I-Silicon carbide Ceramic tray sucker I-Silicon carbide ceramic tube inikeza izinga lokushisa eliphezulu lokucutshungulwa ngokwezifiso kwe-sintering

Izici eziyinhloko:

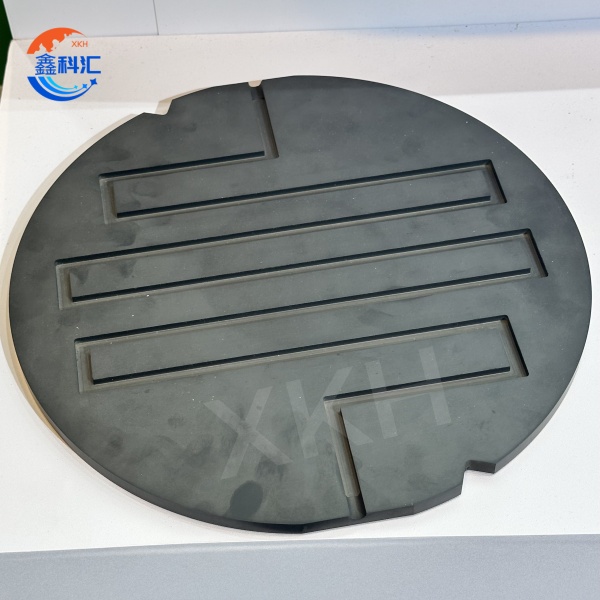

1. Ithreyi ye-ceramic ye-silicon carbide

- Ukuqina okuphezulu nokumelana nokugqoka: ubulukhuni buseduze nedayimane, futhi bungamelana nokugqokwa kwemishini ekucubungulweni kwe-wafer isikhathi eside.

- Ukushisa okuphezulu kwe-thermal kanye ne-coefficient ephansi yokwandisa ukushisa okushisayo: ukuchithwa kokushisa okusheshayo nokuzinza kwe-dimensional, ukugwema ukuguquguquka okubangelwa ukucindezeleka okushisayo.

- Ukucaba okuphezulu nokuqedwa kwendawo: Ukucaba kwendawo kukhuphukela kuzinga le-micron, kuqinisekisa ukuthintana okugcwele phakathi kwe-wafer nediski, kunciphisa ukungcoliswa kanye nokulimala.

Ukuzinza kwamakhemikhali: Ukumelana nokugqwala okuqinile, kulungele ukuhlanzwa okumanzi kanye nezinqubo zokufaka ekwenziweni kwe-semiconductor.

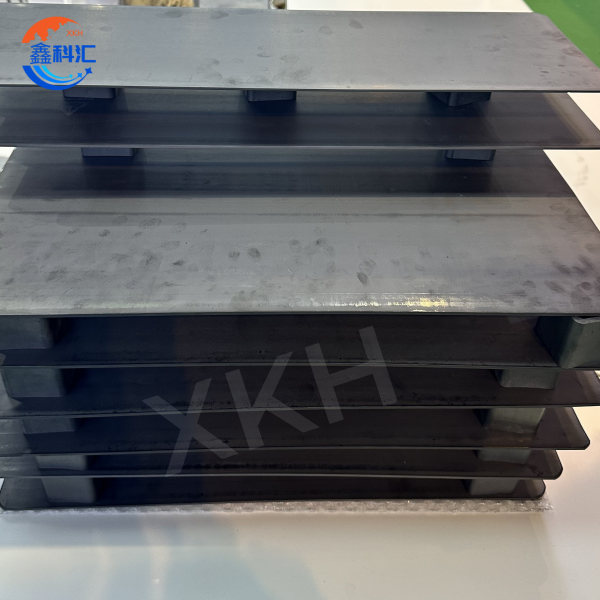

2. Ishubhu ye-ceramic ye-silicon carbide

- Ukumelana nokushisa okuphezulu: Ingasebenza endaweni yokushisa ephezulu ngaphezu kwe-1600 ° C isikhathi eside, ilungele inqubo yokushisa ephezulu ye-semiconductor.

Ukumelana nokugqwala okuhle kakhulu: ukumelana nama-asidi, ama-alkali kanye nezinhlobonhlobo zezinyibilikisi zamakhemikhali, ezifanele indawo yenqubo enokhahlo.

- Ukuqina okuphezulu nokumelana nokugqokwa: ukumelana nokuguguleka kwezinhlayiyana kanye nokuguga kwemishini, kunwebe impilo yesevisi.

- I-conductivity ephezulu ye-thermal kanye ne-coefficient ephansi yokwandisa ukushisa: ukushayela okusheshayo kokushisa nokuzinza kwe-dimensional, ukunciphisa ukuguqulwa noma ukuqhekeka okubangelwa ukucindezeleka okushisayo.

