I-SICOI (I-Silicon Carbide ku-Insulator) I-Wafers SiC Film KU-Silicon

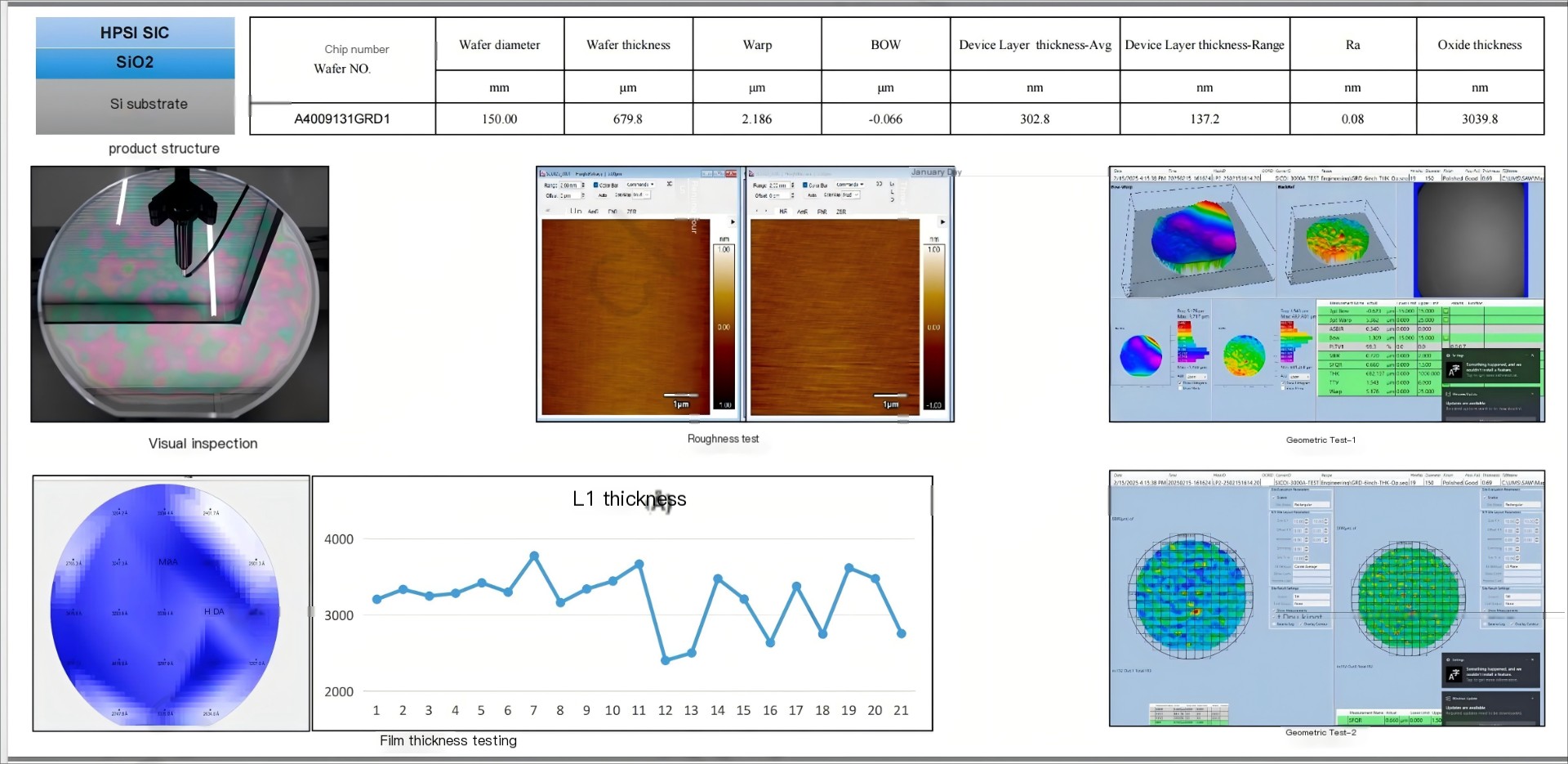

Umdwebo onemininingwane

Sethula ama-wafers e-Silicon Carbide ku-Insulator (SICOI).

