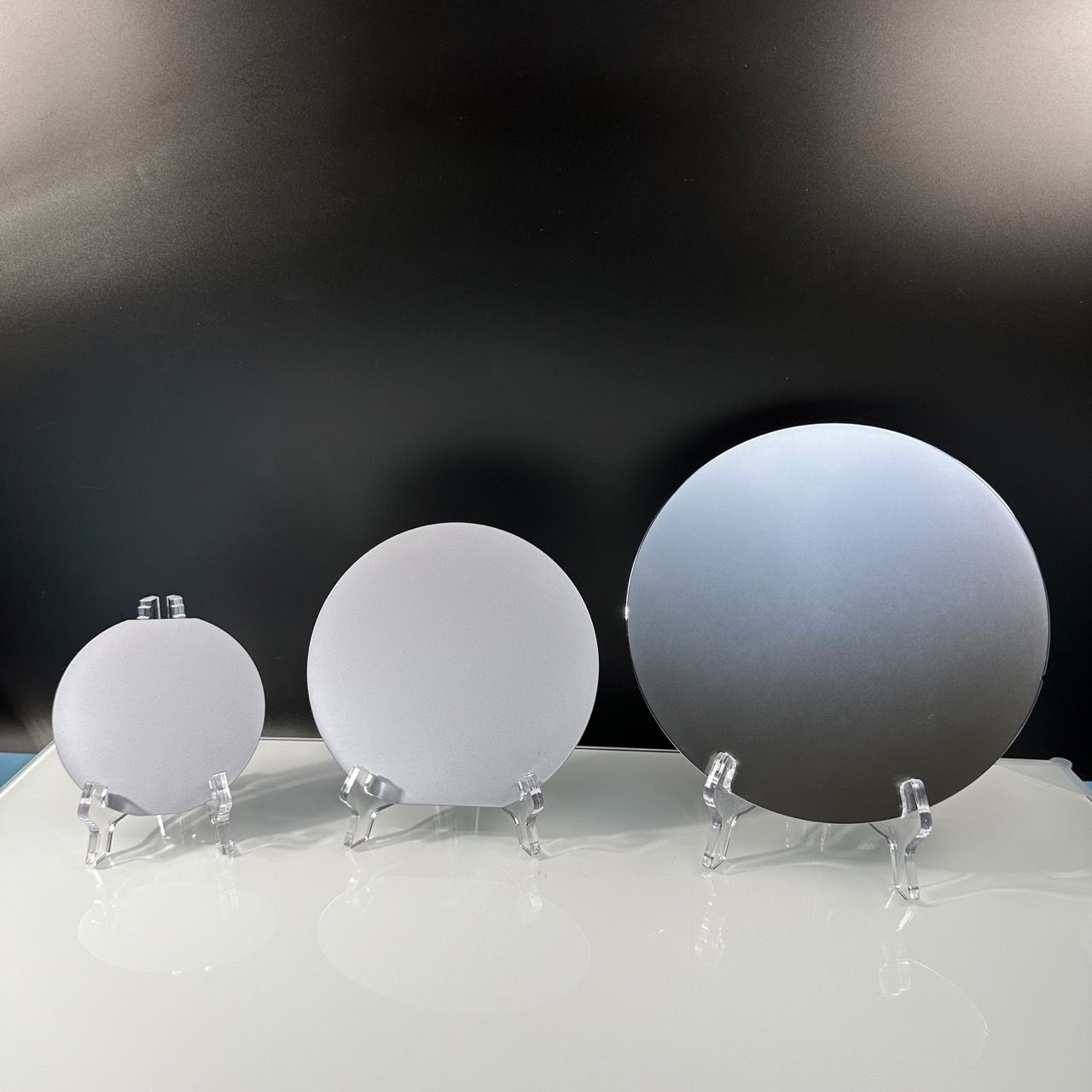

I-4inch Silicon wafer FZ CZ N-Type DSP noma ibanga lokuhlola le-SSP

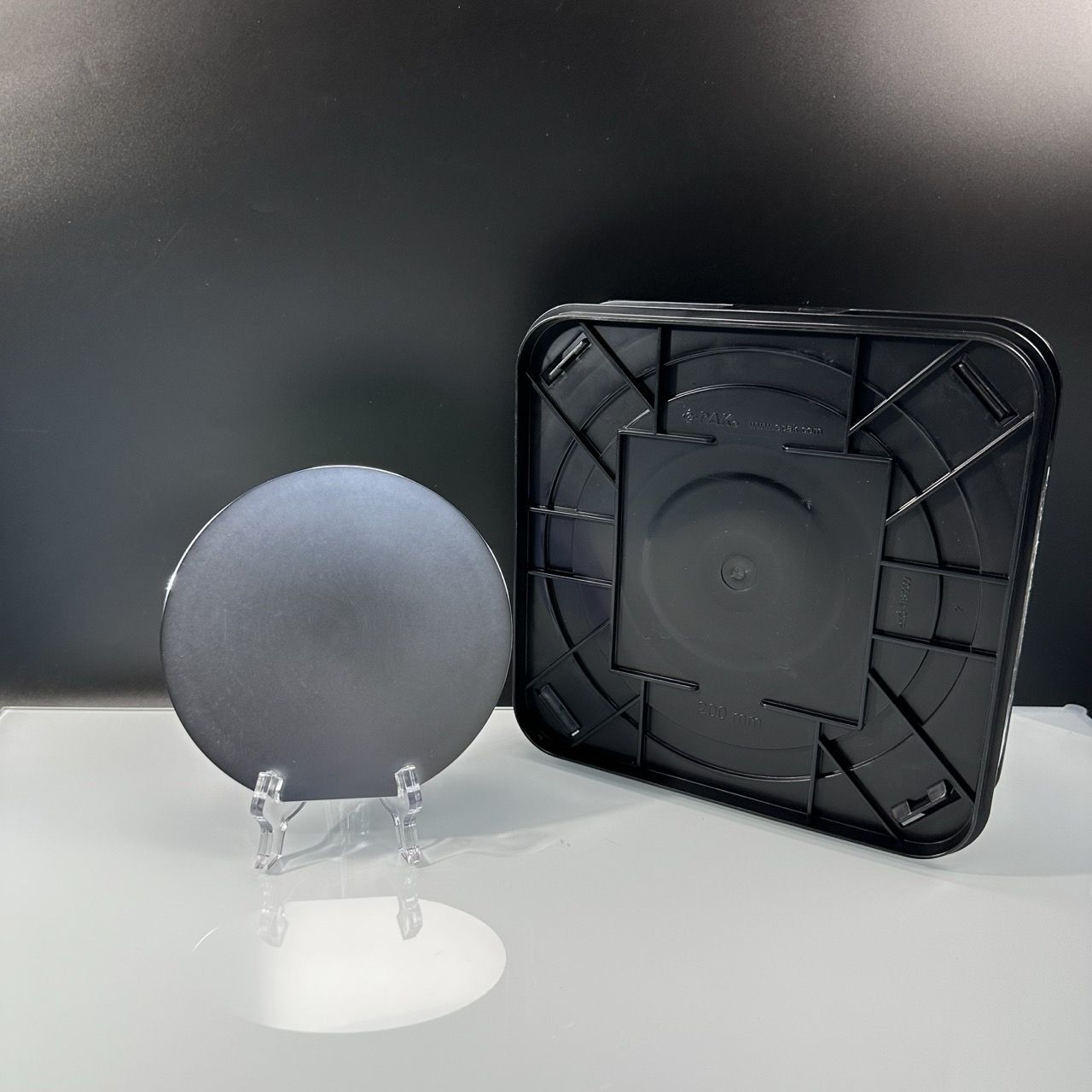

Ukwethulwa kwebhokisi le-wafer

Ama-silicone wafers ayingxenye ebalulekile yomkhakha wezobuchwepheshe okhulayo wanamuhla. Imakethe yezinto zokwakha ze-semiconductor idinga ama-silicon wafers anemininingwane eqondile ukukhiqiza inani elikhulu lamadivayisi wesekethe ahlanganisiwe. Siyaqaphela ukuthi njengoba izindleko zokukhiqiza i-semiconductor zikhuphuka, kanjalo nezindleko zalezo zinto zokukhiqiza, njengama-silicon wafers. Siyakuqonda ukubaluleka kwekhwalithi nokusebenza kahle kwezindleko emikhiqizweni esiyinikeza amakhasimende ethu. Sinikeza ama-wafers angabizi futhi anekhwalithi engashintshi. Sikhiqiza ikakhulukazi ama-silicon wafers nama-ingots (CZ), ama-epitaxial wafers, namawafa e-SOI.

