I-12inch Ngokugcwele Okuzenzakalelayo Okuzenzakalelayo Kokuhlukanisa Isisetshenziswa Sesisetshenziswa Sesicwecwe Esizinikezele Sokusika se-Si/SiC & HBM (Al)

Imingcele yezobuchwepheshe

| Ipharamitha | Ukucaciswa |

| Usayizi Wokusebenza | Φ8", Φ12" |

| I-spindle | I-Dual-eksisi 1.2/1.8/2.4/3.0, Max 60000 rpm |

| Usayizi we-Blade | 2" ~ 3" |

| I-eksisi ye-Y1 / Y2

| Ukunyuka kwesinyathelo esisodwa: 0.0001 mm |

| Ukunemba kokuma: <0.002 mm | |

| Ububanzi bokusika: 310 mm | |

| I-X eksisi | Ibanga lesivinini sokuphakelayo: 0.1–600 mm/s |

| I-Axis ye-Z1 / Z2

| Ukunyuka kwesinyathelo esisodwa: 0.0001 mm |

| Ukunemba kokuma: ≤ 0.001 mm | |

| θ I-eksisi | Ukunemba kokuma: ±15" |

| Isiteshi Sokuhlanza

| Isivinini sokujikeleza: 100-3000 rpm |

| Indlela yokuhlanza: Hlanza ngokuzenzakalelayo futhi usomise | |

| I-Voltage yokusebenza | 3-isigaba 380V 50Hz |

| Ubukhulu (W×D×H) | 1550×1255×1880 mm |

| Isisindo | 2100 kg |

Isimiso Sokusebenza

Imishini ifinyelela ukusika okuphezulu ngobuchwepheshe obulandelayo:

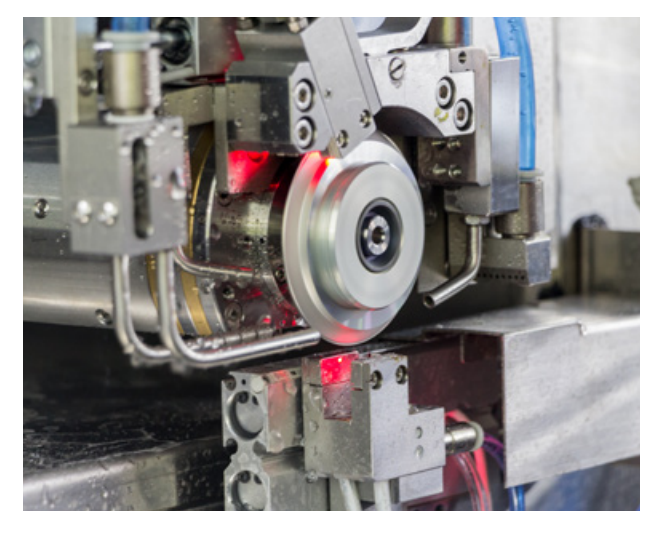

I-1.I-High-Rigidity Spindle System: Isivinini sokujikeleza sifika ku-60,000 RPM, ifakwe ama-diamond blades noma amakhanda okusika ama-laser ukuze avumelane nezakhiwo ezihlukahlukene zezinto ezibonakalayo.

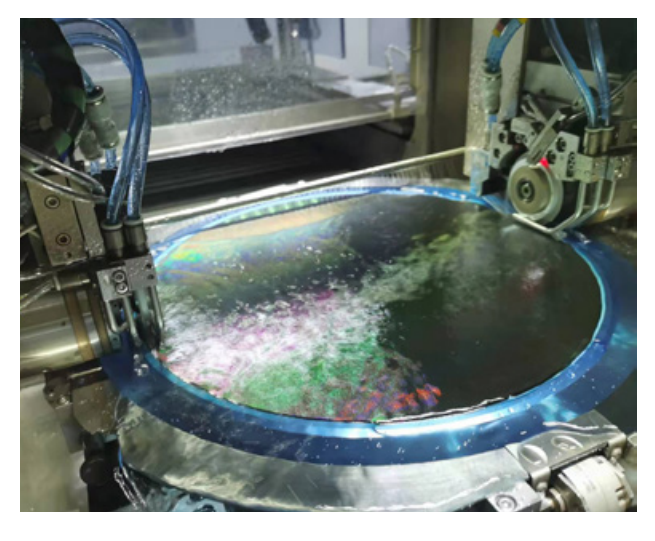

2.I-Multi-Axis Motion Control: Ukunemba kokuma kwe-axis ye-X/Y/Z okungu-±1μm, kubhangqwe nezikali zokugezela ezinembayo ukuze kuqinisekiswe izindlela zokusika ezingenazo ukuchezuka.

