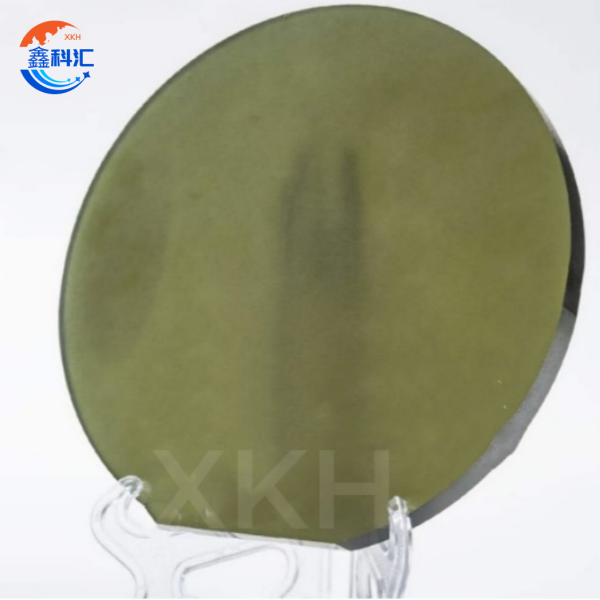

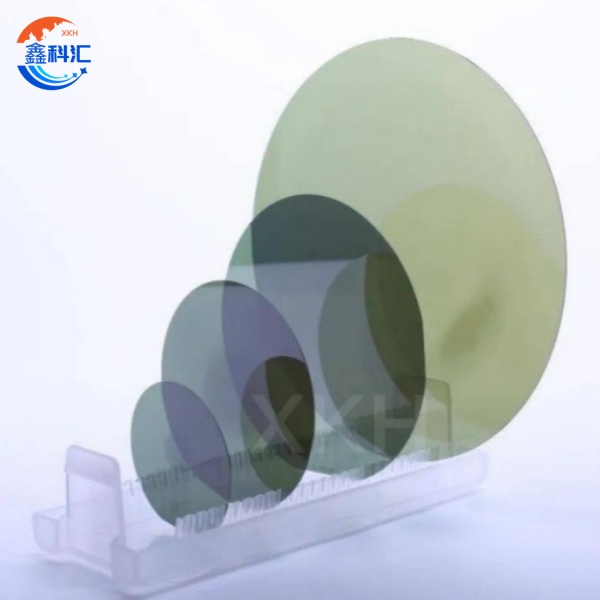

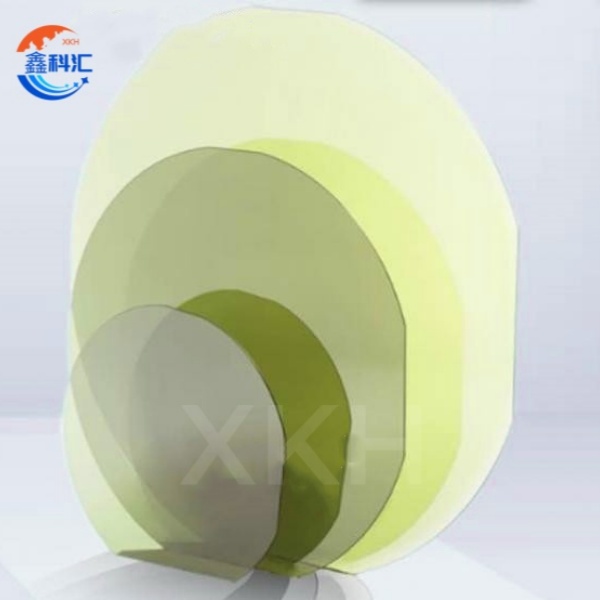

12 inch SIC substrate silicon carbide prime grade diameter 300mm usayizi omkhulu 4H-N Ifanele idivayisi yamandla aphezulu ukuchithwa kokushisa

Izici zomkhiqizo

1. Ukushisa okuphezulu kwe-thermal: i-thermal conductivity ye-silicon carbide ingaphezu kwezikhathi ezingu-3 kune-silicon, efanelekile ukuchithwa kokushisa kwedivayisi yamandla aphezulu.

2. Amandla enkambu yokwephuka okuphezulu: Amandla enkambu yokuwohloka aphindwe izikhathi ezingu-10 awe-silicon, afanele izicelo zokucindezela okukhulu.

I-3.I-bandgap ebanzi: I-bandgap yi-3.26eV (4H-SiC), ifanele izinga lokushisa eliphezulu kanye nezicelo zemvamisa ephezulu.

4. Ukuqina okuphezulu: Ukuqina kwe-Mohs kungu-9.2, okwesibili kuphela kwedayimane, ukumelana okuhle kakhulu kokugqokwa namandla emishini.

