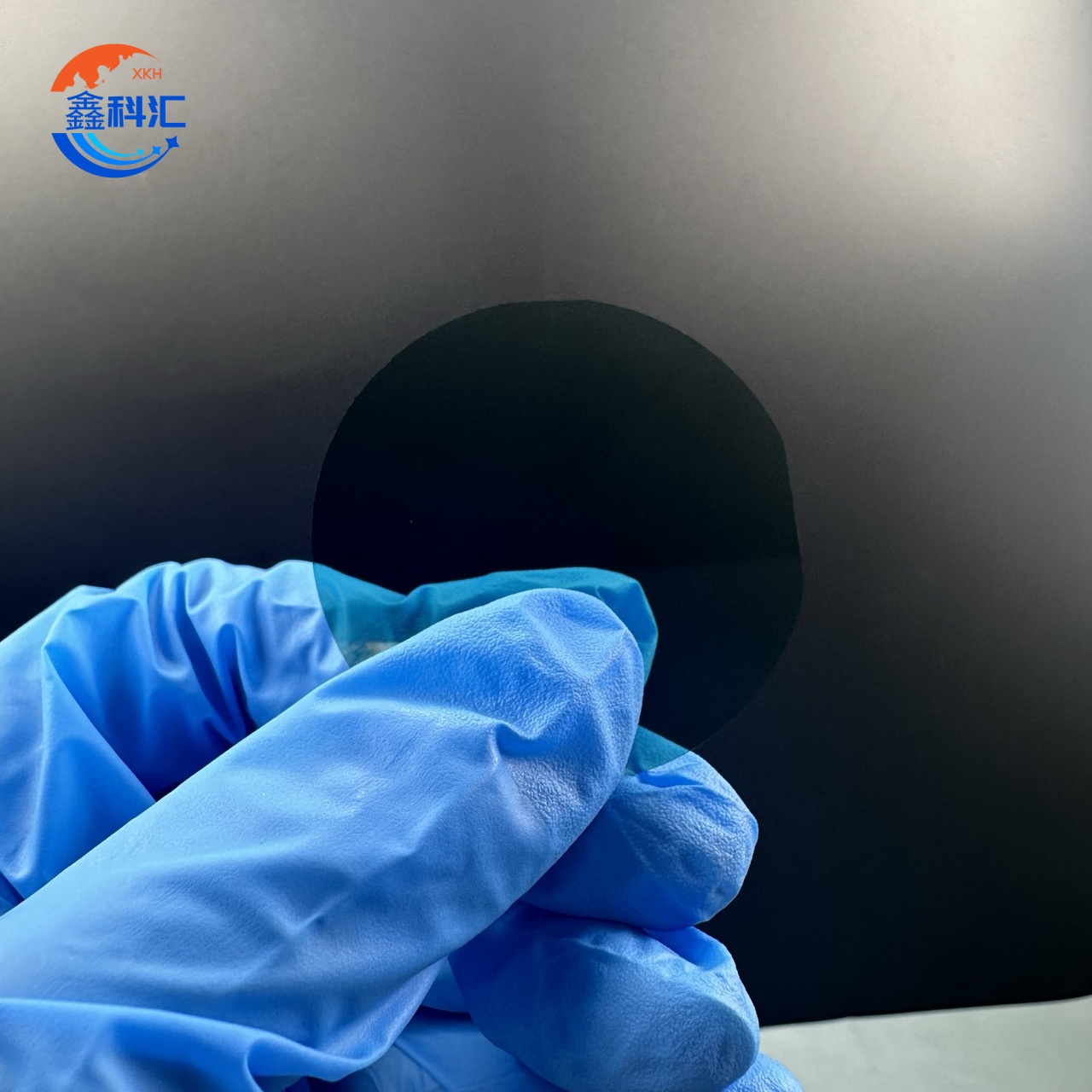

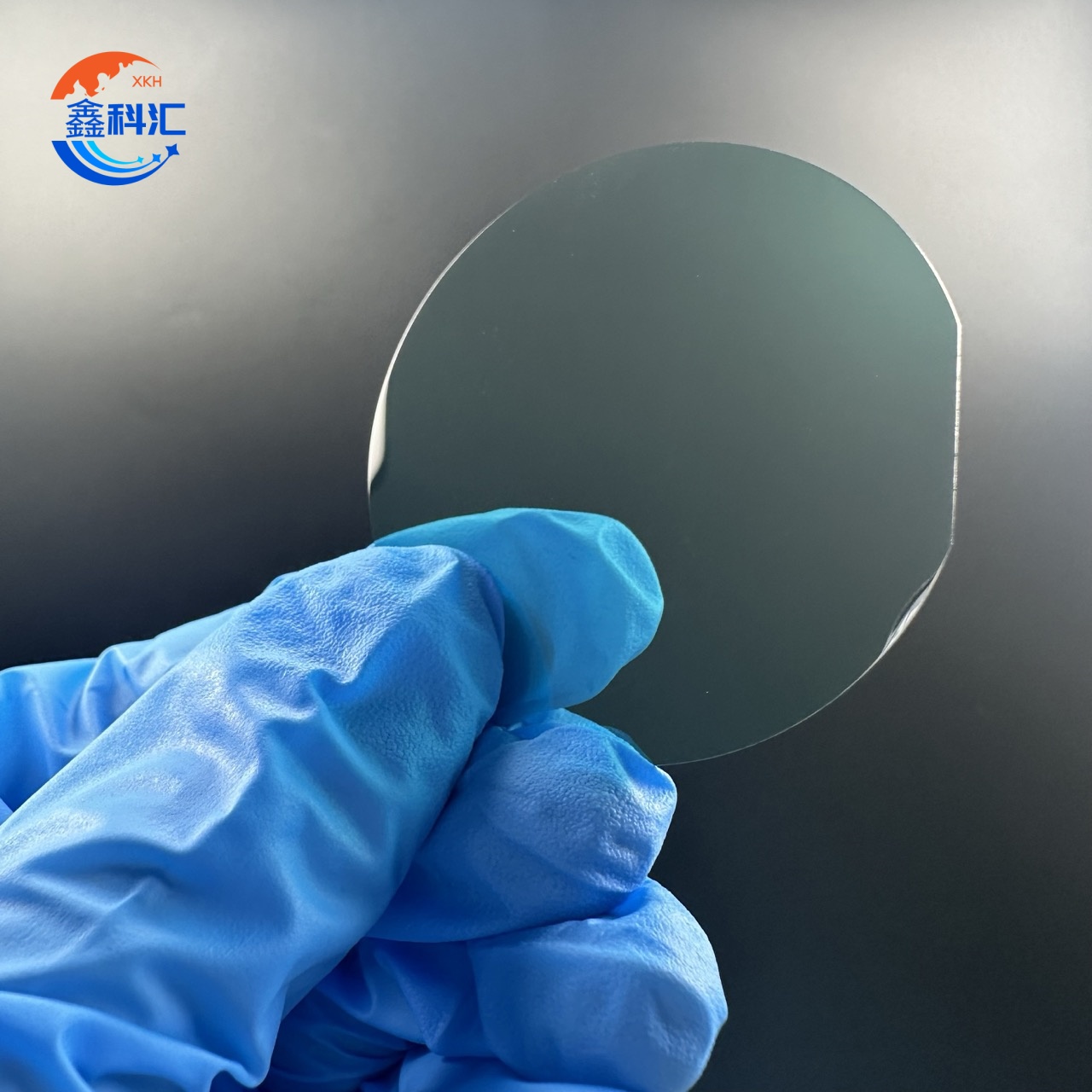

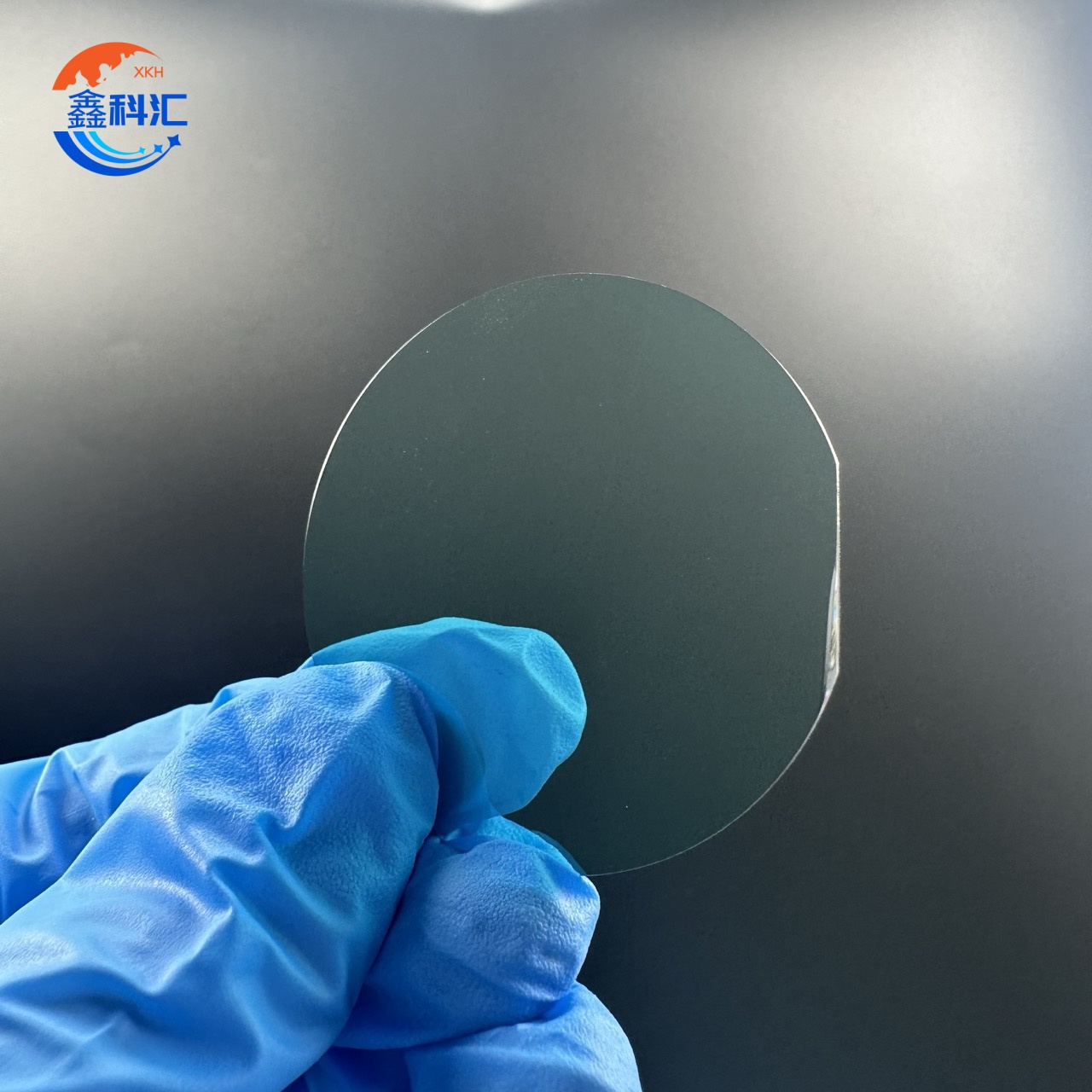

I-2inch silicon carbide substrate 6H-N enezinhlangothi ezimbili ezipholishiwe ububanzi 50.8mm ibanga lokukhiqiza ibanga locwaningo

Okulandelayo yizici ze-2inch silicon carbide wafer:

1. Ukumelana kangcono nemisebe: Ama-wafer e-SIC anokumelana okuqinile nemisebe, okuwenza afanelekele ukusetshenziswa ezindaweni zemisebe. Izibonelo zifaka imikhumbi-mkhathi nezinsiza zenuzi.