3.Ukuqondanisa Okubonakalayo Okukhaliphile: I-CCD enokulungiswa okuphezulu (amamegaphikiseli angu-5) ibona ngokuzenzakalela imigwaqo esikayo futhi inxephezele ukungqubuzana kwezinto noma ukungahambi kahle.

4.Ukupholisa Nokususwa Kothuli: Isistimu yokupholisa amanzi ahlanzekile edidiyelwe kanye nokususwa kothuli lwe-vacuum ukuze kuncishiswe umthelela oshisayo kanye nokungcoliswa kwezinhlayiyana.

Cutting Modes

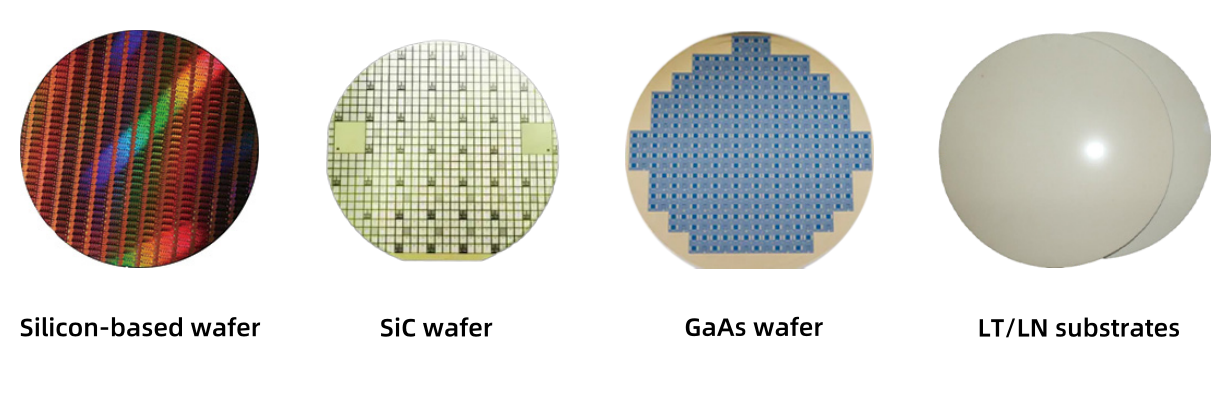

1.I-Blade Dicing: Ifanele izinto ze-semiconductor zendabuko ezifana ne-Si kanye ne-GaAs, enobubanzi be-kerf obungu-50–100μm.

