SiO₂ Quartz Wafer Quartz Wafers SiO₂ MEMS Ithempelesha 2″ 3″ 4″ 6″ 8″ 12″

Umdwebo onemininingwane

Isingeniso

Amawafa e-quartz adlala indima ebalulekile ekuthuthukiseni izimboni ze-electronics, semiconductor, kanye ne-optics. Kutholwe kuma-smartphones aqondisa i-GPS yakho, ashumekwe eziteshini ezinemvamisa ephezulu enika amandla amanethiwekhi e-5G, futhi ahlanganiswe namathuluzi akhiqiza ama-microchip esizukulwane esilandelayo, amawafa e-quartz abalulekile. Lawa ma-substrates anobumsulwa obuphezulu anika amandla amasha kukho konke kusuka ku-quantum computing kuya kuma-photonics athuthukile. Naphezu kokuthi ethathwe kwelinye lamaminerali amaningi kakhulu emhlabeni, ama-wafer e-quartz akhiwe ngamazinga angavamile wokunemba nokusebenza.

Ayini ama-Quartz Wafers

Amawafa e-quartz azacile, amadiski ayindilinga adalwe ngekristalu ye-quartz yokwenziwa ye-ultra-pure. Atholakala ngobubanzi obujwayelekile obusuka kumayintshi angu-2 ukuya kwangu-12, amawafa e-quartz ngokuvamile ahluka ngogqinsi ukusuka ku-0.5 mm ukuya ku-6 mm. Ngokungafani ne-quartz yemvelo, eyenza amakristalu e-prismatic angajwayelekile, i-quartz yokwenziwa ikhuliswa ngaphansi kwezimo zelebhu elawulwa ngokuqinile, ikhiqiza izakhiwo zekristalu ezifanayo.

Ubucwebe bemvelo bamawafa e-quartz buhlinzeka ngokumelana kwamakhemikhali okungenakuqhathaniswa, ukubonakala kwe-optical, nokuzinza ngaphansi kwezinga lokushisa eliphezulu kanye nengcindezi yemishini. Lezi zici zenza amawafa e-quartz abe ingxenye eyisisekelo yamadivayisi anemba asetshenziswa ekudluliselweni kwedatha, inzwa, ikhompyutha, nobuchwepheshe obusekelwe nge-laser.

I-Quartz Wafer Specifications

| Uhlobo lwe-Quartz | 4 | 6 | 8 | 12 |

|---|---|---|---|---|

| Usayizi | ||||

| Ububanzi (intshi) | 4 | 6 | 8 | 12 |

| Ubukhulu (mm) | 0.05–2 | 0.25–5 | 0.3–5 | 0.4–5 |

| Ukubekezelela Ububanzi (intshi) | ±0.1 | ±0.1 | ±0.1 | ±0.1 |

| Ukubekezelela Ukuqina (mm) | Yenza ngokwezifiso | Yenza ngokwezifiso | Yenza ngokwezifiso | Yenza ngokwezifiso |

| I-Optical Properties | ||||

| I-Refractive Index @365 nm | 1.474698 | 1.474698 | 1.474698 | 1.474698 |

| I-Refractive Index @546.1 nm | 1.460243 | 1.460243 | 1.460243 | 1.460243 |

| I-Refractive Index @1014 nm | 1.450423 | 1.450423 | 1.450423 | 1.450423 |

| I-Transmittance Yangaphakathi (1250–1650 nm) | >99.9% | >99.9% | >99.9% | >99.9% |

| Isamba Sokudlulisa (1250–1650 nm) | >92% | >92% | >92% | >92% |

| Ikhwalithi Yomshini | ||||

| I-TTV (Total Thickness Variation, µm) | <3 | <3 | <3 | <3 |

| Ukucaba (µm) | ≤15 | ≤15 | ≤15 | ≤15 |

| Ukuqina Kobuso (nm) | ≤1 | ≤1 | ≤1 | ≤1 |

| Khothama (µm) | <5 | <5 | <5 | <5 |

| Izakhiwo Zomzimba | ||||

| Ukuminyana (g/cm³) | 2.20 | 2.20 | 2.20 | 2.20 |

| I-Young's Modulus (GPA) | 74.20 | 74.20 | 74.20 | 74.20 |

| Mohs Ukuqina | 6–7 | 6–7 | 6–7 | 6–7 |

| I-Shear Modulus (GPa) | 31.22 | 31.22 | 31.22 | 31.22 |

| Isilinganiso sikaPoisson | 0.17 | 0.17 | 0.17 | 0.17 |

| Amandla Acindezelayo (GPA) | 1.13 | 1.13 | 1.13 | 1.13 |

| Amandla Okuqina (MPa) | 49 | 49 | 49 | 49 |

| I-Dielectric Constant (1 MHz) | 3.75 | 3.75 | 3.75 | 3.75 |

| Izakhiwo ezishisayo | ||||

| I-Strain Point (10¹⁴.⁵ Pa·s) | 1000°C | 1000°C | 1000°C | 1000°C |

| I-Annealing Point (10¹³ Pa·s) | 1160°C | 1160°C | 1160°C | 1160°C |

| Iphoyinti Lokuthambisa (10⁷.⁶ Pa·s) | 1620°C | 1620°C | 1620°C | 1620°C |

Izicelo ze-Quartz Wafers

Ama-wafer e-quartz enziwe ngokwezifiso ukuze ahlangabezane nezicelo ezidingekayo kuzo zonke izimboni ezihlanganisa:

Ama-Electronics kanye namadivayisi e-RF

- Amawafa e-quartz awumongo kuma-quartz crystal resonators nama-oscillator ahlinzeka ngamasignali wewashi kuma-smartphones, amayunithi e-GPS, amakhompyutha, namadivayisi okuxhumana angenantambo.

