Umshini wokubhoboza wetafula elincane we-laser 1000W-6000W ubuncane bembobo obungu-0.1MM ungasetshenziselwa izinto zokwakha zengilazi zensimbi

Izinto ezisetshenziswayo

1. Izinto zensimbi: njenge-aluminium, ithusi, i-titanium alloy, insimbi engagqwali, njll.

2. Izinto ezingezona ezensimbi: njengepulasitiki (okuhlanganisa i-polyethylene PE, i-polypropylene PP, i-polyester PET namanye amafilimu epulasitiki), ingilazi (kuhlanganise nengilazi evamile, ingilazi ekhethekile njengengilazi emhlophe kakhulu, ingilazi ye-K9, ingilazi ephezulu ye-borosilicate, ingilazi ye-quartz, njll. ku.

3. Impahla eyinhlanganisela: yakhiwe ngezinto ezimbili noma ngaphezulu ezinezakhiwo ezihlukene kusetshenziswa izindlela ezibonakalayo noma zamakhemikhali, ezinezakhiwo ezinhle kakhulu ezihlanganisayo.

I-4.Izinto ezikhethekile: Ezindaweni ezithile, imishini yokubhoboza i-laser ingasetshenziswa futhi ukucubungula ezinye izinto ezikhethekile.

Imingcele yokucaciswa

| Igama | Idatha |

| Amandla e-Laser: | 1000W-6000W |

| Ukunemba kokusika: | ±0.03MM |

| Imbobo yenani elincane: | 0.1MM |

| Ubude bokusika: | 650MM×800MM |

| Ukunemba kwesikhundla: | ≤±0.008MM |

| Ukunemba okuphindaphindiwe: | 0.008MM |

| Igesi yokusika: | Umoya |

| Imodeli engashintshi: | I-pneumatic edge clamping, ukusekelwa kwe-fixture |

| Isistimu yokushayela: | I-Magnetic suspension linear motor |

| Ukusika ukujiya | 0.01MM-3MM |

Izinzuzo zobuchwepheshe

I-1.Ukugaya okusebenzayo: Ukusetshenziswa kwe-laser beam ephezulu yamandla ekucubunguleni okungathintana naye, ngokushesha, isekhondi elingu-1 ukuqedela ukucutshungulwa kwezimbobo ezincane.

I-2.Ukunemba okuphezulu: Ngokulawula ngokunembile amandla, imvamisa ye-pulse kanye nesimo sokugxila se-laser, ukusebenza kokumba ngokunemba kwe-micron kungafinyelelwa.

3. Okusebenza kakhulu: kungacubungula izinhlobonhlobo ze-brittle, okunzima ukucubungula kanye nezinto ezikhethekile, njengepulasitiki, irabha, insimbi (insimbi engagqwali, i-aluminium, ithusi, i-titanium alloy, njll.), ingilazi, izitsha zobumba nokunye.

4. Ukusebenza okuhlakaniphile: Umshini wokubhoboza nge-laser ufakwe uhlelo lokulawula izinombolo oluthuthukisiwe, oluhlakaniphe kakhulu futhi olulula ukuhlanganisa nomklamo osizwa yikhompyutha kanye nohlelo lokukhiqiza olusizwa ngekhompiyutha ukuze kuqashwe uhlelo olusheshayo kanye nokwenza kahle kokudlula okuyinkimbinkimbi kanye nendlela yokucubungula.

Izimo zokusebenza

I-1.Diversity: ingakwazi ukwenza izinhlobonhlobo zokucutshungulwa kwezimbobo eziyinkimbinkimbi, njengezimbobo eziyindilinga, izimbobo eziyisikwele, izimbobo ezinxantathu nezinye izimbobo ezimise okukhethekile.

I-2.Ikhwalithi ephezulu: Ikhwalithi yembobo iphezulu, unqenqema lubushelelezi, akukho umuzwa onzima, futhi ukuguqulwa kuncane.

I-3.I-Automation: Ingakwazi ukuqedela ukucubungula kwe-micro-hole ngosayizi ofanayo wokuvula kanye nokusabalalisa okufanayo ngesikhathi esisodwa, futhi isekela ukucutshungulwa kwemigodi yeqembu ngaphandle kokungenelela okwenziwa ngesandla.

