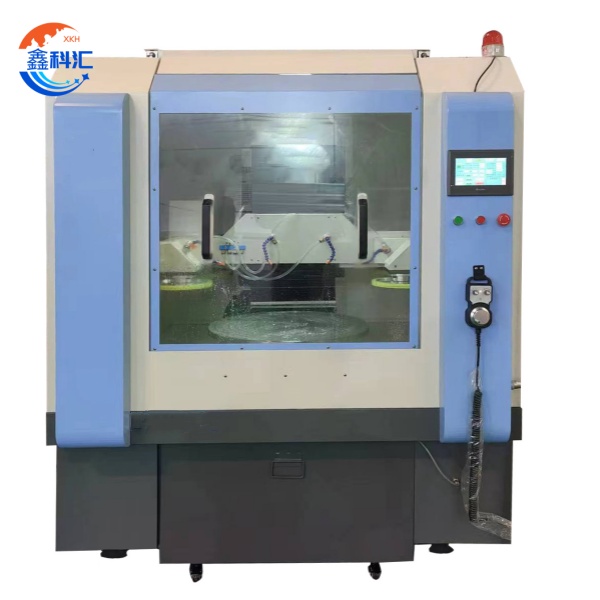

Isisetshenziswa sokusika indandatho ye-wafer ezenzakalelayo Ngokugcwele Usayizi Osebenzayo 8inch/12inch Wafer Ring Cutting

Imingcele yezobuchwepheshe

| Ipharamitha | Iyunithi | Ukucaciswa |

| Ubukhulu Usayizi Womsebenzi | mm | ø12" |

| I-spindle | Ukucushwa | I-Single Spindle |

| Isivinini | 3,000-60,000 rpm | |

| Amandla Okukhiphayo | 1.8 kW (2.4 ozikhethela) ku-30,000 min⁻¹ | |

| UMax Blade Dia. | Ø58 mm | |

| I-X-eksisi | Cutting Range | 310 mm |

| I-Y-eksisi | Cutting Range | 310 mm |

| Isinyathelo Ukunyuka | 0.0001 mm | |

| Ukunemba Kokumisa | ≤0.003 mm/310 mm, ≤0.002 mm/5 mm (iphutha elilodwa) | |

| I-Z-Axis | Ukulungiswa Kokunyakaza | 0.00005 mm |

| Ukuphindaphinda | 0.001 mm | |

| θ-I-eksisi | Ukujikeleza Okukhulu | 380 deg |

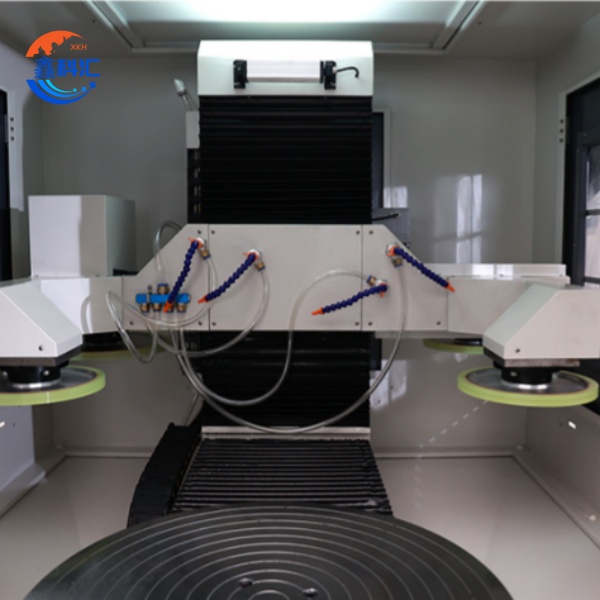

| Uhlobo lwe-Spindle | I-spindle eyodwa, ifakwe i-blade eqinile yokusika indandatho | |

| Ukunemba kokusika indandatho | μm | ±50 |

| Ukunemba kwe-Wafer Positioning | μm | ±50 |

| Ukusebenza Kwe-Single-Wafer | iminithi/isinkwa | 8 |

| I-Multi-Wafer Efficiency | Kufika kuma-wafers angu-4 acutshungulwa kanyekanye | |

| Isisindo Sezisetshenziswa | kg | ≈3,200 |

| Ubukhulu besisetshenziswa (W×D×H) | mm | 2,730 × 1,550 × 2,070 |

Isimiso sokusebenza

Isistimu izuza ukusebenza okukhethekile kokunquma ngalabu buchwepheshe obuyinhloko:

1.I-Intelligent Motion Control System:

· Idrayivu yemoto yomugqa enembe kakhulu (phinda ukunemba kokuma: ±0.5μm)

· Ukulawula okuhambisanayo kwe-eksisi eyisithupha okusekela ukuhlela okuyinkimbinkimbi komgudu

· I-Real-time vibration suppression algorithms eqinisekisa ukuzinza kokusika

2.Isistimu Yokuthola Okuthuthukisiwe:

· Inzwa yobude be-laser ye-3D ehlanganisiwe (ukunemba: 0.1μm)

· Indawo yokubuka ye-CCD yokulungiswa okuphezulu (ama-megapixel angu-5)

· Imojula yokuhlola ikhwalithi eku-inthanethi

3.Inqubo Ezenzakalelayo Ngokugcwele:

· Ukulayisha/ukukhipha okuzenzakalelayo (i-FOUP interface ejwayelekile iyahambisana)

· Uhlelo lokuhlunga oluhlakaniphile

· Iyunithi yokuhlanza iluphu evaliwe (ukuhlanzeka: Ikilasi le-10)

