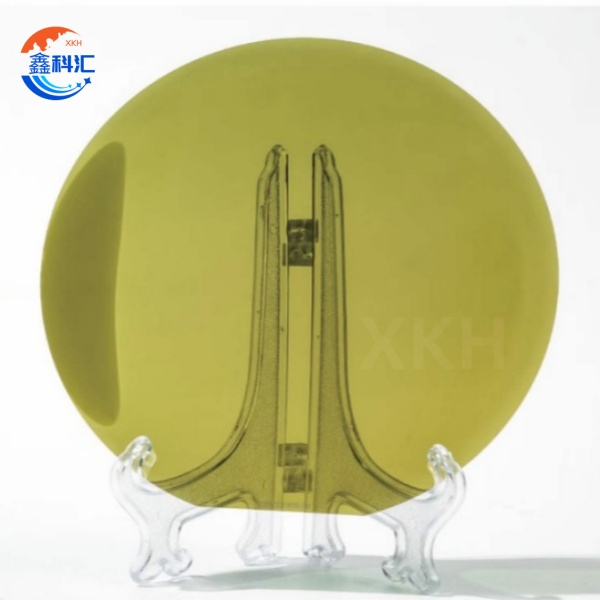

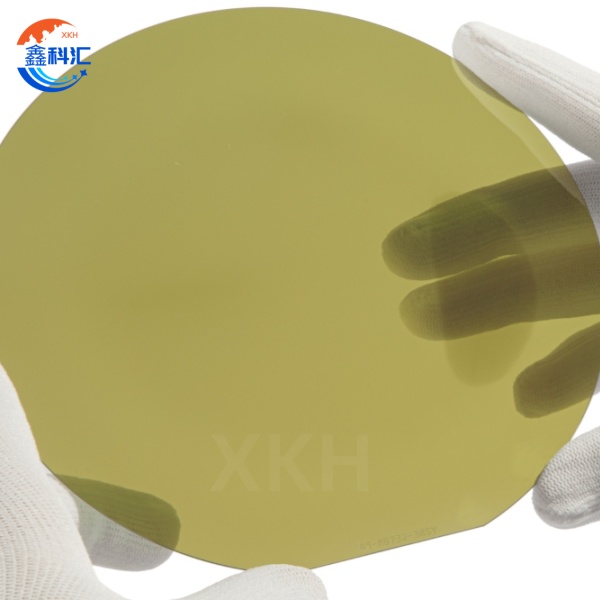

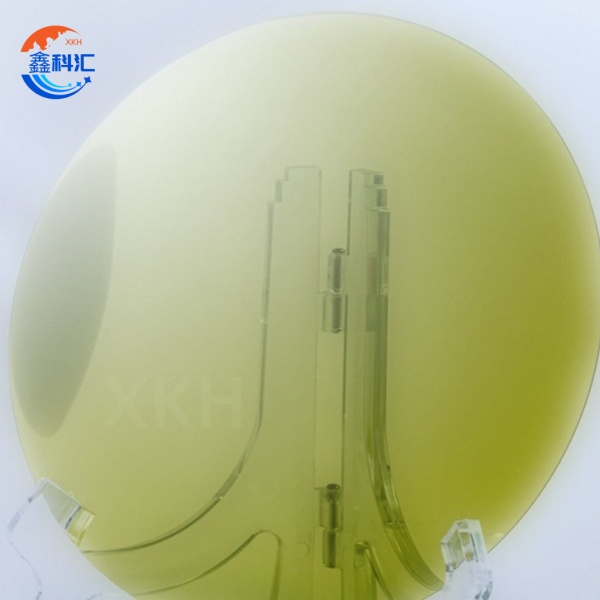

I-6 Inch Conductive SiC Composite Substrate 4H Ububanzi 150mm Ra≤0.2nm Warp≤35μm

Imingcele yezobuchwepheshe

| Izinto | Ukukhiqizaibanga | Dummyibanga |

| Ububanzi | 6-8 intshi | 6-8 intshi |

| Ubukhulu | 350/500±25.0 μm | 350/500±25.0 μm |

| I-Polytype | 4H | 4H |

| Ukungazweli | 0.015-0.025 ohm·cm | 0.015-0.025 ohm·cm |

| I-TTV | ≤5 μm | ≤20 μm |

| I-Wap | ≤35 μm | ≤55 μm |

| Ngaphambili (Si-face) roughness | I-Ra≤0.2 nm (5μm×5μm) | I-Ra≤0.2 nm (5μm×5μm) |

Izici Eziyinhloko

1.Inzuzo Yezindleko: Ingxenye yethu engaphansi engu-6-intshi eyinhlanganisela ye-SiC isebenzisa ubuchwepheshe bobunikazi "bosendlalelo sebhafa" obuthuthukisa ukwakheka kwempahla ukuze kwehliswe izindleko zempahla eluhlaza ngo-38% kuyilapho kugcinwa ukusebenza kahle kukagesi. Izilinganiso zangempela zibonisa ukuthi amadivayisi angu-650V MOSFET asebenzisa le substrate azuza ukuncipha kwezindleko ngo-42% endaweni yeyunithi ngayinye uma kuqhathaniswa nezisombululo ezivamile, okubalulekile ekukhuthazeni ukusetshenziswa kwedivayisi ye-SiC kuma-electronics abathengi.

