Ipuleti/ithreyi ye-ceramic ye-SiC yesibambi se-wafer esingu-4inch 6inch se-ICP

Ipuleti le-ceramic ye-SiC Abstract

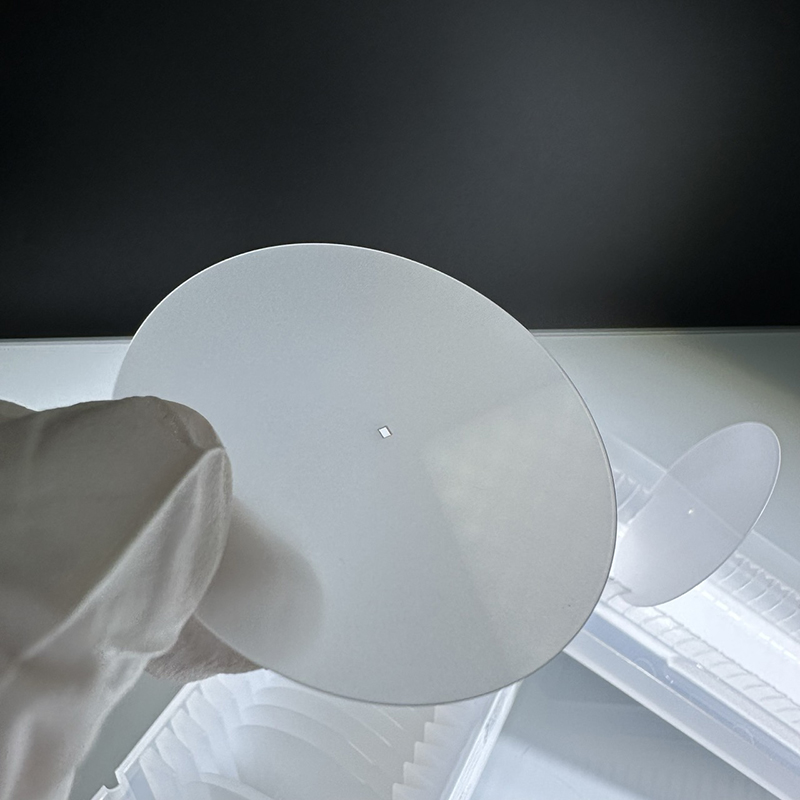

Ipuleti le-ceramic le-SiC liyingxenye esebenza kahle kakhulu eyakhiwe kusukela ku-Silicon Carbide ehlanzekile kakhulu, eklanyelwe ukusetshenziswa ezindaweni ezishisa kakhulu, zamakhemikhali, nezemishini. Idume ngobulukhuni bayo obumangalisayo, ukuqhutshwa kokushisa okushisayo, kanye nokumelana nokugqwala, ipuleti le-SiC lisetshenziswa kabanzi njengesithwali esilucwecwana, i-susceptor, noma isakhi sesakhiwo ku-semiconductor, i-LED, i-photovoltaic, kanye nezimboni ze-aerospace.

Ngokusimama okushisayo okuvelele okufika ku-1600 ° C kanye nokumelana okuhle kakhulu namagesi asebenzayo kanye nezindawo ze-plasma, ipuleti le-SiC liqinisekisa ukusebenza okungaguquki phakathi nezinqubo zokushisa ezishisa kakhulu, zokubeka, nokusabalalisa. I-microstructure yayo eminyene, engenazimbobo inciphisa ukukhiqizwa kwezinhlayiyana, ikwenze ilungele izinhlelo zokusebenza ezihlanzekile kakhulu ku-vacuum noma izilungiselelo zegumbi lokuhlanza.

SiC Ceramic plate Isicelo

1. Ukukhiqiza I-Semiconductor

Amapuleti e-ceramic e-SiC avame ukusetshenziswa njengabathwali be-wafer, ama-susceptors, namapuleti ahamba ngezinyawo emishinini yokwakha ye-semiconductor efana ne-CVD (Chemical Vapor Deposition), i-PVD (i-Physical Vapor Deposition), kanye nezinhlelo zokuhlanganisa. I-thermal conductivity enhle kakhulu kanye nokwanda okuphansi kokushisa kuzivumela ukuthi zigcine ukusabalalisa kwezinga lokushisa okufanayo, okubalulekile ekucutshungulweni kwe-wafer okunemba okuphezulu. Ukumelana kwe-SiC namagesi abolayo nama-plasma kuqinisekisa ukuqina ezindaweni ezinokhahlo, kusiza ukunciphisa ukungcoliswa kwezinhlayiyana nokugcinwa kwemishini.

