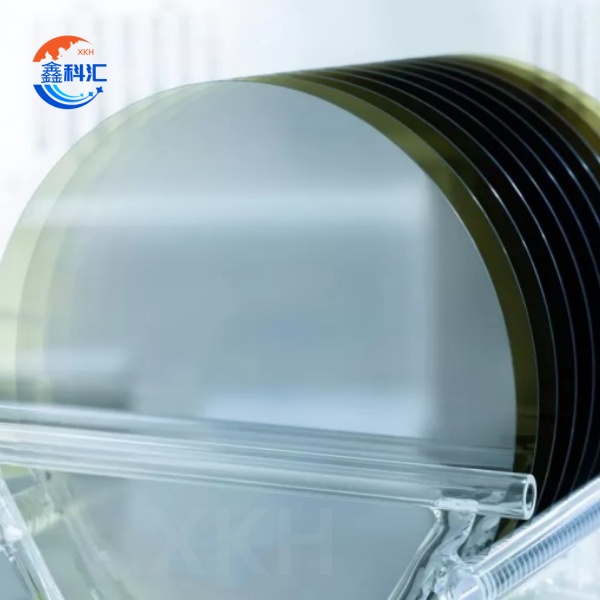

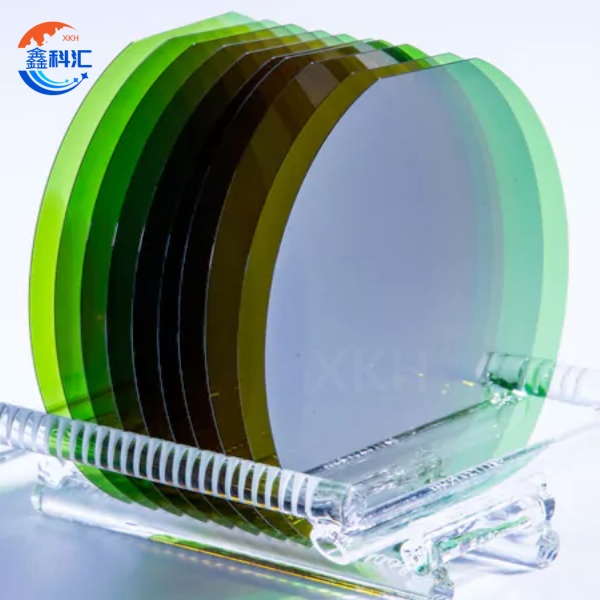

I-12 intshi ye-SiC Substrate N Uhlobo Lwezicelo Ze-RF Ezinosayizi Omkhulu Osebenza Kakhulu

Imingcele yezobuchwepheshe

| I-12 inch Silicon Carbide (SiC) Ukucaciswa kweSubstrate | |||||

| Ibanga | Ukukhiqizwa kwe-ZeroMPD Ibanga(Z Grade) | Ukukhiqizwa Okujwayelekile Ibanga(P Grade) | Dummy Grade (D Grade) | ||

| Ububanzi | 3 0 0 mm ~ 1305mm | ||||

| Ubukhulu | 4H-N | 750μm±15 μm | 750μm±25 μm | ||

| 4H-SI | 750μm±15 μm | 750μm±25 μm | |||

| I-Wafer Orientation | Ku-axis evaliwe : 4.0° kuya ku-<1120 >±0.5° ku-4H-N, Ku-eksisi : <0001>±0.5° ku-4H-SI | ||||

| I-Micropipe Density | 4H-N | ≤0.4cm-2 | ≤4cm-2 | ≤25cm-2 | |

| 4H-SI | ≤5cm-2 | ≤10cm-2 | ≤25cm-2 | ||

| Ukungazweli | 4H-N | 0.015~0.024 Ω·cm | 0.015~0.028 Ω·cm | ||

| 4H-SI | ≥1E10 Ω·cm | ≥1E5 Ω·cm | |||

| Isisekelo se-Flat Orientation | {10-10} ±5.0° | ||||

| Ubude Befulethi obuyisisekelo | 4H-N | N/A | |||

| 4H-SI | Inothi | ||||

| Ukukhishwa komkhawulo | 3 mm | ||||

| LTV/TTV/Bow/Warp | ≤5μm/≤15μm/≤35 μm/≤55 μm | ≤5μm/≤15μm/≤35 □ μm/≤55 □ μm | |||

| Ubulukhuni | I-Polish Ra≤1 nm | ||||

| I-CMP Ra≤0.2 nm | I-Ra≤0.5 nm | ||||

| I-Edge Cracks By High Intensity Light I-Hex Plates Ngokukhanya Okunamandla Okuphezulu Izindawo ze-Polytype Ngokukhanya Okunamandla Okuphezulu I-Visual Carbon Inclusions I-Silicon Surface Scratches By High Intensity Light | Lutho Indawo eqoqiwe ≤0.05% Lutho Indawo eqoqiwe ≤0.05% Lutho | Ubude obuqongelelwayo ≤ 20 mm, ubude obubodwa≤2 mm Indawo eqoqiwe ≤0.1% Indawo eqoqiwe≤3% Indawo eqoqiwe ≤3% Ubude obuqongelelwayo≤1× ububanzi bewafa | |||

