I-Silicon Carbide SiC Ceramic Fork Ingalo/Isandla Sezinhlelo Zokuphatha Ezibucayi

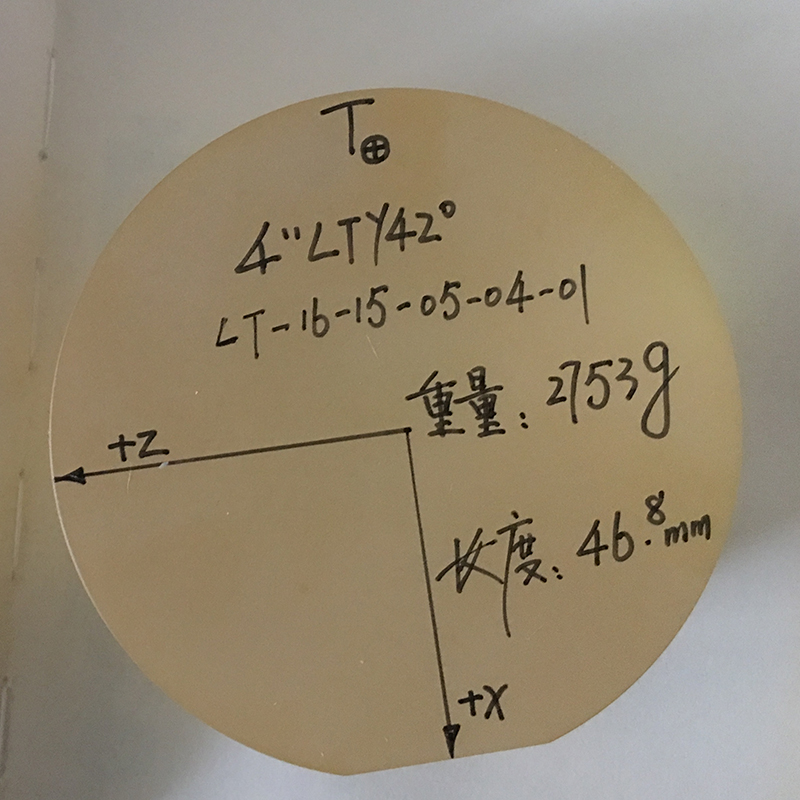

Umdwebo onemininingwane

Ukwethulwa kweSilicon Carbide Ceramic Fork Arm/Hand

II-Silicon Carbide Ceramic Fork Ingalo/Isandlaiyingxenye esezingeni eliphezulu eyenzelwe i-automation yezimboni ethuthukisiwe, ukucutshungulwa kwe-semiconductor, kanye nezindawo ezihlanzeke kakhulu. Isakhiwo sayo esinemfoloko esihlukile kanye nendawo ye-ceramic eyi-ultra-flat iyenza ilungele ukuphatha ama-substrates athambile, okuhlanganisa amawafa e-silicon, amaphaneli engilazi, namadivayisi abonakalayo. Iklanywe ngokunemba futhi yakhiwe nge-silicon carbide ehlanzekile, i-I-Silicon Carbide Ceramic Fork Ingalo/Isandlainikeza amandla angenakuqhathaniswa emishini, ukwethembeka kokushisayo, nokulawula ukungcoliswa.

Ngokungafani nezingalo ezivamile zensimbi noma zepulasitiki, iI-Silicon Carbide Ceramic Fork Ingalo/Isandlailetha ukusebenza okuzinzile ezimweni ezishisayo, zamakhemikhali, kanye ne-vacuum. Kungakhathaliseki ukuthi isebenza kugumbi lokuhlanza Lekilasi 1 noma ngaphakathi kwegumbi le-plasma elinevacuum ephezulu, le ngxenye iqinisekisa ukuthuthwa okuphephile, okuphumelelayo, nokungenazinsalela kwezingxenye ezibalulekile.

Ngesakhiwo esiklanyelwe izingalo zerobhothi, izibambi ze-wafer, namathuluzi okudlulisa azenzakalelayo, iI-Silicon Carbide Ceramic Fork Ingalo/Isandlaiwukuthuthukiswa okuhlakaniphile kwanoma iyiphi isistimu enembayo ephezulu.

Inqubo Yokukhiqiza Ye-Silicon Carbide Ceramic Fork Ingalo/Isandla

Ukwakha ukusebenza okuphezuluI-Silicon Carbide Ceramic Fork Ingalo/Isandlaibandakanya ukuhamba komsebenzi kobunjiniyela be-ceramic okulawulwa ngokuqinile okuqinisekisa ukuphindaphinda, ukwethembeka, namazinga amaphutha aphansi kakhulu.

1. Ubunjiniyela Bezinto ezibonakalayo

Kusetshenziswa i-ultra-high-purity silicon carbide powder kuphela ekwenzeni i-I-Silicon Carbide Ceramic Fork Ingalo/Isandla, ukuqinisekisa ukungcola okuphansi kwe-ionic namandla enqwaba. Ama-powders ahlanganiswe ngokunembile nezithasiselo ze-sintering kanye nama-binders ukuze kuzuzwe ukuminyana okuphelele.

