I-Precision Microjet Laser System ye-Hard & Brittle Materials

Izici Eziyinhloko

1. Dual-Wavelength Nd:YAG Laser Source

Isebenzisa i-diode-pumped solid-state laser Nd:YAG, isistimu isekela kokubili ubude begagasi obuluhlaza (532nm) kanye ne-infrared (1064nm). Leli khono le-dual-band lenza ukuhambisana okuphakeme nenqwaba yamaphrofayili okumuncwa okubalulekile, ukuthuthukisa isivinini sokucubungula kanye nekhwalithi.

2. I-Innovative Microjet Laser Transmission

Ngokuhlanganisa i-laser ne-microjet yamanzi enengcindezi ephezulu, le sistimu isebenzisa ukuboniswa okuphelele kwangaphakathi ukuze kushaneli amandla e-laser eduze komfudlana wamanzi. Le ndlela yokulethwa eyingqayizivele iqinisekisa ukugxila okuhle kakhulu okunokuhlakazeka okuncane futhi iletha ububanzi bomugqa obucolisekileyo njengo-20μm, ihlinzeka ngekhwalithi yokusikwa engenakuqhathaniswa.

3. Ukulawula Okushisayo Esikalini Esincane

Imojuli ehlanganisiwe yokunemba yokupholisa amanzi ilawula izinga lokushisa endaweni yokucubungula, igcine indawo ethinteke ukushisa (HAZ) ngaphakathi kuka-5μm. Lesi sici sibaluleke kakhulu uma usebenza ngezinto ezingezwani nokushisa nezinto ezivame ukuphuka njenge-SiC noma i-GaN.

4. Ukucushwa kwe-Modular Power

Inkundla isekela izinketho ezintathu zamandla e-laser—50W, 100W, kanye no-200W—okuvumela amakhasimende ukuthi akhethe ukulungisa okufana nezidingo zawo zokuphuma nokuxazulula.

5. I-Precision Motion Control Platform

Uhlelo luhlanganisa isigaba sokunemba okuphezulu ngokuma okungu-±5μm, okuhlanganisa ukunyakaza kwe-axis engu-5 kanye namamothoni angakhethwa alayini noma ashayelayo. Lokhu kuqinisekisa ukuphindaphindwa okuphezulu kanye nokuguquguquka, ngisho namajiyometri ayinkimbinkimbi noma ukucubungula kwenqwaba.

Izindawo Zokufaka Isicelo

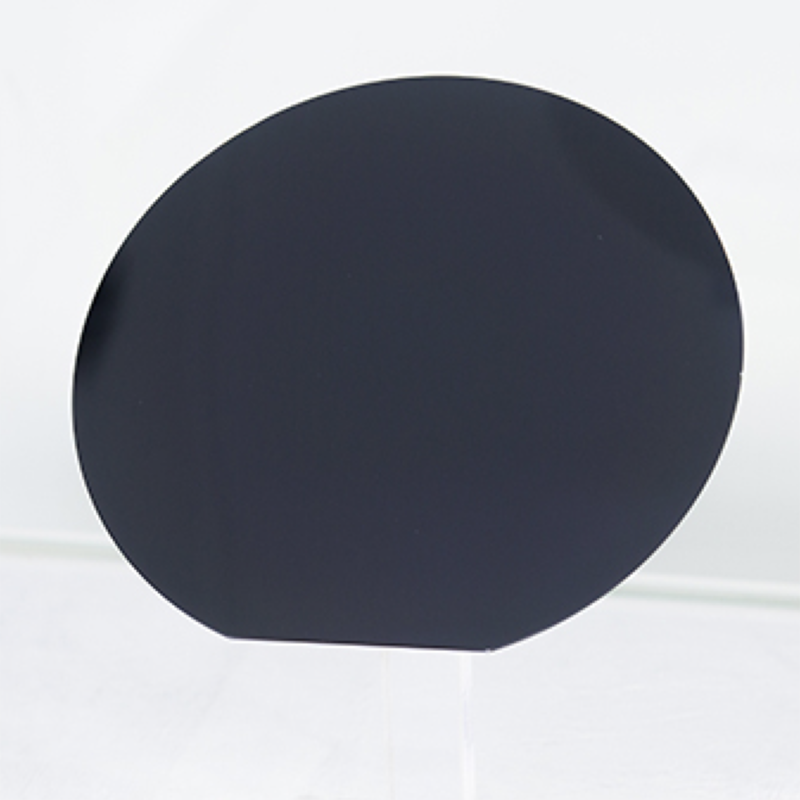

I-Silicon Carbide Wafer Processing:

Ilungele ukusika onqenqemeni, ukusika, nokudayela ama-wafer e-SiC ku-electronics power.