Ipharamitha yomkhiqizo:

Ipharamitha yethreyi ye-silicon carbide ceramic:

| (Impahla) | (Iyunithi) | (sic) | |

| (Okuqukethwe kwe-SiC) | (Wt)% | >99 | |

| (Isilinganiso sikasayizi wokusanhlamvu) | micron | 4-10 | |

| (Ukuminyana) | kg/dm3 | >3.14 | |

| (I-porosity ebonakalayo) | I-Vo1% | <0.5 | |

| (Vickers hardness) | I-HV 0.5 | I-GPa | 28 |

| *() Amandla e-Flexural* (amaphuzu amathathu) | 20ºC | I-MPa | 450 |

| (Amandla acindezelayo) | 20ºC | I-MPa | 3900 |

| (I-Elastic Modulus) | 20ºC | I-GPa | 420 |

| (Ukuphuka kokuqina) | MPa/m'% | 3.5 | |

| (I-Thermal conductivity) | 20°C | W/(m*K) | 160 |

| (Ukumelana) | 20°C | Ohm.cm | 106-108 |

(I-thermal expansion coefficient) | a(RT**...80ºC) | K-1*10-6 | 4.3 |

(Izinga lokushisa eliphezulu lokusebenza) | oºC | 1700 | |

Ipharamitha yeshubhu ye-silicon carbide ceramic:

| Izinto | Inkomba |

| I-α-SIC | 99% iminithi |

| I-Porosity ebonakalayo | 16% ubuningi |

| Ukuminyana kwenqwaba | 2.7g/cm3 iminithi |

| Amandla Okugoba Emazingeni Okushisa aphezulu | 100 Mpa min |

| I-Coefficient of Thermal Expansion | K-1 4.7x10 -6 |

| I-Coefficient of Thermal Conductivity(1400ºC) | 24 W/mk |

| Ubukhulu. Izinga Lokushisa Lokusebenza | 1650ºC |

Izinhlelo zokusebenza eziyinhloko:

1. Ipuleti ye-ceramic ye-silicon carbide

- Ukusika nokupholishwa kwe-wafer: kusebenza njengenkundla ethwalayo ukuze kuqinisekiswe ukunemba okuphezulu nokuzinza ngesikhathi sokusika nokupholisha.

- Inqubo ye-Lithography: Iwafa igxilile emshinini we-lithography ukuze kuqinisekiswe ukuma okunembayo okuphezulu ngesikhathi sokuchayeka.

- I-Chemical Mechanical Polishing (CMP) : isebenza njengenkundla yokusekela yamaphedi wokupholisha, ehlinzeka ngokucindezela okufanayo nokusabalalisa ukushisa.

2. Ishubhu ye-ceramic ye-silicon carbide

- Ishubhu yokushisa yokushisa ephezulu: isetshenziselwa imishini yokushisa ephezulu njenge-diffusion furnace kanye ne-oxidation furnace ukuthwala ama-wafers okwelashwa kwenqubo yokushisa okuphezulu.

- Inqubo ye-CVD/PVD: Njengeshubhu elithwalayo ekamelweni lokusabela, elimelana nokushisa okuphezulu namagesi agqwalayo.

- Izesekeli zemishini ye-Semiconductor: zokushintshanisa ukushisa, amapayipi egesi, njll., ukuthuthukisa ukusebenza kahle kokuphathwa kokushisa kwemishini.

I-XKH inikeza uhla olugcwele lwezinsizakalo zangokwezifiso zamathileyi e-silicon carbide ceramic, izinkomishi zokumunca namashubhu e-silicon carbide ceramic. Amathreyi e-silicon carbide ceramic kanye nezinkomishi zokumunca, i-XKH ingenziwa ngokwezifiso ngokuya ngezidingo zamakhasimende ezinosayizi abahlukene, ubujamo nobulukhuni bobuso, futhi isekele ukwelashwa okukhethekile kokumboza, ukuthuthukisa ukumelana nokuguga nokumelana nokugqwala; Kumashubhu e-silicon carbide ceramic, i-XKH ingakwazi ukwenza ngokwezifiso ububanzi bangaphakathi obuhlukahlukene, ububanzi bangaphandle, ubude nesakhiwo esiyinkimbinkimbi (njengeshubhu elibunjiwe noma ishubhu elinombobo), futhi inikeze ukupholisha, ukumbozwa kwe-anti-oxidation nezinye izinqubo zokwelashwa kwendawo. I-XKH iqinisekisa ukuthi amakhasimende angakwazi ukusebenzisa ngokugcwele izinzuzo zokusebenza kwemikhiqizo ye-silicon carbide ceramic ukuze ahlangabezane nezidingo ezidingekayo zezinkambu zokukhiqiza ezisezingeni eliphezulu njengama-semiconductors, amaledi nama-photovoltaics.

Umdwebo onemininingwane