| Ama-Edge Chips Ngokukhanya Okunamandla Okuphezulu | Akukho okuvunyelwe ≥0.2mm ububanzi nokujula | 7 okuvunyelwe, ≤1 mm ngakunye | |||

| (TSD) Ukukhipha isikulufu sochungechunge | ≤500 cm-2 | N/A | |||

| (BPD) Ukususwa kwendiza okuyisisekelo | ≤1000 cm-2 | N/A | |||

| I-Silicon Surface Contamination By High Intensity Light | Lutho | ||||

| Ukupakisha | Ikhasethi elinesinkwa esilucwecwana noma Isitsha Esiyisinkwa Esikodwa | ||||

| Amanothi: | |||||

| 1 Imikhawulo yokukhubazeka isebenza kuyo yonke indawo eyiwafa ngaphandle kwendawo engabaliwe enqenqemeni. 2Ukuklwebheka kufanele kubhekwe ku-Si face kuphela. 3 Idatha yokususwa isuka kumawafa aqoshiwe e-KOH kuphela. | |||||

Izici Eziyinhloko

1. Inzuzo Yosayizi Omkhulu: I-substrate ye-SiC engu-12-intshi (i-12-inch silicon carbide substrate) inikeza indawo enkulu ye-wafer eyodwa, eyenza ama-chips amaningi akhiqizwe ngewafa ngayinye, ngaleyo ndlela kuncishiswe izindleko zokukhiqiza nokwandisa isivuno.

2. I-High-Performance Material: Ukumelana nezinga lokushisa eliphezulu kwe-silicon carbide namandla enkambu yokwephuka okuphezulu kwenza i-substrate engu-12-intshi ifaneleke kuhlelo lwamandla kagesi aphezulu kanye nama-high-frequency, njengama-EV inverters kanye nezinhlelo zokushaja ngokushesha.

3. Ukuvumelana Kokucubungula: Naphezu kobunzima obukhulu kanye nezinselele zokucubungula ze-SiC, i-substrate ye-SiC engu-12-intshi ifinyelela amaphutha angaphansi ngokusebenzisa amasu okusika athuthukisiwe nokupholisha, ukuthuthukisa isivuno sedivayisi.

4. Ukulawulwa Okushisayo Okuphezulu: Ngokusebenza okungcono kwe-thermal kunezinto ezisekelwe ku-silicon, i-substrate engu-12-intshi ibhekana ngokuphumelelayo nokuchithwa kokushisa kumadivayisi anamandla amakhulu, yandisa isikhathi sokuphila kwemishini.

Izicelo Eziyinhloko

1. Izimoto zikagesi: I-substrate ye-SiC engu-12 intshi (i-12-inch silicon carbide substrate) iyingxenye eyinhloko yezinhlelo zokushayela zikagesi zesizukulwane esilandelayo, evumela ama-inverters asebenza kahle kakhulu athuthukisa ububanzi futhi anciphise isikhathi sokushaja.

2. I-5G Base Stations: Ama-substrates e-SiC anosayizi omkhulu asekela amadivayisi we-RF anemvamisa ephezulu, ahlangabezana nezidingo zeziteshi eziyisisekelo ze-5G zamandla aphezulu nokulahlekelwa okuncane.

I-3.Impahla Yamandla Embonini: Ku-solar inverters namagridi ahlakaniphile, i-substrate engu-12-intshi ingakwazi ukumelana nama-voltage aphezulu kuyilapho inciphisa ukulahlekelwa kwamandla.

4.I-Consumer Electronics: Amashaja asheshayo esikhathi esizayo nezinto zikagesi zesikhungo sedatha zingasebenzisa ama-substrates e-SiC angu-12-intshi ukuze kuzuzwe usayizi ohlangene nokusebenza kahle okuphezulu.

Izinkonzo ze-XKH

Sisebenza ngokukhethekile ezinsizeni zokucubungula ezenziwe ngokwezifiso zama-substrates e-SiC angu-12-inch (12-inch silicon carbide substrates), okuhlanganisa:

1. Ukudayela nokupholisha: Ukonakala okuphansi, ukucutshungulwa kwe-substrate ephansi ehambisana nezimfuneko zekhasimende, okuqinisekisa ukusebenza okuzinzile kwedivayisi.

2. Ukusekelwa Kokukhula Kwe-Epitaxial: Izinsizakalo zekhwalithi ephezulu ze-epitaxial wafer ukusheshisa ukukhiqizwa kwama-chip.

3. I-Small-Batch Prototyping: Isekela ukuqinisekiswa kwe-R&D ezikhungweni zocwaningo namabhizinisi, kufinyezwe imijikelezo yentuthuko.

4. I-Technical Consulting: Izixazululo zokuphela-kuya-ekupheleni kusukela ekukhethweni kwezinto ezibonakalayo kuya ekucutshungulweni kokusebenza kahle, ukusiza amakhasimende ukunqoba izinselele zokucubungula i-SiC.

Kungakhathaliseki ukuthi okokukhiqiza ngobuningi noma ukwenza ngokwezifiso okukhethekile, izinsiza zethu ze-SiC substrate engu-12 intshi zihambisana nezidingo zephrojekthi yakho, zinika amandla intuthuko yezobuchwepheshe.