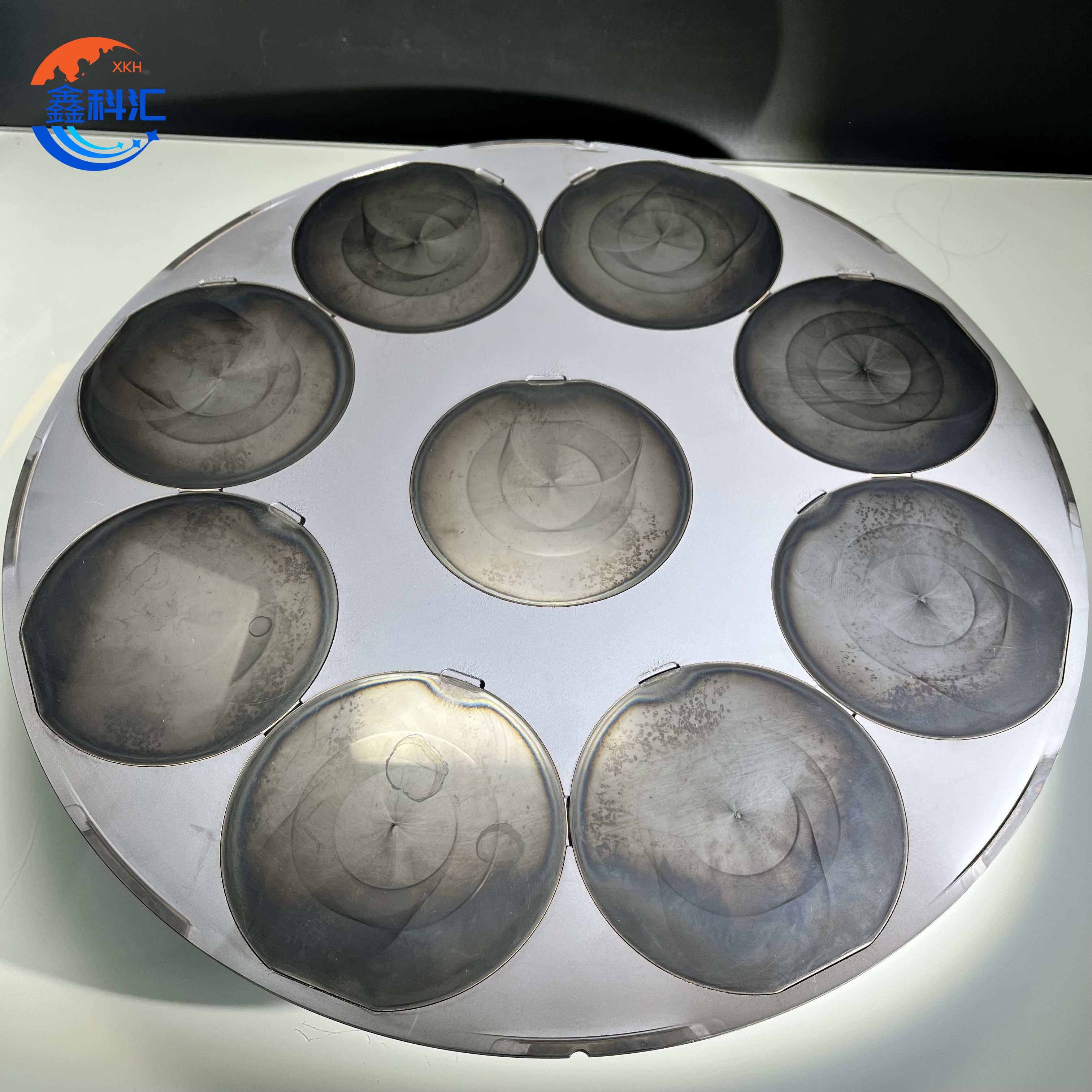

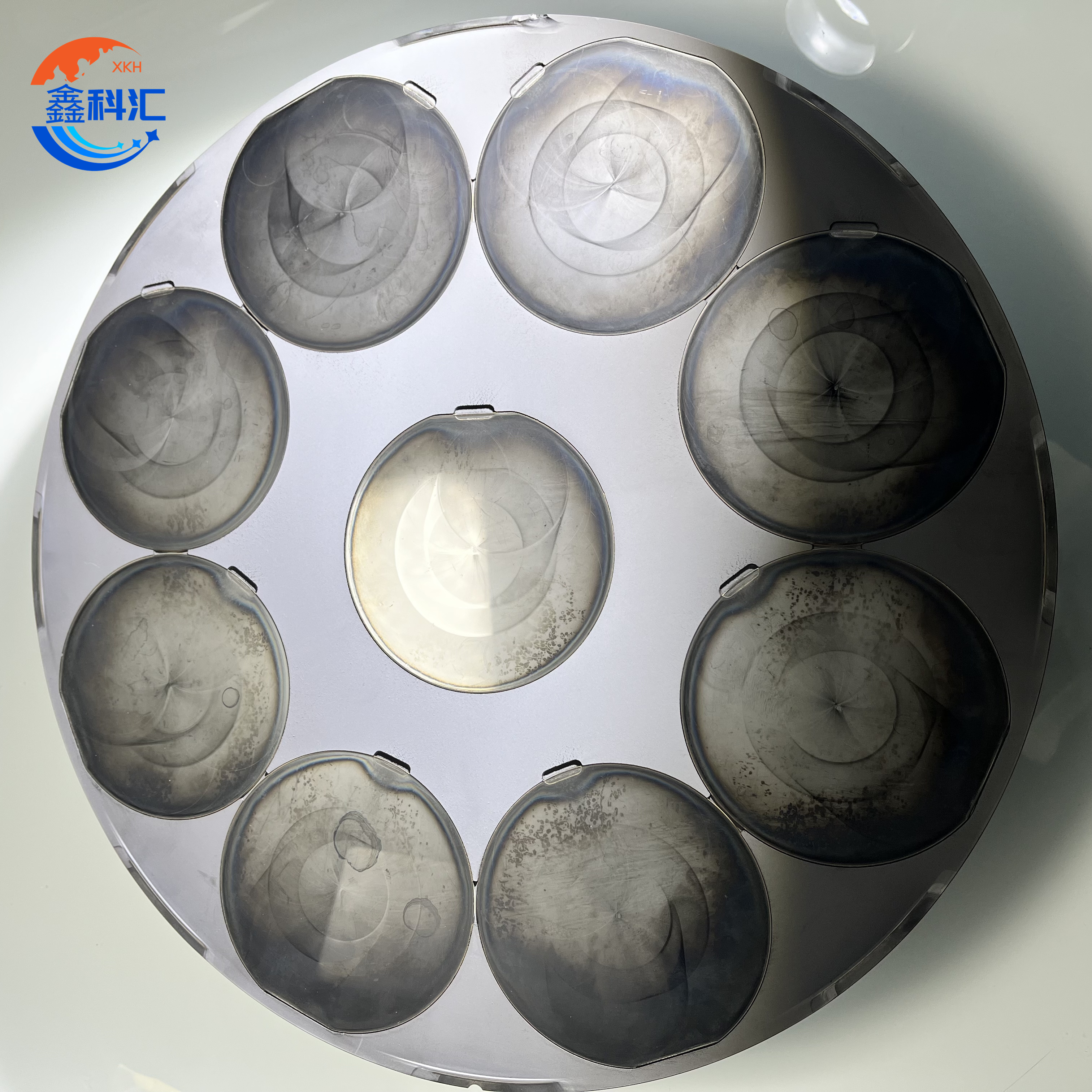

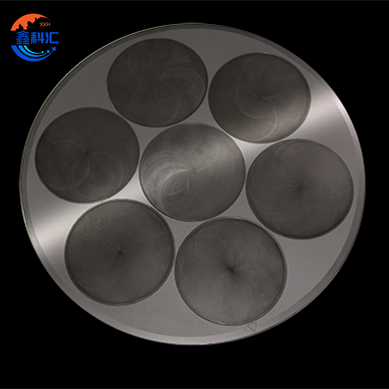

2. Imboni ye-LED - ICP Etching

Emkhakheni wokukhiqiza we-LED, amapuleti e-SiC ayizingxenye ezibalulekile ezinhlelweni zokunamathisela ze-ICP (Inductively Coupled Plasma). Zisebenza njengezibambi ze-wafer, zinikeza inkundla ezinzile futhi eqinile ngokushisa okushisayo ukusekela ama-sapphire noma ama-wafers e-GaN ngesikhathi sokucutshungulwa kwe-plasma. Ukumelana ne-plasma yabo okuhle kakhulu, ukucaba kwendawo, nokuzinza kwe-dimensional kusiza ukuqinisekisa ukunemba okuphezulu nokufana, okuholela ekwenyukeni kwesivuno nokusebenza kwedivayisi kuma-chips e-LED.

