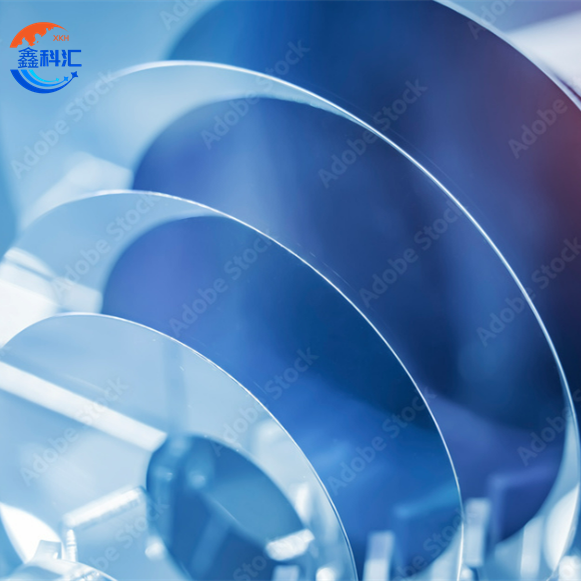

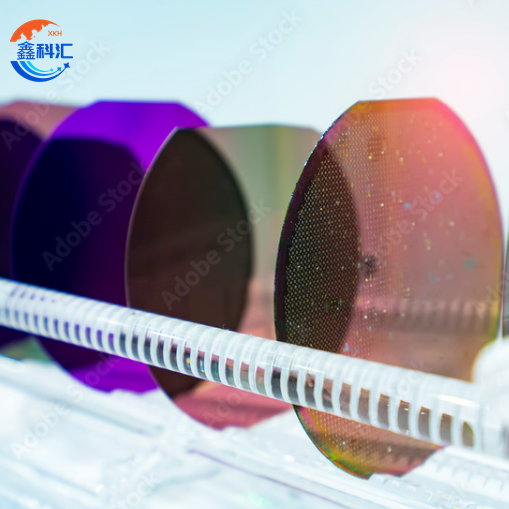

I-HPSI SiCOI wafer 4 6inch Hydropholic Bonding

I-SiCOI Wafer (Silicon Carbide-on-Insulator) Uhlolojikelele Lwezakhiwo

Ama-wafer e-SiCOI ayingxenye yesizukulwane esisha se-semiconductor ehlanganisa i-Silicon Carbide (SiC) nesendlalelo sokuvikela, ngokuvamile i-SiO₂ noma isafire, ukuze kuthuthukiswe ukusebenza kwamandla kagesi, i-RF, nezithombe. Ngezansi ukubuka konke okunemininingwane yezakhiwo zabo ezihlukaniswe ngezigaba ezibalulekile:

| Impahla | Incazelo |

| Ukwakheka Kwezinto Ezibalulekile | Isendlalelo se-Silicon Carbide (SiC) esiboshwe ku-substrate evikelayo (imvamisa i-SiO₂ noma isafire) |

| Isakhiwo Sekristalu | Ngokuvamile i-4H noma i-6H polytypes ye-SiC, eyaziwa ngekhwalithi ephezulu yekristalu nokufana |

| Izakhiwo zikagesi | Inkambu kagesi ephukile (~3 MV/cm), i-bandgap ebanzi (~3.26 eV ye-4H-SiC), ukuvuza okuphansi kwamanje |

| I-Thermal Conductivity | I-thermal conductivity ephezulu (~300 W/m·K), enika amandla ukulahlwa kokushisa okusebenzayo |

| Isendlalelo seDielectric | Ungqimba oluvikelayo (i-SiO₂ noma isafire) luhlinzeka ngokuhlukaniswa kukagesi futhi lunciphisa amandla e-parasitic |

| Izakhiwo Zemishini | Ukuqina okuphezulu (~9 Mohs isikali), amandla amahle kakhulu wokusebenza, nokuzinza kwe-thermal |

| I-Surface Qeda | Ivamise ukuba bushelelezi obushelelezi ngokuminyana okunesici esiphansi, ifanele ukwenziwa kwedivayisi |

| Izinhlelo zokusebenza | Izinto zikagesi zamandla, amadivaysi e-MEMS, amadivaysi e-RF, izinzwa ezidinga izinga lokushisa eliphezulu nokubekezelela i-voltage |

Amawafa e-SiCOI (Silicon Carbide-on-Insulator) amele ukwakheka kwe-semiconductor substrate ethuthukisiwe, ehlanganisa ungqimba oluncane lwekhwalithi ephezulu lwe-silicon carbide (SiC) oluboshelwe kungqimba oluvikelayo, ngokuvamile i-silicon dioxide (SiO₂) noma isafire. I-Silicon carbide iyi-wide-bandgap semiconductor eyaziwa ngekhono layo lokumelana nama-voltage aphezulu kanye namazinga okushisa aphakeme, kanye nokuhamba kahle kwe-thermal nokuqina komshini okuphakeme, okuyenza ilungele ukusetshenziswa kwe-elekthronikhi enamandla amakhulu, imvamisa ephezulu, kanye nezinga eliphezulu lokushisa.

