Isisetshenziswa Sokucwecwa Okuyisicwecwana se-4 Inch-12 Inch Sapphire/SiC/Si Wafers Processing

Isimiso Sokusebenza

Inqubo ye-wafer thinning isebenza ngezigaba ezintathu:

Ukugaya Okumahhadla: Isondo ledayimane (usayizi wegrit 200–500 μm) lisusa u-50–150 μm wempahla ngo-3000–5000 rpm ukuze unciphise ukujiya ngokushesha.

Ukugaya Kahle: Isondo elicolekile (usayizi wegrit 1–50 μm) lehlisa ukujiya libe ngu-20–50 μm ku-<1 μm/s ukuze kuncishiswe umonakalo ongaphansi komhlaba.

I-Polishing (CMP): I-chemical-mechanical slurry iqeda umonakalo osele, ukufeza u-Ra <0.1 nm.

Izinto Ezivumelanayo

I-Silicon (Si): Okujwayelekile kwamawafa e-CMOS, ancishiswe abe ngu-25 μm ekupakishweni kwe-3D.

I-Silicon Carbide (SiC): Idinga amasondo edayimane akhethekile (80% ukugxila kwedayimane) ukuze kuqine ukufudumala.

I-Sapphire (Al₂O₃): Izaciwe ibe ngu-50 μm ezinhlelweni zokusebenza ze-UV LED.

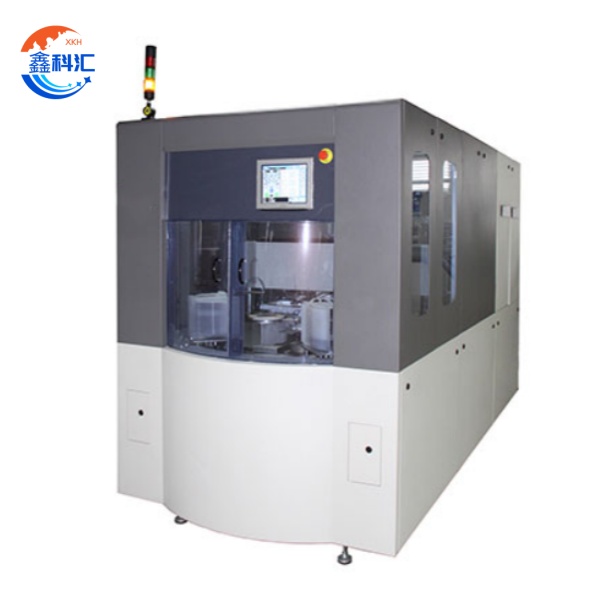

Izingxenye Zesistimu Eziyinhloko

1. Isistimu Yokugaya

I-Dual-Axis Grinder: Ihlanganisa ukugaya okuqinile/okucolile endaweni eyodwa, kunciphisa isikhathi somjikelezo ngo-40%.

I-Aerostatic Spindle: 0–6000 rpm ibanga lejubane elino-<0.5 μm ophumayo weradial.

2. I-Wafer Handling System

I-Vacuum Chuck: >50 N yokubamba amandla anokunemba kokuma okungu-±0.1 μm.

Ingalo yeRobhothi: Ithutha amawafa angama-4–12-intshi ngo-100 mm/s.

3. Isistimu yokulawula

I-Laser Interferometry: Ukuqapha ukujiya kwesikhathi sangempela (ukulungiswa 0.01 μm).

I-AI-Driven Feedforward: Ibikezela ukuguga kwamasondo futhi ilungise amapharamitha ngokuzenzakalelayo.

4. Ukupholisa nokuhlanza

I-Ultrasonic Cleaning: Isusa izinhlayiya >0.5 μm ngokusebenza kahle okungu-99.9%.

Amanzi Ahlanganisiwe: Apholisa iwafa ibe ngu-<5°C ngaphezu kwe-ambient.

Izinzuzo Eziyinhloko

1. Ukunemba Okuphezulu Okuphezulu: I-TTV (Isamba Sokuhlukahluka Kokuqina) <0.5 μm, WTW (Ukwehluka Kokuqina Kwangaphakathi Kwe-Wafer) <1 μm.

2. Ukuhlanganiswa Kwezinqubo Eziningi: Kuhlanganisa ukugaya, i-CMP, ne-plasma etching emshinini owodwa.

3. Ukuhambisana Kwezinto:

I-Silicon: Ukunciphisa ukuqina kusuka ku-775 μm kuya ku-25 μm.

I-SiC: Ifinyelela i-<2 μm TTV yezinhlelo zokusebenza ze-RF.

Ama-Doped Wafers: Amawafa e-Phosphorus-doped InP ane-<5% resistivity drift.

