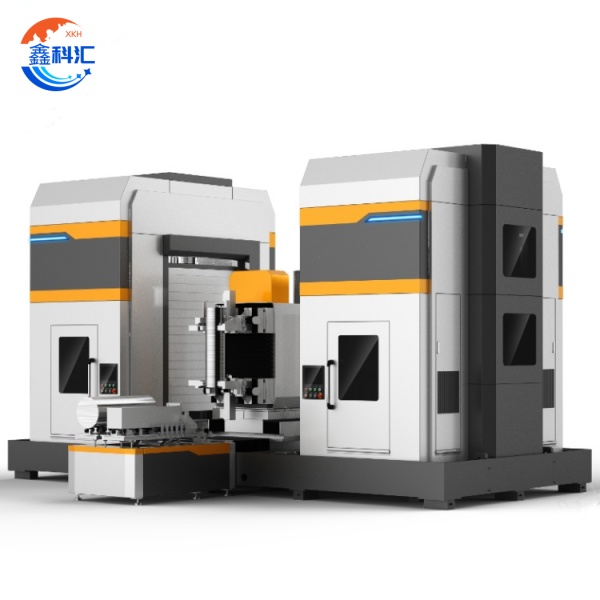

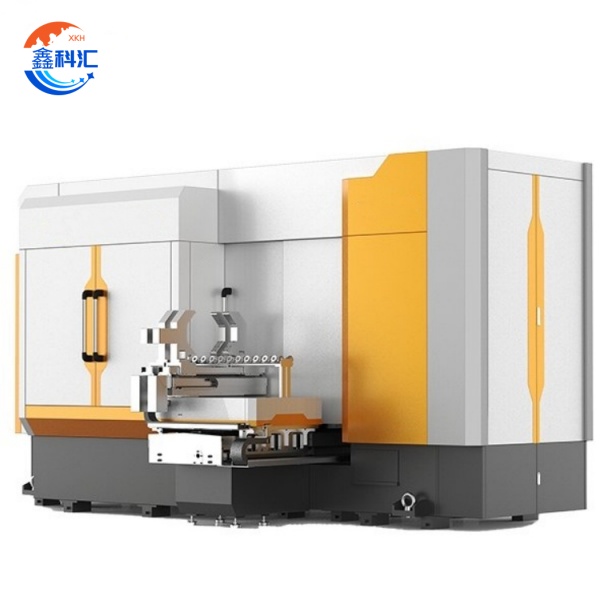

Umshini wesikwele wesiteshi esiphindwe kabili i-monocrystalline induku ye-silicon icubungula i-6/8/12 inch surface flatness Ra≤0.5μm

Izici zesisetshenziswa:

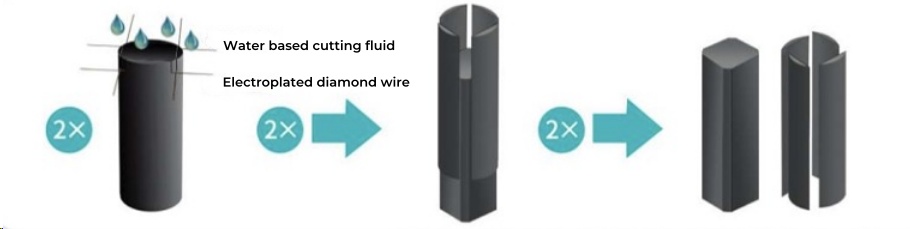

(1) Ukucubungula okuhambisanayo kwesiteshi esikabili

· Ukusebenza kahle okuphindwe kabili: Ukucubungula ngesikhathi esisodwa kwezinduku ezimbili ze-silicon (Ø6"-12") kukhulisa ukukhiqiza ngo-40% -60% uma kuqhathaniswa nemishini ye-Simplex.

· Ukulawula okuzimele: Isiteshi ngasinye singazilungisa ngokuzimela imingcele yokusika (ukushuba, isivinini sokuphakelayo) ukuze sivumelane nezicaciso ezahlukene zenduku ye-silicon.

(2) Ukusika okunembe kakhulu

· Ukunemba kobukhulu: ukubekezelelana kwebanga lebha yesikwele ±0.15mm, ububanzi ≤0.20mm.

· Ikhwalithi yobuso: ukuphuka konqenqema <0.5mm, ukunciphisa inani lokugaya okulandelayo.

(3) Ukulawula okuhlakaniphile

· Ukusika okuguquguqukayo: ukuqapha ngesikhathi sangempela se-silicon rod morphology, ukulungiswa okuguquguqukayo kwendlela yokusika (njengokucubungula induku ye-silicon egobile).

