I-Soda-Lime Glass Substrates – Ukunemba Okupholishiwe futhi Kungabizi kakhulu Embonini yethu

Umdwebo onemininingwane

Uhlolojikelele lwe-Quartz Glass

I-Soda-lime substratesamawafa engilazi anembe enziwe ngengilazi ye-soda-lime silicate yezinga eliphezulu - into eguquguqukayo futhi eyongayo esetshenziswa kakhulu ezimbonini zokubuka, zikagesi, nezimboza. Eyaziwa ngokudluliswa kokukhanya okuhle kakhulu, ikhwalithi yendawo eyisicaba, nokuzinza kwemishini, ingilazi ye-soda-lime inikeza isisekelo esithembekile sokubekwa kwefilimu emincane ehlukahlukene, i-photolithography, nezicelo zaselabhorethri.

Ukusebenza kwayo okulinganiselwe ngokomzimba nokubonayo kuyenza ibe yinketho engokoqobo yazo zombili izindawo ze-R&D kanye nokukhiqizwa kwevolumu.

Izici Ezibalulekile Nezinzuzo

-

Ukucaca okuphezulu kwe-Optical:Ukudluliswa okukhethekile ku-spectrum ebonakalayo (400–800 nm), kulungele ukuhlolwa nokubonwayo.

-

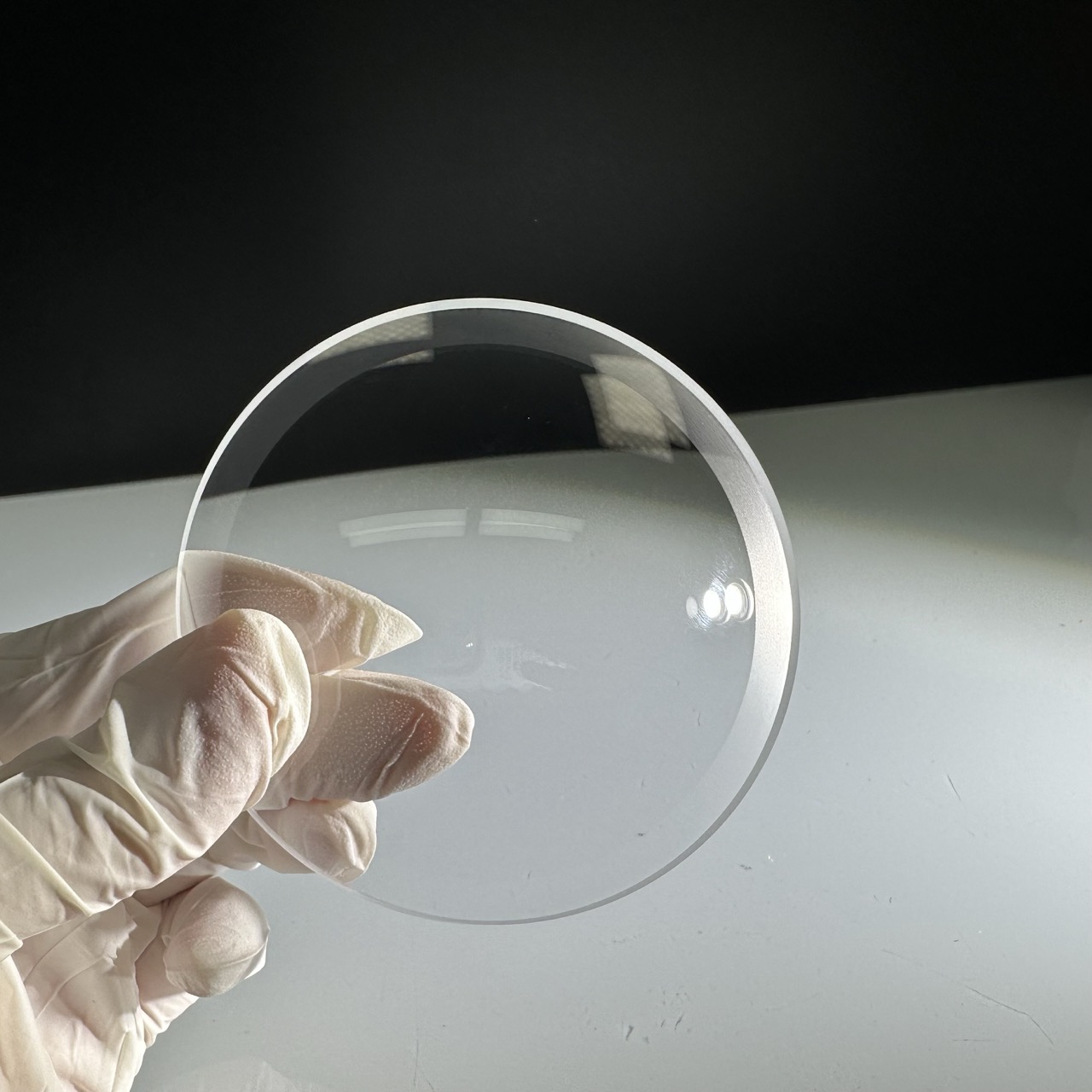

Indawo Epholile Ebushelelezi:Zombili izinhlangothi zingapholishwa kahle ukuze kuzuzwe ubulukhuni obusezingeni eliphansi (<2 nm), kuqinisekiswe ukunamathela okuhle kakhulu kokumbozwa.