- Ukunwebeka kwabo okushisayo okuphansi kanye ne-Q-factor ephezulu kwenza amawafa e-quartz alungele amasekethe esikhathi azinzile kanye nezihlungi ze-RF.

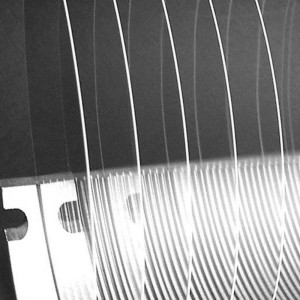

I-Optoelectronics kanye ne-Imaging

- Amawafa e-quartz anikezela ngokudluliswa kwe-UV ne-IR okuhle kakhulu, okuwenza alungele amalensi optical, ama-beam splitters, amafasitela e-laser, nezitholi.

- Ukumelana kwabo nemisebe kwenza ukusetshenziswa kwe-high-energy physics kanye nezinsimbi zasemkhathini.

I-Semiconductor kanye ne-MEMS

- Amawafa e-quartz asebenza njengama-substrates amasekhethi e-semiconductor anemvamisa ephezulu, ikakhulukazi ezinhlelweni ze-GaN ne-RF.

- Ku-MEMS (I-Micro-Electro-Mechanical Systems), ama-wafer e-quartz aguqula amasiginali omshini abe awagesi ngomphumela we-piezoelectric, evumela izinzwa ezifana nama-gyroscopes nama-accelerometer.

Ukukhiqiza Okuthuthukile namalebhu

- Ama-wafer e-quartz ahlanzekile asetshenziswa kakhulu kumalebhu amakhemikhali, e-biomedical, kanye ne-photonic kumaseli okukhanya, ama-UV cuvettes, kanye nokuphatha amasampula okushisa okuphezulu.

- Ukuhambisana kwazo nezindawo ezeqisayo kuzenza zilungele amakamelo e-plasma namathuluzi okubeka.

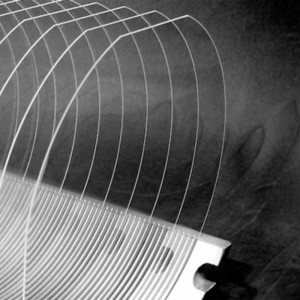

Indlela Ama-Quartz Wafers Enziwa Ngayo

Kunezindlela ezimbili zokukhiqiza eziyinhloko zamawafa e-quartz:

I-Quartz Wafers ehlanganisiwe

Amawafa e-quartz ahlanganisiwe enziwa ngokuncibilikisa ama-quartz granules engilazini e-amorphous, bese esika futhi epholisha ibhulokhi eliqinile libe amawafa amancane. Lawa mawafa e-quartz anikeza:

- Ukukhanya kwe-UV okukhethekile

- Ibanga elibanzi le-thermal yokusebenza (>1100°C)

- Ukumelana nokushaqeka okuhle kakhulu kwe-thermal

Zilungele imishini ye-lithography, izithando zokushisa eziphezulu, namafasitela optical kodwa azifanele izicelo ze-piezoelectric ngenxa yokuntuleka kwe-crystalline order.

Ama-Wafers e-Quartz akhiwe

Amawafa e-quartz akhiwe akhuliswa ngendlela yokwenziwa ukuze akhiqize amakristalu angenasici anomumo oqondile we-lattice. Lawa mawafa akhelwe izinhlelo zokusebenza ezidinga:

- Ama-engeli asikiwe ncamashi (X-, Y-, Z-, AT-cut, njll.)

- Ama-oscillator aphezulu kanye nezihlungi ze-SAW

- Ama-polarizer abonakalayo kanye namadivayisi athuthukile we-MEMS

Inqubo yokukhiqiza ibandakanya ukukhula kwembewu kuma-autoclave, okulandelwa ukusika, ukuma, ukuhlanganisa, nokupholisha.

Abahlinzeki be-Quartz Wafer Abahamba phambili

Abahlinzeki bomhlaba wonke abasebenza ngokunemba okuphezulu kwe-quartz wafers bafaka:

- Heraeus(Germany) - i-quartz ehlanganisiwe neyokwenziwa

- I-Shin-Etsu Quartz(Japan) – izixazululo ezicwecwe ezicwebezelayo

- I-WaferPro(USA) – amawafa equartz nobubanzi obubanzi

- Korth Kristalle(eJalimane) - amawafa amakristalu okwenziwa

Iqhaza Eliguqukayo Lama-Quartz Wafers

Ama-wafer e-quartz ayaqhubeka nokuvela njengezingxenye ezibalulekile ezindaweni zobuchwepheshe ezivelayo:

- I-Miniaturization- Ama-wafer e-quartz akhiwa ngokubekezelela okuqinile kokuhlanganiswa kwedivayisi ehlangene.