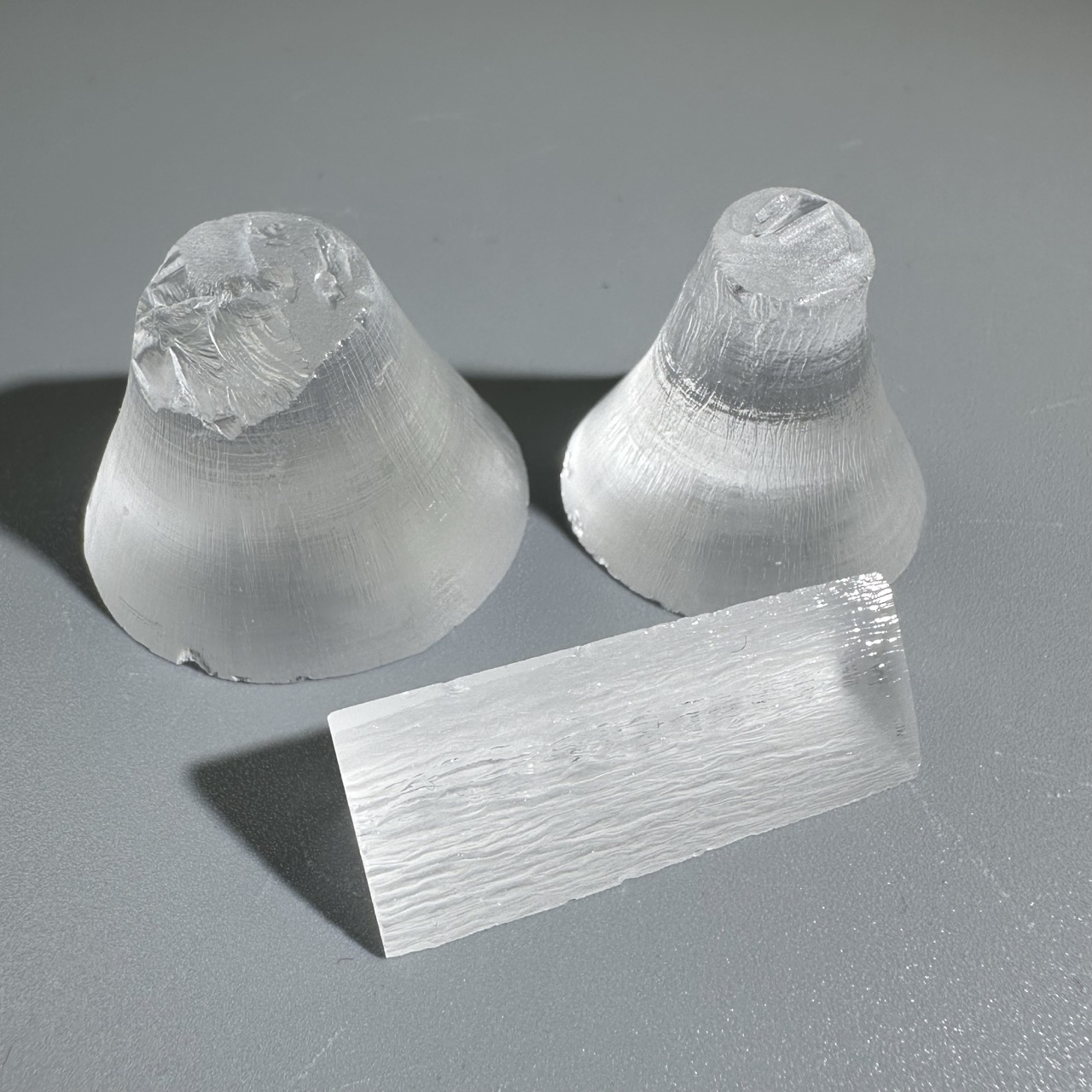

2.I-Stealth Laser Dicing: Isetshenziselwa amawafa amancane kakhulu (<100μm) noma izinto ezithambile (isb, i-LT/LN), evumela ukuhlukana okungenakucindezeleka.

Izicelo Ezijwayelekile

| Izinto Ezivumelanayo | Inkambu yohlelo lokusebenza | Icubungula Izidingo |

| I-silicon (Si) | Ama-IC, izinzwa ze-MEMS | Ukusika okunembe kakhulu, ukusika <10μm |

| I-Silicon Carbide (SiC) | Amadivayisi kagesi (MOSFET/diodes) | Ukusika okunomonakalo ophansi, ukwenziwa ngcono kokuphathwa kokushisa |

| I-Gallium Arsenide (GaAs) | Amadivaysi e-RF, ama-optoelectronic chips | Ukuvimbela imifantu emincane, ukulawula inhlanzeko |

| I-LT/LN Substrates | Izihlungi ze-SAW, ama-modulators optical | Ukusika okungenakucindezeleka, ukulondoloza izakhiwo ze-piezoelectric |

| I-Ceramic Substrates | Amamojula wamandla, ukupakishwa kwe-LED | High-hardness material processing, umphetho flatness |

| QFN/DFN Frames | Ukupakisha okuthuthukile | Ukusika kwe-Multi-chip kanyekanye, ukwenziwa kahle |

| I-WLCSP Wafers | Ukupakishwa kwezinga le-wafer | Ukudayela okungenakulimala kwama-wafers amancanyana kakhulu (50μm) |

Izinzuzo

1. Ukuskena kozimele wekhasethi lesivinini esikhulu ngama-alamu okuvimbela ukushayisana, ukuma kokudlulisa okusheshayo, namandla aqinile okulungisa amaphutha.