2.Izakhiwo Ezinhle Kakhulu Eziqhubayo: Ngezinqubo ezinembile zokulawula i-nitrogen doping, i-substrate yethu eyinhlanganisela ye-SiC eqhutshwayo engu-6 intshi ifinyelela ukumelana ne-ultra-low of 0.012-0.022Ω·cm, ngokuhlukahluka okulawulwa ngaphakathi ±5%. Ngokuphawulekayo, sigcina ukufana kokumelana ngisho nangaphakathi kwesifunda sonqenqema esingu-5mm se-wafer, sixazulula inkinga yomphumela omude embonini.

3.I-Thermal Performance: Imojula engu-1200V/50A ethuthukiswe kusetshenziswa i-substrate yethu ibonisa kuphela izinga lokushisa elingu-45℃ le-junction likhuphuka ngaphezu kwe-ambient ekusebenzeni komthwalo ogcwele - 65℃ ngaphansi kuka-65℃ kunamadivayisi asekelwe ku-silicon aqhathaniswayo. Lokhu kunikwe amandla isakhiwo sethu esiyinhlanganisela "yesiteshi esishisayo se-3D" esithuthukisa ukusebenza kahle kwe-thermal okungemuva ukuya ku-380W/m·K kanye ne-thermal conductivity eqondile iye ku-290W/m·K.

