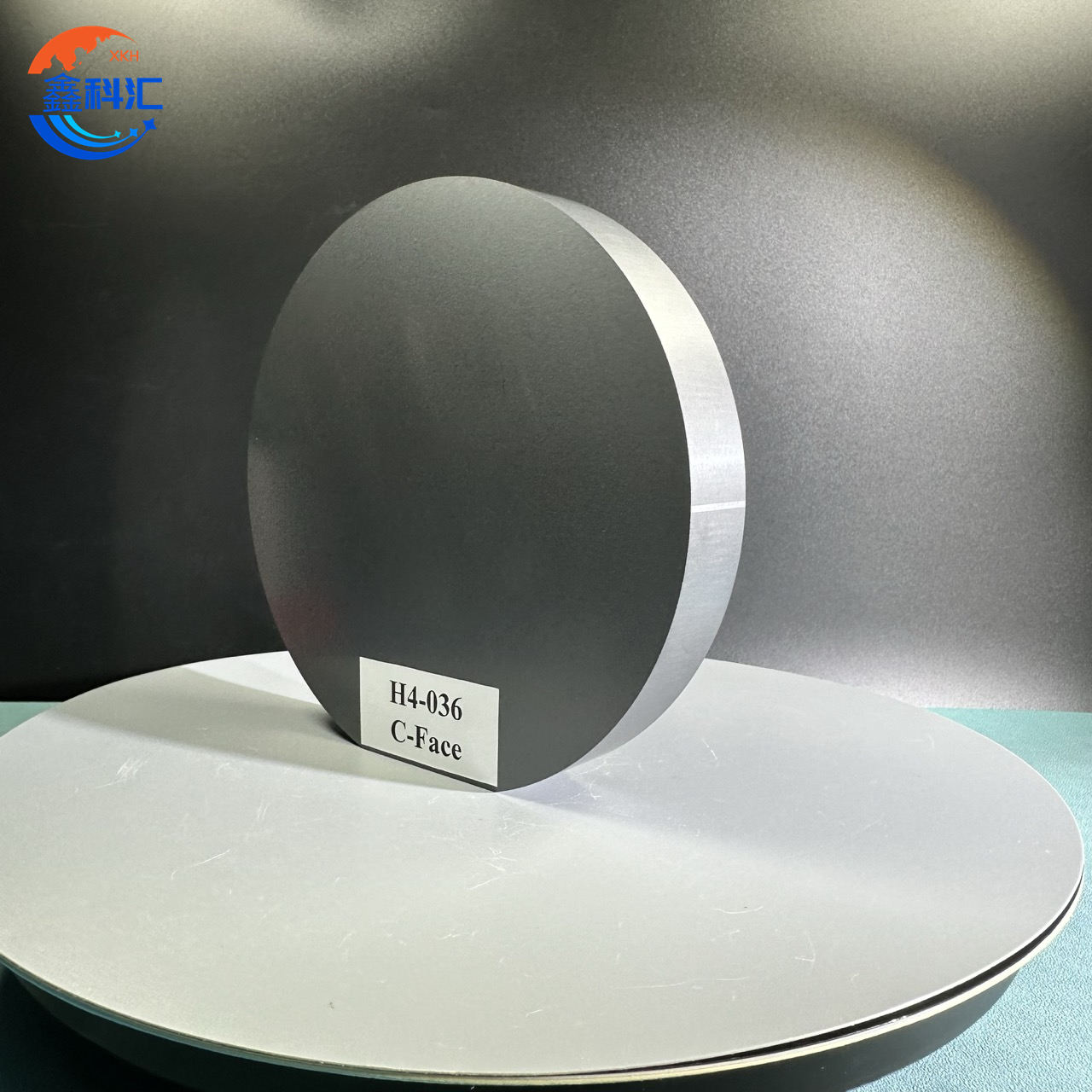

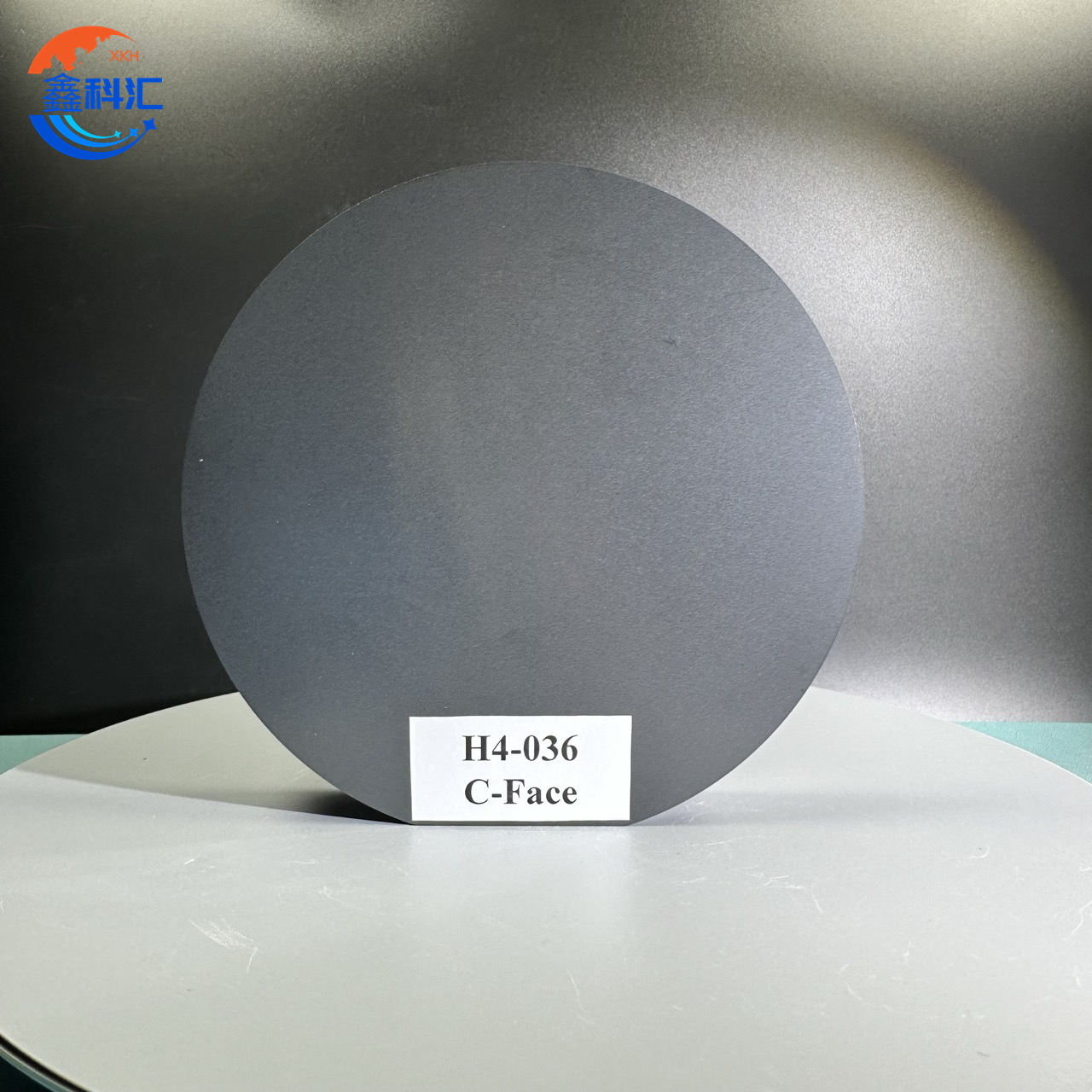

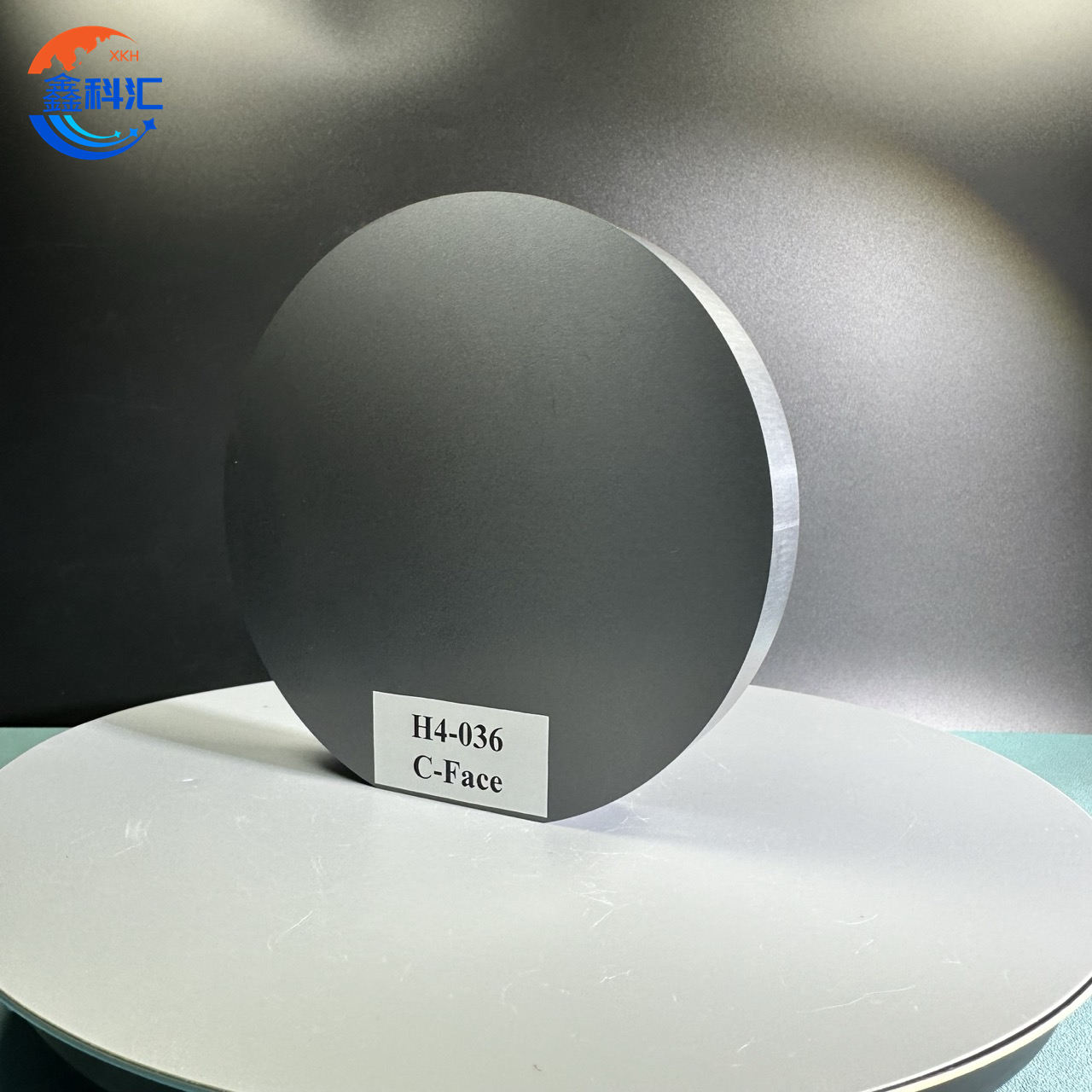

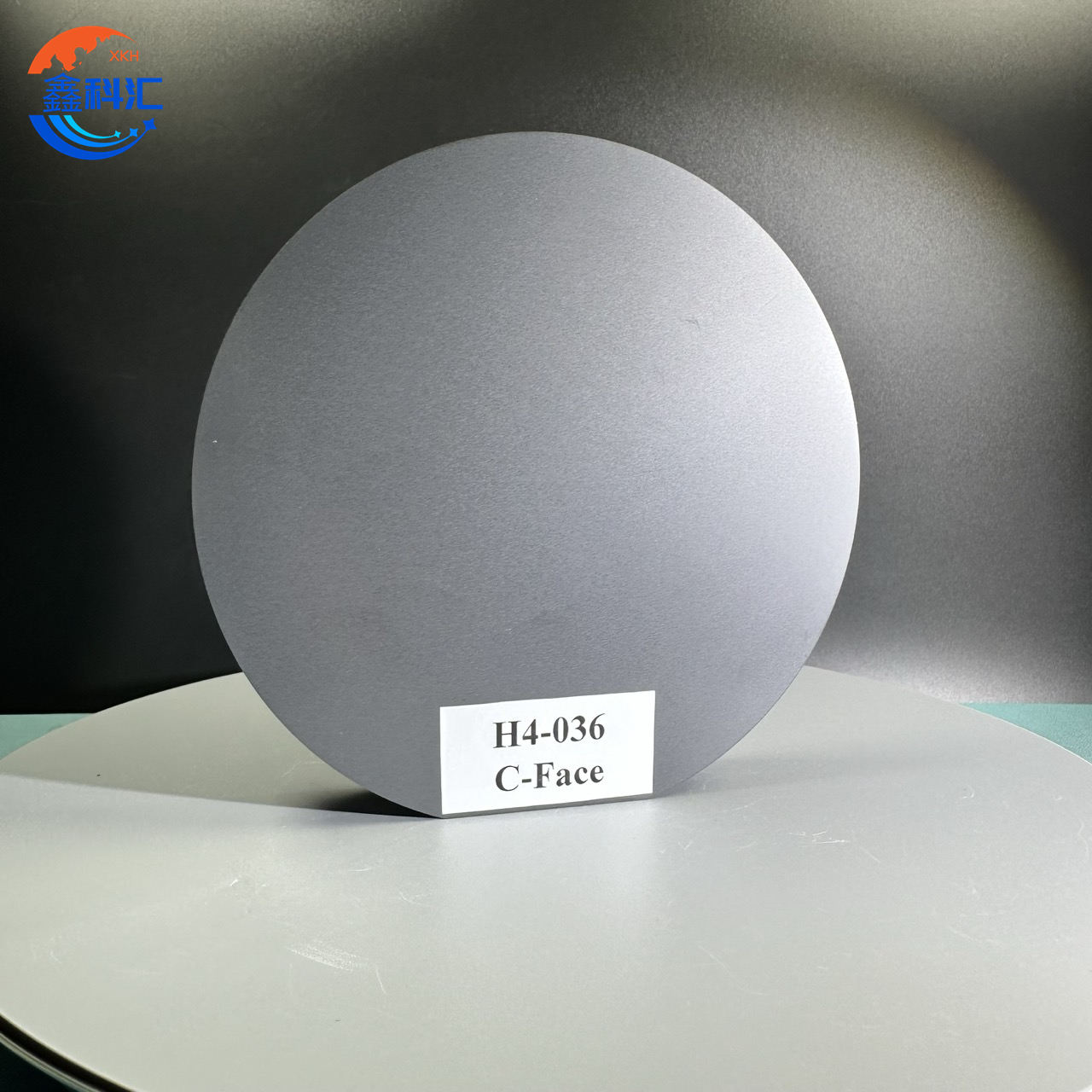