· Ukulandeleka kwedatha: rekhoda amapharamitha wokucubungula wenduku ngayinye ye-silicon ukuze usekele ukudotshwa kwesistimu ye-MES.

(4) Izindleko eziphansi ezisebenzisekayo

· Ukusetshenziswa kwentambo yedayimane: ≤0.06m/mm (ubude benduku ye-silicon), ububanzi bentambo ≤0.30mm.

· Ukujikeleza okupholile: Isistimu yokuhlunga inweba impilo yesevisi futhi inciphise ukulahlwa koketshezi olubi.

Ubuchwepheshe nezinzuzo zentuthuko:

(1) Ukuthuthukiswa kobuchwepheshe bokusika

- Ukusika kwemigqa eminingi: imigqa yedayimane eyi-100-200 isetshenziswa ngokufana, futhi ijubane lokusika liyi-≥40mm/min.

- Ukulawula ukuqina: Isistimu yokulungiswa kwe-loop evaliwe (±1N) ukunciphisa ubungozi bokuphuka kwentambo.

(2) Isandiso sokuhambisana

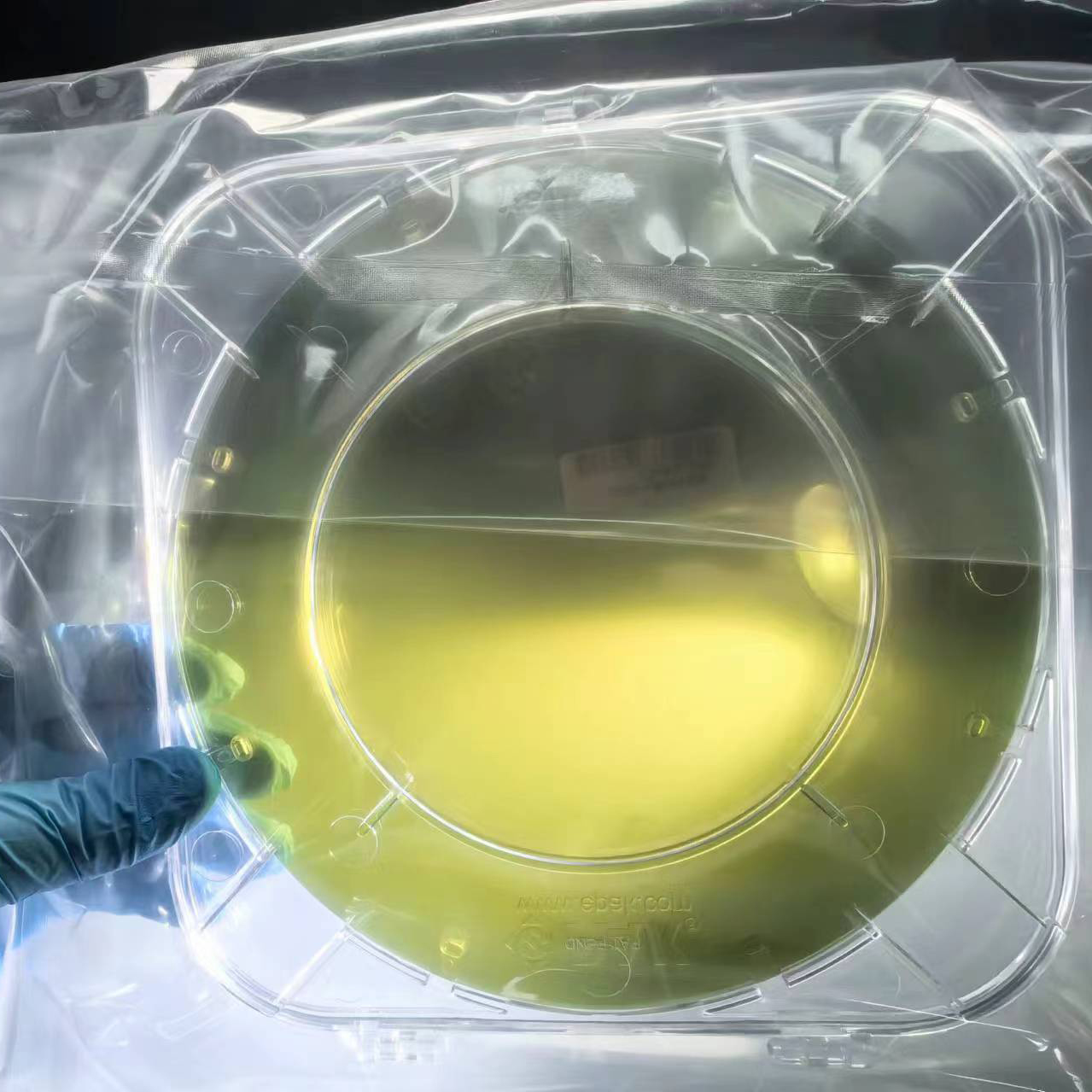

- Ukuzijwayeza kwezinto: Ukusekela i-P-type/N-type monocrystalline silicon, ehambisana ne-TOPCon, i-HJT nezinye izinduku ze-silicon ezisebenza kahle kakhulu zebhethri.

- Usayizi oguquguqukayo: ubude benduku ye-silicon 100-950mm, ibanga lehlangothi lwenduku yesikwele 166-233mm eliguquguqukayo.

(3) Ukuthuthukiswa okuzenzakalelayo

- Ukulayisha nokulayishwa kwerobhothi: ukulayisha/ukulayishwa okuzenzakalelayo kwezinduku ze-silicon, shaya imizuzu engu-≤3.

- Ukuxilonga okuhlakaniphile: Ukulungiswa okuqagelayo ukuze kuncishiswe isikhathi sokuphumula esingahlelelwe.

(4) Ubuholi bemboni

- Ukusekelwa kwe-wafer: ingacubungula i-silicone engu-≥100μm ezondile kakhulu enezinduku eziyisikwele, izinga lokuhlukana <0.5%.

- Ukuthuthukisa ukusetshenziswa kwamandla: Ukusetshenziswa kwamandla ngeyunithi ngayinye ye-silicon rod kwehliswe ngo-30% (uma kuqhathaniswa nemishini yendabuko).

Imingcele yezobuchwepheshe:

| Igama lepharamitha | Inani lenkomba |

| Inombolo yamabha acutshunguliwe | 2 izingcezu/isethi |