5. Ukuzinza kwamakhemikhali: ukumelana nokugqwala okuqinile, ukusebenza okuzinzile ekushiseni okuphezulu kanye nemvelo enokhahlo.

6. Usayizi omkhulu: 12 inch (300mm) substrate, ngcono ukukhiqiza ukusebenza kahle, ukunciphisa iyunithi izindleko.

I-7.I-Defect Defect Density: Ikhwalithi ephezulu yobuchwepheshe bokukhula kwekristalu eyodwa ukuze kuqinisekiswe ukuminyana kwesici esiphansi nokuvumelana okuphezulu.

Isiqondiso sohlelo lokusebenza oluyinhloko lomkhiqizo

1. Izinto zikagesi:

Ama-Mosfets: Asetshenziswa ezimotweni zikagesi, amadrayivu ezimoto zezimboni kanye neziguquli zamandla.

Ama-Diode: njenge-Schottky diodes (SBD), asetshenziselwa ukulungisa kahle nokushintsha izinto zamandla.

2. Amadivayisi we-Rf:

Isikhulisi samandla e-Rf: sisetshenziswa eziteshini eziyisisekelo zokuxhumana ze-5G nokuxhumana ngesathelayithi.

Imishini ye-Microwave: Ifanele i-radar nezinhlelo zokuxhumana ezingenazintambo.

3. Izimoto zamandla amasha:

Amasistimu okushayela kagesi: izilawuli zezimoto nama-inverter ezimotweni zikagesi.

Inqwaba yokushaja: Imojula yamandla yemishini yokushaja ngokushesha.

4. Izicelo zezimboni:

I-inverter ye-voltage ephezulu: yokulawulwa kwezimoto zezimboni kanye nokuphathwa kwamandla.

Igridi ehlakaniphile: Okokudlulisela kwe-HVDC kanye neziguquli zamandla kagesi.

5. Umkhathi:

I-electronics yokushisa ephezulu: ifanele izindawo zokushisa eziphezulu zemishini ye-aerospace.

6. Inkambu yocwaningo:

Ucwaningo olubanzi lwe-bandgap semiconductor: lokuthuthukiswa kwezinto ezintsha ze-semiconductor namadivayisi.

I-12-intshi ye-silicon carbide substrate iwuhlobo lwe-semiconductor material substrate esebenza kahle kakhulu enezindawo ezinhle kakhulu ezifana ne-thermal conductivity ephezulu, amandla ensimu yokuwohloka okuphezulu kanye negebe lebhande elibanzi. Isetshenziswa kakhulu kuma-electronics anamandla, ezinsizakalweni zefrikhwensi yomsakazo, ezimotweni ezintsha zamandla, ekulawuleni izimboni kanye ne-aerospace, futhi iyinto ebalulekile yokukhuthaza ukuthuthukiswa kwesizukulwane esilandelayo semishini kagesi enamandla kakhulu nanamandla.

Nakuba ama-silicon carbide substrates njengamanje anezinhlelo ezimbalwa eziqondile ezisebenza ku-electronics abathengi njengezibuko ze-AR, amandla azo ekulawuleni amandla ngendlela ephumelelayo nezinto zikagesi ezincane zingasekela izixazululo zokuphakela amandla ezingasindi, ezisebenza kahle kakhulu zamadivayisi esikhathi esizayo e-AR/VR. Njengamanje, ukuthuthukiswa okuyinhloko kwe-silicon carbide substrate kugxile emikhakheni yezimboni efana nezimoto ezintsha zamandla, ingqalasizinda yezokuxhumana kanye ne-automation yezimboni, futhi ikhuthaza imboni ye-semiconductor ukuthi ithuthuke ngendlela esebenza kahle futhi enokwethenjelwa.

I-XKH izibophezele ekunikezeni izinga eliphezulu 12 "ama-SIC substrates anosekelo olubanzi lobuchwepheshe namasevisi, okuhlanganisa:

1. Ukukhiqizwa okwenziwe ngokwezifiso: Ngokwezidingo zekhasimende ukuhlinzeka ngokumelana okuhlukile, ukuma kwekristalu kanye ne-substrate yokwelashwa komhlaba.

2. Ukuthuthukisa inqubo: Nikeza amakhasimende ngosekelo lobuchwepheshe lokukhula kwe-epitaxial, ukukhiqizwa kwedivayisi nezinye izinqubo zokuthuthukisa ukusebenza komkhiqizo.

3. Ukuhlola kanye nesitifiketi: Nikeza ukutholwa kokukhubazeka okuqinile kanye nesitifiketi sekhwalithi ukuze kuqinisekiswe ukuthi indawo engaphansi ihlangabezana nezindinganiso zomkhakha.