| Ububanzi | Ububanzi | Ipholishiwe | I-Doped | Ukuqondisa | Ukumelana/Ω.cm | Ubukhulu/um |

| 2intshi | 50.8±0.5mm | I-SSP I-DSP | P/N | 100 | 1-20 | 200-500 |

| 3inch | 76.2±0.5mm | I-SSP I-DSP | P/B | 100 | NA | 525±20 |

| 4intshi | 101.6±0.2 101.6±0.3 101.6±0.4 | I-SSP I-DSP | P/N | 100 | 0.001-10 | 200-2000 |

| 6intshi | 152.5±0.3 | I-SSPI-DSP | P/N | 100 | 1-10 | 500-650 |

| 8inch | 200±0.3 | I-DSPI-SSP | P/N | 100 | 0.1-20 | 625 |

Ukusetshenziswa kwama-wafers e-silicon

I-Substrate: I-PECVD/LPCVD enamathela, i-magnetron sputtering

I-Substrate: I-XRD, i-SEM, i-atomic force infrared spectroscopy, i-electron microscopy yokudlulisa, i-fluorescence spectroscopy nezinye izivivinyo zokuhlaziya, ukukhula kwe-molecular beam epitaxial, ukuhlaziya i-X-ray yokucubungula kwe-crystal microstructure: i-etching, i-bonding, amadivayisi we-MEMS, amadivayisi kagesi, amadivayisi we-MOS nokunye ukucutshungulwa.