| Icubungula ibanga lobude bebha | 100 ~ 950mm |

| Ububanzi bemajini bomshini | 166-233 mm |

| Ukusika isivinini | ≥40mm/min |

| Isivinini socingo lwedayimane | 0~35m/s |

| Ububanzi bedayimane | 0.30 mm noma ngaphansi |

| Ukusetshenziswa komugqa | 0.06 m/mm noma ngaphansi |

| I-diameter yenduku eyindilinga ehambisanayo | Ububanzi benduku yesikwele eqediwe +2mm, Qinisekisa izinga lokuphasa lokupholisha |

| Ukulawula ukuphuka konqenqema | I-Raw Edge ≤0.5mm, Akukho ukukhipha, ikhwalithi ephezulu yendawo |

| Ukufana kobude be-arc | Ibanga lokuqagela <1.5mm, Ngaphandle kokuhlanekezelwa kwenduku ye-silicon |

| Ubukhulu bomshini (umshini owodwa) | 4800×3020×3660mm |

| Isamba samandla alinganiselwe | 56kw |

| Isisindo esifile semishini | 12t |

Ithebula lenkomba yokunemba komshini:

| Into yokunemba | Ibanga lokubekezelelana |

| Ukubekezelela kwemajini yebha yesikwele | ±0.15mm |

| Ububanzi bonqenqema lwebha yesikwele | ≤0.20mm |

| I-engeli kuzo zonke izinhlangothi zenduku yesikwele | 90°±0.05° |

| Ukucaba kwenduku yesikwele | ≤0.15mm |

| Ukunemba kokumisa okuphindaphindiwe kwerobhothi | ±0.05mm |

Izinsizakalo ze-XKH:

I-XKH ihlinzeka ngezinsizakalo zomjikelezo ogcwele wemishini ye-mono-crystalline silicon dual-station, okuhlanganisa ukwenza ngokwezifiso okokusebenza (okuhambisana nezinduku ezinkulu ze-silicon), ukugunyazwa kwenqubo (ukwenza kahle ipharamitha), ukuqeqeshwa kokusebenza nokusekelwa kwangemva kokuthengisa (ukunikezwa kwezingxenye ezibalulekile, ukuxilongwa okukude), ukuqinisekisa ukuthi amakhasimende athola isivuno esikhulu (>99%) kanye nokukhiqizwa kwezindleko eziphansi, kanye nokuhlinzeka ngokuthuthukiswa kobuchwepheshe njengama-AI (ukusika). Isikhathi sokulethwa yizinyanga ezingu-2-4.

Umdwebo onemininingwane