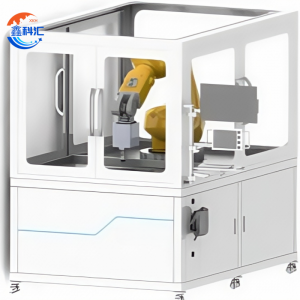

Umshini Wokupholisha Irobhothi - Ukuqedwa Okuzenzakalelayo Okuzenzakalelayo Okuphezulu

Umdwebo onemininingwane

Uhlolojikelele Lomshini Wokupholisha I-Robotic

Umshini Wokupholisha I-Robotic uwuhlelo oluthuthukisiwe, olusebenza ngokugcwele olusebenza ngokuzenzakalelayo oluklanyelwe ukuhlangabezana nezidingo eziphakeme kakhulu ekukhiqizeni okunembayo. Ihlanganisa isilawuli serobhothi esinama-axis ayisithupha, ubuchwepheshe bokupholisha i-force-feedback, kanye nokucushwa kwekhanda elikabili ukuze kuphathe inhlobonhlobo yezinto ezibonakalayo namajiyometri ayinkimbinkimbi ngokunemba okukhethekile nokungaguquguquki.

Kungakhathaliseki ukuthi ngamalensi okubona, izingxenye ze-aerospace, izingxenye zobunjiniyela obunembayo, noma izinhlelo zokusebenza ze-semiconductor, lo mshini uletha ukuqedwa okuzinzile, okuphindaphindekayo, kanye nekhwalithi ephezulu—ngisho nokubekezelela izinga le-nanometer.

Ukuhambisana Okuphelele Kwezingcezu Zokusebenza Zomshini Wokupholisha I-Robotic

Uhlelo lusekela ukucubungula:

-

Izindawo eziyisicabaokwengilazi, izitsha zobumba, nezingcwecwe zensimbi

-

Amajamo angama-cylindrical kanye ne-conicalnjengama-roller, shafts, namashubhu

-

Izingxenye eziyindilinga kanye ne-asphericalamasistimu optical

-

I-Freeform nezindawo ezingaphandle kwe-axisngamajika ayinkimbinkimbi kanye noguquko

Ukuguquguquka kwayo kuyenza ifanelekekokubili ukukhiqizwa ngobuningi kanye nokukhiqizwa ngokwezifiso okuphezulu.

Izici Ezibalulekile Nezinzuzo Zomshini Wokupholisha Irobhothi

1. I-Dual polishing Head Technology

-

Ifakweukuzungezisa okukodwafuthiukuzishintshanisaukupholisha amakhanda ukuze kube nezimo.

-

Ikhono lokushintsha ithuluzi elisheshayo lisekela izindlela eziningi zokucubungula ngaphandle kokuphumula isikhathi eside.

-

Ilungele ukushintsha phakathi kwezigaba zokupholisha ezimahhadlahhadla nezicolekileyo.

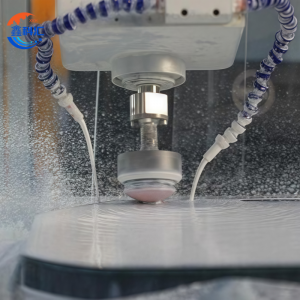

2. Precision Force-Control System

-

Ukuqapha kwesikhathi sangempela kweumfutho, izinga lokushisa, nokupholisha ukugeleza koketshezi.

-

Ukusetshenziswa kwamandla okungaguquki kuqinisekisa ukuphela kwendawo efanayo kuwo wonke umsebenzi.

-

Iyakwazi ukuzivumelanisa nokungahambi kahle kwendawo ngokuzenzakalelayo.

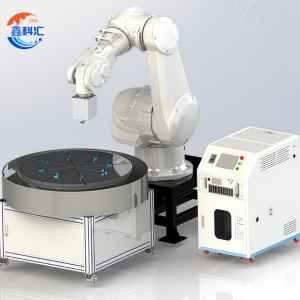

3. I-Six-Axis Robotic Control

-

Inkululeko egcwele yokunyakaza yokusingatha amajiyometri ayinkimbinkimbi.

-

Izindlela zokunyakaza ezibushelelezi, ezinembile ezibalwa ngama-algorithms athuthukile.

-

Ukunemba kokuma okuphindayo okuphezulu kusuka ku-±0.04 mm kuya ku-±0.1 mm kuye ngemodeli.

4. I-Smart Automation & Isilinganiso

-

Amathuluzi okulinganisa okuzenzakalelayo okusetha okunembile nokuqondanisa.

-

Isistimu yokulinganisa yokuhlanganisa ukuze uthole ukuma okunembile.

-

Ongakukhethaukuqapha ukushuba kwe-inthanethiukulawula ikhwalithi ngesikhathi sangempela.

5. Ikhwalithi Yokwakhiwa Kwezimboni-Ibanga

-

Idizayini ye-servo-motor ekabili inyusa ukusebenza kahle kokupholisha nokuzinza.

