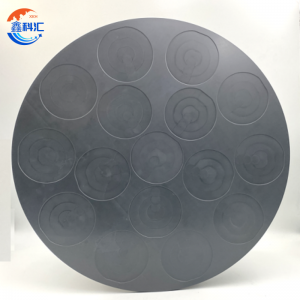

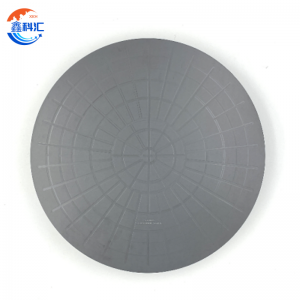

Ithreyi ye-Silicon Carbide Ceramic - Amathreyi Aqinile, Asebenza Kakhulu Okusetshenziswa Kwezinto Ezishisayo Namakhemikhali

Umdwebo onemininingwane

Isingeniso Somkhiqizo

Amathreyi e-Silicon carbide (SiC) e-ceramic ayizingxenye ezisebenza kakhulu ezisetshenziswa kakhulu endaweni enezinga lokushisa eliphezulu, enomthwalo omkhulu, kanye nezindawo zezimboni ezinokhahlo lwamakhemikhali. Akhiwe ngezinto ezithuthukisiwe ze-silicon carbide ceramic, lawa mathreyi aklanyelwe ukuletha amandla akhethekile wemishini, ukuqhutshwa kwe-thermal okuphezulu, nokumelana okuhle kakhulu nokushaqeka okushisayo, i-oxidation, nokugqwala. Imvelo yabo eqinile ibenza bafaneleke kakhulu ekusetshenzisweni kwezimboni ezahlukene okuhlanganisa ukukhiqizwa kwe-semiconductor, ukucubungula i-photovoltaic, ukucwiliswa kwezingxenye ze-powder metallurgy, nokuningi.

Amathreyi e-silicon carbide asebenza njengabathwali ababalulekile noma abasekela phakathi nezinqubo zokwelapha ezishisayo lapho ukunemba kobukhulu, ubuqotho besakhiwo, nokumelana namakhemikhali kubalulekile. Uma kuqhathaniswa nezinto zobumba zendabuko ezifana ne-alumina noma i-mullite, amathreyi e-SiC anikezela ngokusebenza okuphezulu kakhulu, ikakhulukazi ezimeni ezibandakanya ukuhamba kwamabhayisikili okushisayo okuphindaphindiwe kanye nomkhathi onolaka.

Inqubo Yokukhiqiza Nokubunjwa Kwezinto

Ukukhiqizwa kwamathreyi e-ceramic e-SiC kufaka phakathi ubunjiniyela obunembayo kanye nobuchwepheshe be-sintering obuthuthukisiwe ukuze kuqinisekiswe ukuminyana okuphezulu, i-microstructure efanayo, nokusebenza okungaguquki. Izinyathelo ezijwayelekile zihlanganisa:

-

Ukukhethwa Kwezinto Ezingavuthiwe

I-silicon carbide powder ye-high-purity (≥99%) ikhethiwe, ngokuvamile enokulawula usayizi wezinhlayiyana ezithile kanye nokungcola okuncane ukuze kuqinisekiswe izakhiwo eziphezulu zemishini nezokushisa. -

Izindlela Zokwakha

Ngokuya ngokucaciswa kwethreyi, izindlela ezahlukahlukene zokwakha zisetshenziswa:-

I-Cold Isostatic Pressing (CIP) ye-high-density, ama-compact compacts

-

Ukukhishwa kwe-extrusion noma ukushelela komumo oyinkimbinkimbi

-

Ukubumba komjovo kumajiyometri anemininingwane, anemininingwane

-

-

Sintering Techniques

Umzimba oluhlaza ushiswa emazingeni okushisa aphezulu kakhulu, ngokuvamile ebangeni elingu-2000°C, ngaphansi kwe-inert noma i-vacuum atmospheres. Izindlela ezijwayelekile ze-sintering zifaka:-

I-Reaction Bonded SiC (RB-SiC)

-

I-Pressureless Sintered SiC (SSiC)

-

I-Recrystallized SiC (RBSiC)

Indlela ngayinye iphumela ezintweni ezibonakalayo ezihluke kancane, ezifana ne-porosity, amandla, kanye ne-thermal conductivity.

-

-

Precision Machining

Ngemuva kokucwiliswa, amathreyi enziwa ngomshini ukuze afinyelele ukubekezelela okuqinile, ukuqedwa kwendawo okubushelelezi, kanye nokucaba. Ukwelapha okungaphezulu njengokugxusha, ukugaya, nokupholisha kungasetshenziswa ngokuya ngezidingo zamakhasimende.

Izicelo Ezijwayelekile

Amathreyi e-silicon carbide ceramic asetshenziswa ezimbonini ezahlukahlukene ngenxa yokuguquguquka kwawo nokuqina. Izicelo ezijwayelekile zifaka:

-

Imboni yeSemiconductor

Amathreyi e-SiC asetshenziswa njengabathwali ngesikhathi se-wafer annealing, diffusion, oxidation, epitaxy, kanye nezinqubo zokufakelwa. Ukuzinza kwabo kuqinisekisa ukusatshalaliswa kwezinga lokushisa okufanayo kanye nokungcola okuncane. -

Imboni ye-Photovoltaic (PV).