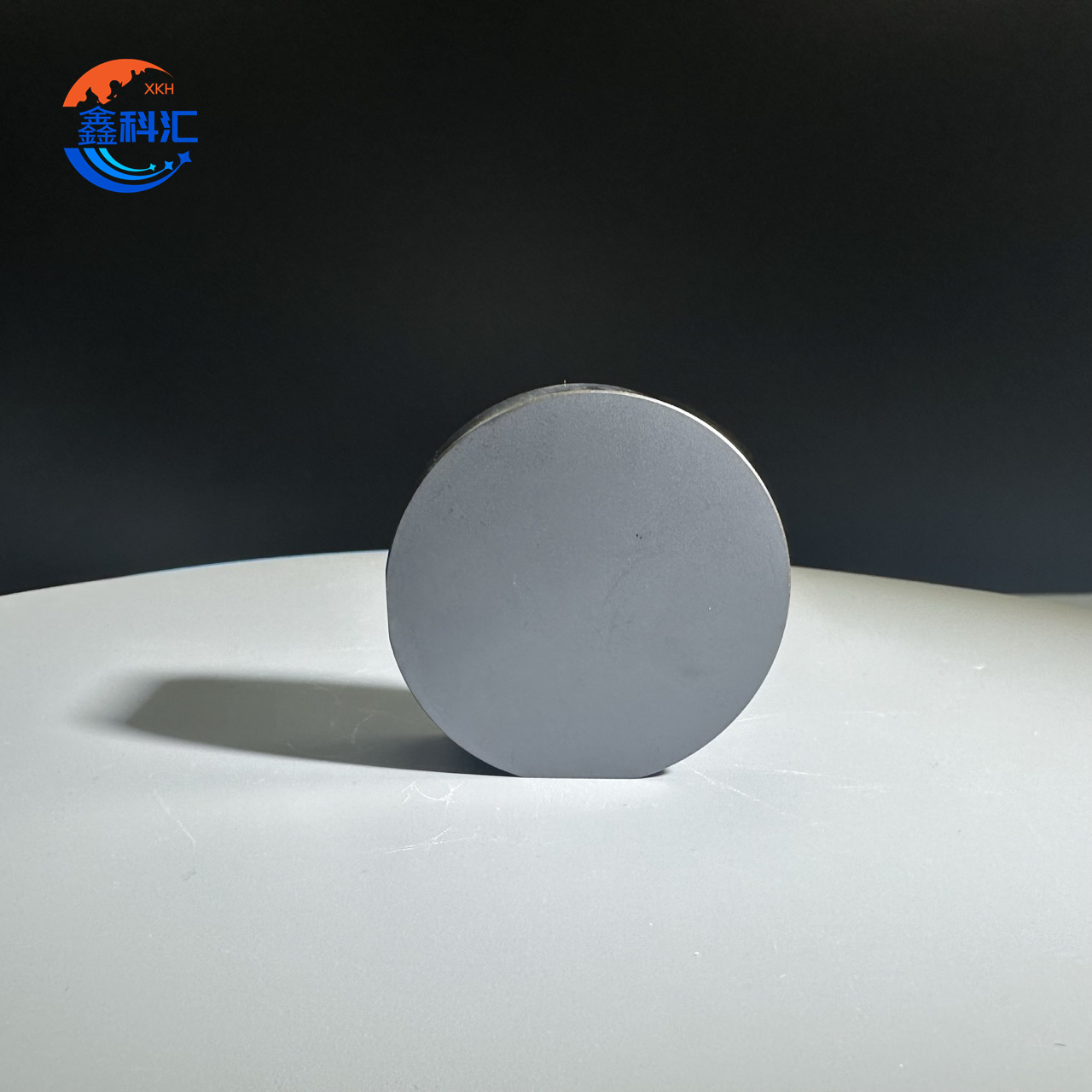

I-Silicon Carbide SiC Ingot engu-6inch N yohlobo lweDummy/ugqinsi lwebanga lokuqala lungenziwa ngokwezifiso

Izakhiwo

Ibanga: Ibanga Lokukhiqiza (I-Dummy/Prime)

Usayizi: 6-intshi ububanzi

Ububanzi: 150.25mm ± 0.25mm

Ubukhulu: > 10mm (Ukujiya okungenziwa ngokwezifiso kuyatholakala uma ucelwa)

I-Surface Orientation: 4° ukuya ku-<11-20> ± 0.2°, okuqinisekisa ikhwalithi yekristalu ephezulu nokuqondanisa okunembile kokwenziwa kwedivayisi.

I-Primary Flat Orientation: <1-100> ± 5°, isici esibalulekile sokusika okusebenzayo kwe-ingot ibe ama-wafers kanye nokukhula kwekristalu okuphelele.