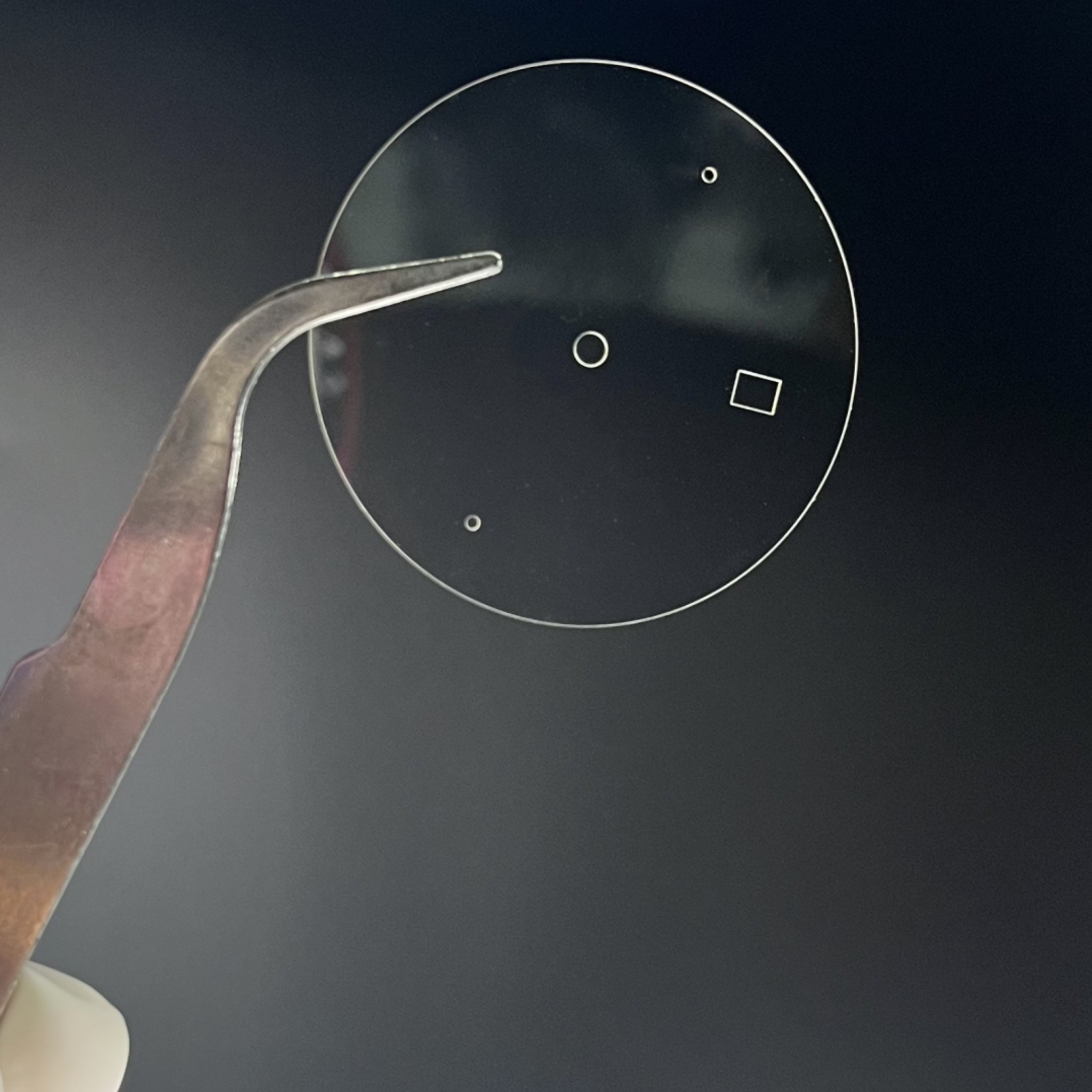

4.Ukuhambelana Kwenqubo: Ngesakhiwo esiyingqayizivele sama-intshi ayi-6-inch conductive SiC composite substrates, sithuthukise inqubo yokudayela nge-laser stealth efanayo esifinyelela isivinini sokusika esingu-200mm/s ngenkathi silawula ukusika komphetho ngaphansi kuka-0.3μm. Ukwengeza, sinikeza izinketho ze-pre-nickel-plated substrate ezivumela i-direct die bonding, okusindisa amakhasimende izinyathelo ezimbili zenqubo.

Izicelo Eziyinhloko

Isisetshenziswa Esibalulekile Segridi Ehlakaniphile:

Kumasistimu kagesi we-ultra-high voltage direct current (UHVDC) asebenza ku-±800kV, amadivaysi e-IGCT asebenzisa ama-substrate ayinhlanganisela ye-SiC yethu engu-6-intshi abonisa izithuthukisi zokusebenza ezimangalisayo. Lawa madivayisi athola ukuncipha kwama-55% ekushintsheni ukulahlekelwa phakathi nezinqubo zokushintsha, kuyilapho enyusa ukusebenza kahle kohlelo lonke ukuze kudlule ama-99.2%. I-substrates 'i-thermal conductivity ephakeme kakhulu (380W/m·K) inika amandla amadizayini okuguqula ahlanganisayo anciphisa indawo yesiteshi ngo-25% uma kuqhathaniswa nezixazululo ezivamile ezisekelwe ku-silicon.