Amawafa e-Silicon Carbide ku-Insulator (SICOI) angama-semiconductor substrates esizukulwane esilandelayo ahlanganisa izakhiwo eziphakeme zomzimba neze-elekthronikhi ze-silicon carbide (SiC) nezici ezivelele zokuhlukanisa zikagesi zesendlalelo se-insulating buffer, njenge-silicon dioxide (SiO₂) noma i-silicon nitride (Si₃N₄). Iwafa ye-SICOI evamile iqukethe ungqimba oluncane lwe-epitaxial SiC, ifilimu evikelayo emaphakathi, kanye nesisekelo esingaphansi esisekelayo, esingaba i-silicon noma i-SiC.

Lesi sakhiwo esiyingxubevange sakhiwe ukuze sihlangabezane nezidingo eziqinile zamadivayisi kagesi anamandla aphezulu, ama-high-frequency, kanye nezinga eliphezulu lokushisa. Ngokuhlanganisa ungqimba oluvikelayo, ama-wafer e-SICOI anciphisa amandla e-parasitic futhi acindezela amaza avuzayo, ngaleyo ndlela aqinisekise amaza okusebenza aphezulu, ukusebenza kahle okungcono, nokuphathwa okushisayo okuthuthukisiwe. Lezi zinzuzo zizenza zibe yigugu kakhulu emikhakheni efana nezimoto zikagesi, ingqalasizinda yezokuxhumana ye-5G, amasistimu we-aerospace, ugesi we-RF othuthukisiwe, kanye nobuchwepheshe bezinzwa be-MEMS.

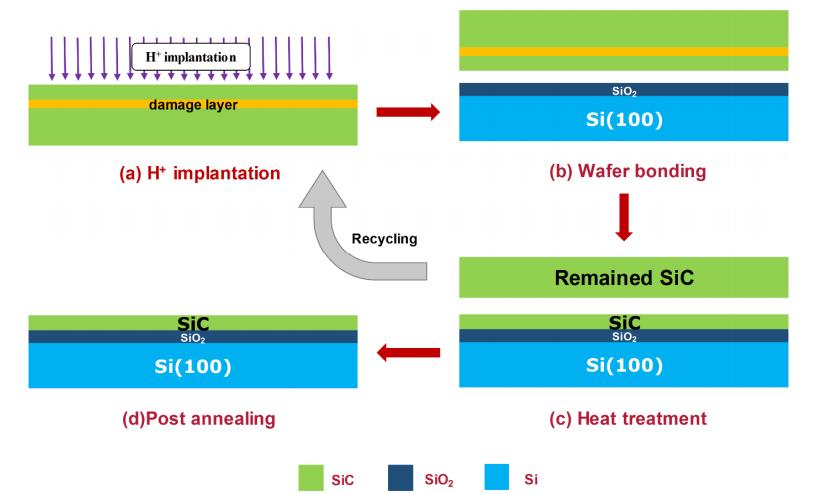

Umgomo Wokukhiqiza wama-SICOI Wafers

Ama-wafer e-SICOI (Silicon Carbide on Insulator) akhiqizwa ngokusebenzisa i-Advancedi-wafer bonding kanye nenqubo yokunciphisa:

-

Ukukhula kwe-SiC Substrate- Iwafa ye-SiC ye-crystal eyodwa yekhwalithi ephezulu (4H/6H) ilungiswa njengempahla yabanikelayo.

-

I-Insulating Layer Deposition- Ifilimu evikelayo (i-SiO₂ noma i-Si₃N₄) yakheka ku-wafer yenethiwekhi (Si noma i-SiC).

-

I-Wafer Bonding- I-wafer ye-SiC kanye ne-wafer yenethiwekhi kuhlanganiswe ngaphansi kwezinga lokushisa eliphezulu noma usizo lwe-plasma.

-

Ukucwenga & Ukupholisha- I-wafer ye-SiC donor incishiswe ibe ngama-micrometer ambalwa futhi ipholishwe ukuze kuzuzwe indawo ebushelelezi ye-athomu.