Ubude Befulethi Eliyisisekelo: 47.5mm ± 1.5mm, yakhelwe ukuphatha kalula nokusika ngokunemba.

Ukumelana: 0.015–0.0285 Ω·cm, ilungele izinhlelo zokusebenza ezikumadivayisi asebenza kahle kakhulu amandla.

Ukuminyana Kwe-Micropipe: <0.5, iqinisekisa ukukhubazeka okuncane okungaba nomthelela ekusebenzeni kwamadivayisi akhiwe.

I-BPD (I-Boron Pitting Density): <2000, inani eliphansi elibonisa ubumsulwa bekristalu obuphezulu kanye nokuminyana kokukhubazeka okuphansi.

I-TSD (I-Threading Screw Dislocation Density): <500, iqinisekisa ubuqotho bezinto ezibonakalayo kumadivayisi asebenza kahle kakhulu.

Izindawo ze-Polytype: Azikho - ingot ayinazo iziphambeko ze-polytype, enikeza ikhwalithi yezinto ezibonakalayo eziphezulu zezinhlelo zokusebenza ezisezingeni eliphezulu.

Ama-Edge Indents: <3, anobubanzi nokujula okungu-1mm, okuqinisekisa ukulimala okuncane kwendawo kanye nokugcina ubuqotho be-ingot ukuze kusikeke i-wafer esebenza kahle.

Imifantu ye-Edge: 3, <1mm ngayinye, enezenzeko eziphansi zomonakalo onqenqemeni, iqinisekisa ukuphatha okuphephile kanye nokucutshungulwa okuqhubekayo.

Ukupakisha: Ikesi le-wafer - ingot ye-SiC ipakishwe ngokuvikelekile kukesi le-wafer ukuze kuqinisekiswe ukuthutha nokuphathwa okuphephile.

Izinhlelo zokusebenza

Amandla kagesi:Ingot ye-SiC engu-6 intshi isetshenziswa kakhulu ekukhiqizeni amandla kagesi njengama-MOSFET, ama-IGBT, nama-diode, okuyizingxenye ezibalulekile ezinhlelweni zokuguqula amandla. Lawa madivaysi asetshenziswa kakhulu kuma-inverter emoto kagesi (EV), amadrayivu ezimoto zezimboni, izinsiza zikagesi, nezinhlelo zokugcina amandla. Amandla e-SiC okusebenza ngama-voltage aphezulu, amaza aphezulu, kanye namazinga okushisa adlulele ayenza ilungele izinhlelo zokusebenza lapho amadivayisi e-silicon (Si) endabuko angadonsa kanzima ukuze asebenze kahle.

Izimoto zikagesi (EVs):Ezimotweni zikagesi, izingxenye ezisekelwe ku-SiC zibalulekile ekuthuthukisweni kwamamojula wamandla kuma-inverter, iziguquli ze-DC-DC, namashaja asebhodini. I-Thermal conductivity ephakeme ye-SiC ivumela ukukhiqizwa kokushisa okuncishisiwe nokusebenza kangcono ekuguquleni amandla, okubalulekile ekuthuthukiseni ukusebenza nokushayela uhla lwezimoto zikagesi. Ukwengeza, amadivayisi we-SiC anika amandla izingxenye ezincane, ezilula, nezithembekile, okunikela ekusebenzeni okuphelele kwezinhlelo ze-EV.

Amasistimu Amandla Avuselelekayo:Ama-SiC ingots ayinto ebalulekile ekuthuthukisweni kwamadivayisi okuguqula amandla asetshenziswa ezinhlelweni zamandla avuselelekayo, okuhlanganisa ama-solar inverters, izinjini zomoya, nezixazululo zokugcina amandla. Amandla aphezulu okubamba amandla e-SiC nokuphatha okushisayo okusebenzayo kuvumela ukuguqulwa kwamandla okusebenza kahle nokuthembeka okuthuthukisiwe kulezi zinhlelo. Ukusetshenziswa kwawo emandleni avuselelekayo kusiza ukuqhubela phambili imizamo yomhlaba wonke ekusimamiseni amandla.

