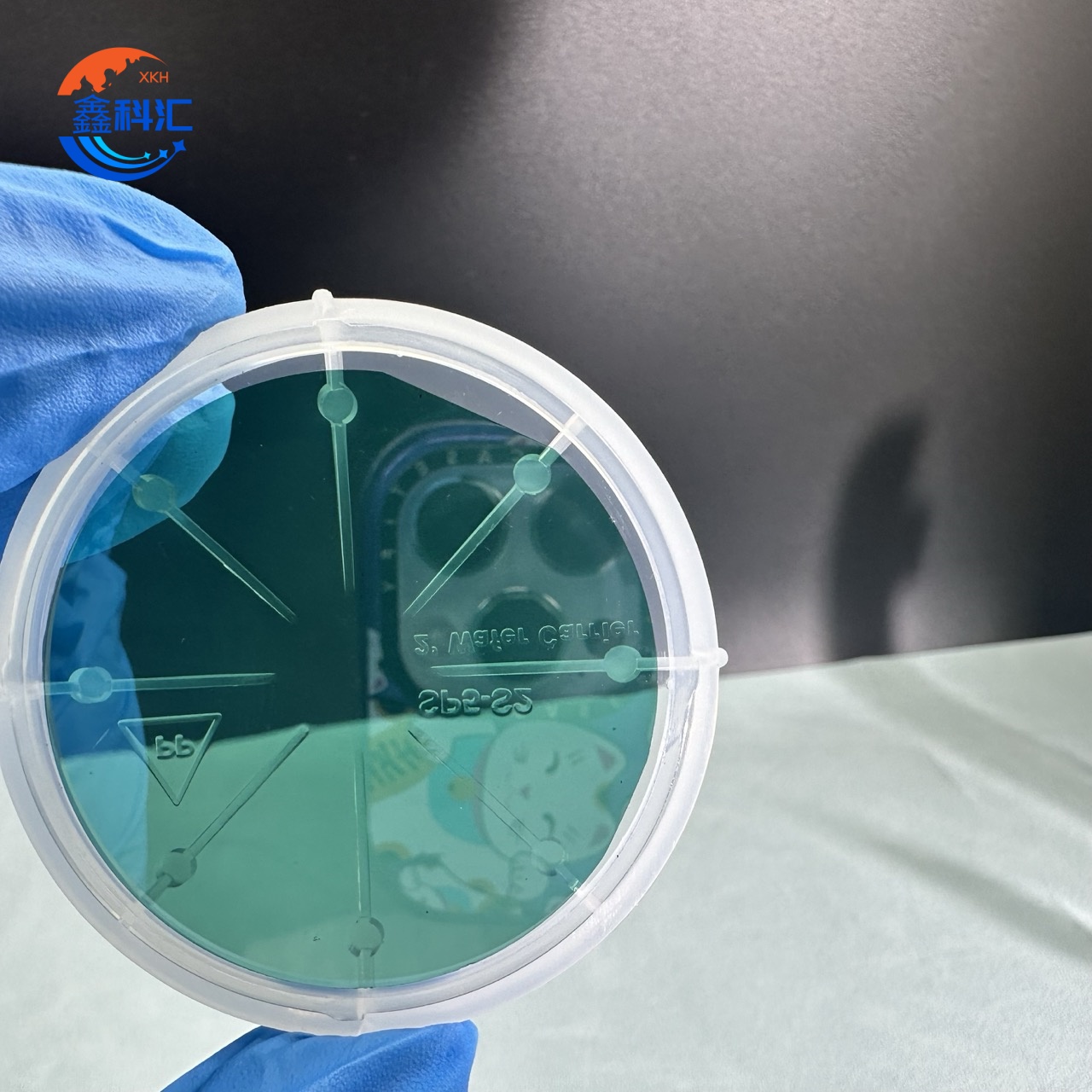

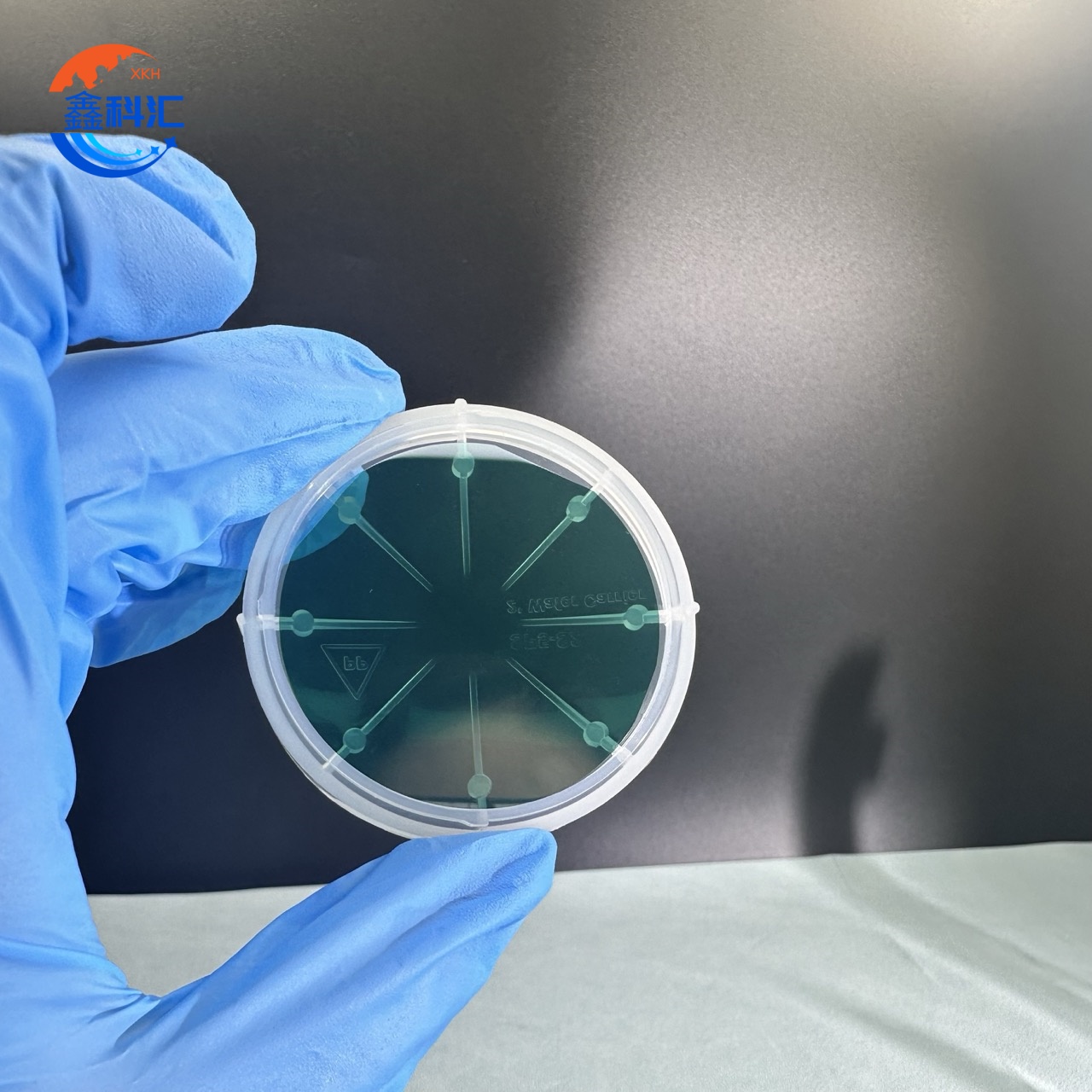

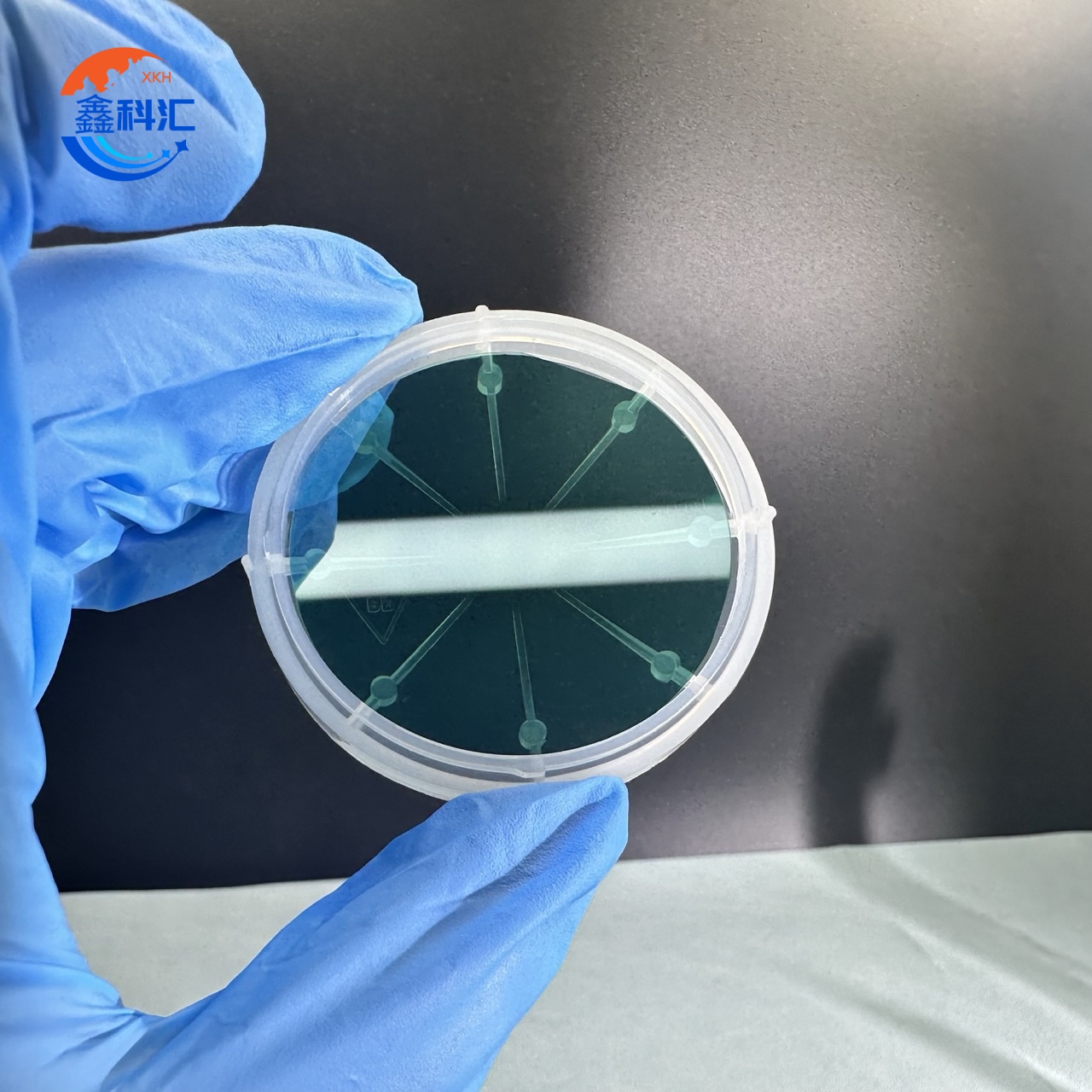

I-2inch Silicon Carbide Wafer 6H-N Uhlobo Lwebanga Le-Prime Ibanga Ucwaningo Ibanga Le-Dummy Ibanga 330μm 430μm Ukuqina

Okulandelayo yizici ze-silicon carbide wafer:

I-1.Silicon carbide (SiC) wafer inezindawo ezinhle zikagesi kanye nezakhiwo ezinhle kakhulu zokushisa. I-Silicon carbide (SiC) wafer inokwanda okuphansi kokushisa.

I-2.Silicon carbide (SiC) isicwecwana sinezinto zokuqina eziphakeme. I-Silicon carbide (SiC) wafer yenza kahle emazingeni okushisa aphezulu.

I-3.Silicon carbide (SiC) wafer inokumelana okuphezulu nokugqwala, ukuguguleka kanye ne-oxidation. Ngaphezu kwalokho, i-silicon carbide (SiC) wafer nayo icwebezela kakhulu kunamadayimane noma i-cubic zirconia.

I-4.Ingcono ukumelana nemisebe: Ama-wafer e-SIC anokumelana okunamandla emisebeni, okuwenza afanelekele ukusetshenziswa ezindaweni zemisebe. Izibonelo zifaka imikhumbi-mkhathi nezinsiza zenuzi.

I-5.Ukuqina okuphezulu: Ama-wafer e-SIC anzima kune-silicon, okuthuthukisa ukuqina kwama-wafers ngesikhathi sokucubungula.

6.Lower dielectric constant: I-dielectric constant ye-SIC wafers iphansi kune-silicon, esiza ukunciphisa amandla e-parasitic kudivayisi futhi kuthuthukise ukusebenza kwe-high-frequency.