2. Ukwakha Isakhiwo Sesisekelo

I-geometry eyisisekelo ye-imfoloko ingalo/isandlakwakhiwa kusetshenziswa ukucindezela okubandayo kwe-isostatic noma ukubunjwa komjovo, okuqinisekisa ukuminyana okuphezulu okuluhlaza kanye nokusabalalisa ukucindezeleka okufanayo. Ukucushwa komumo we-U kulungiselelwe isilinganiso sokuqina kwesisindo kanye nokuphendula okuguquguqukayo.

3. Sintering Process

Umzimba oluhlaza weI-Silicon Carbide Ceramic Fork Ingalo/Isandlaushiswa esithandweni segesi esinezinga lokushisa eliphezulu, esingaphezu kuka-2000°C. Lesi sinyathelo siqinisekisa ukuminyana okuseduze kwethiyori, sikhiqiza ingxenye emelana nokuqhekeka, ukugoqa, nokuchezuka kohlangothi ngaphansi kwemithwalo eshisayo yomhlaba wangempela.

4. Precision Ukugaya kanye Machining

Ithuluzi ledayimane le-CNC elithuthukisiwe lisetshenziselwa ukubumba ubukhulu bokugcina be-I-Silicon Carbide Ceramic Fork Ingalo/Isandla. Ukubekezelela okuqinile (± 0.01 mm) kanye nokuqedwa kweleveli yesibuko kunciphisa ukukhululwa kwezinhlayiya kanye nokucindezeleka komshini.

5. I-Surface Conditioning kanye Nokuhlanza

Ukuqedwa kwendawo yokugcina kuhlanganisa ukupholisha kwamakhemikhali kanye nokuhlanza kwe-ultrasonic ukulungiselelaimfoloko ingalo/isandlaukuhlanganiswa okuqondile kumasistimu ahlanzekile kakhulu. Izembatho zokuzikhethela (i-CVD-SiC, izendlalelo eziphikisana ne-reflective) nazo ziyatholakala.

Le nqubo ngokucophelela iqinisekisa ukuthi ngamunyeI-Silicon Carbide Ceramic Fork Ingalo/Isandlaihlangabezana nezindinganiso eziqinile zezimboni, okuhlanganisa ne-SEMI kanye nezidingo zegumbi lokuhlanza le-ISO.

I-Paramete ye-Silicon Carbide Ceramic Fork Arm/Hand

| Into | Izimo Zokuhlola | Idatha | Iyunithi |

| Okuqukethwe kwe-Silicon Carbide | / | >99.5 | % |

| Usayizi Wokusanhlamvu Omaphakathi | / | 4-10 | micron |

| Ukuminyana | / | >3.14 | g/cm3 |

| I-Porosity ebonakalayo | / | <0.5 | Ivolumu % |

| Vickers Ukuqina | I-HV0.5 | 2800 | Kg/mm2 |

| I-Modulus Of Rapture (3 Amaphuzu) | Usayizi webha yokuhlola: 3 x 4 x 40mm | 450 | I-MPa |

| Amandla Wokucindezela | 20°C | 3900 | I-MPa |

| I-Modulus ye-Elasticity | 20°C | 420 | I-GPa |

| Ukuphuka Kokuqina | / | 3.5 | I-MPa/m1/2 |

| I-Thermal Conductivity | 20°C | 160 | W/(mK) |

| Ukungazweli Kagesi | 20°C | 106-108 | Ωcm |

| I-Coefficient of Thermal Expansion | 20°C-800°C | 4.3 | K-110-6 |

| Ubukhulu. Izinga Lokushisa Lokusebenza | I-Oxide Atmosphere | 1600 | °C |

| Ubukhulu. Izinga Lokushisa Lokusebenza | I-Inter Atmosphere | 1950 | °C |

Izicelo zeSilicon Carbide Ceramic Fork Arm/Hand

II-Silicon Carbide Ceramic Fork Ingalo/Isandlayakhelwe ukusetshenziswa ekunembeni okuphezulu, engcupheni ephezulu, kanye nezinhlelo zokusebenza ezizwela ukungcola. Inika amandla ukuphatha okuthembekile, ukudluliswa, noma ukwesekwa kwezingxenye ezibalulekile ezingenakho ukuvumelana.

➤ Imboni ye-semiconductor

-

Isetshenziswa njengemfoloko yerobhothi ekudluliselweni kwewafa engaphambili kanye naseziteshini ze-FOUP.

-

Kuhlanganiswe kumagumbi e-vacuum okufakwa kwe-plasma kanye nezinqubo ze-PVD/CVD.

-

Isebenza njengengalo yenethiwekhi ku-metrology namathuluzi wokuqondanisa ama-wafer.

II-Silicon Carbide Ceramic Fork Ingalo/Isandlaiqeda ubungozi bokukhishwa kwe-electrostatic discharge (ESD), isekela ukunemba kobukhulu, futhi imelana nokugqwala kwe-plasma.

