Izinto Zokuphatha Ukushisa Ezihlanganisiwe Zedayimane Nethusi

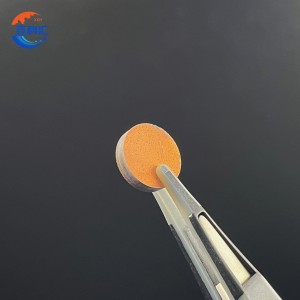

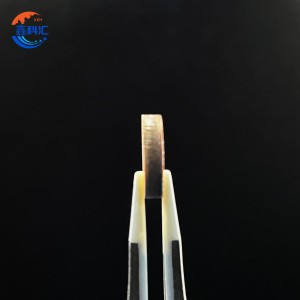

Umdwebo Oningiliziwe

Isingeniso Somkhiqizo

II-Diamond-Copper Composite (I-Cu-Diamond)kuyintoizinto zokuphatha ukushisa ezisebenza kahle kakhuluehlanganisa umqhubi wokushisa ongcono kakhulu emhlabeni —idayimane— ngezakhiwo zikagesi nezomshini eziphakeme kakhuluithusi.

Yakhelwe amadivayisi kagesi nawamandla asezingeni eliphezulu, le nhlanganisela ifinyelela ibhalansi ehlukileukuhanjiswa kokushisa okukhulu, ukwanda kokushisa okulawulwayo, futhiukuzinza komshini, okuvumela ukusebenza okuthembekile ngisho nangaphansi kwezimo ezishisayo ezidinga kakhulu.

Ngokungafani ne-substrates ezisekelwe ku-copper, tungsten, noma i-molybdenum, i-Diamond-Copper composites ilethakufika kabili ekuqhutshweni kokushisangenkathi kunciphisa kakhulu isisindo, okwenza kube ukukhetha okuthandwayoukupakishwa kwe-semiconductor, izinhlelo ze-laser, i-electronics yezindiza, kanye namamojula e-LED anamandla aphezulu.

Isimiso Sezinto Ezibonakalayo

Enhliziyweni yamanga ahlanganisiweizinhlayiya zedayimanekufakwe ngokulinganayo ngaphakathi kwei-matrix yethusi.

Inhlayiya ngayinye yedayimane isebenza njengesinki sokushisa esincane, isakaza ukushisa ngokushesha, kuyilapho i-matrix yethusi iqinisekisa ukuqhutshwa kukagesi kanye nokuqina kwesakhiwo.

Ngezindlela zokukhiqiza ezithuthukisiwe — okuhlanganisaukungena kwe-vacuum, ukugqoka kwamakhemikhali, futhii-spark plasma sintering (SPS)— kwakheka isibopho esiqinile nesizinzile se-interface, okuqinisekisa ukuthembeka kwesikhathi eside ngaphansi kokujikeleza kokushisa okuqhubekayo.

Okuvelele Kobuchwepheshe

| | |

|---|---|

| | |

| | |

| | |

| | |

| | |

Izicelo

-

Amamojula E-Semiconductor Anamandla Aphezulu(Amaphakheji e-IGBT, MOSFET, RF kanye nama-microwave)

-

Ama-Diode e-Laser kanye namadivayisi e-Optoelectronic

-

Izinhlelo Zokupholisa Zezindiza Nezokuvikela

-

Izisabalalisi Zokushisa ze-LED Ezisebenza Kakhulu

-

Ama-IC kanye nama-CPU Heat Sinks e-Advanced Computing

-

Ama-Amplifiers Amandla kanye Nemishini Yokuxhumana Ebonakalayo

Kungani Kufanele Ukhethe I-Diamond-Copper Composite?

Ngobaizinto ezithinta ukushisa.

Esikhathini sokwenziwa kube lula kanye nokuminyana kwamandla aphezulu, ukuphatha ukushisa kuchaza kahle isikhathi sokuphila kanye nokusebenza kwedivayisi ngayinye.

Inhlanganisela ye-Cu-Diamond iqinisekisa:

-

Isikhathi eside sokuphila kwedivayisi

-

Ukuqina kokusebenza okuthuthukisiwe

-

Ukusebenza kahle kwamandla okuthuthukisiwe

-

Ukukhathala okuncishisiwe kokushisa

Imibuzo Evame Ukubuzwa Ngezingilazi Ze-Quartz

Q1: Ingabe izinhlanganisela ze-Cu-Diamond zingenziwa ngezifiso zezinto ezithile ze-chip?

Yebo. Ingxenye yevolumu yedayimane kanye ne-CTE kungalungiswa ngokunembile ukuze kufane namadivayisi asekelwe ku-Si, GaN, noma i-SiC.

Umbuzo 2: Ingabe i-metallization iyadingeka ngaphambi kokuyihlanganisa nge-solder?

Yebo. Ukuqiniswa kwensimbi engaphezulu (i-Ni/Au, i-Ti/Ni/Au) kuyanconywa ukuqinisekisa ukubopha okuhle kakhulu kanye nokumelana okuncane kokushisa.

Q3: Isebenza kanjani ngaphansi kwezimo zokushisa ezivame kakhulu noma eziqhutshwa yi-pulse?

Ukusabalala kokushisa okuphezulu kwe-Diamond kuqinisekisa ukulingana kwezinga lokushisa okusheshayo, okwenza kube kuhle kakhulu ezingxenyeni ezivama kakhulu nezigcwele i-pulse.

Q4: Lingakanani izinga lokushisa lokusebenza eliphezulu?

Inhlanganisela ihlala izinzile kuze kube600°Cezindaweni ezingasebenzi kahle noma ezingenalutho, kuye ngokuthi i-coating kanye ne-bonding interface iyasebenza yini.

Mayelana NATHI

I-XKH igxile ekuthuthukisweni kobuchwepheshe obuphezulu, ekukhiqizweni, nasekuthengisweni kwengilazi ekhethekile ye-optical kanye nezinto ezintsha zekristalu. Imikhiqizo yethu ihlinzeka nge-optical electronics, i-consumer electronics, kanye nezempi. Sinikeza izingxenye ze-optical ze-Sapphire, izembozo zelensi yeselula, i-Ceramics, i-LT, i-Silicon Carbide SIC, i-Quartz, kanye nama-semiconductor crystal wafers. Ngobuchwepheshe obunekhono kanye nemishini esezingeni eliphezulu, sihamba phambili ekucutshungulweni komkhiqizo okungewona ojwayelekile, sihlose ukuba yibhizinisi elihamba phambili lezinto ze-optoelectronic tech.