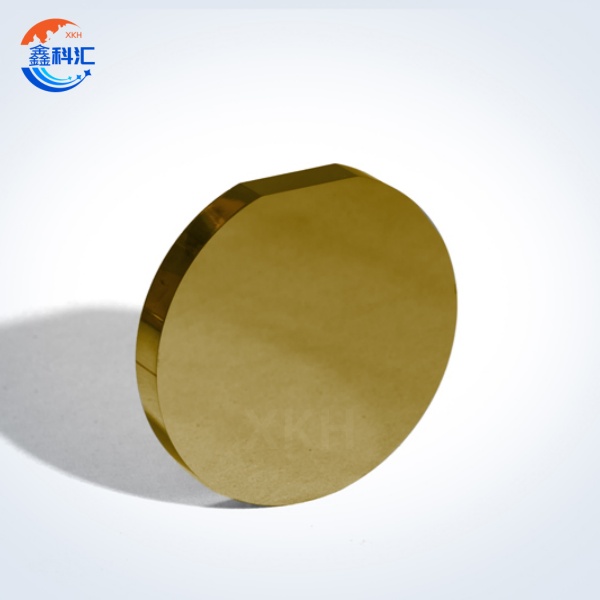

I-12 Intshi ye-SiC substrate Ububanzi 300mm Ubukhulu 750μm 4H-N Uhlobo lungenziwa ngendlela oyifisayo

Imingcele yezobuchwepheshe

| I-12 inch Silicon Carbide (SiC) Substrate Specification | |||||

| Ibanga | Ukukhiqizwa kwe-ZeroMPD Ibanga(Z Grade) | Ukukhiqizwa Okujwayelekile Ibanga(P Grade) | Dummy Grade (D Grade) | ||

| Ububanzi | 3 0 0 mm ~ 1305mm | ||||

| Ubukhulu | 4H-N | 750μm±15 μm | 750μm±25 μm | ||

| 4H-SI | 750μm±15 μm | 750μm±25 μm | |||

| I-Wafer Orientation | Ku-axis evaliwe : 4.0° kuya ku-<1120 >±0.5° ku-4H-N, Ku-eksisi : <0001>±0.5° ku-4H-SI | ||||

| I-Micropipe Density | 4H-N | ≤0.4cm-2 | ≤4cm-2 | ≤25cm-2 | |

| 4H-SI | ≤5cm-2 | ≤10cm-2 | ≤25cm-2 | ||

| Ukungazweli | 4H-N | 0.015~0.024 Ω·cm | 0.015~0.028 Ω·cm | ||

| 4H-SI | ≥1E10 Ω·cm | ≥1E5 Ω·cm | |||

| Isisekelo se-Flat Orientation | {10-10} ±5.0° | ||||

| Ubude Befulethi obuyisisekelo | 4H-N | N/A | |||

| 4H-SI | Inothi | ||||

| Ukukhishwa komkhawulo | 3 mm | ||||

| LTV/TTV/Bow/Warp | ≤5μm/≤15μm/≤35 μm/≤55 μm | ≤5μm/≤15μm/≤35 □ μm/≤55 □ μm | |||

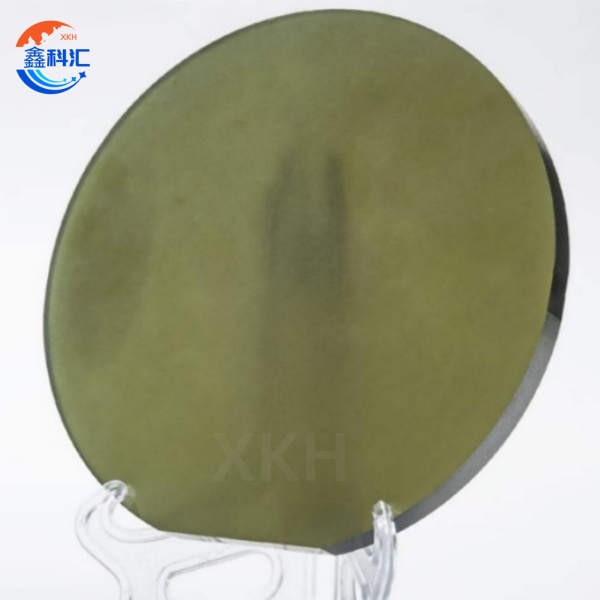

| Ubulukhuni | I-Polish Ra≤1 nm | ||||

| I-CMP Ra≤0.2 nm | I-Ra≤0.5 nm | ||||

| I-Edge Cracks By High Intensity Light I-Hex Plates Ngokukhanya Okunamandla Okuphezulu Izindawo ze-Polytype Ngokukhanya Okunamandla Okuphezulu I-Visual Carbon Inclusions I-Silicon Surface Scratches By High Intensity Light | Lutho Indawo eqoqiwe ≤0.05% Lutho Indawo eqoqiwe ≤0.05% Lutho | Ubude obuqongelelwayo ≤ 20 mm, ubude obubodwa≤2 mm Indawo eqoqiwe ≤0.1% Indawo eqoqiwe≤3% Indawo eqoqiwe ≤3% Ubude obuqongelelwayo≤1× ububanzi bewafa | |||

