I-Crystal Silicon Wafer Si Substrate Eyodwa Uhlobo lwe-N/P Ongakukhetha lwe-Silicon Carbide Wafer

Ukusebenza okuhlukile kwe-monocrystal Silicon Wafer kubangelwa ubumsulwa bayo obuphezulu kanye nesakhiwo esinembene sekristalu. Lesi sakhiwo siqinisekisa ukufana nokuvumelana kwe-Silicon wafer, ngaleyo ndlela kuthuthukisa ukusebenza nokuthembeka kwamadivayisi. Ngaphansi kwezimo zokusebenza ezinzima, njengamazinga okushisa aphezulu, umswakama ophezulu, noma imisebe ephezulu, i-Si substrate iyakwazi ukugcina ukusebenza kwayo, iqinisekisa ukusebenza okuzinzile kwemishini kagesi ezindaweni ezimbi kakhulu.

Ngaphezu kwalokho, ukushisa okuphezulu kwe-Silicon wafer kuyenza ibe ukukhetha okuhle kwezicelo zamandla aphezulu. Ihambisa kahle ukushisa kude nedivayisi, ivimbele ukunqwabelana kokushisa nokuvikela idivayisi emonakalweni wokushisa, ngaleyo ndlela inwebe isikhathi sayo sokuphila. Emkhakheni wama-elekthronikhi wamandla, ukusetshenziswa kwe-Silicon wafer kungathuthukisa ukusebenza kahle kokuguqulwa, kunciphise ukulahleka kwamandla, futhi kuvumele ukuguqulwa kwamandla okusebenza kahle kakhulu.

Kumasekhethi ahlanganisiwe namamojula wamandla athuthukile, ukuzinza kwamakhemikhali we-Silicon wafer nakho kudlala indima ebalulekile. Ihlala izinzile ezindaweni ezonakalisa amakhemikhali, iqinisekisa ukwethembeka kwesikhathi eside kwamadivayisi. Ukwengeza, ukuhambisana kwe-Silicon wafer nezinqubo zokukhiqiza ze-semiconductor ezikhona kusiza ukuhlanganiswa nokukhiqizwa ngobuningi.

I-Silicon wafer yethu iyisinqumo esifanelekile sezinhlelo zokusebenza ezisebenza kahle ze-semiconductor. Ngekhwalithi yekristalu ehlukile, ukulawulwa kwekhwalithi okuqinile, izinsizakalo zokwenza ngokwezifiso, kanye nezinhlelo zokusebenza ezahlukahlukene, singahlela nokwenza ngokwezifiso ngokwezidingo zakho. Imibuzo yamukelekile!

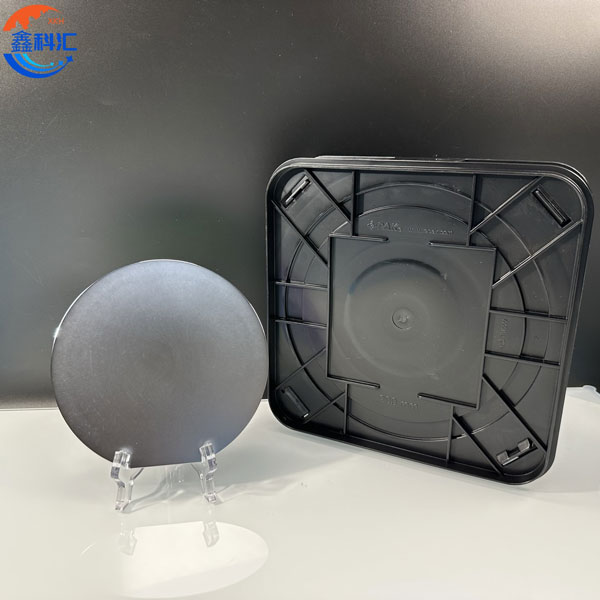

Umdwebo onemininingwane