-

Ukuzinza kweDimensional:Igcina ukucaba okungaguquki nokufana, kuhambisana nokuqondanisa okunembayo nokusetha kwe-metrology.

-

Impahla Ebiza Izindleko:Inikeza enye indlela enezindleko eziphansi ku-borosilicate noma i-silica substrates ehlanganisiwe yokusetshenziswa kwezinga lokushisa elijwayelekile.

-

Ukusebenziseka:Ukusikwa kalula, ukubhobolwa, noma ukulolongwa ngemiklamo yangokwezifiso ye-optical neye-elekthronikhi.

-

Ukuhambisana Kwekhemikhali:Ihambisana nama-photoresists, ama-adhesives, kanye nezinto eziningi zokubeka ifilimu emincane emincane (ITO, SiO₂, Al, Au).

Ngenhlanganisela yayo yokucaca, amandla, nokufinyeleleka,ingilazi ye-soda-limeihlala ingenye yezinto ezisetshenziswa kakhulu ze-substrate kumalabhorethri, ama-workshops optical, kanye nezindawo zokumboza ifilimu elincanyana.

Ukukhiqiza Nekhwalithi Yokuphezulu

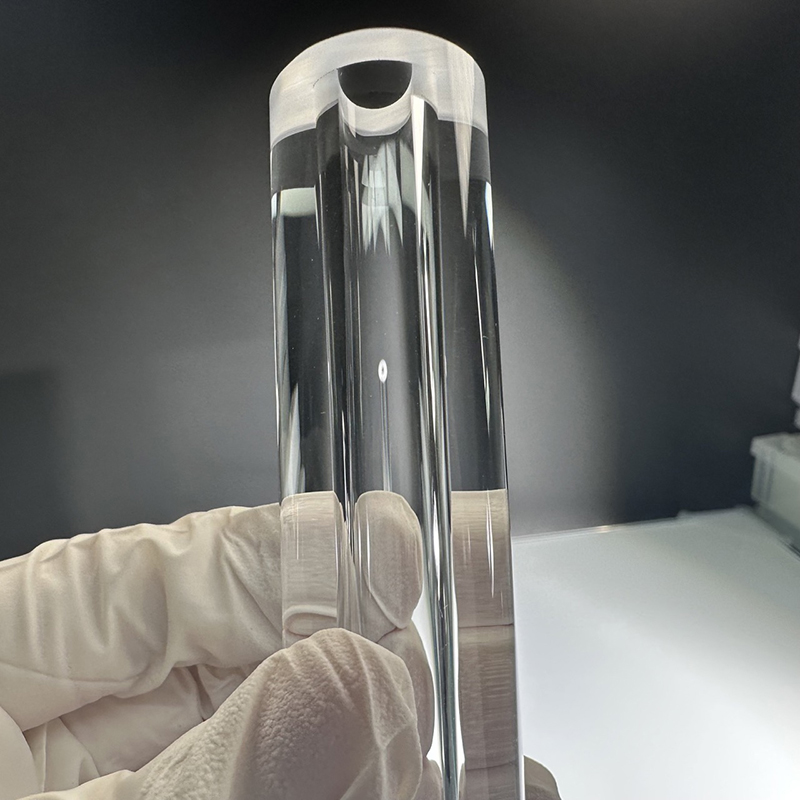

Ngamunyei-soda-lime substrateyakhiwe kusetshenziswa ingilazi entantayo yekhwalithi ephezulu enqunywa ngokunemba, ukugoqa, kanye nokupholishwa okukabili ukuze kuzuzwe indawo eyisicaba ekhanyayo.

Izinyathelo zokukhiqiza ezijwayelekile zihlanganisa:

-

Inqubo yokuntanta:Ikhiqiza amashidi engilazi ayi-ultra-flat, afanayo ngobuchwepheshe bokuntanta okuncibilikisiwe.

-

Ukusika nokubumba:Ukusika kwe-laser noma kwedayimane kube amafomethi e-substrate ayindilinga noma angama-rectangular.

-

Ukupholisha Kahle:Ukuthola ukucaba okuphezulu nokushelela kwe-optical-grade ohlangothini olulodwa noma zombili.

-

Ukuhlanza nokupakisha:Ukuhlanza nge-Ultrasonic emanzini angcolile, ukuhlolwa okungenazinhlayiya, kanye nokupakishwa kwegumbi elihlanzekile.

