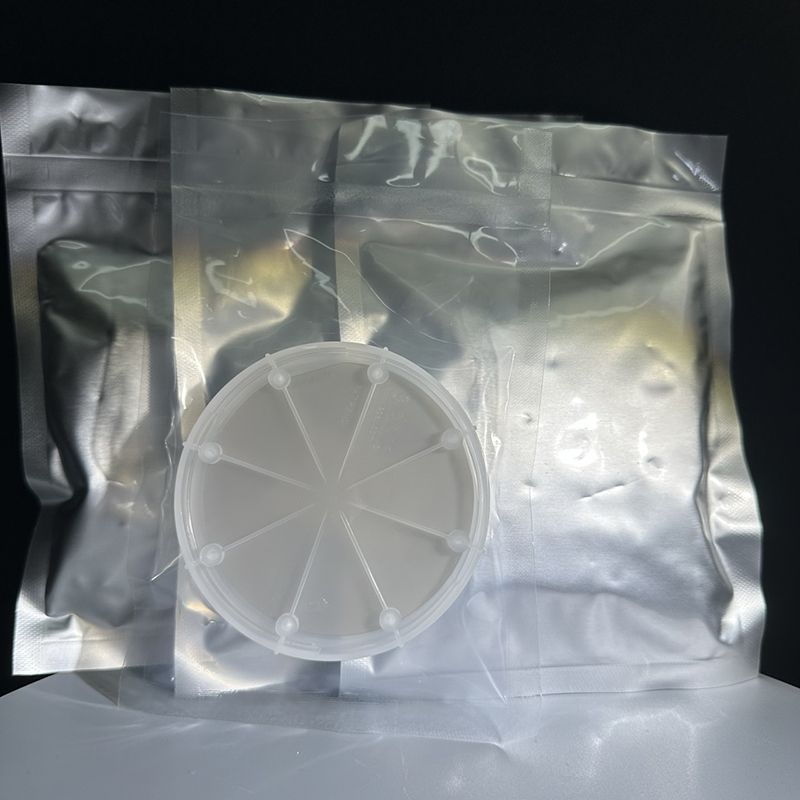

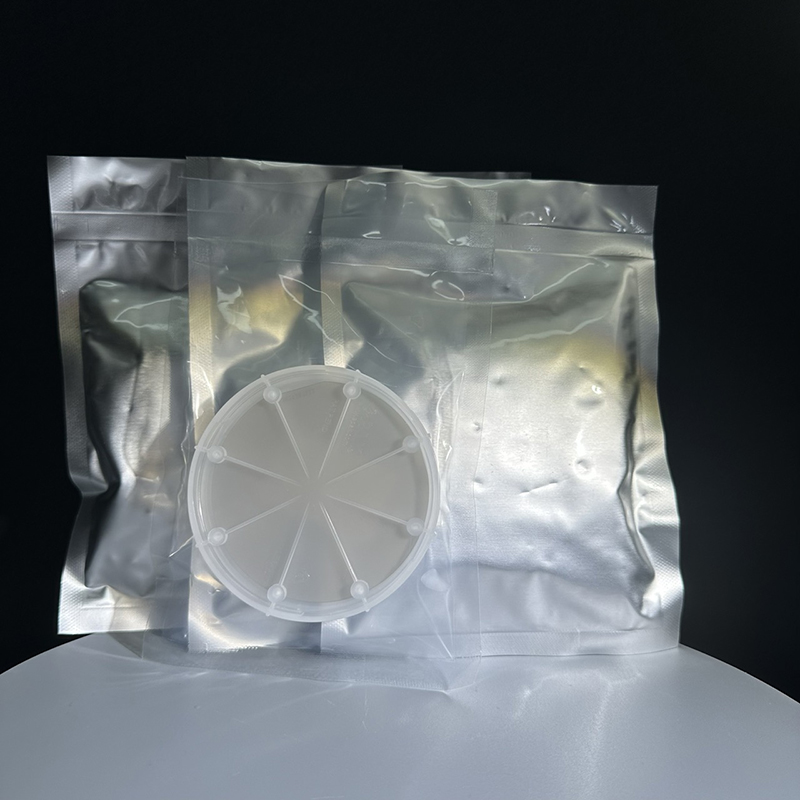

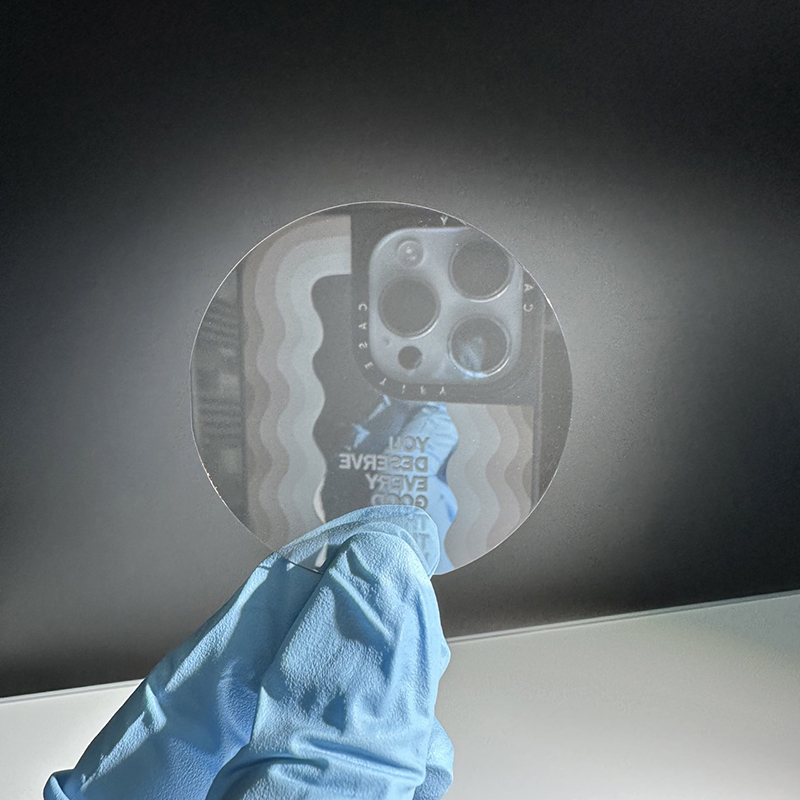

4inch Semi-insulting SiC wafers HPSI SiC substrate Prime Production grade

Ukucaciswa Komkhiqizo

I-Silicon carbide (i-SiC) iyinhlanganisela ye-semiconductor impahla eyakhiwe izakhi ze-carbon ne-silicon, futhi ingenye yezinto ezikahle zokwenza amadivaysi ashisa kakhulu, ama-high-frequency, amandla aphezulu kanye namandla kagesi aphezulu. Uma kuqhathaniswa nempahla ye-silicon yendabuko (Si), ububanzi bebhande obunqatshelwe be-silicon carbide buphindwe kathathu kune-silicon; i-thermal conductivity izikhathi ezingu-4-5 kune-silicon; i-voltage yokuwohloka iphindwe izikhathi ezingu-8-10 kune-silicon; futhi izinga lokukhukhuleka kwe-electron liphindwe izikhathi ezingu-2-3 kune-silicon, ehlangabezana nezidingo zemboni yesimanje yamandla aphezulu, i-voltage ephezulu, ne-high-frequency, futhi isetshenziselwa kakhulu ukwenza izingxenye ze-elekthronikhi ezinesivinini esikhulu, imvamisa ephezulu, amandla aphezulu nezikhipha ukukhanya, futhi izindawo zayo zokusebenza ezingaphansi komfula zihlanganisa amandla egridi, njll. wemishini yamandla, i-silicon carbide diode kanye nama-MOSFET aseqalile ukusetshenziselwa ukuhweba.

Izinzuzo ze-SiC wafers/SiC substrate

