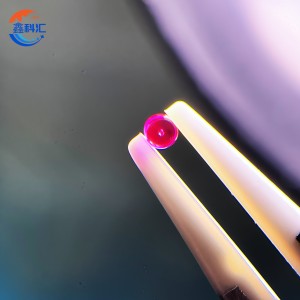

Nge-Hole Ruby Bearing

Umdwebo onemininingwane

Uhlolojikelele Lomkhiqizo

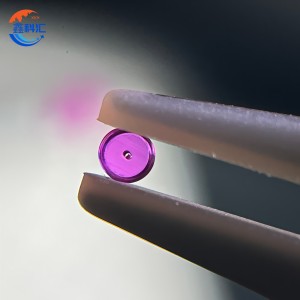

Amabheringi e-ruby embobo yizici ezakhiwe ngokunemba ezenziwe ngerubi yekristalu eyodwa (i-Al₂O₃ efakwe nge-Cr₂O₃). Lawa ma-bearings aklanywe ngesakhiwo esimaphakathi sembobo esivumela ama-shaft, izikhonkwane, noma imicu yokubona ukuthi idlule ngokushelela kuyilapho kunciphisa ukungqubuzana nokuguga. Ngenxa yokuqina okwedlulele kwe-ruby (i-Mohs 9), ukuzinza kwamakhemikhali okuvelele, kanye nokuqedwa okuhle kakhulu kwendawo, lawa ma-bheringi asetshenziswa kakhulu kumathuluzi anembayo, amadivaysi okulinganisa, ama-fiber optic assemblies, nezinhlelo ezincane zemishini lapho ukuzinza nokuphila isikhathi eside kubalulekile.

Impahla kanye nesakhiwo

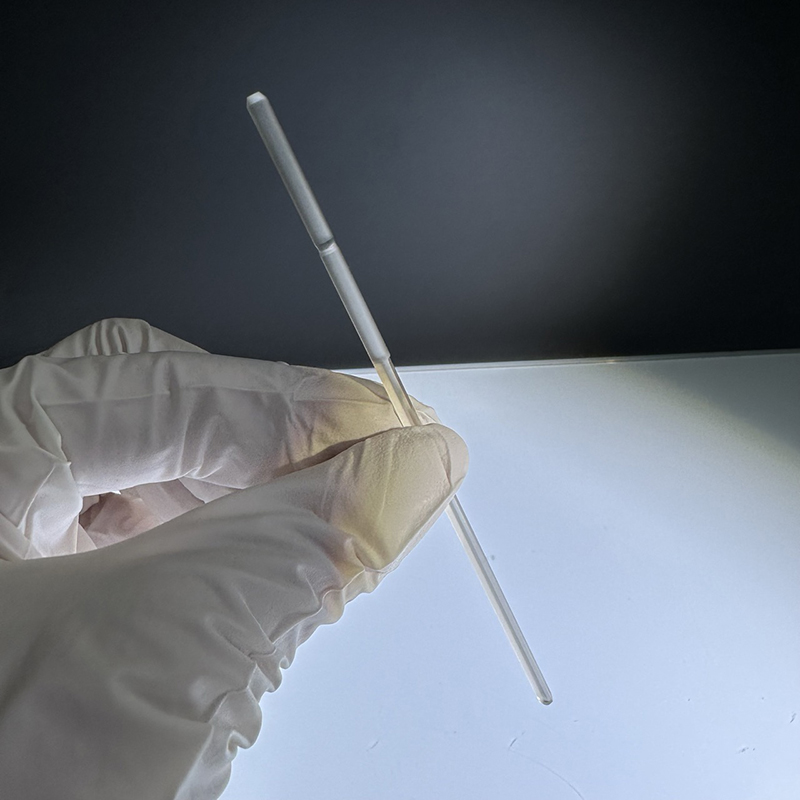

Umzimba othwele wenziwe nge-synthetic corundum crystal, ekhule ngaphansi kwezimo ezilawulwayo ukuze kuqinisekiswe ubulukhuni obufanayo nobumsulwa. I-Chromium doping inika okokusebenza umbala obomvu oyisici futhi yengeza ukucaca kokubona kanye nokumelana nokugqwala. Imbobo yomgodi yenziwe kahle futhi yapholishwa ukuze kuzuzwe ukunemba nobushelelezi bezinga le-micron, iqinisekisa ukubambisana okuhle kakhulu nokungqubuzana okuphansi ekunyakazeni okujikelezayo noma okuzuzisayo.

Amapharamitha ajwayelekile

| Ipharamitha | Inani |

|---|---|

| Okubalulekile | I-Synthetic Ruby (Al₂O₃ + trace Cr₂O₃) |

| Ukuqina | 9 esikalini se-Mohs |

| Ukuminyana | 3.98 g/cm³ |

| Izinga Lokushisa Lokusebenza | -60°C kuya ku-500°C |

| I-Bore Diameter | 0.05–5.0 mm (okuzenzakalelayo kuyatholakala) |

| Ububanzi bangaphandle | 0.5–10 mm |

| I-Roundness Tolerance | ≤ 0.0025 mm |

| I-Surface Qeda | I-Ra ≤ 0.02 μm |

Izici Zobuchwepheshe

Ukuqina Nokuzinza Okudlulele - Ikristalu ye-ruby imelana nokuguquka, ukuhuzuka, nokuhlaselwa kwamakhemikhali ngisho nasezindaweni zokusebenza ezinzima.

