I-SiCOI wafer 4inch 6inch HPSI SiC SiO2 Si subatrate structure

Isakhiwo se-wafer ye-SiCOI

I-HPB (I-High-Performance Bonding) BIC (I-Bonded Integrated Circuit) kanye ne-SOD (i-Silicon-on-Diamond noma ubuchwepheshe obufana ne-Silicon-on-Insulator). Kuhlanganisa:

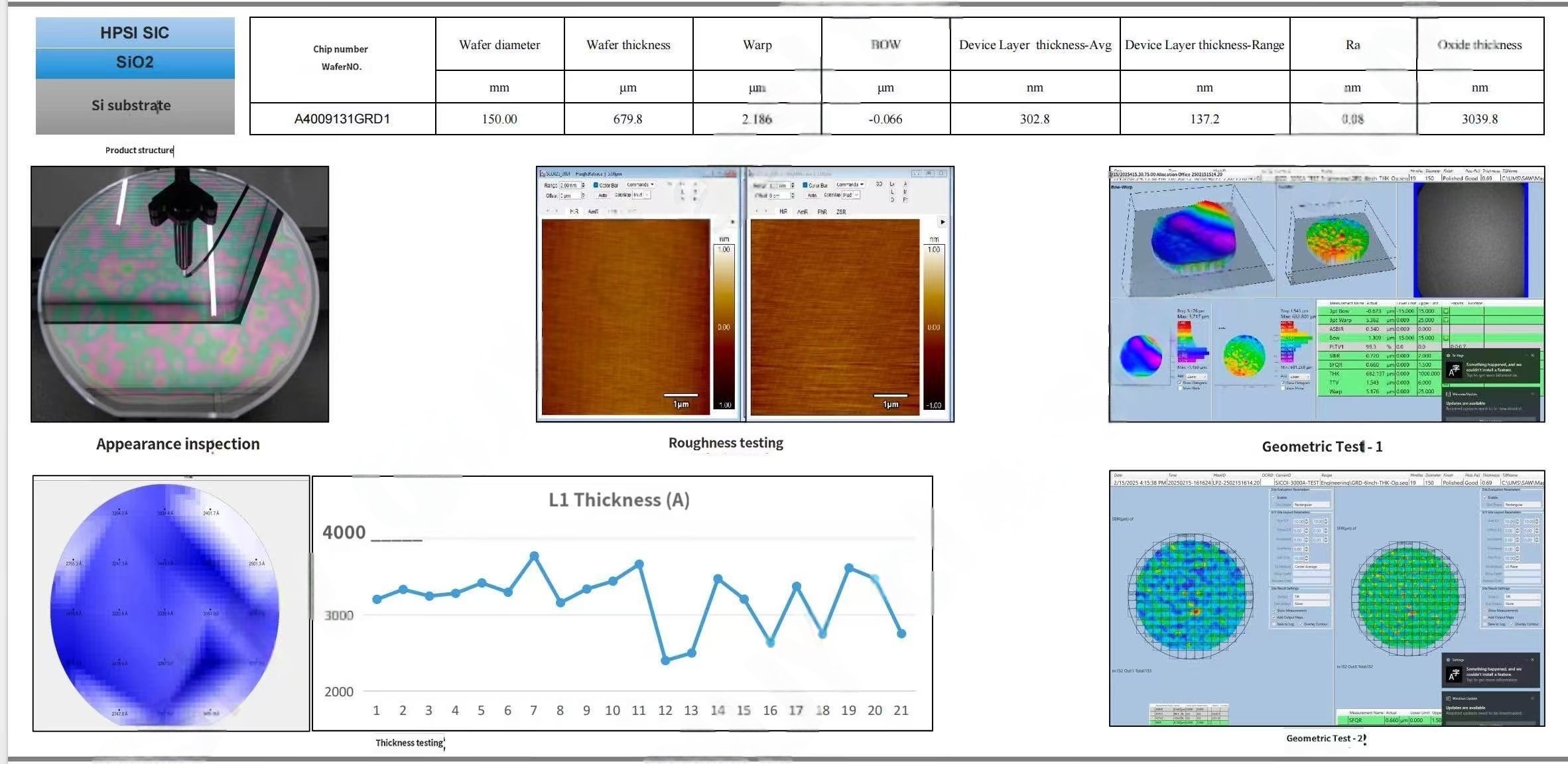

Amamethrikhi okusebenza:

Ibala amapharamitha afana nokunemba, izinhlobo zamaphutha (isb, "Alikho iphutha," "Ibanga lenani"), kanye nezilinganiso zokushuba (isb., "Ukujiya Kwengqimba Eqondile/kg").