4. I-Smart Automation: Ukuhlanganiswa kwe-MES kunciphisa amaphutha abantu ngo-70%.

5. Ukusebenza kahle kwamandla: 30% ukusetshenziswa kwamandla okuphansi ngokubhuleka kabusha.

Izinhlelo zokusebenza ezibalulekile

1. Ukupakisha Okuthuthukile

• I-3D ICs: I-Wafer thinning inika amandla ukupakishwa okuqondile kwama-logic/memory chips (isb, izitaki ze-HBM), kufinyelelwe umkhawulokudonsa ongu-10× ophezulu kanye no-50% oncishisiwe wokusetshenziswa kwamandla uma kuqhathaniswa nezixazululo ze-2.5D. Izisetshenziswa zisekela i-hybrid bonding kanye nokuhlanganiswa kwe-TSV (Nge-Silicon Via), okubalulekile kuma-AI/ML processors adinga i-<10 μm interconnect pitch. Isibonelo, amawafa angu-12-intshi azacile abe ngu-25 μm avumela ukupakisha izendlalelo ezingu-8+ kuyilapho kugcinwa i-warpage engu-<1.5%, ibalulekile ezinhlelweni zezimoto ze-LiDAR.

• Iphakheji Ye-Fan-Out: Ngokunciphisa ukujiya kwe-wafer kuya ku-30 μm, ubude bokuxhuma bufushaniswa ngo-50%, kunciphisa ukulibaziseka kwesignali (<0.2 ps/mm) futhi kuvumela ama-chiplets angu-0.4 mm ama-ultra-thin kuma-SoCs eselula. Inqubo isekela ama-algorithms okugaya anxeshezelwe ukucindezelwa ukuze kuvinjwe i-warpage (>50 μm TTV control), iqinisekisa ukwethembeka ezinhlelweni ze-RF zemvamisa ephezulu.

2. Amandla kagesi

• Amamojula e-IGBT: Ukunciphisa ukuya ku-50 μm kunciphisa ukumelana nokushisa ku-<0.5°C/W, okwenza i-1200V SiC MOSFETs isebenze kumazinga okushisa okuhlanganisa angu-200°C. Okokusebenza kwethu kusebenzisa ukugaya okunezigaba eziningi(okumahhadla: 46 μm grit → inhlawulo: 4 μm grit) ukuze kuqedwe umonakalo ongaphansi komhlaba, ukufeza > imijikelezo engu-10,000 yokuthembeka kokuhamba ngebhayisikili. Lokhu kubalulekile kuma-inverter e-EV, lapho ama-SiC wafers angu-10 μm-thick athuthukisa isivinini sokushintsha ngo-30%.

• Amadivayisi Amandla e-GaN-on-SiC: Ukuncipha kwe-wafer kuya ku-80 μm kuthuthukisa ukuhamba kwe-electron (μ > 2000 cm²/V·s) kuma-650V GaN HEMTs, kunciphisa ukulahleka kokusebenza ngo-18%. Inqubo isebenzisa ukudayela okusizwa nge-laser ukuvikela ukuqhekeka ngesikhathi sokuncipha, ukuzuza u-<5 μm onqenqemeni wokuchipha izikhulisamandla ze-RF.

3. I-Optoelectronics

• Ama-LED e-GaN-on-SiC: Ama-substrates esafire angu-50 μm athuthukisa ukusebenza kahle kokukhipha ukukhanya (LEE) kuya ku-85% (vs. 65% kuma-wafers angu-150 μm) ngokunciphisa ukucupha ama-photon. Isilawuli se-TTV esiphansi kakhulu semishini yethu (<0.3 μm) siqinisekisa ukuphuma kwe-LED okufanayo kuwo wonke amawafa angama-intshi angu-12, okubalulekile kuzibonisi ze-Micro-LED ezidinga ukufana kwe-wavelength engu-<100nm.

• I-Silicon Photonics: Ama-silicon wafers angu-25μm-awugqinsi anika amandla ukulahlekelwa okusakazeka okuphansi okungu-3 dB/cm kuma-waveguides, kubalulekile kuma-transceivers optical angu-1.6 Tbps. Inqubo ihlanganisa ukushelela kwe-CMP ukuze kuncishiswe ukuhwalala komhlaba ku-Ra <0.1 nm, ithuthukise ukusebenza kahle kokuhlanganisa ngo-40%.

4. Izinzwa ze-MEMS

• Ama-Accelerometers: Amawafa e-silicon angu-25 μm afinyelela ku-SNR >85 dB (vs. 75 dB kuma-wafers angu-50 μm) ngokwandisa ukuzwela kobufakazi bokususwa kwendawo. Uhlelo lwethu lokugaya lwe-dual-eksisi lunxephezela ama-gradients engcindezi, luqinisekisa ukuthi ukuzwela okungu-<0.5% kukhukhuleka ngaphezu kokungu-40°C kuya ku-125°C. Izinhlelo zokusebenza zifaka ukutholwa kokuphahlazeka kwezimoto kanye nokulandelela ukunyakaza kwe-AR/VR.

