I-Silicon Carbide Ceramic Fork Ingalo/Isandla

Umdwebo onemininingwane

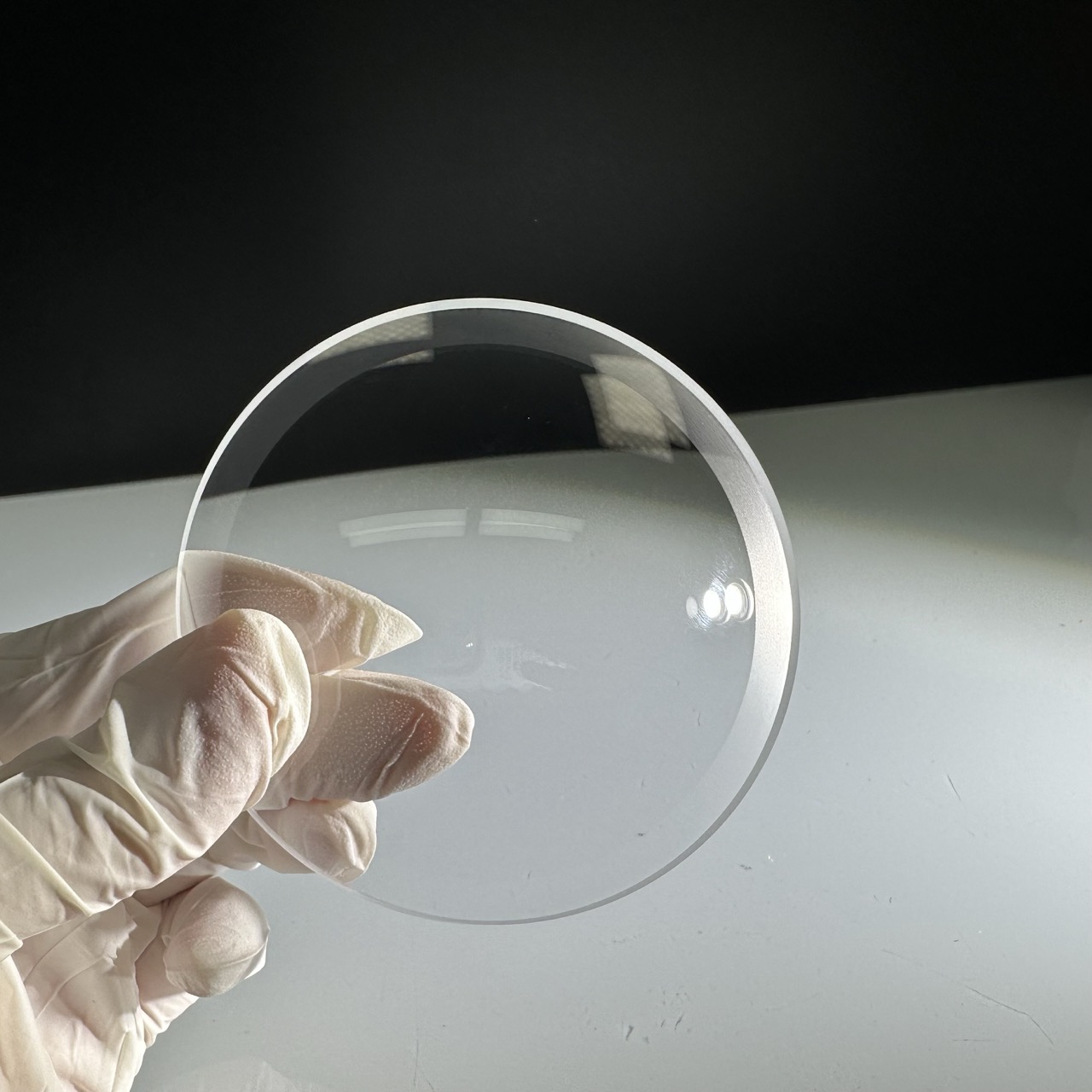

Ukwethulwa kweSilicon Carbide Ceramic Fork Arm/Hand

II-Silicon Carbide Ceramic Fork Ingalo/Isandlaiyingxenye yokuphatha ethuthukisiwe eyenzelwe amasistimu e-automation anembe kakhulu, ikakhulukazi ezimbonini ze-semiconductor ne-optical. Le ngxenye inomklamo ohlukile we-U-shape olungiselelwe ukuphatha i-wafer, eqinisekisa kokubili amandla emishini kanye nokunemba kobukhulu ngaphansi kwezimo zemvelo ezimbi kakhulu. Yakhiwe nge-high-purity silicon carbide ceramic, i-imfoloko ingalo/isandlailetha ukuqina okukhethekile, ukuzinza kokushisa, nokumelana namakhemikhali.

Njengoba amadivaysi e-semiconductor eguqukela kumajiyometri amahle kanye nokubekezelelana okuqinile, isidingo sezingxenye ezingangcolisi nezizinzile ngokokushisa siba bucayi. II-Silicon Carbide Ceramic Fork Ingalo/Isandlaihlangabezana nale nselele ngokunikeza ukukhiqizwa kwezinhlayiyana eziphansi, izindawo ezibushelelezi, kanye nobuqotho obuqinile besakhiwo. Kungakhathaliseki ukuthi kukuthuthwa kwe-wafer, ukuma kwe-substrate, noma izinhloko zamathuluzi e-robotic, le ngxenye yakhelwe ukwethembeka nokuphila isikhathi eside.

Izizathu ezibalulekile zokukhetha lokhuI-Silicon Carbide Ceramic Fork Ingalo/Isandlazihlanganisa:

-

Ukunwetshwa okushisayo okuncane kokunemba kwe-dimensional

-

Ukuqina okuphezulu kwempilo ende yesevisi

-

