I-Wafer Orientation System ye-Crystal Orientation Measurement

Isingeniso Sezisetshenziswa

Amathuluzi e-wafer orientation angamadivayisi anemba asuselwa kuzimiso ze-X-ray diffraction (XRD), asetshenziswa kakhulu ekukhiqizweni kwe-semiconductor, izinto ezibonakalayo, izitsha zobumba, nezinye izimboni ze-crystalline material.

Lawa mathuluzi anquma umumo we-crystal lattice futhi aqondise ukusika okunembayo noma izinqubo zokupholisha. Izici ezibalulekile zifaka:

- Izilinganiso zokunemba okuphezulu:Iyakwazi ukuxazulula izindiza zekristalu ezinezinqumo ezingu-angular ezifika ku-0.001°.

- Ukuhambisana kwesampula enkulu:Isekela ama-wafers afinyelela ku-450 mm ububanzi nezisindo ezingama-30 kg, afanele izinto ezifana ne-silicon carbide (SiC), isafire, ne-silicon (Si).

- Idizayini ye-modular:Imisebenzi enwebekayo ihlanganisa ukuhlaziywa kwe-rocking curve, imephu ye-3D surface defect, kanye namadivayisi wokupakisha wokucubungula amasampula amaningi.

Amapharamitha Abalulekile Wezobuchwepheshe

| Isigaba sepharamitha | Amanani Ajwayelekile/Ukucushwa |

| Umthombo we-X-ray | I-Cu-Kα (indawo okugxilwe kuyo engu-0.4×1 mm), 30 kV amandla kagesi asheshayo, 0–5 mA ishubhu yamanje eshintshwayo |

| I-Angular Range | θ: -10 ° kuya +50 °; 2θ: -10° ukuya +100° |

| Ukunemba | Ukulungiswa kwe-engeli etshekile: 0.001°, ukutholwa kokonakala kwendawo: ±30 arcseconds (ijika elinyakazayo) |

| Isivinini sokuskena | Ukuskena kwe-Omega kuqeda ukuma okugcwele kwe-lattice ngemizuzwana emi-5; Ukuskena kwe-Theta kuthatha iminithi elingu-1 |

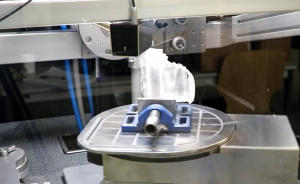

| Isiteji sesampula | I-V-groove, ukumunca umoya, ukuzungezisa okunama-engeli amaningi, kuhambisana namawafa angama-intshi angu-2–8 |

| Imisebenzi Enwebekayo | Ukuhlaziya ijika elinyakazayo, ukumepha i-3D, idivayisi yokupakisha, ukutholwa kokukhubazeka kwamehlo (imihuzuko, ama-GB) |

Isimiso Sokusebenza

1. I-X-ray Diffraction Foundation

- Ama-X-ray asebenzisana nama-nuclei e-athomu nama-electron ku-crystal lattice, akhiqiza amaphethini okushintshashintsha. Umthetho kaBragg (nλ = 2d sinθ) ulawula ubudlelwano phakathi kwama-engeli e-diffraction (θ) nesikhala se-lattice (d).

Izitholi zithwebula lawa maphethini, ahlaziywa ukuze akhe kabusha ukwakheka kwecrystallographic.

2. I-Omega Scanning Technology

- Ikristalu izungeza ngokuqhubekayo izungeze i-eksisi egxilile kuyilapho ama-X-ray ayikhanyisa.

- Izihloli ziqoqa amasiginali wokuhlukanisa phakathi kwezindiza eziningi ze-crystallographic, ezivumela ukuzimisela okugcwele kokuma kwe-lattice ngemizuzwana emi-5.

3. Ukuhlaziya ijika le-Rocking

- I-engeli yekristalu egxilile enama-engeli e-X-ray esenzeko ukuze kukale ububanzi obuphakeme (i-FWHM), ihlola ukukhubazeka kwe-lattice kanye nobunzima.

4. Ukulawula Okuzenzakalelayo

- I-PLC ne-touchscreen interface inika amandla ama-engeli okusika asethiwe, impendulo yesikhathi sangempela, nokuhlanganiswa nemishini yokusika yokulawula iluphu evaliwe.

Izinzuzo kanye nezici

1. Ukunemba nokusebenza kahle

- Ukunemba kwe-angular ±0.001°, ukulungiswa kokutholwa kokukhubazeka <30 arcsecond.

- Isivinini sokuskena se-Omega singu-200× ngokushesha kunezikena ze-Theta ezivamile.

2. I-Modularity kanye ne-Scalability

- Anwebeka ezinsizeni ezikhethekile (isb., amawafa e-SiC, ama-turbine blades).

- Ihlanganisa nezinhlelo ze-MES zokuqapha ukukhiqizwa kwesikhathi sangempela.

3. Ukuhambisana nokuzinza

- Ivumela amasampula amise ngendlela engavamile (isb., ama-sapphire ingots).

- Idizayini epholile emoyeni inciphisa izidingo zokunakekela.

4. Ukusebenza Okukhaliphile

- Ukulinganisa ngokuchofoza okukodwa nokucutshungulwa kwemisebenzi eminingi.

- Ukulinganisa okuzenzakalelayo ngamakristalu ayizethenjwa ukuze kuncishiswe iphutha lomuntu.

Izinhlelo zokusebenza

1. Ukukhiqiza I-Semiconductor

- I-wafer dicing orientation: Inquma i-Si, i-SiC, i-GaN wafer orientation ngokusebenza kahle kokusika.

- Imephu enesici: Ikhomba ukuklwebheka kwendawo noma ukugudluka ukuze kuthuthukiswe ukuvunwa kwe-chip.

2. Izinto ezibonakalayo

- Amakristalu angaqondile (isb, i-LBO, i-BBO) yamadivayisi we-laser.

- Ireferensi ye-Sapphire wafer surface marking ye-LED substrates.

3. I-Ceramics kanye ne-Composites

- Ihlaziya umumo wokusanhlamvu ku-Si3N4 kanye ne-ZrO2 ukuze uthole izinhlelo zokusebenza ezisezingeni eliphezulu.

4. Ucwaningo Nokulawulwa Kwekhwalithi

- Amanyuvesi/amalebhu okuthuthukiswa kwezinto ezinoveli (isb, ama-alloys aphezulu).

- I-Industrial QC ukuqinisekisa ukufana kwenqwaba.

Izinkonzo ze-XKH

I-XKH inikezela ngosekelo olubanzi lomjikelezo wempilo wamathuluzi e-wafer orientation, okuhlanganisa ukufakwa, ukuthuthukiswa kwepharamitha yenqubo, ukuhlaziya ijika elinyakazayo, kanye nemephu yokukhubazeka kwe-3D. Izixazululo ezenzelwe wena (isb, ubuchwepheshe bokupakisha ingot) zihlinzekwa ukuthuthukisa ukusebenza kahle kwe-semiconductor kanye ne-optical material yokukhiqiza ngama-30%. Ithimba elizinikele liqhuba ukuqeqeshwa endaweni, kuyilapho ukwesekwa okukude okungu-24/7 nokushintshwa kwengxenye eyisipele ngokushesha kuqinisekisa ukwethembeka kwemishini.