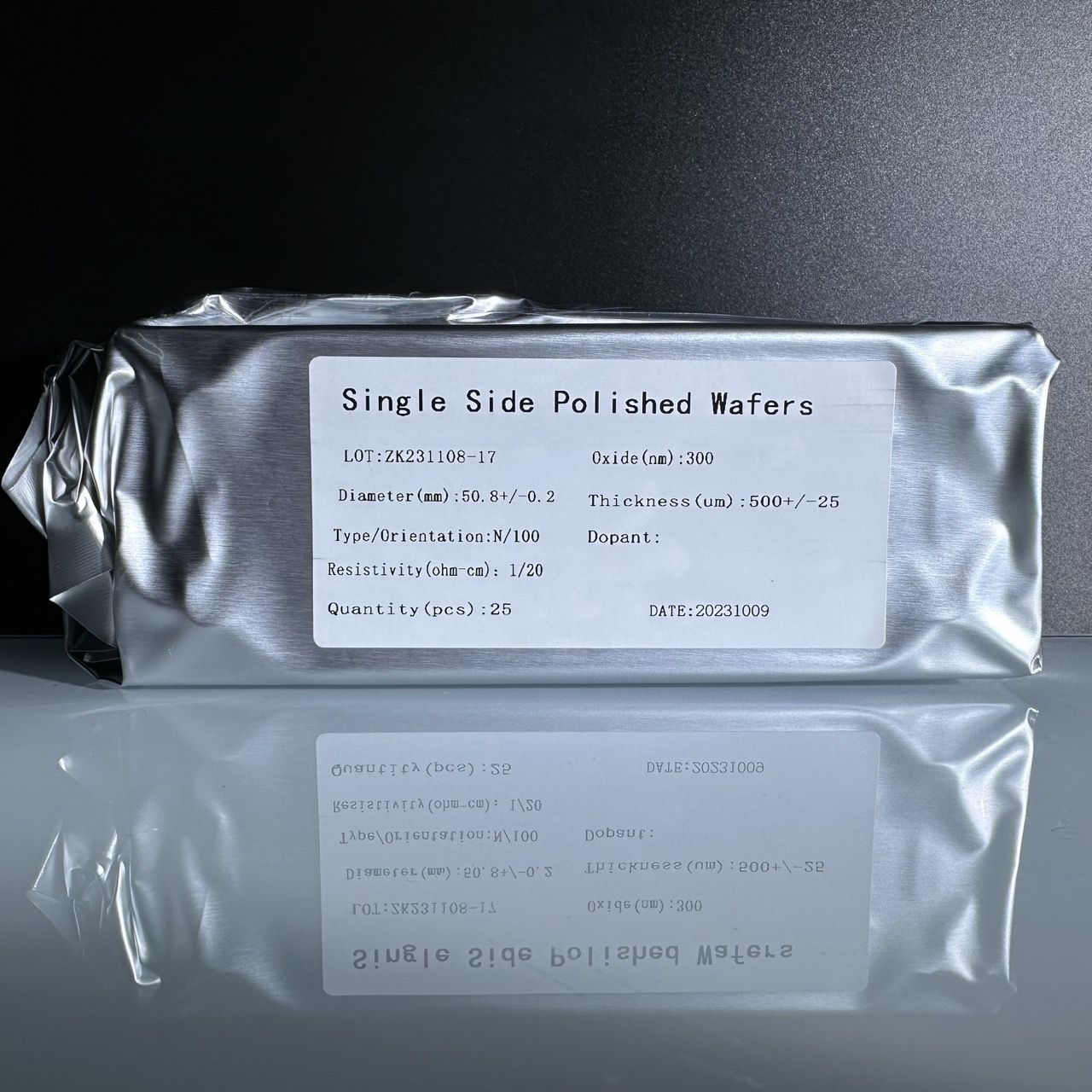

2inch 50.8mm Silicon wafer FZ N-Type SSP

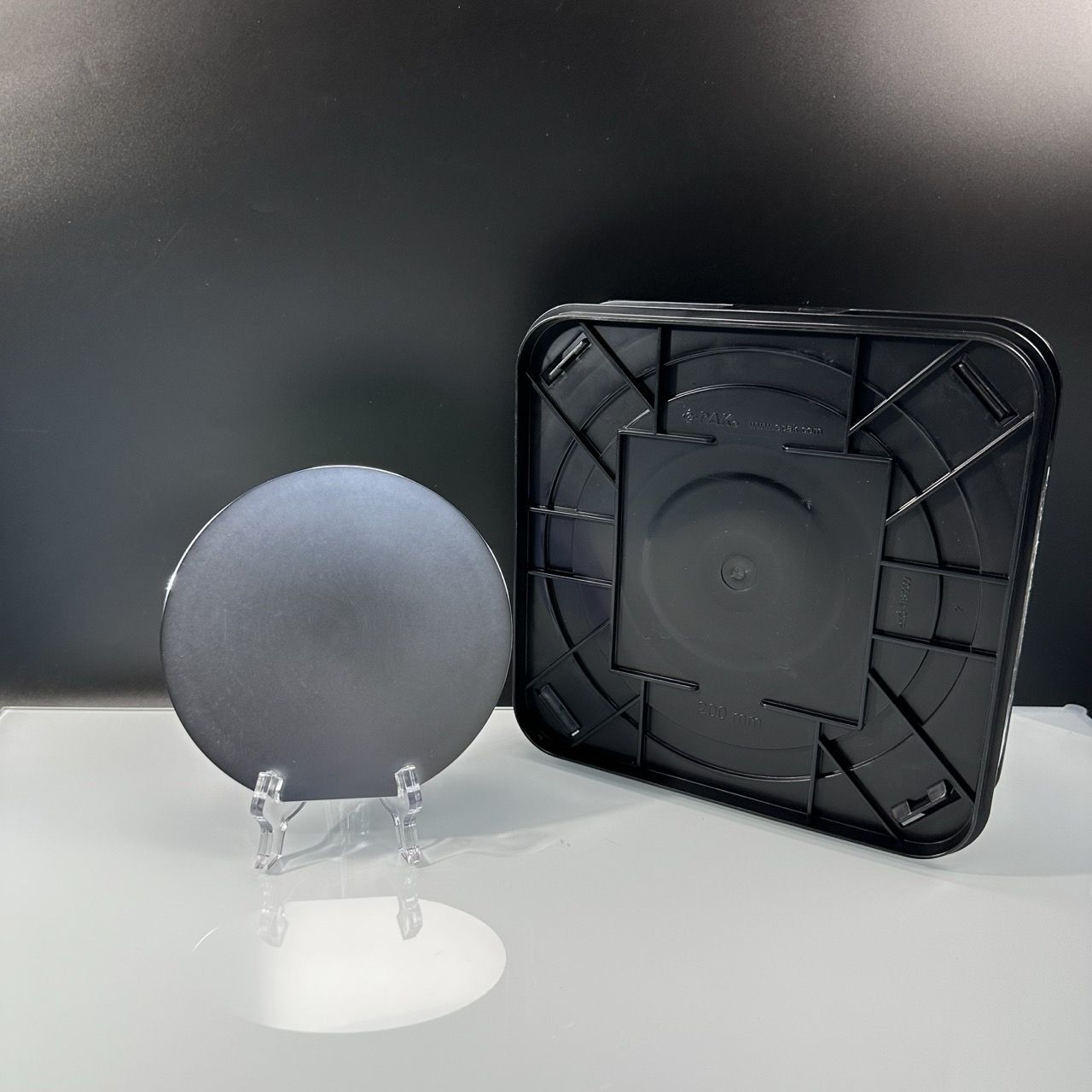

Ukwethulwa kwebhokisi le-wafer

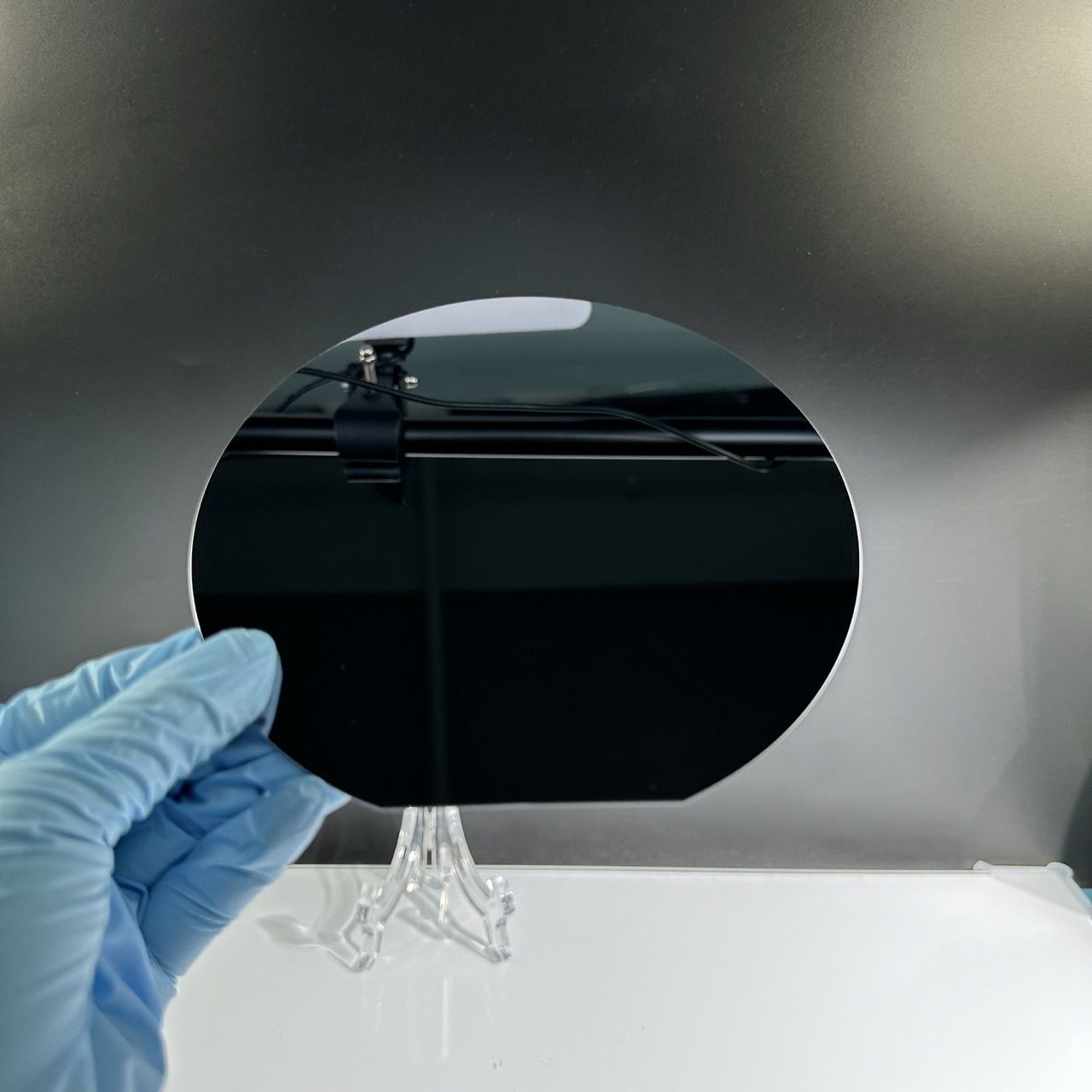

I-wafer engu-2-intshi i-silicon substrate enosayizi omncane evame ukusetshenziselwa ukwenza amadivaysi e-microelectronic njengamasekhethi amancane ahlanganisiwe nezinzwa. Ukusetshenziswa kwayo kufaka phakathi, kodwa akukhawulelwe, izinzwa ezincane, ama-micro actuators, namadivayisi emincane eyimishini. Ngenxa yobukhulu bayo obuncane, umbono wezohwebo kungenzeka ukuthi ube semakethe yama-microelectronics kanye nasekusetshenzisweni kwezinzwa. Ngaphezu kwalokho, ngokuthuthukiswa kwe-IoT, izinto ezigqokwayo, nezinye izinkambu, isidingo semishini kagesi enziwe ama-miniaturized nanamandla aphansi singase sikhule, okuphinde kulethe amathuba okuthuthukiswa kwezentengiselwano amawafa e-silicon angu-2-intshi.

| I-Silicon Wafer Technology: Usayizi we-Wafer nokuqina | ||