Ukumelana nama-asidi, ama-alkali, namagesi asebenzayo

-

Ukuhambisana nezindawo ezihlanzekile zegumbi le-ISO Class 1

Isimiso Sokukhiqiza Se-Silicon Carbide Ceramic Fork Ingalo/Isandla

II-Silicon Carbide Ceramic Fork Ingalo/Isandlaikhiqizwa ngokusebenza okulawulwa kakhulu kwe-ceramic processing eklanyelwe ukuqinisekisa izakhiwo zezinto ezibonakalayo eziphezulu kanye nokungaguquguquki kwe-dimensional.

1. Ukulungiswa Kwempushana

Inqubo iqala ngokukhethwa kwezimpushana ze-silicon carbide ze-ultra-fine. Lezi zimpushana zixubene nezibophezelo kanye nezinsiza-sintering ukuze kube lula ukuminyana kanye nokuminyana. Kwalokhuimfoloko ingalo/isandla, i-β-SiC noma i-α-SiC powders isetshenziselwa ukuqinisekisa kokubili ubulukhuni nokuqina.

2. Ukubunjwa kanye Preforming

Kuye ngobunkimbinkimbi be-imfoloko ingalo/isandlaidizayini, ingxenye ibunjwe kusetshenziswa ukucindezelwa kwe-isostatic, ukubumba umjovo, noma ukuslip cast. Lokhu kuvumela ijometri eyinkimbinkimbi kanye nezakhiwo zodonga oluncane, olubalulekile kumvelo engasindi ye-I-Silicon Carbide Ceramic Fork Ingalo/Isandla.

3. I-High-Temperature Sintering

I-Sintering yenziwa emazingeni okushisa angaphezu kuka-2000°C ku-vacuum noma emkhathini we-argon. Lesi sigaba siguqula umzimba oluhlaza ube ingxenye ye-ceramic ehlanganiswe ngokugcwele. The sinteredimfoloko ingalo/isandlaifinyelela ukuminyana okuseduze kwethiyori, ihlinzeka ngezakhiwo ezivelele zemishini nezokushisa.