-

Isakhiwo semishini esiqinile sinciphisa ukudlidliza futhi siqinisekisa ukuqina kwesikhathi eside.

Imininingwane Yobuchwepheshe Yomshini Wokupholisha I-Robotic

| Imodeli Yezisetshenziswa | Umzimba weRobhothi | Phinda Ukunemba Kokumisa | Icubungula Ibanga Lobubanzi | I-Single Rotation Polishing Head | I-Multi-Rotation Polishing Head | Ithuluzi elincane | Ukupholisha Uhlobo Lwesondo Eliyinhloko | Ukupholisha Ikhanda Eliyisiyingi | Qeda Ushintsho Olusheshayo | Ithuluzi Lokulinganisa Okuzenzakalelayo | Inhloko Yesilinganiso Yokudidiyela | Online Ukujiya Monitoring | Ipulatifomu Yokulawula Izinombolo |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| I-IRP500S | I-Staubli TX2-90L | ±0.04mm / ububanzi obugcwele | Φ50~Φ500mm | √ | × | √ | √ | √ | × | ○ | ○ | ○ | ○ |

| I-IRP600S | I-Staubli TX2-140 | ±0.05mm / ububanzi obugcwele | Φ50~Φ600mm | √ | × | √ | √ | √ | × | ○ | ○ | ○ | ○ |

| I-IRP800S | I-Staubli TX2-160 | ±0.05mm / ububanzi obugcwele | Φ80~Φ800mm | √ | √ | √ | √ | √ | ○ | ○ | ○ | ○ | ○ |

| I-IRP1000S | I-Staubli TX200/L | ±0.06mm / ububanzi obugcwele | Φ100~Φ1000mm | √ | ○ | √ | √ | √ | ○ | ○ | ○ | ○ | ○ |

| I-IRP1000A | I-ABB IRB6700-200/2.6 | ±0.1mm / ububanzi obugcwele | Φ100~Φ1000mm | √ | ○ | √ | √ | √ | ○ | ○ | ○ | ○ | ○ |

| I-IRP2000A | I-ABB IRB6700-150/3.2 | ±0.1mm / ububanzi obugcwele | Φ200~Φ2000mm | √ | ○ | √ | √ | √ | × | × | × | ○ | ○ |

| I-IRP2000AD | I-ABB IRB6700-150/3.2 | ±0.1mm / ububanzi obugcwele | Φ200~Φ2000mm | √ | ○ | √ | √ | √ | × | × | × | ○ | ○ |

I-FAQ - Umshini Wokupholisha Amarobhothi

1. Yiziphi izinhlobo zokusebenza ezingaphathwa ngumshini wokupholisha irobhothi?

Umshini wethu wokupholisha amarobhothi usekela umumo nezindawo ezihlukahlukene, okuhlanganisa indawo eyisicaba, egobile, eyindilinga, ekhululekile, namakhontolo ayinkimbinkimbi. Ifanele izinto ezibonakalayo, isikhunta esinembayo, izindawo zensimbi, nezinye izinhlelo zokusebenza zokupholisha ezinembayo.

2. Uyini umehluko phakathi kwamakhanda okupholisha ama-Single Rotation kanye nama-Multi-Rotation?

-

I-Single Rotation Polishing Head: Ithuluzi lizungeza i-eksisi eyodwa, ilungele ukuqedwa kwendawo okujwayelekile kanye nokususwa kwempahla ngesivinini esikhulu.

-

I-Multi-Rotation Polishing Head: Ithuluzi lihlanganisa ukuzungezisa nokuziphendulela ngokwakho (ukuzungeza), okuvumela ukupholisha okufanayo endaweni egobile nezingajwayelekile.

3. Ingakanani ububanzi bokucubungula okuphezulu?

Kuye ngemodeli:

-

Amamodeli ahlangene (isb., IRP500S) isibamboΦ50–Φ500mm.

-

Amamodeli amakhulu (isb, i-IRP2000AD) aphatha kuze kufikeΦ2000mm.

Mayelana NATHI

I-XKH igxile ekuthuthukisweni kobuchwepheshe obuphezulu, ukukhiqiza, nokudayiswa kwengilazi ekhethekile yokubona nezinto ezintsha zekristalu. Imikhiqizo yethu isebenza ngogesi obonakalayo, ugesi wabathengi, kanye nezempi. Sinikezela ngezinto ezibonakalayo ze-Sapphire, izembozo zamalensi omakhalekhukhwini, i-Ceramics, i-LT, i-Silicon Carbide SIC, i-Quartz, namawafa ekristalu e-semiconductor. Ngobungcweti abanamakhono nemishini esezingeni eliphezulu, sihamba phambili ekucutshungulweni komkhiqizo okungajwayelekile, sihlose ukuba yibhizinisi elihamba phambili le-optoelectronic materials high-tech.