2. Imodi yokusika yokuphotha kabili ethuthukisiwe, ithuthukisa ukusebenza kahle cishe ngo-80% uma kuqhathaniswa nezinhlelo zokuphotha okukodwa.

3. Izikulufu zebhola ezingeniswe ngokunemba, iziqondiso zomugqa, nesikali se-Y-axis grating isilawuli esiyiluphu esivaliwe, esiqinisekisa ukuzinza kwesikhathi eside komshini wokunemba okuphezulu.

4. Ukulayisha/ukukhipha okuzenzakalelayo ngokugcwele, ukuma kokudlulisa, ukusika ukuqondanisa, nokuhlolwa kwe-kerf, kunciphisa kakhulu umthwalo womsebenzi womqhubi (OP).

5.Isakhiwo sokugxumeka sokuphotha sesitayela se-Gantry, esinesikhala esincane se-dual-blade esingu-24mm, esivumela ukuguquguquka okubanzi ezinqubweni zokusika ezikabili.

Izici

1.Isilinganiso sobude esinganembe kakhulu esingathintani nabo.

2.Ukusika ama-Multi-wafer dual-blade ethreyini eyodwa.

3.Ukulinganisa okuzenzakalelayo, ukuhlolwa kwe-kerf, namasistimu okubona ukuphuka kwe-blade.

4.Isekela izinqubo ezihlukahlukene ezinama-algorithms okuqondanisa okuzenzakalelayo.

5.Ukusebenza kokuzilungisa okunephutha kanye nokuqapha kwezindawo eziningi ngesikhathi sangempela.

6.Ikhono lokuhlola lokuqala lokusika ngemuva kokudayela kokuqala.

7.Amamojula we-automation wefekthri angenziwa ngokwezifiso kanye neminye imisebenzi ongayikhetha.

Izinsiza Zezinsiza

Sinikeza ukwesekwa okuphelele kusukela ekukhethweni kwemishini kuya ekulungisweni kwesikhathi eside:

(1) Ukuthuthukiswa Ngokwezifiso

· Ncoma izixazululo zokusika i-blade/laser ngokusekelwe ezintweni ezibonakalayo (isb, ubulukhuni be-SiC, i-GaAs brittleness).

· Nikeza ukuhlolwa kwamahhala kwesampula ukuze uqinisekise ikhwalithi yokusika (okuhlanganisa ukusika, ububanzi be-kerf, ukuhwalala kwendawo, njll.).

(2) Ukuqeqeshwa Kwezobuchwepheshe

· Ukuqeqeshwa Okuyisisekelo: Ukusebenza kwemishini, ukulungiswa kwepharamitha, ukunakekelwa okujwayelekile.

· Izifundo Ezithuthukile: Ukwenza ngcono inqubo yezinto eziyinkimbinkimbi (isb., ukusika okungenakucindezeleka kwama-LT substrates).

(3) Ukusekela Ngemva Kokuthengisa

· 24/7 Impendulo: Ukuxilongwa kwesilawuli kude noma usizo lwesayithi.

· Ukunikezwa kwezingxenye eziyisipele: Izinsimbi zokuphotha, izindwani, nezinto ezibonakalayo ukuze zishintshwe ngokushesha.

· Ukugcinwa Kokuvikela: Ukulinganisa okuvamile ukuze kugcinwe ukunemba nokwelula impilo yesevisi.

Izinzuzo Zethu

✔ Isipiliyoni Semboni: Isebenzela ama-semiconductor angama-300+ womhlaba jikelele kanye nabakhiqizi bezinto zikagesi.

✔ Ubuchwepheshe Be-Cutting-Edge: Imihlahlandlela eqondile eqondile nezinhlelo ze-servo ziqinisekisa ukuzinza okuhamba phambili embonini.

✔ Inethiwekhi Yesevisi Yomhlaba Wonke: Ukusabalala e-Asia, eYurophu naseNyakatho Melika ukuze uthole ukwesekwa kwendawo.

Ukuhlola noma ukubuza, xhumana nathi!