4. Precision Machining

I-post-sintering, iI-Silicon Carbide Ceramic Fork Ingalo/Isandlaigaya idayimane kanye nemishini ye-CNC. Lokhu kuqinisekisa ukucaba phakathi kuka-±0.01 mm futhi kuvumela ukufakwa kwezimbobo ezifakwayo kanye nezici zendawo ezibaluleke kakhulu ekufakweni kwakho ezinhlelweni ezizenzakalelayo.

5. Surface Finishing

Ukupholisha kunciphisa ukuhwalala kwendawo (Ra <0.02 μm), kubalulekile ekwehliseni ukukhiqizwa kwezinhlayiya. Izingubo zokuzikhethela ze-CVD zingasetshenziswa ukuthuthukisa ukumelana ne-plasma noma ukwengeza ukusebenza okufana nokuziphatha okungahambisani ne-static.

Kuyo yonke le nqubo, amaphrothokholi okulawula ikhwalithi asetshenziswa ukuze kuqinisekisweI-Silicon Carbide Ceramic Fork Ingalo/Isandlaisebenza ngokwethembeka ezinhlelweni ezibucayi kakhulu.

Amapharamitha we-Silicon Carbide Ceramic Fork Arm/Hand

| Ukucaciswa Okuyinhloko kwe-CVD-SIC Coating | ||

| Izakhiwo ze-SiC-CVD | ||

| Isakhiwo Sekristalu | I-FCC β isigaba | |

| Ukuminyana | g/cm³ | 3.21 |

| Ukuqina | Vickers ubulukhuni | 2500 |

| Usayizi Wokusanhlamvu | μm | 2~10 |

| I-Chemical Purity | % | 99.99995 |

| Amandla Okushisa | J·kg-1 ·K-1 | 640 |

| I-Sublimation Temperature | ℃ | 2700 |

| Amandla E-Felexural | I-MPa (RT 4-point) | 415 |

| I-Young's Modulus | I-Gpa (4pt bend, 1300℃) | 430 |

| I-Thermal Expansion (CTE) | 10-6K-1 | 4.5 |

| I-Thermal conductivity | (W/mK) | 300 |

Izicelo zeSilicon Carbide Ceramic Fork Arm/Hand

II-Silicon Carbide Ceramic Fork Ingalo/Isandlaisetshenziswa kabanzi kuzo zonke izimboni lapho ubumsulwa obuphezulu, ukuzinza, nokunemba komshini kubalulekile. Lokhu kubandakanya:

1. Ukukhiqiza I-Semiconductor

Ekwenziweni kwe-semiconductor, iI-Silicon Carbide Ceramic Fork Ingalo/Isandlaisetshenziselwa ukuthutha ama-wafers e-silicon ngaphakathi kwamathuluzi enqubo afana nama-etching chamber, izinhlelo zokubeka, kanye nemishini yokuhlola. Ukumelana nokushisa kwayo nokunemba kobukhulu kuyenza ilungele ukunciphisa ukungaboni ngaso linye nokungcoliswa kwe-wafer.

2. Ukukhiqizwa Kwephaneli Yokubonisa

Embonini ye-OLED ne-LCD, iimfoloko ingalo/isandlaisetshenziswa ezinhlelweni zokukhetha nendawo, lapho iphatha ama-substrates ezingilazi ezintekenteke. Ubukhulu bayo obuphansi nokuqina kwayo okuphezulu kwenza ukunyakaza okusheshayo nokuzinzile ngaphandle kokudlidliza noma ukuchezuka.

3. I-Optical and Photonic Systems

Ukuqondanisa nokubeka amalensi, izibuko, noma ama-photonic chips, theI-Silicon Carbide Ceramic Fork Ingalo/Isandlainikeza ukwesekwa okungadlidlizi, okubalulekile ekucutshungulweni kwe-laser kanye nezinhlelo zokusebenza ze-metrology enembile.