Izicelo Ezijwayelekile

Lo mshini uletha inani elibalulekile kuzo zonke izinhlelo zokusebenza zokukhiqiza ze-semiconductor:

| Inkambu yohlelo lokusebenza | Izinto Zokusebenza | Izinzuzo Zobuchwepheshe |

| I-IC Manufacturing | 8/12" ama-Silicon Wafers | Ithuthukisa ukuqondana kwe-lithography |

| Amadivayisi Amandla | I-SiC/GaN Wafers | Igwema amaphutha asemaphethelweni |

| Izinzwa ze-MEMS | Ama-wafers e-SOI | Iqinisekisa ukwethembeka kwedivayisi |

| Amadivayisi e-RF | I-GaAs Wafers | Ithuthukisa ukusebenza kwe-high-frequency |

| Ukupakisha Okuthuthukile | Ama-wafers akhiwe kabusha | Yandisa isivuno sokupakisha |

Izici

1.Four-station ukucushwa for high processing ukusebenza kahle;

2.I-TAIKO eqinile yokuxhuma nokususa indandatho;

3.Ukuhambisana okuphezulu nezinto ezisetshenziswayo ezibalulekile;

4.I-Multi-axis synchronous trimming technology iqinisekisa ukusika onqenqemeni olunembayo;

5.Ukugeleza kwenqubo okuzenzakalelayo ngokugcwele kunciphisa kakhulu izindleko zabasebenzi;

6.Umklamo osebenzayo owenziwe ngokwezifiso wenza ukucubungula okuzinzile kwezakhiwo ezikhethekile;

Imisebenzi

1.Isistimu yokuthola i-ring-drop;

2.Automatic worktable yokuhlanza;

3.I-Intelligent UV debonding system;

4. Ukurekhoda kwelogi yokusebenza;

5.Factory automation module ukuhlanganiswa;

Ukuzibophezela Kwesevisi

I-XKH ihlinzeka ngezinsiza eziphelele, eziphelele zokusekela umjikelezo wempilo yakhelwe ukukhulisa ukusebenza kwemishini nokusebenza kahle kulo lonke uhambo lwakho lokukhiqiza.

1. Amasevisi Okwenza ngokwezifiso

· Ukucushwa Kwezisetshenziswa Ezifanisiwe: Ithimba lethu lonjiniyela lisebenzisana eduze namakhasimende ukuze lithuthukise imingcele yesistimu (isivinini sokusika, ukukhetha i-blade, njll.) ngokusekelwe ezintweni ezibonakalayo ezithile (Si/SiC/GaAs) kanye nezidingo zenqubo.

· Usekelo Lokuthuthukiswa Kwenqubo: Sinikeza ukucutshungulwa kwesampula ngemibiko yokuhlaziya enemininingwane ehlanganisa ukukalwa konqenqema kanye nemephu yokukhubazeka.

· I-Consumables Co-Development: Ngezinto ezisetshenziswayo ezinoveli (isb, i-Ga₂O₃), sibambisene nabakhiqizi abahamba phambili abathengekayo ukuze sithuthukise ama-blade/i-laser optics eqondene nohlelo lokusebenza.

2. Professional Technical Support

· Ukusekelwa Okunikezelwe Kusayithi: Nikeza onjiniyela abaqinisekisiwe ngezigaba ezibalulekile zokukhuphuka (imvamisa amaviki angama-2-4), okuhlanganisa:

Ukulinganiswa kwezisetshenziswa nokucubungula ukushuna kahle

Ukuqeqeshwa kwekhono lomsebenzisi

Isiqondiso sokuhlanganisa igumbi lokuhlanza le-ISO Class 5

· Ukunakekela Okubikezelwayo: Ukuhlolwa kwezempilo kwekota ngokuhlaziywa kokudlidliza kanye nokuxilongwa kwe-servo motor ukuvimbela isikhathi sokuphumula esingahlelelwe.

· Ukuqapha Okukude: Ukulandelela ukusebenza kwemishini ngesikhathi sangempela ngeplathifomu yethu ye-IoT (JCFront Connect®) ngezexwayiso ezizenzakalelayo ezingaqondakali.

3. Izinsizakalo Zokwengeza Inani

Isisekelo Solwazi Lwenqubo: Finyelela ku-300+ izindlela zokupheka eziqinisekisiwe zokusika zezinto ezihlukahlukene (zibuyekezwa njalo ngekota).

· Ukuqondanisa Umhlahlandlela Wobuchwepheshe: Ubufakazi besikhathi esizayo bokutshalwa kwezimali kwakho ngezindlela zokuthuthukisa ihadiwe/isofthiwe (isb., imojula yokutholwa kokukhubazeka okusekelwe ku-AI).

· Impendulo Yezimo Eziphuthumayo: Ukuxilongwa okukude okuqinisekisiwe kwamahora angu-4 kanye nokungenelela endaweni yamahora angu-48 (ukusakazwa komhlaba wonke).

4. Ingqalasizinda Yesevisi

· Isiqinisekiso sokusebenza: Ukuzibophezela kwenkontileka ≥98% kwesikhathi sokusebenza kwemishini nezikhathi zokuphendula ezisekelwa yi-SLA.

Ukuthuthukiswa Okuqhubekayo

Senza izinhlolovo zokwaneliseka kwamakhasimende kabili ngonyaka futhi sisebenzisa izinhlelo ze-Kaizen zokuthuthukisa ukulethwa kwezinsizakalo. Ithimba lethu le-R&D lihumusha imininingwane yenkambu ekuthuthukisweni kwemishini - u-30% wokuthuthukiswa kwe-firmware asuka empendulweni yeklayenti.