• Izinzwa Zengcindezi: Ukuncipha kuye ku-40 μm kunika amandla ububanzi besilinganiso sebha engu-0–300no-<0.1% we-FS hysteresis. Isebenzisa i-bonding yesikhashana (abathwali bengilazi), inqubo igwema ukuqhekeka kwe-wafer ngesikhathi sokunamathisela ngemuva, ukufeza ukubekezelela ukucindezela ngokweqile okungu-<1 μm kwezinzwa ze-IoT zezimboni.

• I-Technical Synergy: Okokusebenza kwethu kokucwenga okuyisicwecwana kuhlanganisa ukugaya, i-CMP, kanye ne-plasma etching ukuze kubhekwane nezinselele zezinto ezihlukahlukene (Si, SiC, Sapphire). Isibonelo, i-GaN-on-SiC idinga ukugaya okuxubile (amasondo edayimane + i-plasma) ukuze ibhalansise ubulukhuni nokunwetshwa kokushisa, kuyilapho izinzwa ze-MEMS zifuna ubulukhuni obungaphezulu kwe-5 nm ngokupholisha i-CMP.

• Umthelela Wemboni: Ngokunika amandla amawafa azacile, asebenza kangcono, lobu buchwepheshe bushayela izinto ezintsha kuma-AI chips, amamojula we-5G mmWave, nezinto zikagesi eziguqukayo, ezinokubekezelelwa kwe-TTV <0.1 μm kwezibonisi ezigoqekayo kanye no-<0.5 μm wezinzwa ze-LiDAR zezimoto.

Izinkonzo ze-XKH

1. Izixazululo ezenziwe ngezifiso

Ukucushwa Okunwebekayo: Imiklamo yegumbi engu-4–12-intshi enokulayisha/ukulayishwa okuzenzakalelayo.

Ukusekelwa Kwe-Doping: Amaresiphi angokwezifiso amakristalu e-Er/Yb-doped namawafa e-InP/GaAs.

2. Ukusekela kokuphela-kuya-Ekupheleni

Ukuthuthukiswa Kwenqubo: Isivivinyo samahhala sisebenza ngokusebenza ngokugcwele.

Ukuqeqeshwa Kwembulunga yonke: Imihlangano yokucobelelana ngolwazi yezobuchwepheshe minyaka yonke mayelana nokugcinwa nokuxazulula izinkinga.

3. I-Multi-Material Processing

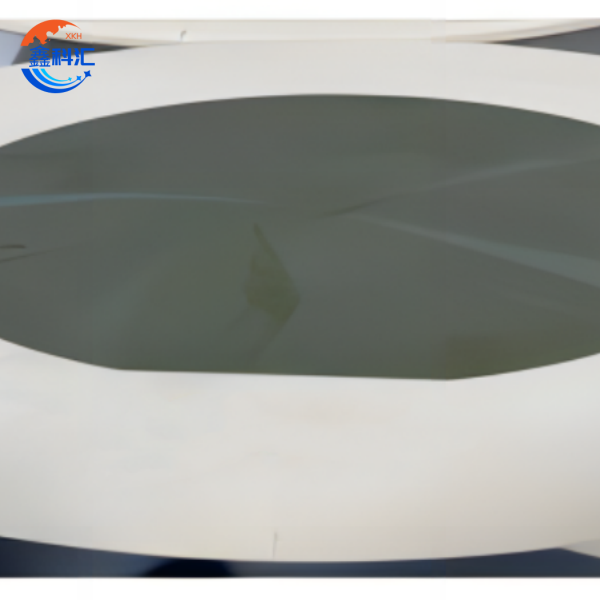

I-SiC: I-wafer izace ibe ngu-100 μm nge-Ra <0.1 nm.

Isafire: 50μm ukujiya amawindi UV laser (transmittance >92%@200 nm).

4. Amasevisi Engeziwe-Value

Izinto Ezisetshenziswayo: Amasondo edayimane (ama-wafers/impilo angu-2000+) kanye nama-slurries e-CMP.

Isiphetho

Lesi sixhobo sokunciphisa i-wafer siletha ukunemba okuhamba phambili embonini, ukuguquguquka kwezinto eziningi, kanye ne-smart automation, okuyenza ibaluleke kakhulu ekuhlanganisweni kwe-3D namandla kagesi. Izinsizakalo ezibanzi ze-XKH—kusukela ekwenzeni ngokwezifiso kuye kokwenziwa ngemva kokucubungula—ukuqinisekisa ukuthi amaklayenti afinyelela ukusebenza kahle kwezindleko nokusebenza kahle ekukhiqizeni ama-semiconductor.