Izici zemishini

■ Usayizi omncane wemishini, ukuxazulula inkinga yesikhala esincane.

■ Ukunemba okuphezulu, imbobo ephezulu ingafinyelela ku-0.005mm.

■ Imishini kulula ukuyisebenzisa futhi kulula ukuyisebenzisa.

■ Umthombo wokukhanya ungashintshwa ngokuya ngezinto ezahlukene, futhi ukuhambisana kunamandla.

■ Indawo encane ethinteke ekushiseni, i-oxidation encane ezungeze izimbobo.

Inkambu yohlelo lokusebenza

1. Imboni yezogesi

●Ukushaywa Kwebhodi Lesifunda Eliphrintiwe (PCB):

Ukwenza ama-microhole machining: Kusetshenziselwa ukwenza ama-microholes anobubanzi obungaphansi kuka-0.1mm ku-PCBS ukuze kuhlangatshezwane nezidingo zamabhodi we-high-density interconnect (HDI).

Izimbobo eziyizimpumputhe nezigqitshiwe: Ukwenza izimbobo eziyimpumputhe nezigqitshiwe kuma-PCBS anezingqimba eziningi ukuze kuthuthukiswe ukusebenza nokuhlanganiswa kwebhodi.

● Iphakheji ye-semiconductor:

Ukubhola kohlaka lomthofu: Izimbobo ezinembayo zenziwa ngomshini kuhlaka lokuhola lwe-semiconductor ukuze kuxhunywe i-chip kusekethe yangaphandle.

I-wafer cutting aid: Faka izimbobo ku-wafer ukusiza ezinqubweni ezilandelayo zokusika nokupakisha.

2. Imishini yokunemba

● Ukucutshungulwa kwezingxenye ezincane:

Ukumba igiya elinembayo: Ukukhanda izimbobo ezinemba okuphezulu kumagiya amancane ukuze uthole amasistimu okudlulisa anemba.

Ukubhola kwengxenye yenzwa: Ukucupha ama-microholes ezingxenyeni zenzwa ukuze kuthuthukiswe ukuzwela kanye nesivinini sokuphendula senzwa.

●Ukukhiqiza Isikhunta:

Imbobo yokupholisa isikhunta: Imbobo yokupholisa ngomshini ekubunjweni komjovo noma isikhunta se-die casting ukuze kuthuthukiswe ukusebenza kokukhipha ukushisa kwesikhunta.

Ukucutshungulwa kwe-vent: Ukwenza ama-vents amancane esibunjeni ukunciphisa ukonakala.

3. Imishini yezokwelapha

●Amathuluzi Okuhlinzwa Ahlaselayo Kancane:

Ukubhobozwa kwe-catheter: Ama-Microholes acutshungulwa kuma-catheter okuhlinza angavaleki kancane ukuze alethwe izidakamizwa noma akhiphe uketshezi.

Izingxenye ze-Endoscope: Izimbobo ezinembayo zenziwa ngomshini kulensi noma ikhanda lethuluzi le-endoscope ukuze kuthuthukiswe ukusebenza kwethuluzi.

●Isistimu yokulethwa kwezidakamizwa:

I-Microneedle array drilling: Ukukhanda ama-microholes esichibini sesidakamizwa noma amalungu e-microneedle ukuze ulawule izinga lokukhululwa kwezidakamizwa.

I-Biochip drilling: Ama-Microholes acutshungulwa kuma-biochips ukuze kutholakale isiko lamaseli noma ukutholwa.

4. Imishini yokubona

●Isixhumi se-Fiber optic:

I-Optical fibre end hole drilling: Ukwenza ama-microholes ekugcineni kobuso besixhumi esibonakalayo ukuthuthukisa ukusebenza kahle kokudluliswa kwesignali.

Ukwenziwa kwe-fiber array: Ukwenza izimbobo ezinemba okuphezulu kupuleti le-fiber array yokuxhumana okubonakalayo kweziteshi eziningi.

● Isihlungi esibonakalayo:

Ukubhoboza okokuhlunga: Ukwenza ama-microholes kusihlungi se-optical ukufeza ukukhethwa kobude obuthile obuthile.