I-Silicon carbide wafer inezinhlelo zokusebenza eziningana

I-SiC isetshenziselwa ukwakhiwa kwamadivayisi ane-voltage ephezulu kakhulu nanamandla amakhulu njengama-diode, ama-transistors kagesi, namadivayisi we-microwave enamandla amakhulu. Uma kuqhathaniswa nama-Si-devices avamile, amadivaysi kagesi asekelwe ku-SiC anesivinini sokushintsha ngokushesha ama-voltage aphezulu, ukumelana ne-parasitic okuphansi, usayizi omncane, ukupholisa okuncane okudingekayo ngenxa yekhono lokushisa eliphezulu.

Ngenkathi i-Silicon carbide (SiC-6H) - i-wafer engu-6H inezinto eziphezulu ze-elekthronikhi, i-silicon carbide (SiC-6H) - i-wafer engu-6H ilungiswa kalula futhi ifundwe kahle kakhulu.

I-1.Amandla kagesi: Ama-Silicon Carbide Wafers asetshenziswa ekukhiqizeni i-Power Electronics, esetshenziswa ezinhlobonhlobo zezinhlelo zokusebenza, okuhlanganisa izimoto zikagesi, izinhlelo zamandla avuselelekayo, kanye nemishini yezimboni. I-thermal conductivity ephezulu kanye nokulahlekelwa kwamandla aphansi kwe-Silicon Carbide kuyenza ibe into efanelekile yalezi zinhlelo zokusebenza.

Ukukhanyisa kwe-2.LED: Ama-Silicon Carbide Wafers asetshenziswa ekukhiqizeni ukukhanya kwe-LED. Amandla aphezulu e-Silicon Carbide enza kube nokwenzeka ukukhiqiza ama-LED ahlala isikhathi eside futhi ahlala isikhathi eside kunemithombo yokukhanyisa evamile.

3.Amadivayisi e-Semiconductor: Ama-Silicon Carbide Wafers asetshenziswa ekukhiqizeni Amadivayisi we-Semiconductor, asetshenziswa ezinhlelweni eziningi ezahlukahlukene, kufaka phakathi ezokuxhumana, ikhompuyutha, nogesi wabathengi. I-thermal conductivity ephezulu kanye nokulahlekelwa kwamandla aphansi kwe-Silicon Carbide kuyenza ibe into efanelekile yalezi zinhlelo zokusebenza.

4.Amaseli eSolar: Ama-Silicon Carbide Wafers asetshenziswa ekukhiqizeni ama-Solar Cells. Amandla aphezulu e-Silicon Carbide enza kube nokwenzeka ukukhiqiza amaSolar Cell ahlala isikhathi eside futhi ahlala isikhathi eside kunamaseli eSolar endabuko.

Sekukonke, i-ZMSH Silicon Carbide Wafer ingumkhiqizo oguquguqukayo futhi osezingeni eliphezulu ongasetshenziswa ezinhlobonhlobo zezinhlelo zokusebenza. I-thermal conductivity ephezulu, ukulahleka kwamandla aphansi, namandla aphezulu kuyenza ibe into efanelekile kumadivayisi we-elekthronikhi anezinga lokushisa eliphezulu namandla aphezulu. Nge-Bow/Warp engu-≤50um, Surface Roughness engu-≤1.2nm, kanye ne-Resistivity of High/Low Resistivity, i-Silicon Carbide Wafer iyinketho ethembekile nephumelelayo yanoma yiluphi uhlelo lokusebenza oludinga indawo eyisicaba futhi ebushelelezi.

Umkhiqizo wethu we-SiC Substrate uza nokusekelwa okuphelele kwezobuchwepheshe kanye nezinsizakalo zokuqinisekisa ukusebenza kahle nokwaneliseka kwamakhasimende.

Ithimba lethu lochwepheshe liyatholakala ukuze lisize ngokukhetha umkhiqizo, ukufakwa, nokuxazulula inkinga.

Sinikeza ukuqeqeshwa nemfundo ngokusetshenziswa nokunakekelwa kwemikhiqizo yethu ukuze sisize amakhasimende ethu akhulise utshalomali lwawo.

Ukwengeza, sihlinzeka ngezibuyekezo eziqhubekayo zomkhiqizo nezithuthukisi ukuqinisekisa ukuthi amakhasimende ethu ahlala efinyelela ubuchwepheshe bamuva.

Umdwebo onemininingwane