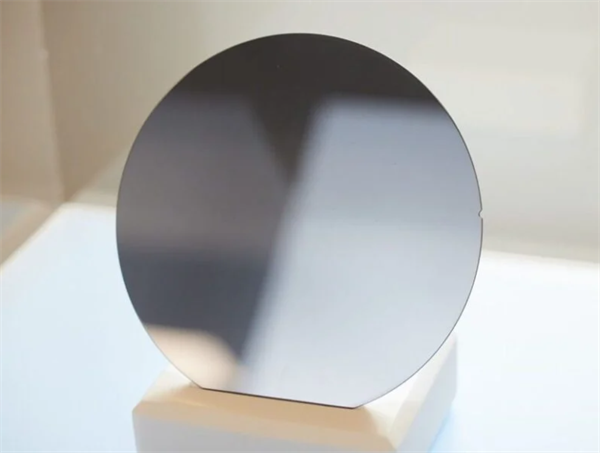

Uhlobo lwe-P-SiC wafer 4H/6H-P 3C-N 6inch ukujiya okungu-350 μm nge-Primary Flat Orientation

Ukucaciswa4H/6H-P Uhlobo lwe-SiC Composite Substrates Ithebula lepharamitha evamile

6 intshi ububanzi Silicon Carbide (SiC) Substrate Ukucaciswa

| Ibanga | Zero MPD ProductionIbanga (Z Ibanga) | Ukukhiqizwa OkujwayelekileIbanga (P Ibanga) | Dummy Grade (D Ibanga) | ||

| Ububanzi | 145.5 mm~150.0 mm | ||||

| Ubukhulu | 350 μm ± 25 μm | ||||

| I-Wafer Orientation | -Offi-eksisi: 2.0°-4.0° ukuya [1120] ± 0.5° ku-4H/6H-P, Ku-eksisi:〈111〉± 0.5° ku-3C-N | ||||

| I-Micropipe Density | 0 cm-2 | ||||

| Ukungazweli | p-uhlobo 4H/6H-P | ≤0.1 Ωꞏcm | ≤0.3 Ωꞏcm | ||

| n-uhlobo 3C-N | ≤0.8 mΩꞏcm | ≤1 m Ωꞏcm | |||

| Isisekelo se-Flat Orientation | 4H/6H-P | -{1010} ± 5.0° | |||

| 3C-N | -{110} ± 5.0° | ||||

| Ubude Befulethi obuyisisekelo | 32.5 mm ± 2.0 mm | ||||

| Ubude Befulethi besibili | 18.0 mm ± 2.0 mm | ||||

| I-Flat Orientation yesibili | I-silicon ibheke phezulu: 90° CW. kusuka kuPrime flat ± 5.0° | ||||

| Ukukhishwa komkhawulo | 3 mm | 6 mm | |||

| LTV/TTV/Bow/Warp | ≤2.5 μm/≤5 μm/≤15 μm/≤30 μm | ≤10 μm/≤15 μm/≤25 μm/≤40 μm | |||

| Ubulukhuni | I-Polish Ra≤1 nm | ||||

| I-CMP Ra≤0.2 nm | I-Ra≤0.5 nm | ||||

| I-Edge Cracks By High Intensity Light | Lutho | Ubude obuqongelelwayo ≤ 10 mm, ubude obubodwa≤2 mm | |||

| I-Hex Plates Ngokukhanya Okunamandla Okuphezulu | Indawo eqoqiwe ≤0.05% | Indawo eqoqiwe ≤0.1% | |||

| Izindawo ze-Polytype Ngokukhanya Okunamandla Okuphezulu | Lutho | Indawo eqoqiwe≤3% | |||

| I-Visual Carbon Inclusions | Indawo eqoqiwe ≤0.05% | Indawo eqoqiwe ≤3% | |||

| I-Silicon Surface Scratches By High Intensity Light | Lutho | Ubude obuqongelelwayo≤1× ububanzi bewafa | |||

| Ama-Edge Chips Aphakeme Ngokukhanya Okunamandla | Akukho okuvunyelwe ≥0.2mm ububanzi nokujula | 5 okuvunyelwe, ≤1 mm ngakunye | |||

| I-Silicon Surface Contamination By High Intensity | Lutho | ||||

| Ukupakisha | I-Multi-wafer Cassette noma Isiqukathi Esiyisicwecwana Esisodwa | ||||