Isendlalelo se-insulating kumawafa e-SiCOI sinikeza ukuhlukaniswa kukagesi okuphumelelayo, kunciphisa kakhulu amandla e-parasitic kanye nokuvuza kwemisinga phakathi kwamadivayisi, ngaleyo ndlela kuthuthukisa ukusebenza kwedivayisi yonke nokuthembeka. Ingaphezulu le-wafer lipholishelwe kahle ukuze kutholwe ubushelelezi obukhulu obunamaphutha amancane, kuhlangatshezwana nezidingo eziqinile zokwenziwa kwedivayisi ye-micro- kanye ne-nano-scale.

Lesi sakhiwo sezinto ezibonakalayo asithuthukisi nje kuphela izici zikagesi zamadivayisi we-SiC kodwa futhi sithuthukisa kakhulu ukuphathwa kokushisa kanye nokuzinza kwemishini. Ngenxa yalokhu, amawafa e-SiCOI asetshenziswa kakhulu kuma-electronics, izingxenye zefrikhwensi yomsakazo (RF), izinzwa ze-microelectromechanical systems (MEMS), kanye ne-electronics high-temperatures. Sekukonke, ama-wafer e-SiCOI ahlanganisa izici ezibonakalayo ezingavamile ze-silicon carbide nezinzuzo zokuhlukanisa zikagesi zesendlalelo se-insulator, ehlinzeka ngesisekelo esifanelekile sesizukulwane esilandelayo samadivayisi asebenza kahle we-semiconductor.

Isicelo se-SiCOI wafer

Amadivayisi we-Power Electronics

Amaswishi ane-voltage ephezulu namandla aphezulu, ama-MOSFET, nama-diode

Zuza ku-bandgap ebanzi ye-SiC, i-voltage ephukile ephezulu, nokuzinza kwe-thermal

Ukulahlekelwa kwamandla okuncishisiwe kanye nokusebenza kahle okuthuthukisiwe kumasistimu okuguqula amandla

Izingxenye zeRadio Frequency (RF).

Ama-high-frequency transistors nama-amplifiers

Amandla e-parasitic aphansi ngenxa yongqimba oluvikelayo luthuthukisa ukusebenza kwe-RF

Ifanele ukuxhumana kwe-5G nezinhlelo ze-radar

I-Microelectromechanical Systems (MEMS)

Izinzwa nama-actuator asebenza ezindaweni ezinokhahlo

Ukuqina kwemishini kanye nokungangenisi kwamakhemikhali kunweba ubude besikhathi sedivayisi

Kufaka phakathi izinzwa zokucindezela, ama-accelerometer, nama-gyroscopes

I-High-Temperature Electronics

Ama-elekthronikhi wezimoto, i-aerospace, kanye nezicelo zezimboni

Sebenza ngokuthembekile emazingeni okushisa aphakeme lapho i-silicon yehluleka khona

Amadivayisi Wezithombe

Ukuhlanganiswa nezingxenye ze-optoelectronic kuma-insulator substrates

Inika amandla ama-on-chip photonics ngokuphathwa okushisayo okuthuthukisiwe

I-Q&A ye-SiCOI wafer

Q:yini i-wafer ye-SiCOI

A:I-SiCOI wafer imele i-Silicon Carbide-on-Insulator wafer. Kuwuhlobo lwe-semiconductor substrate lapho ungqimba oluncane lwe-silicon carbide (SiC) luboshelwa ungqimba oluvikelayo, ngokuvamile i-silicon dioxide (SiO₂) noma ngezinye izikhathi isafire. Lesi sakhiwo siyafana ngomqondo namawafa e-Silicon-on-Insulator (SOI) awaziwayo kodwa sisebenzisa i-SiC esikhundleni se-silicon.

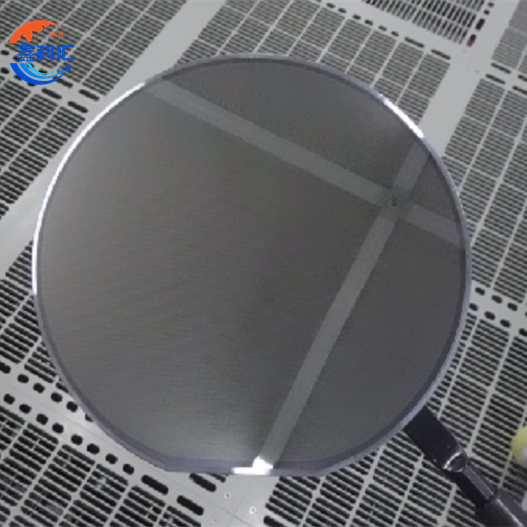

Isithombe