Ukumelana nokushisa okuphezulu. Ububanzi bebhendi obunqatshelwe be-silicon carbide buphindwe izikhathi ezingu-2-3 kune-silicon, ngakho-ke ama-electron mancane amathuba okuthi agxume emazingeni okushisa aphezulu futhi akwazi ukumelana namazinga okushisa aphezulu okusebenza, futhi ukuqhutshwa kwe-thermal ye-silicon carbide kuyizikhathi ezingu-4-5 kune-silicon, okwenza kube lula ukukhipha ukushisa okuvela kudivayisi nokuvumela izinga lokushisa eliphezulu elikhawulelayo lokusebenza. Izici zezinga eliphezulu lokushisa zingakhuphula kakhulu ukuminyana kwamandla, kuyilapho zinciphisa izidingo zesistimu yokukhipha ukushisa, zenze itheminali ibe lula futhi ibe mincane.

Ukumelana ne-voltage ephezulu. Amandla ensimu yokuwohloka kwe-silicon carbide aphindwe ka-10 kunawe-silicon, okuyenza ikwazi ukumelana nama-voltage aphezulu, okuyenza ifaneleke kakhulu kumadivayisi asebenzisa amandla kagesi aphezulu.

Ukumelana ne-high-frequency. I-Silicon carbide inezinga eliphindwe kabili le-electron drift rate ye-silicon, okuholela ekutheni amadivayisi ayo enqubweni yokuvala shaqa angabikho kumkhuba wamanje wokudonsa, ingathuthukisa ngempumelelo imvamisa yokushintsha idivayisi, ukuze kuzuzwe ukuncishiswa kwedivayisi.

Ukulahlekelwa amandla aphansi. I-Silicon carbide inokumelana okuphansi kakhulu uma kuqhathaniswa nezinto ze-silicon, ukulahlekelwa kwe-conduction ephansi; ngesikhathi esifanayo, umkhawulokudonsa ophezulu we-silicon carbide unciphisa kakhulu ukuvuza kwamanje, ukulahlekelwa kwamandla; ngaphezu kwalokho, amadivaysi e-silicon carbide enqubweni yokuvala shaqa awekho kumkhuba wamanje wokudonsa, ukulahlekelwa kokushintsha okuphansi.

Umdwebo onemininingwane