Amanothi:

※ Imikhawulo yokukhubazeka isebenza kuyo yonke indawo eyisicwecwana ngaphandle kwendawo engabaliwe enqenqemeni. # Imihuzuko kufanele ibhekwe ku-Si face o

Iwafa ye-SiC yohlobo lwe-P, i-4H/6H-P 3C-N, enosayizi wayo ongu-6-intshi nogqinsi lwama-350 μm, idlala indima ebalulekile ekukhiqizweni kwezimboni zama-electronics asebenza kahle kakhulu. I-thermal conductivity yayo enhle kakhulu kanye ne-voltage ephezulu yokuwohloka kuyenza ilungele izingxenye zokukhiqiza ezifana nokushintshwa kwamandla, ama-diode, nama-transistors asetshenziswa ezindaweni ezinezinga lokushisa eliphezulu njengezimoto zikagesi, amagridi kagesi, nezinhlelo zamandla avuselelekayo. Amandla e-wafer okusebenza kahle ezimeni ezinzima aqinisekisa ukusebenza okuthembekile ezinhlelweni zezimboni ezidinga ukuminyana okukhulu kwamandla nokusebenza kahle kwamandla. Ukwengeza, umumo wayo oyisicaba oyinhloko usiza ekuqondaneni okunembile ngesikhathi sokwenziwa kwedivayisi, kuthuthukise ukusebenza kahle kokukhiqiza nokuvumelana komkhiqizo.

Izinzuzo ze-N-type SiC composite substrates zihlanganisa

- High Thermal Conductivity: Amawafa e-SiC ohlobo lwe-P ahlakaza kahle ukushisa, awenze alungele ukusetshenziswa kwezinga lokushisa eliphezulu.

- High Breakdown Voltage: Iyakwazi ukumelana nama-voltage aphezulu, iqinisekisa ukwethembeka kugesi wamandla kanye namadivayisi ane-voltage ephezulu.

- Ukumelana Nendawo Enzima: Ukuqina okuhle kakhulu ezimeni ezimbi kakhulu, njengamazinga okushisa aphezulu kanye nezindawo ezigqwalile.

- Ukuguqulwa kwamandla okusebenzayo: I-doping yohlobo lwe-P isiza ukuphatha amandla ngendlela efanele, okwenza iwafa ilungele izinhlelo zokuguqula amandla.

- Isisekelo se-Flat Orientation: Iqinisekisa ukuqondanisa okunembayo ngesikhathi sokukhiqiza, ithuthukisa ukunemba kwedivayisi nokuvumelana.

- Isakhiwo Esincane (350 μm): Ugqinsi olufanele lwe-wafer lusekela ukuhlanganiswa kumadivayisi e-elekthronikhi athuthukile, avaleleke emkhathini.

Sekukonke, iwafa ye-SiC yohlobo lwe-P, 4H/6H-P 3C-N, inikezela ngezinzuzo eziningi eziyenza ifaneleke kakhulu izinhlelo zokusebenza zezimboni nezobuchwepheshe. I-conductivity yayo ephezulu yokushisa kanye ne-voltage yokuwohloka yenza ukusebenza okuthembekile endaweni yokushisa ephezulu kanye ne-high-voltage, kuyilapho ukumelana nezimo ezinzima kuqinisekisa ukuqina. I-doping yohlobo lwe-P ivumela ukuguqulwa kwamandla okusebenzayo, okuyenza ilungele ama-electronics amandla kanye nezinhlelo zamandla. Ukwengeza, ukuma okuyisicaba okuyinhloko kwe-wafer kuqinisekisa ukuqondana okunembayo phakathi nenqubo yokukhiqiza, kuthuthukisa ukungaguquguquki kokukhiqiza. Ngobukhulu obungu-350 μm, ifaneleka kahle ukuhlanganiswa kumadivayisi athuthukile, ahlangene.

Umdwebo onemininingwane