4. I-Aerospace & Vacuum Systems

Kumasistimu okubona kwe-aerospace namathuluzi e-vacuum, lesi sakhiwo esingenazibuthe, esimelana nokugqwala siqinisekisa ukuzinza kwesikhathi eside. Iimfoloko ingalo/isandlaingaphinda isebenze ku-ultra-high vacuum (UHV) ngaphandle kokukhipha umoya.

Kuyo yonke le mikhakha, i-I-Silicon Carbide Ceramic Fork Ingalo/Isandlaidlula ezinye izindlela zensimbi zendabuko noma ze-polymer ngokuthembeka, ukuhlanzeka, kanye nempilo yesevisi.

I-FAQ ye-Silicon Carbide Ceramic Fork Arm/Hand

Q1: Yimaphi amasayizi ama-wafer asekelwa yiSilicon Carbide Ceramic Fork Arm/Hand?

Iimfoloko ingalo/isandlaingenziwa ngokwezifiso ukuze isekele ama-wafers angu-150 mm, 200 mm, kanye nama-300 mm. Ubude bemfoloko, ububanzi bengalo, namaphethini wembobo kungalungiswa ukuze kulingane neplathifomu yakho yokuzenzakalela ethile.

I-Q2: Ingabe i-Silicon Carbide Ceramic Fork Arm/Hand iyahambisana nezinhlelo ze-vacuum?

Yebo. Iimfoloko ingalo/isandlailungele kokubili i-vacuum ephansi kanye nesistimu ye-vacuum ephezulu kakhulu. Inamazinga aphansi okukhipha umoya futhi ayikhiphi izinhlayiya, okuyenza ifaneleke endaweni ehlanzekile nendawo yokuhlanza.

I-Q3: Ngingakwazi yini ukwengeza i-coatings noma ukuguqulwa kwendawo engalweni/isandla semfoloko?

Impela. II-Silicon Carbide Ceramic Fork Ingalo/Isandlaingambozwa nge-CVD-SiC, i-carbon, noma izendlalelo ze-oxide ukuze kuthuthukiswe ukumelana kwayo ne-plasma, izakhiwo zokulwa ne-static, noma ukuqina kwendawo.

Q4: Iqinisekiswa kanjani ikhwalithi yengalo/isandla semfoloko?

NgamunyeI-Silicon Carbide Ceramic Fork Ingalo/Isandlaihlolwa nge-dimensional kusetshenziswa i-CMM namathuluzi e-laser metrology. Ikhwalithi yobuso ihlolwa nge-SEM kanye ne-non-contact profilometry ukuze ihlangabezane namazinga e-ISO ne-SEMI.

I-Q5: Yisiphi isikhathi sokuhola se-oda lemfoloko yangokwezifiso ingalo/yesandla?

Isikhathi sokuhola ngokuvamile sisukela emavikini angu-3 kuye kwayi-5 kuye ngobunkimbinkimbi nenani. I-prototyping esheshayo iyatholakala ngezicelo eziphuthumayo.

Lawa ma-FAQ ahlose ukusiza onjiniyela namaqembu okuthenga aqonde amakhono nezinketho ezitholakalayo lapho kukhethwa i-aI-Silicon Carbide Ceramic Fork Ingalo/Isandla.

Mayelana NATHI

I-XKH igxile ekuthuthukisweni kobuchwepheshe obuphezulu, ukukhiqiza, nokudayiswa kwengilazi ekhethekile yokubona nezinto ezintsha zekristalu. Imikhiqizo yethu isebenza ngogesi obonakalayo, ugesi wabathengi, kanye nezempi. Sinikezela ngezinto ezibonakalayo ze-Sapphire, izembozo zamalensi omakhalekhukhwini, i-Ceramics, i-LT, i-Silicon Carbide SIC, i-Quartz, namawafa ekristalu e-semiconductor. Ngobungcweti abanamakhono nemishini esezingeni eliphezulu, sihamba phambili ekucutshungulweni komkhiqizo okungajwayelekile, sihlose ukuba yibhizinisi elihamba phambili le-optoelectronic materials high-tech.