Ezokuxhumana:Ingot ye-SiC engu-6 intshi iphinde ilungele ukukhiqiza izingxenye ezisetshenziswa ezinhlelweni zokusebenza ze-RF (ifrikhwensi yomsakazo). Lokhu kuhlanganisa ama-amplifiers, ama-oscillator, nezihlungi ezisetshenziswa kwezokuxhumana ngocingo nasezinhlelweni zokuxhumana ngesathelayithi. Ikhono le-SiC lokusingatha amaza aphezulu namandla aphezulu liyenza into enhle kakhulu yamadivayisi ezokuxhumana adinga ukusebenza okuqinile nokulahlekelwa kwesignali okuncane.

I-Aerospace nokuvikela:I-voltage ephezulu yokuwohloka kwe-SiC kanye nokumelana nezinga lokushisa eliphezulu kuyenza ilungele ukusetshenziswa kwe-aerospace nokuvikela. Izingxenye ezenziwe ngama-ingots e-SiC zisetshenziswa ezinhlelweni ze-radar, ezokuxhumana ngesathelayithi, namandla kagesi ezindizeni nasemkhathini. Izinto ezisekelwe ku-SiC zenza izinhlelo ze-aerospace zisebenze ngaphansi kwezimo ezimbi kakhulu ezihlangatshezwana nazo emkhathini nasezindaweni eziphakeme kakhulu.

I-Industrial Automation:Ku-automation yezimboni, izingxenye ze-SiC zisetshenziswa kuzinzwa, ama-actuator, nezinhlelo zokulawula ezidinga ukusebenza ezindaweni ezinokhahlo. Amadivayisi asekelwe ku-SiC asetshenziswa emishinini edinga izingxenye ezisebenza kahle, ezihlala isikhathi eside ezikwazi ukumelana namazinga okushisa aphezulu kanye nengcindezi kagesi.

Ithebula Lokucaciswa Komkhiqizo

| Impahla | Ukucaciswa |

| Ibanga | Ukukhiqiza (I-Dummy/Prime) |

| Usayizi | 6-intshi |

| Ububanzi | 150.25mm ± 0.25mm |

| Ubukhulu | >10mm (Kungenziwa ngokwezifiso) |

| I-Surface Orientation | 4° ukuya ku-<11-20> ± 0.2° |

| Isisekelo se-Flat Orientation | <1-100> ± 5° |

| Ubude Befulethi obuyisisekelo | 47.5mm ± 1.5mm |

| Ukungazweli | 0.015–0.0285 Ω·cm |

| I-Micropipe Density | <0.5 |

| I-Boron Pitting Density (BPD) | <2000 |

| I-Threading Screw Dislocation Density (TSD) | <500 |

| Izindawo ze-Polytype | Lutho |

| Ama-Edge ama-Indents | <3, 1mm ububanzi nokujula |

| Ama-Edge Cracks | 3, <1mm/ea |

| Ukupakisha | Ikesi le-wafer |

Isiphetho

I-SiC Ingot engu-6-intshi - N-type Dummy/Prime grade iwumsebenzi we-premium ohlangabezana nezidingo eziqinile zemboni ye-semiconductor. I-thermal conductivity ephezulu, ukumelana okukhethekile, kanye nokuminyana kokukhubazeka okuphansi kuyenza ibe ukukhetha okuhle kakhulu ekukhiqizeni izinto ezithuthukisiwe ze-elekthronikhi, izingxenye zezimoto, amasistimu ezokuxhumana, kanye nezinhlelo zamandla avuselelekayo. Ukujiya okwenziwa ngendlela oyifisayo nokucaciswa okunembayo kuqinisekisa ukuthi le SiC ingot ingalungiselelwa uhla olubanzi lwezinhlelo zokusebenza, iqinisekise ukusebenza okuphezulu nokuthembeka ezindaweni ezidinga kakhulu. Ukuze uthole ulwazi olwengeziwe noma ukufaka i-oda, sicela uxhumane nethimba lethu labadayisi.

Umdwebo onemininingwane