Izitimela Ezintsha Zemoto Yamandla:

Isistimu yokushayela ehlanganisa izingxenye ezingaphansi zethu eziyinhlanganisela ye-SiC engu-6-intshi ifinyelela ukuminyana kwamandla okuguquguqukayo okungakaze kubonwe angu-45kW/L - ukuthuthuka okungama-60% kunomklamo wawo wangaphambilini osekwe ku-400V. Okuhlaba umxhwele kakhulu, isistimu igcina ukusebenza kahle okungu-98% kulo lonke ibanga lokushisa elisuka ku--40℃ ukuya ku-+175℃, ixazulula izinselele zokusebenza zesimo sezulu esibandayo ezikhungethe ukutholwa kwe-EV ezimeni zezulu ezisenyakatho. Ukuhlolwa komhlaba wangempela kukhombisa ukwenyuka ngo-7.5% kwebanga lasebusika ezimotweni ezihlonyiswe ngalobu buchwepheshe.

Amadrayivu Emvamisa Yezimboni:

Ukwamukelwa kwama-substrates ethu kumamojula wamandla ahlakaniphile (ama-IPM) wezinhlelo ze-servo zezimboni kuguqula ukukhiqiza okuzenzakalelayo. Ezikhungweni zokwenza imishini ye-CNC, lawa mamojula aletha ukusabela kwemoto ngokushesha okungama-40% (ehlisa isikhathi sokusheshisa ukusuka ku-50ms ukuya ku-30ms) kuyilapho esika umsindo kazibuthe ngo-15dB ukuya ku-65dB(A).

I-Consumer Electronics:

Uguquko lwe-elekthronikhi yabathengi luyaqhubeka nama-substrates ethu avumela amashaja asheshayo angu-65W GaN esizukulwaneni esilandelayo. Lawa ma-adaptha amandla ahlangene azuza u-30% wokunciphisa ivolumu (yehle aze afike ku-45cm³) kuyilapho egcina ukukhishwa kwamandla aphelele, ngenxa yezici zokushintsha eziphakeme zemiklamo esekelwe ku-SiC. Isithombe esishisayo sibonisa amazinga okushisa aphezulu angu-68°C ngesikhathi sokusebenza okuqhubekayo - kupholile ngo-22°C kunemiklamo evamile - kuthuthukisa kakhulu ukuphila komkhiqizo nokuphepha.

Izinsizakalo Zokwenza Ngokwezifiso ze-XKH

I-XKH inikeza ukusekelwa okuphelele kokwenza ngokwezifiso kwama-substrates ayinhlanganisela ye-SiC engu-6-intshi:

Ukwenza ngokwezifiso Ukuqina: Izinketho ezifaka i-200μm, 300μm, kanye ne-350μm imininingwane

2. Ukulawula Ukumelana: I-n-type doping concentration elungisekayo ukusuka ku-1×10¹⁸ ukuya ku-5×10¹⁸ cm⁻³

3. I-Crystal Orientation: Ukusekelwa kokuma okuningi okuhlanganisa (0001) off-axis 4° noma 8°

4. Amasevisi Okuhlola: Gcwalisa imibiko yokuhlola ipharamitha yezinga le-wafer

Isikhathi sethu samanje sokuhola kusukela ku-prototyping kuya ekukhiqizeni ngobuningi singaba sifushane njengamaviki angu-8. Kumakhasimende anamasu, sinikeza amasevisi okuthuthukisa inqubo ukuze siqinisekise ukufana okuphelele nezidingo zedivayisi.