Indlela ye-CVD yokukhiqiza izinto zokusetshenziswa ezihlanzekile ze-SiC ku-silicon carbide synthesis synthesis ku-1600 ℃

Umgomo wokusebenza:

1. Ukunikezwa kwesandulela. Umthombo we-silicon (isb. i-SiH₄) kanye nomthombo wekhabhoni (isb. C₃H₈) amagesi axutshwa ngesilinganiso futhi afakwa egumbini lokusabela.

2. Ukubola kwezinga lokushisa eliphezulu: Ekushiseni okuphezulu kuka-1500 ~ 2300℃, ukubola kwegesi kukhiqiza ama-athomu asebenzayo u-Si no-C.

3. Ukusabela okungaphezulu: Ama-athomu ka-Si no-C afakwa endaweni engaphansi ukuze akhe ungqimba lwekristalu ye-SiC.

4. Ukukhula kwekristalu: Ngokulawula i-gradient yezinga lokushisa, ukugeleza kwegesi nokucindezela, ukuze kuzuzwe ukukhula okuqondile eduze kwe-eksisi c noma i-eksisi.

Amapharamitha angukhiye:

· Izinga lokushisa: 1600 ~ 2200℃ (>2000℃ ku-4H-SiC)

Ingcindezi: 50 ~ 200mbar (ingcindezi ephansi yokunciphisa igesi nucleation)

· Isilinganiso segesi: Si/C≈1.0~1.2 (ukugwema izinkinga zokunothisa i-Si noma C)

Izici eziyinhloko:

(1) Ikhwalithi yekristalu

Ukuminyana okunesici esiphansi: ukuminyana kwe-microtubule <0.5cm ⁻², ukuminyana kokuhluka okungu-<10⁴ cm⁻².

Ukulawulwa kohlobo lwe-Polycrystalline: ingakhula i-4H-SiC (ejwayelekile), i-6H-SiC, i-3C-SiC nezinye izinhlobo zekristalu.

(2) Ukusebenza kwezisetshenziswa

Ukuqina kwezinga lokushisa eliphezulu: ukushisa kwe-graphite induction noma ukushisisa ukumelana, izinga lokushisa> 2300 ℃.

Ukulawula okufanayo: ukushintshashintsha kwezinga lokushisa ±5℃, izinga lokukhula 10~50μm/h.

Isistimu yegesi: Ukunemba okuphezulu kwe-flowmeter mass (MFC), ukuhlanzeka kwegesi ≥99.999%.

(3) Izinzuzo zobuchwepheshe

Ukuhlanzeka okuphezulu: Ukugxiliswa kokungcola kwengemuva <10¹⁶ cm⁻³ (N, B, njll.).

Usayizi omkhulu: Sekela ukukhula kwe-substrate engu-6 "/8" ye-SiC.

(4) Ukusetshenziswa kwamandla kanye nezindleko

Ukusetshenziswa kwamandla okuphezulu (200~500kW · h ngesithando somlilo), kubala u-30% ~50% wezindleko zokukhiqiza ze-SiC substrate.

Izinhlelo zokusebenza eziyinhloko:

1. I-substrate ye-semiconductor yamandla: I-SiC MOSFETs yokukhiqiza izimoto zikagesi kanye nama-inverters e-photovoltaic.

2. Idivayisi ye-Rf: I-5G base station GaN-on-SiC epitaxial substrate.

3.Izisetshenziswa zemvelo eziyingozi kakhulu: izinzwa zokushisa eziphezulu ze-aerospace kanye nezitshalo zamandla enyukliya.