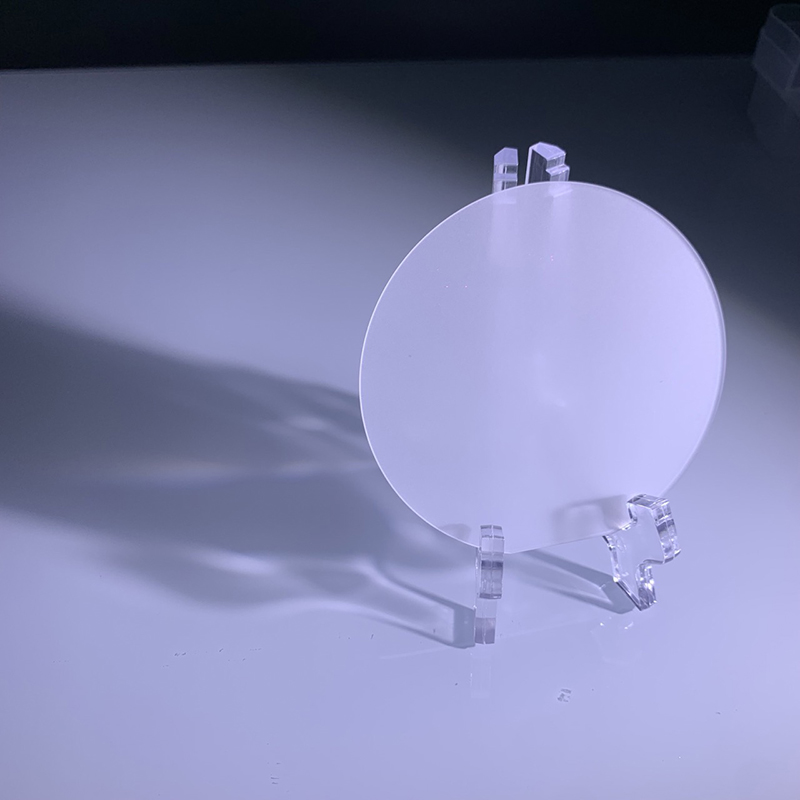

I-Gallium Nitride (GaN) Substrate Machining:

Isekela ukubhala nokusika okunembayo okuphezulu, okwenzelwe izinhlelo zokusebenza ze-RF ne-LED.

Ukuma kwe-Wide Bandgap Semiconductor:

Ihambisana nedayimane, i-gallium oxide, nezinye izinto ezivelayo zokusetshenziswa kwe-high-frequency, high-voltage.

I-Aerospace Composite Cutting:

Ukusikwa okunembile kwezinhlanganisela ze-ceramic matrix kanye nama-substrates ebanga le-aerospace-grade.

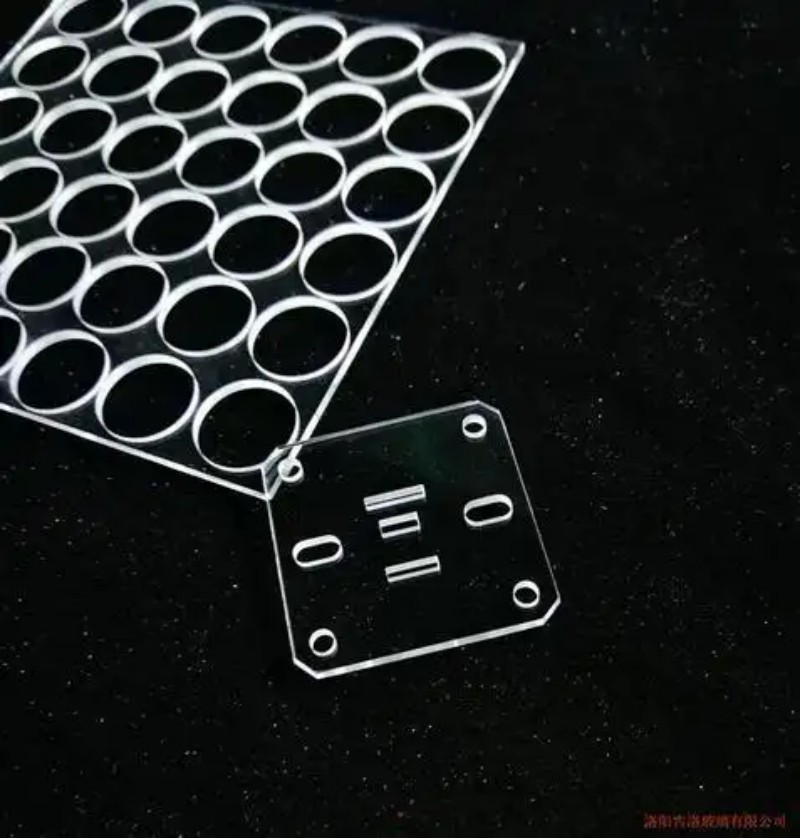

I-LTCC ne-Photovoltaic Materials:

