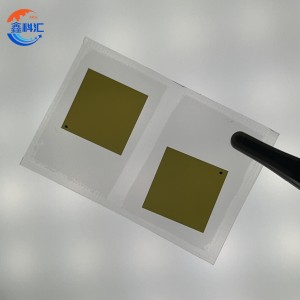

I-Silicon Carbide (SiC) I-Single-Crystal Substrate – 10×10mm Wafer

Umdwebo onemininingwane we-Silicon Carbide (SiC) substrate wafer

Uhlolojikelele lwe-Silicon Carbide (SiC) substrate wafer

II-10×10mm ye-Silicon Carbide (SiC) ye-single-crystal substrate waferiyinto esebenza kahle kakhulu ye-semiconductor eyenzelwe ugesi wamandla wesizukulwane esilandelayo kanye nezicelo ze-optoelectronic. Ifaka i-thermal conductivity engavamile, i-bandgap ebanzi, nokuzinza okuhle kakhulu kwamakhemikhali, iwafa engaphansi ye-Silicon Carbide (SiC) inikeza isisekelo samadivayisi asebenza kahle ngaphansi kwezinga lokushisa eliphezulu, imvamisa ephezulu, nezimo zamandla kagesi aphezulu. Lawa ma-substrates anqunywa ngokunemba10 × 10mm ama-chips square, ilungele ucwaningo, i-prototyping, nokwakhiwa kwedivayisi.

Umgomo Wokukhiqiza we-Silicon Carbide (SiC) substrate wafer

I-Silicon Carbide (SiC) substrate wafer ikhiqizwa ngokusebenzisa I-Physical Vapor Transport (PVT) noma izindlela zokukhula kwe-sublimation. Inqubo iqala nge-high-purity SiC powder elayishwe ku-graphite crucible. Ngaphansi kwezinga lokushisa elidlulele elingaphezu kuka-2,000°C nendawo elawulwayo, impushana ishintshashintsha ibe umhwamuko bese iphinda idiphozithi kukristalu lwembewu olumukelwe ngokucophelela, kwakheka ingot yekristalu eyodwa enkulu, enesici-encane.

Uma i-SiC boule isikhulile, idlula:

- Ukusikwa kwe-ingot: Amasaha wentambo yedayimane eqondile asika ingot ye-SiC ibe ama-wafers noma ama-chips.

- I-Lapping and grinding: Indawo engaphezulu iyalungiswa ukuze kukhishwe amasaha futhi kufinyelele ukujiya okufanayo.

- I-Chemical Mechanical Polishing (CMP): Ifinyelela isibuko esilungele i-epi esinobuhwaba obuphansi kakhulu.

- I-doping yokuzikhethela: I-nitrogen, i-aluminiyamu, noma i-boron doping ingase yethulwe ukuze ihambisane nezakhiwo zikagesi (uhlobo lwe-n noma uhlobo lwe-p).

- Ukuhlolwa kwekhwalithi: I-metrology ethuthukisiwe iqinisekisa ukucaba kwe-wafer, ukufana kogqinsi, nokuminyana kwesici kuhlangabezana nezidingo eziqinile zebanga le-semiconductor.

Le nqubo yezinyathelo eziningi iphumela ekuqineni kwe-10×10mm Silicon Carbide (SiC) ama-wafer chips alungele ukukhula kwe-epitaxial noma ukwenziwa kwedivayisi okuqondile.

Izimpawu Zezinto Ze-Silicon Carbide (SiC) ye-substrate wafer

I-Silicon Carbide (SiC) substrate wafer yenziwe ngokuyinhloko4H-SiC or 6H-SiCama-polytypes:

-

4H-SiC:Ifaka ukuhamba kwama-electron aphezulu, okuyenza ifaneleke kumadivayisi anamandla njengama-MOSFET nama-Schottky diode.

-

6H-SiC:Inikeza izakhiwo eziyingqayizivele ze-RF kanye nezingxenye ze-optoelectronic.

Izici ezibalulekile ze-Silicon Carbide (SiC) substrate wafer:

-

I-bandgap ebanzi:~3.26 eV (4H-SiC) – inika amandla i-voltage ephezulu yokuphuka kanye nokulahlekelwa kokushintsha okuphansi.

-

I-Thermal conductivity:3–4.9 W/cm·K – ikhipha ukushisa ngokuphumelelayo, iqinisekisa ukuzinza kumasistimu anamandla amakhulu.

-

Ukuqina:~9.2 esikalini se-Mohs - iqinisekisa ukuqina komshini phakathi nokucubungula nokusebenza kwedivayisi.

Izicelo ze-Silicon Carbide (SiC) substrate wafer

Ukuguquguquka kwe-Silicon Carbide (SiC) substrate wafer kubenza babe yigugu kuzo zonke izimboni eziningi:

I-Power Electronics: Isisekelo sama-MOSFET, ama-IGBT, nama-Schottky diode asetshenziswa ezimotweni zikagesi (EVs), izinsiza zikagesi zezimboni, neziguquli zamandla avuselelekayo.