Ekukhiqizweni kwamaseli elanga, amathreyi e-SiC asekela ama-silicon ingots noma ama-wafers ngesikhathi sokusatshalaliswa kwezinga lokushisa eliphezulu nezinyathelo ze-sintering. -

I-Powder Metallurgy kanye ne-Ceramics

Isetshenziselwa izingxenye ezisekelayo ngesikhathi sokucwiliswa kwezimpushana zensimbi, izitsha zobumba, nezinto eziyinhlanganisela. -

Ingilazi kanye namaphaneli wokubonisa

Kusetshenziswa njengamathreyi omlilo noma izinkundla zokwenza izibuko ezikhethekile, ama-LCD substrates, noma ezinye izinto ezibonakalayo. -

Ukucutshungulwa Kwamakhemikhali kanye Nezithando Zokushisa Ezishisayo

Isebenza njengezinkampani zenethiwekhi ezimelana nokugqwala kuma-reactor amakhemikhali noma njengamathreyi asekelayo ashisayo kuma-vacuum nama-controlled-atmosphere.

Izici Zokusebenza Ezibalulekile

-

✅I-Thermal Stability Eyingqayizivele

Imelana nokusetshenziswa okuqhubekayo emazingeni okushisa afika ku-1600–2000°C ngaphandle kokungqubuzana noma ukuwohloka. -

✅Amandla Emishini Ephakeme

Inikeza amandla aphezulu okuguquguquka (imvamisa>350 MPa), iqinisekisa ukuqina kwesikhathi eside ngisho nangaphansi kwezimo eziphakeme zomthwalo. -

✅I-Thermal Shock Resistance

Ukusebenza okuhle kakhulu ezindaweni ezinokushintshashintsha kwezinga lokushisa okusheshayo, okunciphisa ingozi yokuqhekeka. -

✅Ukumelana nokugqwala kanye ne-Oxidation

Izinzile ngokwekhemikhali kuma-asidi amaningi, ama-alkali, namagesi e-oxidizing/ehlisayo, alungele izinqubo zamakhemikhali ezinokhahlo. -

✅Ukunemba kweDimensional kanye neFlatness

Ifakwe ngokunemba okuphezulu, iqinisekisa ukucutshungulwa okufanayo nokuhambisana namasistimu azenzakalelayo. -

✅Isikhathi Eside Sempilo Nokusebenza Kahle Kwezindleko

Amazinga aphansi okushintsha kanye nezindleko zokunakekela ezincishisiwe akwenza kube yisixazululo esingabizi kakhulu ngokuhamba kwesikhathi.

Imininingwane Yezobuchwepheshe

| Ipharamitha | Inani Elijwayelekile |

|---|---|

| Okubalulekile | I-Reaction Bonded SiC / Sintered SiC |

| Ubukhulu. Izinga Lokushisa Lokusebenza | 1600–2000°C |

| Amandla e-Flexural | ≥350 MPa |

| Ukuminyana | ≥3.0 g/cm³ |

| I-Thermal Conductivity | ~120–180 W/m·K |

| I-Surface Flatness | ≤ 0.1 mm |

| Ubukhulu | 5–20 mm (kungenziwa ngokwezifiso) |

| Ubukhulu | Okujwayelekile: 200×200 mm, 300×300 mm, njll. |

| I-Surface Qeda | Ifakwe ngomshini, iphucuziwe (ngesicelo) |

Imibuzo Evame Ukubuzwa (FAQ)

I-Q1: Ingabe amathreyi e-silicon carbide angasetshenziswa kuma-vacuum furnaces?

A:Yebo, amathreyi e-SiC alungele izindawo ezingenalutho ngenxa yokuphuma kwawo okuphansi, ukuqina kwamakhemikhali, nokumelana nezinga lokushisa eliphezulu.

Q2: Ingabe umumo ngokwezifiso noma izikhala ziyatholakala?

A:Nakanjani. Sinikezela ngezinsizakalo zokwenza ngokwezifiso ezihlanganisa usayizi wethreyi, umumo, izici ezingaphezulu (isb., imifantu, izimbobo), nokupholishwa kwendawo ukuze kuhlangatshezwane nezimfuneko ezihlukile zamakhasimende.

Q3: I-SiC iqhathaniswa kanjani namathreyi e-alumina noma e-quartz?

A:I-SiC inamandla aphakeme, i-thermal conductivity engcono, nokumelana okuphakeme nokushaqeka okushisayo nokugqwala kwamakhemikhali. Ngenkathi i-alumina ibiza kakhulu, i-SiC isebenza kangcono ezindaweni ezidinga kakhulu.

Q4: Ingabe kukhona ukujiya okujwayelekile kwalawa mathreyi?

A:Ubukhulu buvamise ukuba kububanzi obungu-5–20 mm, kodwa singabulungisa ngokusekelwe kuhlelo lwakho lokusebenza nezimfuneko zokuthwala umthwalo.

Q5: Isiphi isikhathi esijwayelekile sokuhola samathreyi e-SiC enziwe ngokwezifiso?

A:Izikhathi zokuhola ziyahlukahluka kuye ngobunkimbinkimbi kanye nenani kodwa ngokuvamile zisukela emavikini angu-2 kuye kwangu-4 kuma-oda angokwezifiso.

Mayelana NATHI

I-XKH igxile ekuthuthukisweni kobuchwepheshe obuphezulu, ukukhiqiza, nokudayiswa kwengilazi ekhethekile yokubona nezinto ezintsha zekristalu. Imikhiqizo yethu isebenza ngogesi obonakalayo, ugesi wabathengi, kanye nezempi. Sinikezela ngezinto ezibonakalayo ze-Sapphire, izembozo zamalensi omakhalekhukhwini, i-Ceramics, i-LT, i-Silicon Carbide SIC, i-Quartz, namawafa ekristalu e-semiconductor. Ngobungcweti abanamakhono nemishini esezingeni eliphezulu, sihamba phambili ekucutshungulweni komkhiqizo okungajwayelekile, sihlose ukuba yibhizinisi elihamba phambili le-optoelectronic materials high-tech.