Lezi zinqubo ziqinisekisa ukungaguquguquki okuphakeme kanye nokuqedwa kwendawo efanele ukumbozwa kwe-optical noma umsebenzi we-microfabrication.

Izinhlelo zokusebenza

I-Soda-lime substratesasetshenziswa kuhlelo olubanzi lwezinhlelo zokusebenza zesayensi, ze-optical, ne-semiconductor, okuhlanganisa:

-

I-Optical Windows & Mirrors:Amapuleti ayisisekelo okufakwa kwe-optical kanye nokwenza isihlungi.

-

I-Thin-Film Deposition:Ama-substrates enkampani yenethiwekhi afanelekile e-ITO, SiO₂, TiO₂, namafilimu ensimbi.

-

Ubuchwepheshe Bokubonisa:Isetshenziswa engilazini engemuva, ukuvikela isibonisi, namasampuli okulinganisa.

-

Ucwaningo lweSemiconductor:Abathwali bezindleko eziphansi noma amawafa okuhlola ezinqubweni ze-photolithography.

-

I-Laser & Sensor Platforms:Izinto ezisekelayo ezibonisa ngale zokuqondanisa kokubona kanye nokuhlolwa kwe-probe.

-

Ukusetshenziswa Kwezemfundo Nokuhlola:Isetshenziswa ngokujwayelekile kumalebhu wokuhlola, ukuhlanganisa, nokuhlanganisa.

Imininingwane Ejwayelekile

| Ipharamitha | Ukucaciswa |

|---|---|

| Okubalulekile | I-Soda-Lime Silicate Glass |

| Ububanzi | 2", 3", 4", 6", 8" (okwenziwe ngokwezifiso kuyatholakala) |

| Ubukhulu | 0.3–1.1 mm okujwayelekile |

| I-Surface Qeda | Ipholishwe kabili ohlangothini noma olupholishelwe ohlangothini olulodwa |

| Ukucaba | ≤15 µm |

| Ukuqina Kobuso (Ra) | <2 nm |

| Ukudluliswa | ≥90% (Ibanga elibonakalayo: 400–800 nm) |

| Ukuminyana | 2.5 g/cm³ |

| I-Coefficient of Thermal Expansion | ~9 × 10⁻⁶ /K |

| Ukuqina | ~6 Mohs |

| I-Refractive Index (nD) | ~1.52 |

FAQ

Q1: Yiziphi izisekelo ze-soda-lime ezivame ukusetshenziselwa?

A: Asetshenziswa njengezinto eziyisisekelo zokumboza ifilimu elincanyana, ukuhlolwa kwe-optical, ukuhlolwa kwe-photolithography, nokukhiqizwa kwamafasitela okukhanya ngenxa yokucaca nokucaba kwawo.

Q2: Ingabe ama-substrates e-soda-lime angamelana namazinga okushisa aphezulu?

A: Angasebenza aze afike ku-300°C. Ukuze uthole ukumelana nokushisa okuphezulu, kunconywa ama-borosilicate noma ama-silica substrates ahlanganisiwe.

I-Q3: Ingabe ama-substrates afanele ukubekwa kwe-coating?

A: Yebo, izindawo zazo ezibushelelezi nezihlanzekile zilungele ukubekelwa umhwamuko obonakalayo (PVD), i-chemical vapor deposition (CVD), kanye nezinqubo zokufafaza.

Q4: Ingabe ukwenza ngokwezifiso kungenzeka?

A: Nakanjani. Osayizi bangokwezifiso, umumo, ubukhulu, kanye nokuqedwa konqenqema kuyatholakala ngokusekelwe ezidingweni ezithile zohlelo lokusebenza.

Q5: Ziqhathaniswa kanjani nama-borosilicate substrates?

A: Ingilazi ye-Soda-lime iyonga kakhulu futhi kulula ukuyicubungula kodwa inokumelana okuphansi kancane kokushisa namakhemikhali uma kuqhathaniswa nengilazi ye-borosilicate.

Mayelana NATHI

I-XKH igxile ekuthuthukisweni kobuchwepheshe obuphezulu, ukukhiqiza, nokudayiswa kwengilazi ekhethekile yokubona nezinto ezintsha zekristalu. Imikhiqizo yethu isebenza ngogesi obonakalayo, ugesi wabathengi, kanye nezempi. Sinikezela ngezinto ezibonakalayo ze-Sapphire, izembozo zamalensi omakhalekhukhwini, i-Ceramics, i-LT, i-Silicon Carbide SIC, i-Quartz, namawafa ekristalu e-semiconductor. Ngobungcweti abanamakhono nemishini esezingeni eliphezulu, sihamba phambili ekucutshungulweni komkhiqizo okungajwayelekile, sihlose ukuba yibhizinisi elihamba phambili le-optoelectronic materials high-tech.