Ukubambisana kwe-4.R&d: Hlanganisa ngokuhlanganyela amadivayisi amasha e-silicon carbide namakhasimende ukuze kuthuthukiswe ukuqanjwa kabusha kwezobuchwepheshe.

Ishadi ledatha

| 1 2 inch Silicon Carbide (SiC) Substrate Specification | |||||

| Ibanga | Ukukhiqizwa kwe-ZeroMPD Ibanga(Z Grade) | Ukukhiqizwa Okujwayelekile Ibanga(P Grade) | Dummy Grade (D Grade) | ||

| Ububanzi | 3 0 0 mm ~ 305mm | ||||

| Ubukhulu | 4H-N | 750μm±15 μm | 750μm±25 μm | ||

| 4H-SI | 750μm±15 μm | 750μm±25 μm | |||

| I-Wafer Orientation | Ku-axis evaliwe : 4.0° kuya ku-<1120 >±0.5° ku-4H-N, Ku-eksisi : <0001>±0.5° ku-4H-SI | ||||

| I-Micropipe Density | 4H-N | ≤0.4cm-2 | ≤4cm-2 | ≤25cm-2 | |

| 4H-SI | ≤5cm-2 | ≤10cm-2 | ≤25cm-2 | ||

| Ukungazweli | 4H-N | 0.015~0.024 Ω·cm | 0.015~0.028 Ω·cm | ||

| 4H-SI | ≥1E10 Ω·cm | ≥1E5 Ω·cm | |||

| Isisekelo se-Flat Orientation | {10-10} ±5.0° | ||||

| Ubude Befulethi obuyisisekelo | 4H-N | N/A | |||

| 4H-SI | Inothi | ||||

| Ukukhishwa komkhawulo | 3 mm | ||||

| LTV/TTV/Bow/Warp | ≤5μm/≤15μm/≤35 μm/≤55 μm | ≤5μm/≤15μm/≤35 □ μm/≤55 □ μm | |||

| Ubulukhuni | I-Polish Ra≤1 nm | ||||

| I-CMP Ra≤0.2 nm | I-Ra≤0.5 nm | ||||

| I-Edge Cracks By High Intensity Light I-Hex Plates Ngokukhanya Okunamandla Okuphezulu Izindawo ze-Polytype Ngokukhanya Okunamandla Okuphezulu I-Visual Carbon Inclusions I-Silicon Surface Scratches By High Intensity Light | Lutho Indawo eqoqiwe ≤0.05% Lutho Indawo eqoqiwe ≤0.05% Lutho | Ubude obuqongelelwayo ≤ 20 mm, ubude obubodwa≤2 mm Indawo eqoqiwe ≤0.1% Indawo eqoqiwe≤3% Indawo eqoqiwe ≤3% Ubude obuqongelelwayo≤1× ububanzi bewafa | |||

| Ama-Edge Chips Ngokukhanya Okunamandla Okuphezulu | Akukho okuvunyelwe ≥0.2mm ububanzi nokujula | 7 okuvunyelwe, ≤1 mm ngakunye | |||

| (TSD) Ukukhipha isikulufu sochungechunge | ≤500 cm-2 | N/A | |||

| (BPD) Ukususwa kwendiza okuyisisekelo | ≤1000 cm-2 | N/A | |||

| I-Silicon Surface Contamination By High Intensity Light | Lutho | ||||

| Ukupakisha | Ikhasethi elinesinkwa esilucwecwana noma Isitsha Esiyisinkwa Esikodwa | ||||

| Amanothi: | |||||

| 1 Imikhawulo yokukhubazeka isebenza kuyo yonke indawo eyiwafa ngaphandle kwendawo engabaliwe enqenqemeni. 2Ukuklwebheka kufanele kubhekwe ku-Si face kuphela. 3 Idatha yokususwa isuka kumawafa aqoshiwe e-KOH kuphela. | |||||

I-XKH izoqhubeka nokutshala imali ocwaningweni nasekuthuthukisweni ukuze kuthuthukiswe ukuphumelela kwe-12-inch silicon carbide substrates ngobukhulu obukhulu, ukukhubazeka okuphansi nokuvumelana okuphezulu, kuyilapho i-XKH ihlola izinhlelo zayo zokusebenza ezindaweni ezisafufusa ezifana ne-electronics yabathengi (njengamamojula wamandla amadivayisi we-AR/VR) kanye ne-quantum computing. Ngokunciphisa izindleko nokwandisa umthamo, i-XKH izoletha ukuchuma embonini ye-semiconductor.

Umdwebo onemininingwane