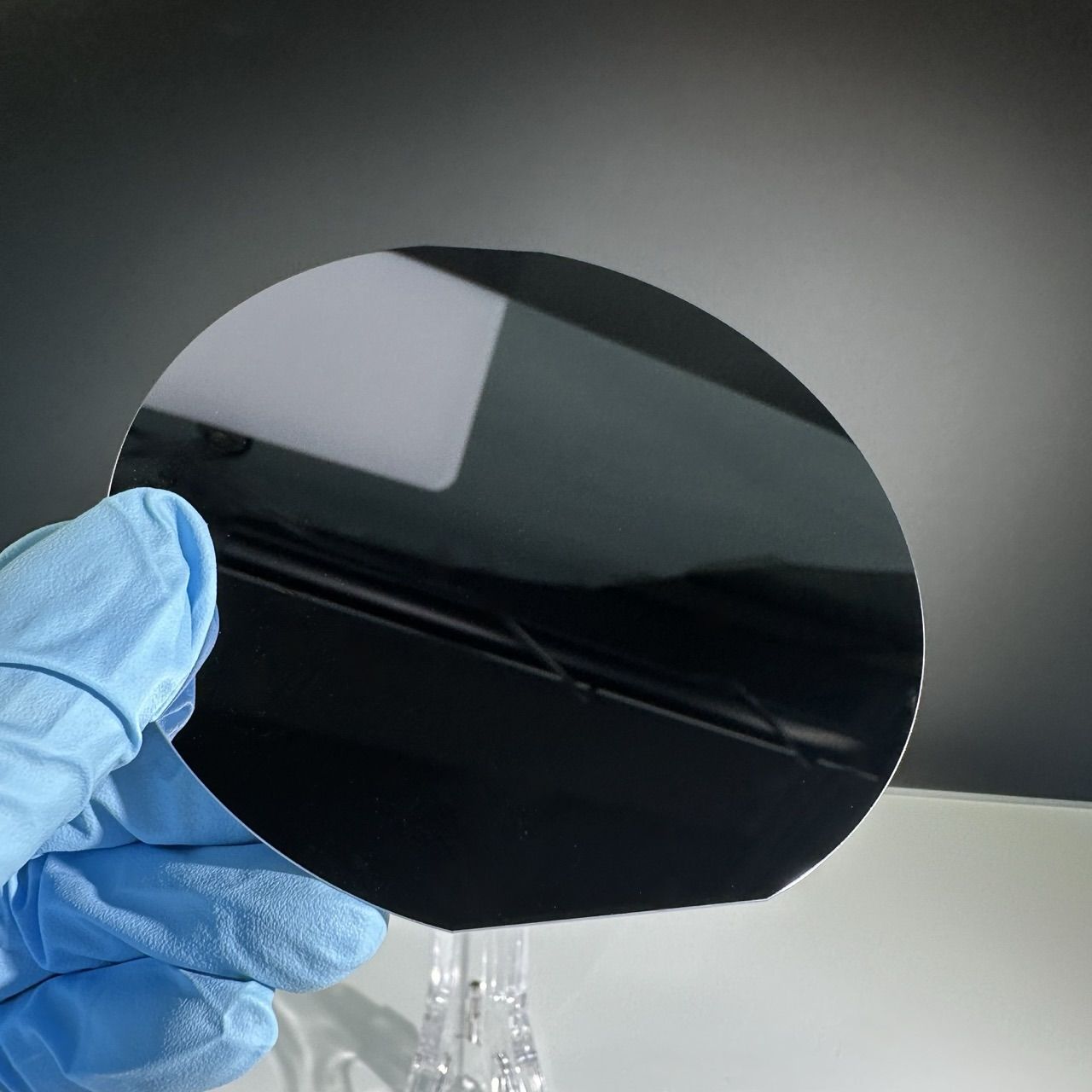

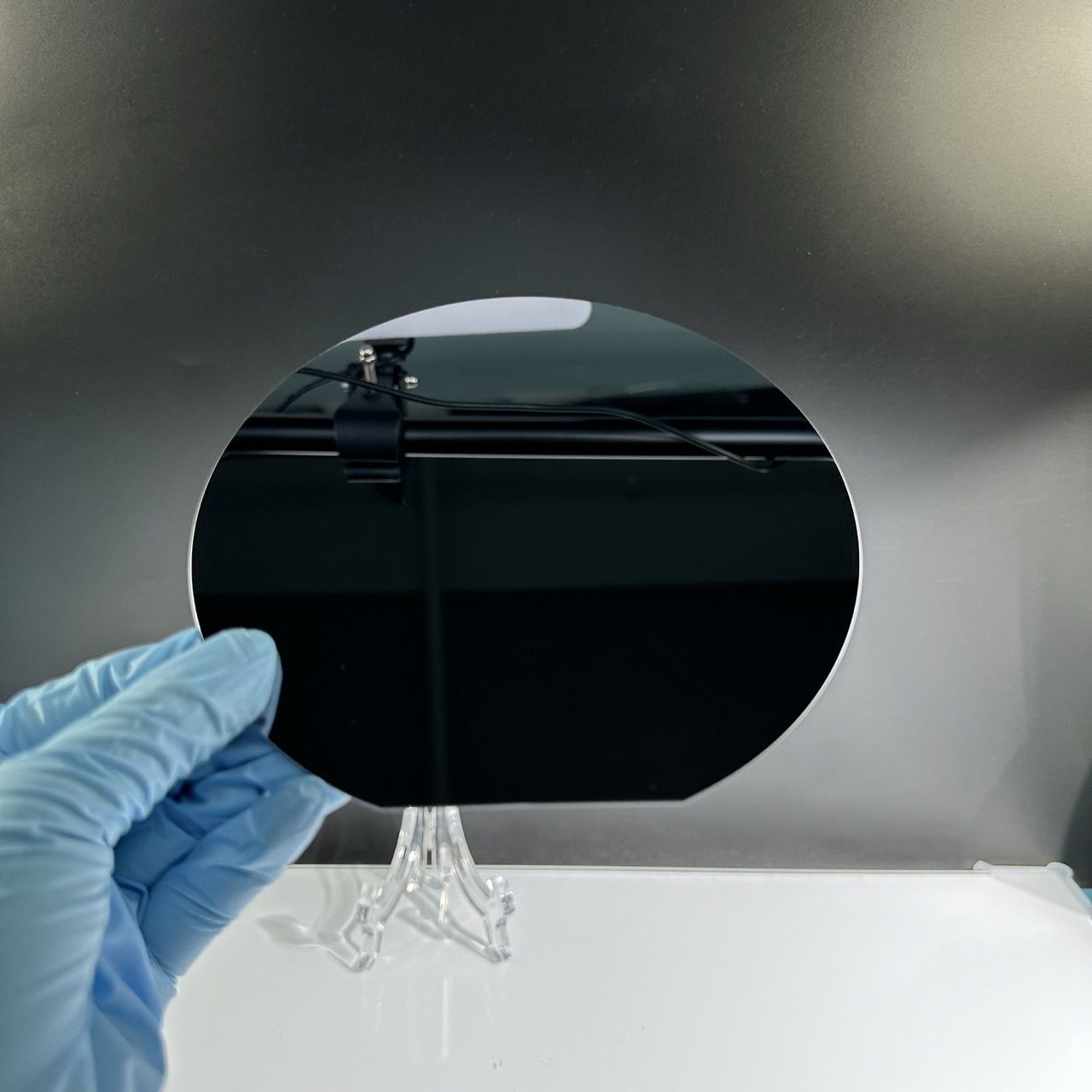

Kusukela 2010, Shanghai XKH Material Tech. I-Co., Ltd izibophezele ekuhlinzekeni amakhasimende ngezixazululo ezibanzi ezingu-4-intshi ze-Silicon Wafer, kusukela kumawafa wezinga lokulungisa i-Dummy Wafer, amawafa wezinga lokuhlola, ama-wafers wezinga lomkhiqizo i-Prime Wafer, kanye namawafa akhethekile, ama-Oxide wafers Oxide, ama-Nitride wafers Si3N4, i-waferd waferd silicon, i-waferd wafer plate Ingilazi ye-MEMS, amawafa aqine kakhulu nayisicaba, njll., anosayizi abasukela ku-50mm-300mm, futhi singahlinzeka ngamawafa e-semiconductor anokupholishwa okuyingxenye eyodwa/ezimbili, ukucwenga, ukudayela, i-MEMS nezinye izinsiza zokucubungula nokwenza ngokwezifiso.

Umdwebo onemininingwane