I-RF & Microwave Devices: Isekela ama-transistors, ama-amplifiers, nezingxenye ze-radar ze-5G, isathelayithi, nezinhlelo zokusebenza zokuvikela.

I-Optoelectronics: Isetshenziswa kuma-LED e-UV, ama-photodetectors, nama-laser diode lapho ukukhanya okuphezulu kwe-UV nokuzinza kubalulekile.

I-Aerospace & Defense: I-substrate ethembekile yezinga lokushisa eliphezulu, ama-electronics aqiniswe ngemisebe.

Izikhungo Zocwaningo Namanyuvesi: Ilungele izifundo zesayensi yezinto ezibonakalayo, ukuthuthukiswa kwedivayisi ye-prototype, kanye nezinqubo ezintsha zokuhlola ze-epitaxial.

Imininingwane ye-Silicon Carbide (SiC) substrate Wafer Chips

| Impahla | Inani |

|---|---|

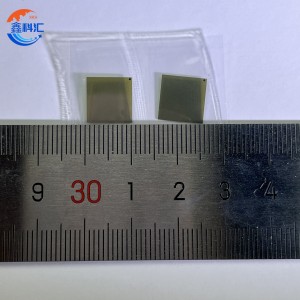

| Usayizi | 10mm × 10mm isikwele |

| Ubukhulu | 330–500 μm (kungenziwa ngokwezifiso) |

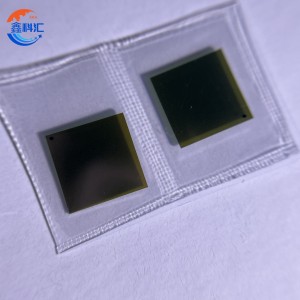

| I-Polytype | I-4H-SiC noma i-6H-SiC |

| Ukuqondisa | Indiza ye-C, i-off-eksisi (0°/4°) |

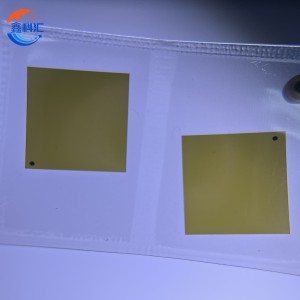

| I-Surface Qeda | Uhlangothi olulodwa noma oluphindwe kabili oluphucuziwe; i-epi-ready iyatholakala |

| Izinketho zeDoping | N-uhlobo noma P-uhlobo |

| Ibanga | Ibanga locwaningo noma ibanga ledivayisi |

I-FAQ ye-Silicon Carbide (SiC) ye-substrate wafer

I-Q1: Yini eyenza i-Silicon Carbide (SiC) substrate wafer iphakame kunezinkwa ze-silicon zendabuko?

I-SiC inikeza amandla ensimu yokuwohloka okungu-10 × okuphezulu, ukumelana nokushisa okuphezulu, nokulahlekelwa okushintshwayo okuphansi, okuyenza ilungele ukusebenza kahle okuphezulu, amadivayisi anamandla amakhulu i-silicon engakwazi ukuwasekela.

Q2: Ingabe i-wafer ye-Silicon Carbide (SiC) engaphansi engu-10 × 10mm inganikezwa izendlalelo ze-epitaxial?

Yebo. Sihlinzeka ngama-substrates alungele i-epi futhi singaletha amawafa anezendlalelo ze-epitaxial ngokwezifiso ukuze ahlangabezane nedivayisi ethile yamandla noma izidingo zokukhiqiza ze-LED.

I-Q3: Ingabe osayizi bangokwezifiso namazinga we-doping ayatholakala?

Nakanjani. Ngenkathi ama-chips angu-10×10mm ejwayelekile ocwaningweni nasekuthathweni kwesampula yedivayisi, ubukhulu bangokwezifiso, ubukhulu, namaphrofayili e-doping ayatholakala uma ecelwa.

Q4: Ahlala isikhathi eside kangakanani lawa mawafa ezindaweni eziyingozi kakhulu?

I-SiC igcina ubuqotho besakhiwo nokusebenza kukagesi ngaphezu kuka-600°C nangaphansi kwemisebe ephezulu, iyenze ilungele i-aerospace kanye nogesi wezinga lezempi.

Mayelana NATHI

I-XKH igxile ekuthuthukisweni kobuchwepheshe obuphezulu, ukukhiqiza, nokudayiswa kwengilazi ekhethekile yokubona nezinto ezintsha zekristalu. Imikhiqizo yethu isebenza ngogesi obonakalayo, ugesi wabathengi, kanye nezempi. Sinikezela ngezinto ezibonakalayo ze-Sapphire, izembozo zamalensi omakhalekhukhwini, i-Ceramics, i-LT, i-Silicon Carbide SIC, i-Quartz, namawafa ekristalu e-semiconductor. Ngobungcweti abanamakhono nemishini esezingeni eliphezulu, sihamba phambili ekucutshungulweni komkhiqizo okungajwayelekile, sihlose ukuba yibhizinisi elihamba phambili le-optoelectronic materials high-tech.