| Ama-Edge Chips Ngokukhanya Okunamandla Okuphezulu | Akukho okuvunyelwe ≥0.2mm ububanzi nokujula | 7 okuvunyelwe, ≤1 mm ngakunye | |||

| (TSD) Ukukhipha isikulufu sochungechunge | ≤500 cm-2 | N/A | |||

| (BPD) Ukususwa kwendiza okuyisisekelo | ≤1000 cm-2 | N/A | |||

| I-Silicon Surface Contamination By High Intensity Light | Lutho | ||||

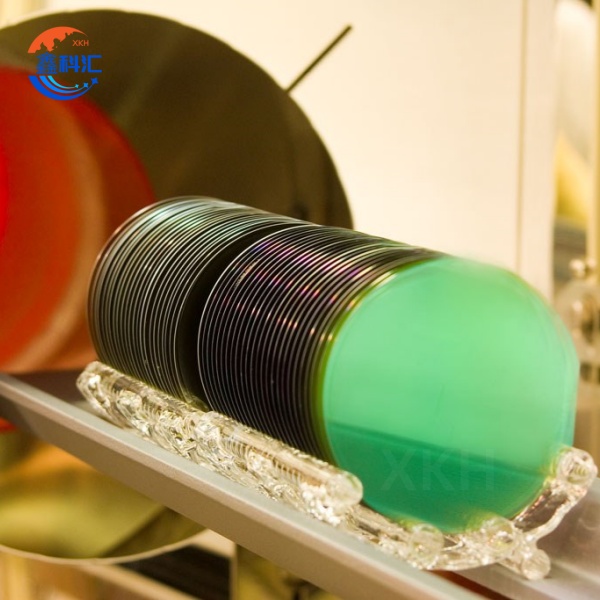

| Ukupakisha | Ikhasethi elinesinkwa esilucwecwana noma Isitsha Esiyisinkwa Esikodwa | ||||

| Amanothi: | |||||

| 1 Imikhawulo yokukhubazeka isebenza kuyo yonke indawo eyiwafa ngaphandle kwendawo engabaliwe enqenqemeni. 2Ukuklwebheka kufanele kubhekwe ku-Si face kuphela. 3 Idatha yokususwa isuka kumawafa aqoshiwe e-KOH kuphela. | |||||

Izici Eziyinhloko

1.Ikhono Lokukhiqiza kanye Nezinzuzo Zezindleko: Ukukhiqizwa ngobuningi be-substrate ye-SiC engu-12-intshi (i-12-inch silicon carbide substrate) kuphawula inkathi entsha ekukhiqizeni i-semiconductor. Inani lama-chips atholakala ku-wafer eyodwa lifinyelela izikhathi ezingu-2.25 kunele-substrate engu-8-intshi, okuholela ngokuqondile ekusebenzeni kahle kokukhiqiza. Impendulo yekhasimende ibonisa ukuthi ukwamukela ama-substrates angu-12-intshi kwehlise izindleko zawo zokukhiqiza amamojula wamandla ngo-28%, okudala inzuzo ewujuqu yokuncintisana emakethe okuqhudelana ngayo kanzima.

2.Izakhiwo Ezivelele Zomzimba: I-substrate ye-SiC engu-12-intshi ithola ifa zonke izinzuzo zezinto ze-silicon carbide - conductivity yayo eshisayo iphindwe izikhathi ezi-3 kune-silicon, kuyilapho amandla ayo enkambu yokuphuka afinyelela izikhathi ezingu-10 kune-silicon. Lezi zici zenza amadivayisi asuselwe kuma-substrates angu-12-intshi ukuthi asebenze ngokuzinzile endaweni enezinga lokushisa eliphezulu elingaphezu kuka-200°C, okuwenza afanelekele ngokukhethekile izinhlelo zokusebenza ezifunwa kakhulu njengezimoto zikagesi.

3.I-Surface Treatment Technology: Senze inqubo yenoveli yokupholisha amakhemikhali (CMP) eqondiswe ngqo kuma-substrates e-SiC angu-12-intshi, kuzuzwe ukucaba komhlaba kweleveli ye-athomu (Ra<0.15nm). Lokhu kuphumelela kuxazulula inselele yomhlaba wonke yokwelashwa kwe-wafer ye-silicon carbide wafer enobubanzi obukhulu, kusula izithiyo zokukhula kwekhwalithi ephezulu ye-epitaxial.