- Higher Frequency Electronics- Imiklamo emisha ye-quartz wafer ingena ezizindeni ze-mmWave ne-THz ze-6G ne-radar.

- I-Next-Gen Sensing- Ukusuka ezimotweni ezizimele kuye ku-IoT yezimboni, izinzwa ezisuselwa ku-quartz ziya zibaluleke kakhulu.

Imibuzo evame ukubuzwa mayelana namawafa e-quartz

1. Iyini iwafa yequartz?

I-wafer ye-quartz iyidiski elincane, eliyisicaba elenziwe nge-crystalline silicon dioxide (SiO₂), ngokuvamile elikhiqizwa ngamasayizi ajwayelekile we-semiconductor (isb., 2", 3", 4", 6", 8", noma 12"). Eyaziwa ngokuhlanzeka kwayo okuphezulu, ukuzinza kwe-thermal, kanye nokukhanyela kokubona, iwafa ye-quartz isetshenziswa njenge-substrate noma umthwali ezinhlelweni ezihlukene zokunemba okuphezulu ezifana nokwakhiwa kwe-semiconductor, amadivayisi we-MEMS, amasistimu optical, nezinqubo ze-vacuum.

2. Uyini umehluko phakathi kwejeli ye-quartz ne-silica?

I-Quartz iwuhlobo oluqinile lwe-crystalline lwe-silicon dioxide (SiO₂), kuyilapho i-silica gel iwuhlobo lwe-amorphous ne-porous ye-SiO₂, evame ukusetshenziswa njenge-desiccant ukuze imunce umswakama.

- I-Quartz iqinile, isobala, futhi isetshenziswa ezinhlelweni zikagesi, ezibonakalayo, nezimboni.

- Ijeli ye-silica ibonakala njengobuhlalu obuncane noma ama-granules futhi ngokuyinhloko isetshenziselwa ukulawula umswakama emaphaketheni, ezintweni zikagesi, nasekugcinweni.

3. Asetshenziselwa ini amakristalu e-quartz?

Amakristalu e-quartz asetshenziswa kakhulu kuma-electronics nakuma-optics ngenxa yezakhiwo zawo ze-piezoelectric (akhiqiza ukushaja kagesi ngaphansi kokucindezeleka komshini). Izicelo ezijwayelekile zifaka:

- Ama-oscillator nokulawula imvamisa(isb, amawashi e-quartz, amawashi, izilawuli ezincane)

- Izingxenye ze-Optical(isb, amalensi, amawaveplate, amafasitela)

- Ama-resonators nezihlungiku-RF namadivayisi wokuxhumana

- Izinzwaingcindezi, ukusheshisa, noma amandla

- Ukwakhiwa kwe-semiconductornjengama-substrates noma amawindi okucubungula

4. Kungani i-quartz isetshenziswa kuma-microchips?

I-Quartz isetshenziswa ezinhlelweni ezihlobene ne-microchip ngoba inikeza:

- Ukuzinza okushisayongesikhathi sezinqubo zezinga lokushisa eliphezulu njengokusabalalisa kanye nokukhipha isisu

- Ukufakwa kukagesingenxa yezakhiwo zayo ze-dielectric

- Ukumelana namakhemikhaliama-acids kanye nezincibilikisi ezisetshenziswa ekwenziweni kwe-semiconductor

- Ukunemba kwe-Dimensionalkanye nokunwetshwa okushisayo okuphansi kokuqondanisa okuthembekile kwe-lithography

- Nakuba i-quartz ngokwayo ingasetshenziswa njengento esebenzayo ye-semiconductor (njenge-silicon), idlala indima ebalulekile esekelayo endaweni yokwenziwa—ikakhulukazi ezithandweni, emakamelweni, nasezindaweni ezingaphansi ze-photomask.

Mayelana NATHI

I-XKH igxile ekuthuthukisweni kobuchwepheshe obuphezulu, ukukhiqiza, nokudayiswa kwengilazi ekhethekile yokubona nezinto ezintsha zekristalu. Imikhiqizo yethu isebenza ngogesi obonakalayo, ugesi wabathengi, kanye nezempi. Sinikezela ngezinto ezibonakalayo ze-Sapphire, izembozo zamalensi omakhalekhukhwini, i-Ceramics, i-LT, i-Silicon Carbide SIC, i-Quartz, namawafa ekristalu e-semiconductor. Ngobungcweti abanamakhono nemishini esezingeni eliphezulu, sihamba phambili ekucutshungulweni komkhiqizo okungajwayelekile, sihlose ukuba yibhizinisi elihamba phambili le-optoelectronic materials high-tech.