➤ I-Photonics kanye ne-Optics

-

Isekela amalensi athambile, amakristalu e-laser, nezinzwa ngesikhathi sokwenziwa noma sokuhlolwa.

Ukuqina kwayo okuphezulu kuvimbela ukudlidliza, kuyilapho umzimba we-ceramic umelana nokungcoliswa kwezindawo ezibonakalayo.

➤ Isibonisi kanye Nokukhiqizwa Kwephaneli

-

Iphatha ingilazi ezacile, amamojula e-OLED, nama-substrates e-LCD ngesikhathi sokuthutha noma sokuhlolwa.

I-flat kanye ne-inert yamakhemikhaliI-Silicon Carbide Ceramic Fork Ingalo/Isandlaivikela ukuklwebheka noma ukuhujwa kwamakhemikhali.

➤ I-Aerospace kanye Nezinsimbi Zesayensi

-

Isetshenziswa ekuhlanganiseni kwesathelayithi optics, vacuum robotics, futhi synchrotron beamline ukusetha.

Isebenza ngokungenasici ezindlini ezihlanzekile zebanga lesikhala nasezindaweni ezithandwa yimisebe.

Emkhakheni ngamunye, iI-Silicon Carbide Ceramic Fork Ingalo/Isandlaithuthukisa ukusebenza kahle kwesistimu, inciphisa ukwehluleka kwengxenye, futhi inciphise isikhathi sokuphumula.

I-FAQ - Imibuzo Evame Ukubuzwa Ye-Silicon Carbide Ceramic Fork Ingalo/Isandla

Q1: Yini eyenza i-Silicon Carbide Ceramic Fork Arm/Hand ibe ngcono kunezinye izindlela zensimbi?

II-Silicon Carbide Ceramic Fork Ingalo/Isandlainobulukhuni obuphakeme, ukuminyana okuphansi, ukumelana namakhemikhali okungcono, kanye nokwanda okushisayo okuncane kakhulu kunezinsimbi. Ibuye ihambisane negumbi elihlanzekile futhi ayinakho ukugqwala noma ukukhiqizwa kwezinhlayiyana.

Q2: Ngingakwazi ukucela ubukhulu bangokwezifiso beSilicon Carbide Ceramic Fork Arm/Hand yami?

Yebo. Sinikeza ukwenza ngokwezifiso okuphelele, okuhlanganisa ububanzi bemfoloko, ukujiya, izimbobo ezifakwayo, ukusikwa, nokwelashwa kwendawo. Kungakhathaliseki ukuthi ngama-wafers angu-6", 8", noma angu-12", eyakhoimfoloko ingalo/isandlaingalungiswa ukuze ilingane.

Q3: I-Silicon Carbide Ceramic Fork Arm/Hand ihlala isikhathi esingakanani ngaphansi kwe-plasma noma i-vacuum?

Ngenxa ye-high-density SiC material kanye nemvelo engasebenzi, iimfoloko ingalo/isandlaihlala isebenza ngisho nangemva kwezinkulungwane zemijikelezo yenqubo. Ibonisa ukuguga okuncane ngaphansi kwe-plasma enolaka noma imithwalo yokushisa ye-vacuum.

Q4: Ingabe umkhiqizo ulungele amagumbi okuhlanza e-ISO Class 1?

Nakanjani. II-Silicon Carbide Ceramic Fork Ingalo/Isandlaikhiqizwa futhi yapakishwa ezindaweni ezihlanzekile eziqinisekisiwe, ezinamazinga ezinhlayiyana angaphansi kakhulu kwezimfuneko ze-ISO Class 1.

I-Q5: Ingakanani izinga lokushisa eliphezulu lokusebenza kwalengalo/isandla semfoloko?

II-Silicon Carbide Ceramic Fork Ingalo/Isandlaingasebenza ngokuqhubekayo kuze kufike ku-1500 ° C, ikwenze ifaneleke ukusetshenziswa ngokuqondile emakamelweni enqubo yokushisa ephezulu kanye nezinhlelo ze-vacuum ezishisayo.

Lawa ma-FAQ akhombisa ukukhathazeka okujwayelekile kobuchwepheshe okuvela konjiniyela, abaphathi bamalebhu, nabahlanganisi besistimu abasebenzisa i-I-Silicon Carbide Ceramic Fork Ingalo/Isandla.

Mayelana NATHI

I-XKH igxile ekuthuthukisweni kobuchwepheshe obuphezulu, ukukhiqiza, nokudayiswa kwengilazi ekhethekile yokubona nezinto ezintsha zekristalu. Imikhiqizo yethu isebenza ngogesi obonakalayo, ugesi wabathengi, kanye nezempi. Sinikezela ngezinto ezibonakalayo ze-Sapphire, izembozo zamalensi omakhalekhukhwini, i-Ceramics, i-LT, i-Silicon Carbide SIC, i-Quartz, namawafa ekristalu e-semiconductor. Ngobungcweti abanamakhono kanye nemishini esezingeni eliphezulu, sihamba phambili ekucutshungulweni komkhiqizo okungajwayelekile, sihlose ukuba yibhizinisi elihamba phambili le-optoelectronic materials high-tech.