2. Ubulukhuni obuphakeme: Amawafa e-SIC anzima kune-silicon, okuthuthukisa ukuqina kwama-wafers ngesikhathi sokucubungula.

3. I-dielectric constant ephansi: I-dielectric constant yama-wafers e-SIC iphansi kune-silicon, esiza ukunciphisa amandla e-parasitic kudivayisi nokuthuthukisa ukusebenza kwe-high-frequency.

4. Isivinini esiphezulu se-electron drift esigcwele: Amawafa e-SIC anesivinini esiphezulu sokukhukhuleka se-electron kune-silicon, enikeza amadivayisi we-SIC inzuzo ezinhlelweni zokusebenza zamafrikhwensi aphezulu.

5. Ukuminyana kwamandla okuphezulu: Ngezici ezingenhla, amadivayisi we-SIC wafer angafinyelela ukukhishwa kwamandla aphezulu ngosayizi omncane.

I-2inch silicon carbide wafer inezinhlelo zokusebenza ezimbalwa.

1. Izinto zikagesi zamandla: Amawafa e-SiC asetshenziswa kakhulu ezintweni zikagesi zamandla njengeziguquli zamandla, ama-inverter, namaswishi ane-voltage ephezulu ngenxa yokwehla kwamandla kagesi aphezulu kanye nezici zokulahlekelwa kwamandla aphansi.

2. Izimoto zikagesi: Amawafa e-silicon carbide asetshenziswa kugesi wamandla emoto kagesi ukuze kuthuthukiswe ukusebenza kahle nokunciphisa isisindo, okuholela ekushajweni okusheshayo kanye nebanga lokushayela elide.

3. Amandla avuselelekayo: Amawafa e-silicon carbide adlala indima ebalulekile ekusetshenzisweni kwamandla avuselelekayo njengama-solar inverters nezinhlelo zamandla omoya, ukuthuthukisa ukusebenza kahle kokuguqulwa kwamandla nokuthembeka.

4.I-Aerospace kanye Nokuvikela: Amawafa e-SiC abalulekile embonini ye-aerospace neyokuvikela ekushiseni okuphezulu, amandla aphezulu kanye nezicelo ezimelana nemisebe, okuhlanganisa izinhlelo zamandla ezindiza kanye nezinhlelo ze-radar.

I-ZMSH ihlinzeka ngezinsizakalo zokwenza ngokwezifiso umkhiqizo kumawafa ethu e-silicon carbide. Amawafa ethu enziwe ngezingqimba zekhwalithi ephezulu ze-silicon carbide ezitholakala e-China ukuze kuqinisekiswe ukuqina nokwethembeka. Amakhasimende angakhetha ekukhetheni kwethu osayizi be-wafer kanye nokucaciswa kokuhlangabezana nezidingo zabo ezithile.

Amawafa ethu eSilicon Carbide afika ngamamodeli nosayizi abahlukene, imodeli iSilicon Carbide.

Sinikeza izinhlobonhlobo zokwelapha zangaphandle ezihlanganisa ukupholishwa okuhlangene okukodwa/okukabili okunobulukhuni obungaphezulu ≤1.2nm kanye ne-Lambda/10 flatness. Siphinde sinikeze izinketho eziphezulu/eziphansi zokumelana nezingenziwa ngokwezifiso zakho. I-EPD yethu engu-≤1E10/cm2 iqinisekisa ukuthi ama-wafers ethu ahlangabezana nezindinganiso eziphakeme zomkhakha.

Sithinta imininingwane ngayinye yephakheji , ukuhlanzwa , i-anti-static , ukwelashwa kokushaqeka .Ngokwenani nokuma komkhiqizo , sizothatha inqubo yokupakisha ehlukile! Cishe ngamakhasethi ayi-wafer eyodwa noma amakhasethi angama-25pcs egumbini lokuhlanza lebanga eliyi-100.

Umdwebo onemininingwane