Ithebula elinamanani ezinombolo (mhlawumbe amapharamitha okuhlola noma okucubungula) ngaphansi kwezihloko ezifana nokuthi "ADDR/SYGBDT," "10/0," njll.

Idatha Yokuqina Kwesendlalelo:

Okufakiwe okuphindaphindayo okunabile okulebulwe ngokuthi "L1 Ukuqina (A)" kuya kokuthi "L270 Ukuqina (A)" (cishe kokuthi Ångströms, 1 Å = 0.1 nm).

Iphakamisa isakhiwo esinezendlalelo eziningi esinokulawula ukujiya okunembayo kwesendlalelo ngasinye, okujwayelekile kumawafa we-semiconductor athuthukile.

Isakhiwo se-SiCOI Wafer

I-SiCOI (i-Silicon Carbide ku-Insulator) iyisakhiwo esiyisicwecwana esikhethekile esihlanganisa i-silicon carbide (SiC) nongqimba oluvikelayo, olufana ne-SOI (i-Silicon-on-Insulator) kodwa elungiselelwe izinhlelo zokusebenza ezinamandla/zezinga lokushisa eliphezulu. Izici ezibalulekile:

Ukwakhiwa Kwesendlalelo:

Isendlalelo Esiphezulu: I-Silicon Carbide Eyikristalu Eyodwa (SiC) yokuhamba nge-electron ephezulu kanye nokuzinza kwe-thermal.

I-Insulator Engcwatshiwe: Ngokuvamile i-SiO₂ (i-oxide) noma idayimane (ku-SOD) ukunciphisa amandla e-parasitic nokuthuthukisa ukuhlukaniswa.

I-Base Substrate: I-Silicon noma i-polycrystalline SiC yokusekelwa ngomshini

Izakhiwo ze-SiCOI wafer

Izakhiwo zikagesi I-Wide Bandgap (i-3.2 eV ye-4H-SiC):Inika amandla i-voltage yokuphuka okuphezulu (>10× ngaphezulu kune-silicon).Yehlisa ukuvuza kwama-currents, ithuthukisa ukusebenza kahle kumadivayisi kagesi.

I-High Electron Mobility:~900 cm²/V·s (4H-SiC) vs. ~1,400 cm²/V·s (Si), kodwa ukusebenza okungcono kwenkundla ephezulu.

Ukumelana Okuphansi:Ama-transistors asuselwa ku-SiCOI (isb, ama-MOSFET) akhombisa ukulahleka kokusebenza okuphansi.

I-Insulation enhle kakhulu:I-oxide engcwatshiwe (SiO₂) noma isendlalelo sedayimane kunciphisa amandla e-parasitic kanye ne-crosstalk.

- Izakhiwo ezishisayoHigh Thermal Conductivity:SiC (~490 W/m·K for 4H-SiC) vs. Si (~150 W/m·K).Idayimane (uma lisetshenziswa njengesivikelo) lingadlula u-2,000 W/m·K, lithuthukise ukunqanyulwa kokushisa.

Ukuqina Kokushisa:Isebenza ngokuthembekile kokuthi >300°C (vs. ~150°C ku-silicon).Yehlisa izimfuneko zokupholisa kugesi wamandla.

3. Izakhiwo zeMechanical & ChemicalUkuqina Okudlulele (~9.5 Mohs):Imelana nokugqoka, okwenza i-SiCOI iqine ezindaweni ezinokhahlo.

Ukungena Kwamakhemikhali:Imelana ne-oxidation nokugqwala, ngisho nasezimeni ezine-acidic/alkaline.

Ukwandiswa Kokushisa Okuphansi:Ihambisana kahle nezinye izinto ezisezingeni eliphezulu (isb, i-GaN).

4. Izinzuzo Zesakhiwo (vs. Bulk SiC noma i-SOI)

Ukulahleka Kwe-Substrate Eyehlisiwe:Isendlalelo sokuvikela sivimbela ukuvuza kwamanje ku-substrate.

Ukusebenza Kwe-RF Okuthuthukisiwe:I-Lower capacitance ye-parasitic inika amandla ukushintsha okusheshayo (kuwusizo kumadivayisi we-5G/mmWave).

Idizayini Eguqukayo:I-Thin SiC top layer ivumela ukukalwa kwedivayisi okuthuthukisiwe (isb, amashaneli azacile kakhulu kuma-transistors).

