehlisa kakhulu isikhathi se-R&D kumakhasimende. Kuzinhlelo zokusebenza ezikhethekile, izinsizakalo zokuthuthukiswa kwangokwezifiso zivumela ukwenza ngokwezifiso umgodi (Φ200–400 mm) kanye nezinhlelo ze-doping ezithuthukisiwe (i-Cr/Ti/Ni), ezisekela izakhi ezisebenza kahle ezibonakalayo nezinto ezimelana nemisebe.

Amasevisi engezwe inani ahlanganisa ukucutshungulwa kwangemva kokukhula njengokusika, ukugaya, nokupholishwa, okuhambisana nohlu olugcwele lwemikhiqizo yesafire efana namawafa, amashubhu, nezikhala zetshe eliyigugu. Le minikelo ibhekelela imikhakha kusukela kubathengi be-electronics kuya ku-aerospace. Ukusekelwa kwethu kobuchwepheshe kuqinisekisa iwaranti yezinyanga ezingama-24 kanye nokuxilongwa okukude kwesikhathi sangempela, okuqinisekisa ukuphumula okuncane nokusebenza kahle kokukhiqiza okuqhubekayo.