I-TGV Glass substrates 12inch wafer Glass punching

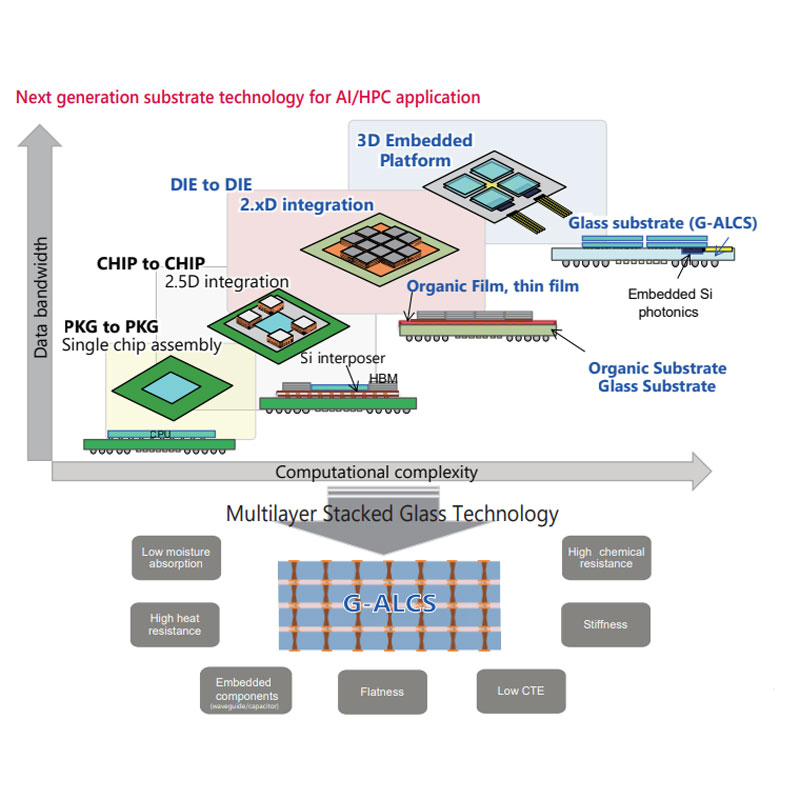

Ama-substrates engilazi asebenza kangcono ngokwezindawo ezishisayo, ukuzinza komzimba, futhi ayakwazi ukumelana nokushisa futhi awathambekele kakhulu ezinkingeni zokungqubuzana noma ukuwohloka ngenxa yamazinga okushisa aphezulu;

Ngaphezu kwalokho, izakhiwo eziyingqayizivele zikagesi ze-glass core zivumela ukulahlekelwa kwe-dielectric ephansi, okuvumela isignali ecacile kanye nokudluliswa kwamandla. Ngenxa yalokho, ukulahlekelwa amandla ngesikhathi sokudlulisa isignali kuyancipha futhi ukusebenza kahle okuphelele kwe-chip kukhushulwa ngokwemvelo. Ugqinsi lwe-glass core substrate lungancishiswa cishe ngesigamu uma kuqhathaniswa nepulasitiki ye-ABF, futhi ukuncishiswa kuthuthukisa isivinini sokudlulisa isignali nokusebenza kahle kwamandla.

Ubuchwepheshe bokwakha izimbobo be-TGV:

Indlela ye-laser etching etching isetshenziselwa ukunxenxa indawo eqhubekayo yokuguqula nge-laser pulsed, bese ingilazi ephathwa nge-laser ifakwa kusixazululo se-hydrofluoric acid ukuze sishuthwe. Izinga lokunamathisela lengilazi ye-denaturation zone ku-hydrofluoric acid liyashesha kunalelo lengilazi engafakwanga ukuze yakheke emigodini.

Gcwalisa i-TGV:

Okokuqala, kwenziwa izimbobo eziyimpumputhe ze-TGV. Okwesibili, ungqimba lwembewu lwafakwa ngaphakathi kwembobo eyimpumputhe ye-TGV nge- physical vapor deposition (PVD). Okwesithathu, i-electroplating ephansi phezulu ifinyelela ukugcwaliswa okungenamthungo kwe-TGV; Ekugcineni, ngokubopha okwesikhashana, ukugaya emuva, ukuchayeka kwekhopha ngamakhemikhali (CMP), ukuqaqa, ukwakha ipuleti lokudlulisa eligcwele insimbi ye-TGV.

Umdwebo onemininingwane