-

Ukuhlola Okokugcina- Iwafa ye-SICOI eqediwe ihlolelwa ukufana kogqinsi, ukuhwaqazeka kwendawo, kanye nokusebenza kokufakelwa.

Ngale nqubo, aungqimba oluncane lwe-SiC olusebenzayoenezindawo ezinhle kakhulu zikagesi nezishisayo kuhlanganiswe nefilimu evikelayo kanye ne-substrate yokusekela, okwenza isiteji sokusebenza okuphezulu kwamandla esizukulwane esilandelayo kanye namadivayisi we-RF.

Izinzuzo ezibalulekile zama-SICOI Wafers

| Isigaba sesici | Izici Zobuchwepheshe | Izinzuzo Eziyinhloko |

|---|---|---|

| Isakhiwo Sempahla | I-4H/6H-SiC isendlalelo esisebenzayo + ifilimu evikelayo (SiO₂/Si₃N₄) + Si noma inkampani yenethiwekhi ye-SiC | Ifinyelela ukuhlukaniswa okunamandla kagesi, kunciphisa ukuphazamiseka kwe-parasitic |

| Izakhiwo zikagesi | Amandla okuphuka okuphezulu (>3 MV/cm), ukulahleka kwe-dielectric okuphansi | Ilungiselelwe ukusebenza kwe-high-voltage kanye ne-high-frequency |

| Izakhiwo ezishisayo | I-Thermal conductivity kufika ku-4.9 W/cm·K, izinzile ngaphezu kuka-500°C | Ukukhipha ukushisa okusebenzayo, ukusebenza okuhle kakhulu ngaphansi kwemithwalo eshisayo eqinile |

| Izakhiwo Zemishini | Ukuqina okudlulele (Mohs 9.5), i-coefficient ephansi yokunwetshwa kwe-thermal | Iqinile ngokumelene nengcindezi, ithuthukisa impilo ende yedivayisi |

| Ikhwalithi Yobuso | Indawo ebushelelezi kakhulu (Ra <0.2 nm) | Iphromotha i-epitaxy engenasici kanye nokwakhiwa kwedivayisi okuthembekile |

| I-Insulation | Ukumelana >10¹⁴ Ω·cm, ukuvuza okuphansi kwamanje | Ukusebenza okuthembekile ku-RF kanye nezinhlelo zokusebenza zokuhlukaniswa kwe-voltage ephezulu |

| Usayizi Nokwenza Ngokwezifiso | Itholakala ngamafomethi angu-4, 6, kanye namayintshi angu-8; Ubukhulu be-SiC 1-100 μm; ukufakwa kwe-insulation 0.1-10 μm | Idizayini eguquguqukayo yezidingo ezahlukahlukene zohlelo lokusebenza |

Izindawo Zokusebenza Eziyinhloko

| Umkhakha Wezicelo | Amacala Okusetshenziswa Okujwayelekile | Izinzuzo Zokusebenza |

|---|---|---|

| Amandla kagesi | Ama-inverter e-EV, iziteshi zokushaja, amadivayisi kagesi wezimboni | I-voltage yokuwohloka ephezulu, ukulahleka kokushintsha okuncishisiwe |

| I-RF ne-5G | Izikhulisi zamandla esiteshi sesisekelo, izingxenye zamagagasi emilimitha | Ama-parasitics aphansi, asekela ukusebenza kobubanzi be-GHz |

| Izinzwa ze-MEMS | Izinzwa zokucindezela kwemvelo ezinokhahlo, i-MEMS yebanga lokuzulazula | Ukuzinza okuphezulu kokushisa, ukumelana nemisebe |

| I-Aerospace & Defense | Ukuxhumana ngesathelayithi, amamojula wamandla we-avionics | Ukuthembeka emazingeni okushisa aphezulu kanye nokuchayeka emisebeni |

| Igridi ehlakaniphile | Iziguquli ze-HVDC, ama-solid-state circuit breakers | Ukwahlukanisa okuphezulu kunciphisa ukulahleka kwamandla |

| I-Optoelectronics | Ama-LED ama-UV, ama-laser substrates | Ikhwalithi ephezulu yekristalu isekela ukuphuma kokukhanya okusebenzayo |

Ukwakhiwa kwe-4H-SiCOI

Ukukhiqizwa kwama-wafers we-4H-SiCOI kufezwa ngokusebenzisai-wafer bonding kanye nezinqubo zokunciphisa, evumela izixhumanisi zekhwalithi ephezulu ze-insulating nezendlalelo ezisebenzayo ze-SiC ezingenasici.