| Ubukhulu Ububanzi | Izinzuzo | Ukucatshangelwa |

| Ubugqinsi obuncane | Ukwenziwa ngcono kwe-thermal I-warpage encishisiwe I-compact kanye ne-miniaturization | Amandla emishini encishisiwe Ukuba sengozini kokuphuka |

| Ukuqina Okukhudlwana | Ubuqotho bomshini obuthuthukisiwe Ukuba sengozini okuphansi kokukhubazeka okubangelwa ingcindezi | I-thermal conductivity elinganiselwe Amathuba akhulayo we-warpage |

| 300 mm ububanzi | Izinga lemboni Ukukhiqiza okuhle kanye nezindleko | Ukuba sengozini okumaphakathi |

| 450 mm ububanzi | Ukuminyana kwe-chip okuphezulu ngewafa ngayinye Ukwenyuka kokukhiqiza nokusebenza kahle kwezindleko | Ukwanda kokungakwazi ukukhubazeka Kudingeka ukutshalwa kwezimali okukhulu kwemishini nengqalasizinda ukuze uthole isivuno esiphezulu |

Nakuba kunenqwaba yezinto ezisetshenziselwa ukwenza ama-semiconductors, i-silicon iyona evame kakhulu. I-silicon akulula nje ukusebenza nayo, kodwa futhi igcwele kangangokuthi inikeza inketho engabizi kakhulu.

Njengoba ama-wafer e-silicon anemisebenzi eminingi ebalulekile kanye nezinhlelo zokusebenza ekuphileni kwansuku zonke, ukuhlukanisa okubaluleke kakhulu kungaba umsebenzi onzima. Njengoba ama-wafer e-silicon esetshenziswa kakhulu futhi enezinhlelo eziningi zokusebenza, kungaba okungalungile ukugxila kokukodwa kuphela kwezinhlelo zokusebenza zawo. Lapha, sizogxila ekusetshenzisweni nasekusetshenzisweni kwama-silicon wafers emkhakheni wezinto zikagesi. Uma ufuna ukufunda okwengeziwe ngokubaluleka kwama-wafers e-silicon empilweni yansuku zonke, qhubeka ufunda.

I-semiconductor ethandwa kakhulu yi-silicon ngenxa yokushisa kwayo okuphezulu nokuhamba okuphezulu ekamelweni lokushisa, nakuba abanye abaqhubi banokusetshenziswa okuhlukile kuzinhlelo zokusebenza eziqondile. Emishinini kagesi, kuyisinqumo esimangalisayo ngoba okwamanje idlula kuma-silicon semiconductors ngokushesha kakhulu kunabahlinzeki abaningi.

Umdwebo onemininingwane