Ukuqhathanisa ne-SOI & Bulk SiC

| Impahla | I-SiCOI | I-SOI (Si/SiO₂/Si) | I-Bulk SiC |

| I-Bandgap | 3.2 eV (SiC) | 1.1 eV (Si) | 3.2 eV (SiC) |

| I-Thermal Conductivity | Phezulu (SiC + idayimane) | Phansi (SiO₂ ikhawulela ukugeleza kokushisa) | Phezulu (SiC kuphela) |

| Ukuhlukaniswa kwe-Voltage | Phezulu kakhulu | Kuphakathi | Phezulu kakhulu |

| Izindleko | Phezulu | Phansi | Okuphakeme kakhulu (pure SiC) |

Izinhlelo zokusebenza ze-SiCOI wafer

Amandla kagesi

Amawafa e-SiCOI asetshenziswa kakhulu kumadivayisi asebenzisa amandla kagesi aphezulu kanye nanamandla aphezulu njengama-MOSFET, ama-Schottky diode, kanye nokushintsha kwamandla. I-bandgap ebanzi kanye ne-voltage ephezulu yokuwohloka kwe-SiC inika amandla ukuguqulwa kwamandla okusebenzayo nokulahlekelwa okuncishisiwe nokusebenza okushisayo okuthuthukisiwe.

Amadivayisi weRadio Frequency (RF).

Isendlalelo esivikelayo kumawafer e-SiCOI sehlisa amandla e-parasitic, siwenze afanelekele ama-transistors ama-high-frequency transistors nama-amplifiers asetshenziswa kwezokuxhumana, i-radar, kanye nobuchwepheshe be-5G.

I-Microelectromechanical Systems (MEMS)

Ama-wafer e-SiCOI ahlinzeka ngenkundla eqinile yokwenza izinzwa ze-MEMS nama-actuator asebenza ngokwethembeka ezindaweni ezinokhahlo ngenxa yokungangeni kwamakhemikhali e-SiC namandla emishini.

I-High-Temperature Electronics

I-SiCOI inika amandla ama-elekthronikhi agcina ukusebenza nokuthembeka emazingeni okushisa aphakeme, azuzisa izimoto, i-aerospace, nezinhlelo zokusebenza zezimboni lapho amadivayisi ajwayelekile e-silicon ehluleka.

Amadivayisi we-Photonic kanye ne-Optoelectronic

Inhlanganisela yezinto ezibonakalayo ze-SiC kanye nongqimba oluvikelayo kusiza ukuhlanganiswa kwamasekhethi ezithombe nokuphathwa okushisayo okuthuthukisiwe.

I-Electronics Eqiniswe Ngemisebe

Ngenxa yokubekezelelana kwemvelo kwemisebe kwe-SiC, amawafa e-SiCOI alungele indawo kanye nezicelo zenuzi ezidinga imishini ekwazi ukumelana nezindawo ezinemisebe ephezulu.

I-Q&A ye-SiCOI wafer

Q1: Yini iwafa ye-SiCOI?

A: I-SiCOI imele i-Silicon Carbide-on-Insulator. Kuyisakhiwo se-wafer se-semiconductor lapho ungqimba oluncane lwe-silicon carbide (SiC) luboshelwe kungqimba oluvikelayo (ngokuvamile i-silicon dioxide, i-SiO₂), esekelwa i-silicon substrate. Lesi sakhiwo sihlanganisa izakhiwo ezinhle kakhulu ze-SiC nokuhlukaniswa kukagesi kusivikeli.

Q2: Yiziphi izinzuzo eziyinhloko zamawafa e-SiCOI?

A: Izinzuzo eziyinhloko zifaka i-voltage ephezulu yokuphuka, i-bandgap ebanzi, ukuqhutshwa kwe-thermal okuhle kakhulu, ubulukhuni bemishini obuphakeme, kanye nokunciphisa amandla e-parasitic ngenxa yesendlalelo se-insulating. Lokhu kuholela ekusebenzeni okuthuthukisiwe kwedivayisi, ukusebenza kahle, nokuthembeka.

Q3: Yiziphi izinhlelo zokusebenza ezijwayelekile zamawafa e-SiCOI?

A: Asetshenziswa kuma-electronics anamandla, kumadivayisi e-RF avela kuma-high-frequency, izinzwa ze-MEMS, ama-electronics ashisa kakhulu, amadivaysi e-photonic, kanye ne-electronic-hardened electronics.

Umdwebo onemininingwane