4.Ukusebenza Kokuphatha Okushisayo: Kuzinhlelo zokusebenza ezingokoqobo, ama-substrates e-SiC angu-12 intshi abonisa amandla amangalisayo okukhipha ukushisa. Idatha yokuhlola ibonisa ukuthi ngaphansi kokuminyana kwamandla okufanayo, amadivayisi asebenzisa ama-substrates angu-12-intshi asebenza emazingeni okushisa angu-40-50°C aphansi kunamadivayisi asekelwe ku-silicon, andisa kakhulu impilo yesevisi yemishini.

Izicelo Eziyinhloko

1.I-New Energy Vehicle Ecosystem: I-substrate ye-SiC engu-12-intshi (i-silicon carbide substrate engu-12-intshi) iguqula izakhiwo ze-powertrain yemoto kagesi. Kusukela kumashaja angaphakathi (i-OBC) kuya kuma-inverter amakhulu namasistimu okuphatha amabhethri, ukuthuthukiswa kokusebenza kahle okulethwa ama-substrates angu-12-intshi kwenyusa ibanga lezimoto ngo-5-8%. Imibiko evela kumenzi wezimoto ohamba phambili ibonisa ukuthi ukusebenzisa ama-substrates ethu angu-12-intshi kwehlisa ukulahlekelwa kwamandla kusistimu yabo eshaja ngokushesha ngo-62%.

2.Umkhakha Wamandla Avuselelekayo: Eziteshini zamandla e-photovoltaic, ama-inverter asekelwe kuma-substrates e-SiC angu-12-intshi awagcini nje ngokufaka izici zefomu ezincane kodwa futhi afinyelela ukusebenza kahle kokuguqulwa okudlula u-99%. Ikakhulukazi ezimweni ezisabalalisiwe zokukhiqiza, lokhu kusebenza kahle okuphezulu kuhumushela ukongiwa konyaka kwamakhulu ezinkulungwane zama-yuan ekulahlekeni kukagesi kubasebenzisi.

I-3.Industrial Automation: Iziguquli zemvamisa ezisebenzisa ama-substrates angu-12-intshi zibonisa ukusebenza okuhle kakhulu kumarobhothi ezimboni, amathuluzi omshini we-CNC, nezinye izinto zokusebenza. Izici zabo zokushintsha imvamisa ephezulu zithuthukisa isivinini sokuphendula kwemoto ngo-30% kuyilapho kunciphisa ukuphazamiseka kazibuthe kuyingxenye eyodwa kwezintathu yezixazululo ezivamile.

4.I-Consumer Electronics Innovation: Ubuchwepheshe obushaja ngokushesha be-smartphone yesizukulwane esilandelayo sebuqale ukusebenzisa ama-substrate e-SiC angu-12-intshi. Kucatshangwa ukuthi imikhiqizo eshaja ngokushesha engaphezu kuka-65W izoshintshela ngokugcwele kuzixazululo ze-silicon carbide, nama-substrates angu-12-intshi avela njengokukhethwa kokusebenza kwezindleko ezifanele.

Izinsizakalo Ezenziwe Ngokwezifiso ze-XKH ze-SiC Substrate engu-12 intshi

Ukuze kuhlangatshezwane nezidingo ezithile zama-substrates e-SiC angu-12-inch (12-inch silicon carbide substrates), i-XKH inikeza ukusekelwa kwesevisi okuphelele:

1. Ukwenza Ngokwezifiso Ubukhulu:

Sihlinzeka ngama-substrates angu-12-intshi ekucacisweni kogqinsi okuhlukahlukene okuhlanganisa no-725μm ukuze kuhlangatshezwane nezidingo ezihlukene zohlelo lokusebenza.

2. I-Doping concentration:

Ukukhiqiza kwethu kusekela izinhlobo eziningi ze-conductivity ezihlanganisa uhlobo lwe-n-type kanye ne-p-type substrates, enokulawula okunembe kwe-resistivity ebangeni lika-0.01-0.02Ω·cm.

3.Amasevisi okuhlola:

Ngempahla ephelele yokuhlola izinga le-wafer, sinikeza imibiko yokuhlola egcwele.

I-XKH iyaqonda ukuthi ikhasimende ngalinye linezidingo ezihlukile zama-substrates e-SiC angu-12-intshi. Ngakho-ke sinikeza amamodeli wokubambisana webhizinisi avumelana nezimo ukuze sinikeze izixazululo ezincintisana kakhulu, noma ngabe:

· Amasampula e-R&D

· Ukuthengwa kwevolumu

Amasevisi ethu angokwezifiso aqinisekisa ukuthi singakwazi ukuhlangabezana nezidingo zakho ezithile zobuchwepheshe nezokukhiqiza zama-substrates angu-12-intshi we-SiC.