I-Precision Through-Hole Design - I-bore ngayinye iqedwa ngokupholishwa kwe-optical-grade ukunyakaza okubushelelezi kanye nokungqubuzana okuncane.

I-Corrosion and Wear Resistance - Ama-ruby bearings agcina ukusebenza kumswakama, izincibilikisi, nama-asidi ngaphandle kokuwohloka.

Ukunemba Okuhle Kakhulu Kwejiyomethri - Ukukhiqiza okulawulwa ngokuqinile kuqinisekisa ukuqondanisa okuphelele kwe-coaxial kanye nokujikeleza kokujikeleza okushelelayo.

Ukuthembeka Kwesikhathi Eside - Kusebenza iminyaka ngaphandle kokugcotshwa noma ukukhukhuleka okulinganayo, ilungele izinhlelo zokusebenza eziqhubekayo noma eziphindaphindayo.

Izinhlelo zokusebenza

Ama-ruby bearings asetshenziswa kaningi ku-:

-

Izinsimbi Zokukala Ngokunemba:Ama-Micrometer, amageji, namathuluzi e-metrology adinga ukunemba okungaguquki kokunyakaza.

-

I-Optical kanye ne-Laser Systems:Isebenza njengama-elementi aqondisayo nokubeka endaweni amafiber optical, amalensi, namadivayisi wokuqondanisa i-laser.

-

Amawashi nama-Miniature Motors:Inikeza amaphoyinti e-pivot angagugi kumashafu amancane azungezayo nama-ekseli.

-

Amadivayisi Ezokwelapha:Kusetshenziswa kumaphampu aketshezi, amasistimu okuxilonga, namayunithi okulawula ukugeleza lapho ukunemba komshini kubalulekile.

-

I-Aerospace kanye Nezisetshenziswa Zokuzulazula:Ukuqinisekisa ukuzinza nokunemba ezindleleni ezihlangene nezimelana nokudlidliza.

FAQ

I-Q1: Yini eyenza ama-ruby bearings afanele izinsimbi ezinembayo?

IMP: Ubulukhuni bazo, ukuzungeza, kanye ne-ultra-sherelende bore kunciphisa ukudlidliza nokungqubuzana, okubalulekile ekunyakazeni okunembile nokuzinzile kumishini yokulinganisa enembayo.

I-Q2: Zingasetshenziswa yini endaweni ye-vacuum noma ye-cleanroom?

A: Yebo. Ama-ruby bearings awanazo nhlobo izinto eziguquguqukayo futhi asebenza kahle ngaphandle kokugcotshwa, okuwenza alungele izindawo ze-vacuum noma ze-semiconductor.

I-Q3: Ingabe kukhona ukulinganiselwa kokusebenza kwe-shaft noma ukuqeda phezulu?

A: Ukuze usebenze kahle, ama-shafts enziwe ngensimbi engagqwali ephucuziwe, i-tungsten carbide, noma isafire ayanconywa ukuze kuncishiswe ukungqubuzana nokuguga.

Q4: Ngingakwazi ukucela usayizi we-bore ongajwayelekile noma ijometri yangaphandle?

A: Yebo. Sisekela amabheringi e-ruby enziwe ngokwezifiso ngokugcwele ngokuya ngemidwebo, okuhlanganisa ama-asymmetric bores, countersink, nemiklamo ye-flange.

I-Q5: I-ruby iqhathaniswa kanjani nesafire yokufaka izicelo?

A: Bobabili babelana ngezinhlaka zekristalu ezifanayo nobulukhuni, kodwa i-chromium doping ye-ruby ithuthukisa ukubonakala nokulandelela ukuguga, ikwenze kuthandeke kancane ukubhekwa ngomshini kanye nokuhlolwa kokubona.

Mayelana NATHI

I-XKH igxile ekuthuthukisweni kobuchwepheshe obuphezulu, ukukhiqiza, nokudayiswa kwengilazi ekhethekile yokubona nezinto ezintsha zekristalu. Imikhiqizo yethu isebenza ngogesi obonakalayo, ugesi wabathengi, kanye nezempi. Sinikezela ngezinto ezibonakalayo ze-Sapphire, izembozo zamalensi omakhalekhukhwini, i-Ceramics, i-LT, i-Silicon Carbide SIC, i-Quartz, namawafa ekristalu e-semiconductor. Ngobungcweti abanamakhono nemishini esezingeni eliphezulu, sihamba phambili ekucutshungulweni komkhiqizo okungajwayelekile, sihlose ukuba yibhizinisi elihamba phambili le-optoelectronic materials high-tech.