-

a: I-Schematic ye-4H-SiCOI yokwenziwa kweplathifomu yezinto ezibonakalayo.

-

b: Isithombe se-wafer engu-4-intshi engu-4H-SiCOI sisebenzisa i-bonding kanye nokunciphisa; izindawo ezinesici ezimakiwe.

-

c: Ukulinganiswa kokuqina kokufana kwe-substrate ye-4H-SiCOI.

-

d: Isithombe esibonakalayo se-4H-SiCOI die.

-

e: Ukugeleza kwenqubo yokwenza i-SiC microdisk resonator.

-

f: I-SEM ye-microdisk resonator eqediwe.

-

g: I-SEM ekhulisiwe ebonisa udonga oluseceleni lwe-resonator; Isisetshenziswa se-AFM sibonisa ukushelela kwe-nanoscale surface.

-

h: I-SEM enesigaba esiphambanayo ekhombisa indawo engaphezulu emise okwe-parabolic.

I-FAQ kuma-SICOI Wafers

Q1: Yiziphi izinzuzo amawafa e-SICOI anazo ngaphezu kwamawafa endabuko e-SiC?

I-A1: Ngokungafani nama-substrates e-SiC avamile, ama-wafer e-SICOI afaka ungqimba oluvikelayo olunciphisa amandla e-parasitic kanye nokuvuza kwemisinga, okuholela ekusebenzeni kahle okuphezulu, ukuphendula okungcono kwemvamisa, kanye nokusebenza okushisayo okuphakeme.

Q2: Yimaphi amasayizi we-wafer avame ukutholakala?

A2: Amawafa e-SICOI avame ukukhiqizwa ngamafomethi angu-4 intshi, 6-intshi, kanye namayintshi angu-8, ane-SiC eyenziwe ngokwezifiso kanye nogqinsi lwesendlalelo sokuvikela olutholakalayo kuye ngezidingo zedivayisi.

Q3: Yiziphi izimboni ezizuza kakhulu kuma-wafer e-SICOI?

I-A3: Izimboni ezibalulekile zihlanganisa amandla kagesi ezimotweni zikagesi, i-RF electronics yamanethiwekhi e-5G, i-MEMS yezinzwa ze-aerospace, nama-optoelectronics njengama-UV LED.

I-Q4: Isendlalelo se-insulating sithuthukisa kanjani ukusebenza kwedivayisi?

I-A4: Ifilimu evikelayo (i-SiO₂ noma i-Si₃N₄) ivimbela ukuvuza kwamanje futhi inciphisa inkulumo-mpikiswano kagesi, ivumela ukubekezelela i-voltage ephakeme, ukushintsha okuphumelelayo, nokunciphisa ukulahlekelwa ukushisa.

I-Q5: Ingabe ama-wafer e-SICOI afanele izicelo zokushisa okuphezulu?

I-A5: Yebo, ngokusebenza okuphezulu kwe-thermal nokumelana okungaphezu kuka-500°C, amawafa e-SICOI aklanyelwe ukusebenza ngokwethembeka ngaphansi kokushisa okukhulu nasezindaweni ezinokhahlo.

Q6: Ingabe ama-wafer e-SICOI angenziwa ngezifiso?

A6: Impela. Abakhiqizi banikela ngemiklamo evumelanisiwe yobukhulu obuthile, amazinga e-doping, nezinhlanganisela ze-substrate ukuze kuhlangatshezwane nezidingo ezahlukahlukene zocwaningo nezimboni.