3. I-Photovoltaics (PV) kanye ne-Solar Energy

Amapuleti e-ceramic e-SiC nawo asetshenziswa ekukhiqizeni amaseli elanga, ikakhulukazi ngesikhathi sokushiswa kwezinga lokushisa eliphezulu kanye nezinyathelo zokudonsa. Ukungangeni kwabo emazingeni okushisa aphakeme kanye nekhono lokumelana ne-warping kuqinisekisa ukucutshungulwa okungaguquki kwamawafa e-silicon. Ukwengeza, ingozi yabo yokungcola ephansi ibalulekile ekugcineni ukusebenza kahle kwamaseli e-photovoltaic.

I-SiC Ceramic plate Properties

1. Amandla Omshini Nokuqina Okungavamile

Amapuleti e-ceramic e-SiC abonisa amandla emishini aphezulu kakhulu, anamandla ajwayelekile okuguquguquka adlula ama-MPa angama-400 kanye nobulukhuni be-Vickers obufinyelela ku->2000 HV. Lokhu kubenza bamelane kakhulu nokuguga kwemishini, ukuhuzuka, kanye nokuguqulwa, okuqinisekisa impilo yesevisi ende ngisho nangaphansi komthwalo omkhulu noma ukuphindaphinda amabhayisikili ashisayo.

2. High Thermal Conductivity

I-SiC ine-thermal conductivity enhle kakhulu (imvamisa engu-120–200 W/m·K), eyivumela ukuthi isabalalise ngokulinganayo ukushisa endaweni yayo yonke. Lesi sakhiwo sibalulekile ezinqubweni ezifana ne-wafer etching, deposition, noma sintering, lapho ukufana kwezinga lokushisa kuthinta ngokuqondile isivuno nekhwalithi yomkhiqizo.

3. Superior Thermal Ukuzinza

Ngephuzu lokuncibilika eliphezulu (2700°C) kanye ne-coefficient ephansi yokwandisa okushisayo (4.0 × 10⁻⁶/K), amapuleti e-ceramic e-SiC agcina ukunemba kobukhulu kanye nobuqotho besakhiwo ngaphansi kwemijikelezo yokushisisa nokupholisa okusheshayo. Lokhu kubenza balungele ukusetshenziswa eziko lokushisa eliphezulu, emagumbini e-vacuum, nasezindaweni ze-plasma.

| Izakhiwo Zobuchwepheshe | ||||

| Inkomba | Iyunithi | Inani | ||

| Igama Lempahla | Ukusabela Sintered Silicon Carbide | Pressureless Sintered Silicon Carbide | I-Recrystallized Silicon Carbide | |

| Ukwakheka | I-RBSiC | I-SSiC | I-R-SiC | |

| Ukuminyana kwenqwaba | g/cm3 | 3 | 3.15 ± 0.03 | 2.60-2.70 |

| Amandla e-Flexural | I-MPa (kpsi) | 338(49) | 380(55) | 80-90 (20°C) 90-100(1400°C) |

| Amandla Acindezelayo | I-MPa (kpsi) | 1120(158) | 3970(560) | > 600 |

| Ukuqina | Knoop | 2700 | 2800 | / |

| Breaking Tenacity | I-MPa m1/2 | 4.5 | 4 | / |

| I-Thermal Conductivity | W/mk | 95 | 120 | 23 |

| I-Coefficient of Thermal Expansion | 10-6.1/°C | 5 | 4 | 4.7 |

| Ukushisa Okuthize | I-Joule/g 0k | 0.8 | 0.67 | / |

| Izinga lokushisa eliphezulu emoyeni | ℃ | 1200 | 1500 | 1600 |

| I-Elastic Modulus | I-Gpa | 360 | 410 | 240 |

Ipuleti le-SiC ceramic Q&A

Q: Yiziphi izakhiwo ze-silicon carbide plate?

A: Amapuleti e-Silicon carbide (SiC) aziwa ngamandla awo aphezulu, ubulukhuni, kanye nokuzinza kwe-thermal. Banikeza i-thermal conductivity enhle kakhulu kanye nokwanda okuphansi kwe-thermal, ukuqinisekisa ukusebenza okuthembekile ngaphansi kwamazinga okushisa aphezulu. I-SiC futhi ayisebenzi ngamakhemikhali, imelana nama-asidi, ama-alkali, nezindawo ze-plasma, okuyenza ilungele ukucutshungulwa kwe-semiconductor ne-LED. Indawo yayo eminyene, ebushelelezi inciphisa ukukhiqizwa kwezinhlayiya, igcine ukuhambisana kwegumbi elihlanzekile. Amapuleti e-SiC asetshenziswa kabanzi njengabathwali be-wafer, ama-susceptors, kanye nezingxenye zokusekela endaweni enezinga lokushisa eliphezulu kanye ne-corronary kuwo wonke ama-semiconductor, i-photovoltaic, kanye nezimboni ze-aerospace.