I-Diffractive element machining: Ukwenza ama-microholes kuma-elementi e-optical e-diffractive ukuze kuhlukaniswe noma ukubunjwa kwe-laser beam.

5. Ukukhiqiza izimoto

●Isistimu yokujova amafutha:

Ukubhoboza komlomo womjovo: Kucutshungulwa izimbobo ezincane kubhobho lomjovo ukuze kuthuthukiswe umphumela we-athomu kaphethiloli futhi kuthuthukiswe ukusebenza kahle kokuvutha.

●Ukwenziwa kwezinzwa:

Ukubhobolwa kwenzwa yokucindezela: Ukwenza ama-microholes ku-diaphragm yenzwa yokucindezela ukuthuthukisa ukuzwela nokunemba kwenzwa.

●Ibhethri lamandla:

I-Battery pole chip drilling: Ukwenza ama-microholes ku-lithium battery pole chips ukuthuthukisa ukungena kwe-electrolyte kanye nokuthuthwa kwe-ion.

I-XKH inikezela ngezinsiza ezigcwele zokuma okukodwa kwama-perforators etafula amancane, okuhlanganisa kodwa kungagcini kulokhu: Ukubonisana ngokuthengisa okuphrofeshinali, ukwakheka kohlelo olwenziwe ngokwezifiso, ukuhlinzekwa kwemishini yekhwalithi ephezulu, ukufakwa okuhle nokugunyazwa, ukuqeqeshwa okunemininingwane yokusebenza, ukuze kuqinisekiswe ukuthi amakhasimende athola isipiliyoni sesevisi esisebenza kahle kakhulu, esinembile nesingenandaba nenqubo yokushaya.

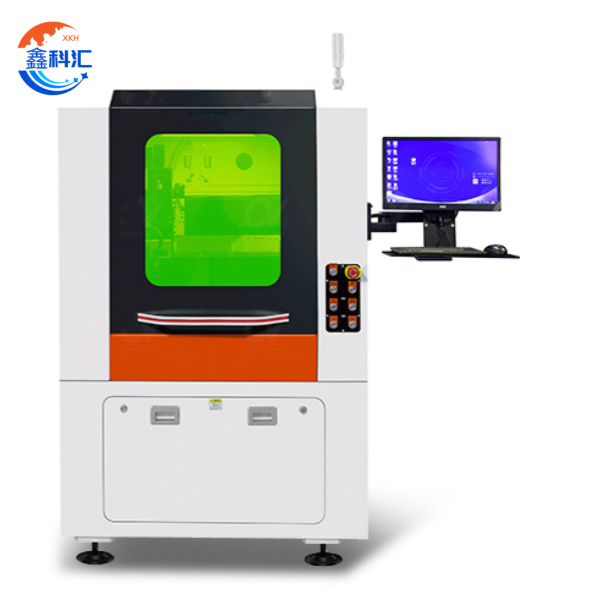

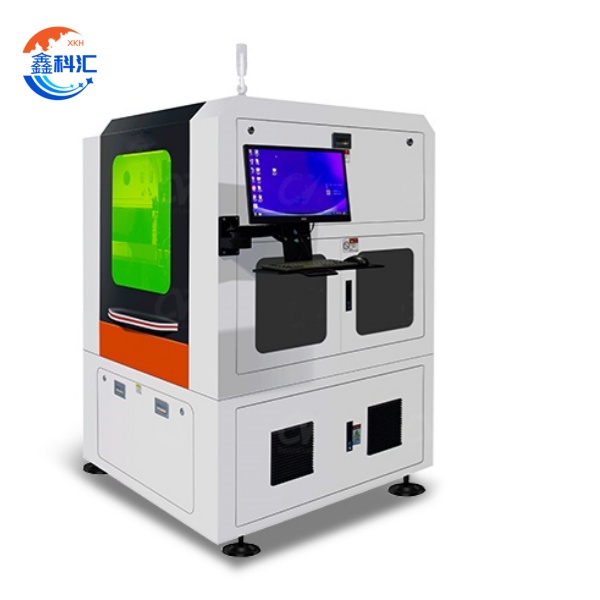

Umdwebo onemininingwane