Isetshenziselwa i-micro ngokubhola, i-trenching, kanye ne-scribing ku-PCB ye-high-frequency kanye nokukhiqizwa kwamaseli elanga.

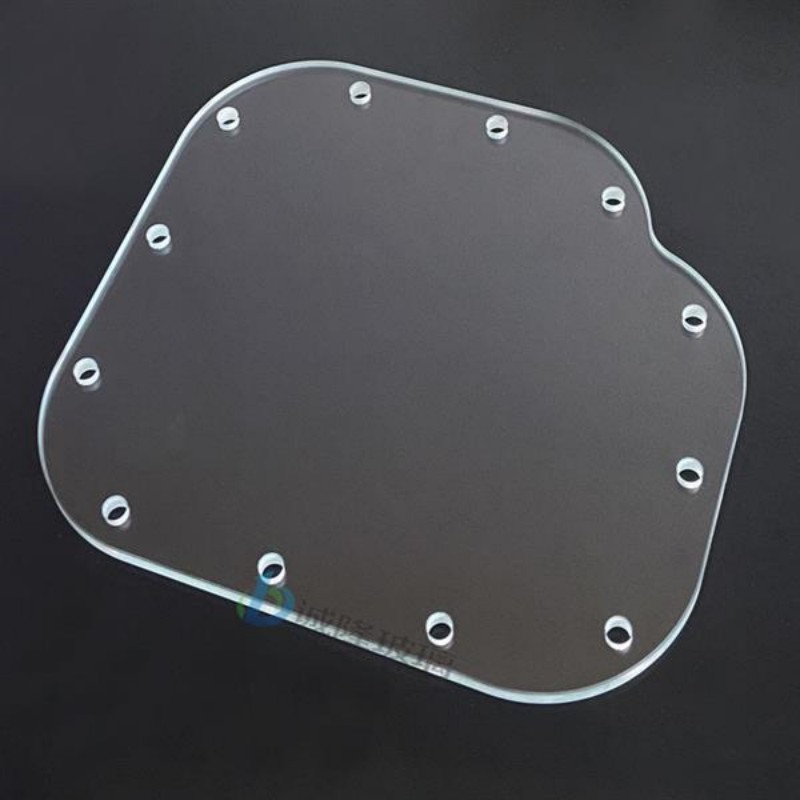

I-Scintilator & Optical Crystal Shaping:

Inika amandla ukusika okunesici esiphansi kwe-yttrium-aluminium garnet, LSO, BGO, namanye ama-optics anembile.

Ukucaciswa

| Ukucaciswa | Inani |

| Uhlobo lweLaser | I-DPSS Nd:YAG |

| Ama-Wavelengths Asekelwe | 532nm / 1064nm |

| Izinketho zamandla | 50W / 100W / 200W |

| Ukunemba Kokumisa | ±5μm |

| Ubuncane Bobubanzi Bolayini | ≤20μm |

| Indawo Ethinteke Ukushisa | ≤5μm |

| Uhlelo Lokunyakaza | I-Linear / Direct-drive motor |

| I-Max Energy Density | Kufika ku-10⁷ W/cm² |

Isiphetho

Lolu hlelo lwe-laser microjet luchaza kabusha imikhawulo yemishini ye-laser yezinto eziqinile, eziphukayo, nezizwela ukushisa. Ngokuhlanganiswa kwayo okuyingqayizivele kwe-laser-amanzi, ukuhambisana kwe-wavelength ekabili, kanye nesistimu yokunyakaza eguquguqukayo, inikeza isisombululo esilungiselelwe abacwaningi, abakhiqizi, nabahlanganisi besistimu abasebenza ngezinto ezisezingeni eliphezulu. Kungakhathaliseki ukuthi isetshenziswa kundwangu ye-semiconductor, amalebhu e-aerospace, noma ukukhiqizwa kwephaneli yelanga, le nkundla iletha ukwethembeka, ukuphindaphinda, nokunemba okunika amandla ukucubungula kwezinto zesizukulwane esilandelayo.

Umdwebo onemininingwane