Ukucaciswa kobuchwepheshe:

| Ukucaciswa | Imininingwane |

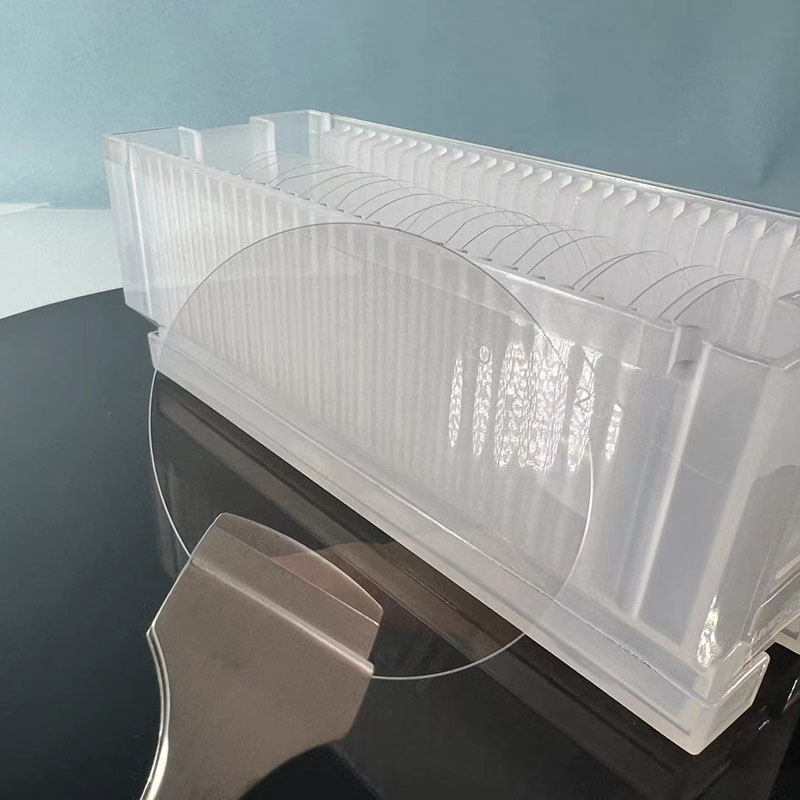

| Ubukhulu (L × W × H) | 4000 x 3400 x 4300 mm noma wenze ngendlela oyifisayo |

| Ububanzi begumbi lesithando somlilo | 1100mm |

| Umthamo wokulayisha | 50kg |

| Umkhawulo wedigri ye-vacuum | 10-2Pa(2h ngemva kokuqala kwephampu yamangqamuzana) |

| Izinga lokukhuphuka komfutho wekamelo | ≤10Pa/h(ngemuva kokubala) |

| Isiqephu sokuphakamisa ikhava yesithando somlilo esiphansi | 1500mm |

| Indlela yokushisa | Ukushisa kokungeniswa |

| Izinga lokushisa eliphezulu esithandweni somlilo | 2400°C |

| Ukunikezwa kwamandla okushisa | 2x40kW |

| Ukulinganisa izinga lokushisa | Isilinganiso sezinga lokushisa le-infrared esinemibala emibili |

| Izinga lokushisa | 900 ~ 3000 ℃ |

| Ukunemba kokulawula izinga lokushisa | ±1°C |

| Lawula ububanzi bengcindezi | 1 ~ 700 mr |

| Ukunemba Kokulawula Ukucindezela | 1 ~ 5mbar ±0.1mbar; 5~100mbar ±0.2mbar; 100 ~ 700mbar ±0.5mbar |

| Indlela yokulayisha | Ukulayisha okuphansi; |

| Ukucushwa ongakukhetha | Iphoyinti lokulinganisa izinga lokushisa eliphindwe kabili, i-forklift yokuthula. |

Izinsizakalo ze-XKH:

I-XKH ihlinzeka ngezinsizakalo ezigcwele umjikelezo we-silicon carbide CVD furnaces, okuhlanganisa ukwenziwa ngokwezifiso kwemishini (i-temperature zone design, i-gas system configuration), ukuthuthukiswa kwenqubo (crystal control, defect optimization), ukuqeqeshwa kobuchwepheshe (ukusebenza nokugcinwa) kanye nokwesekwa kokuthengiswa (izingxenye ezisele zokunikezwa kwezingxenye ezibalulekile, ukuxilongwa okukude) ukusiza amakhasimende afinyelele izinga eliphezulu lokukhiqizwa kwe-SiC substrate. Futhi unikeze ngezinsizakalo zokuthuthukisa inqubo ukuze uthuthukise ngokuqhubekayo isivuno sekristalu nokusebenza kahle kokukhula.