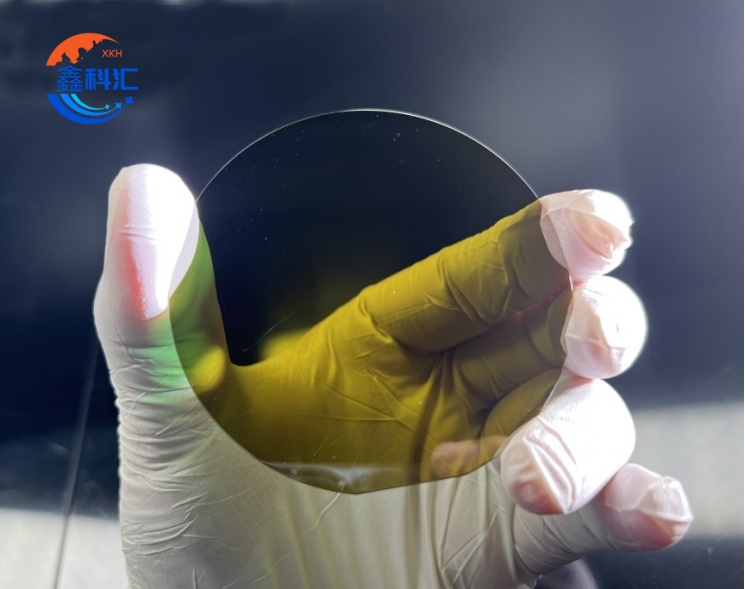

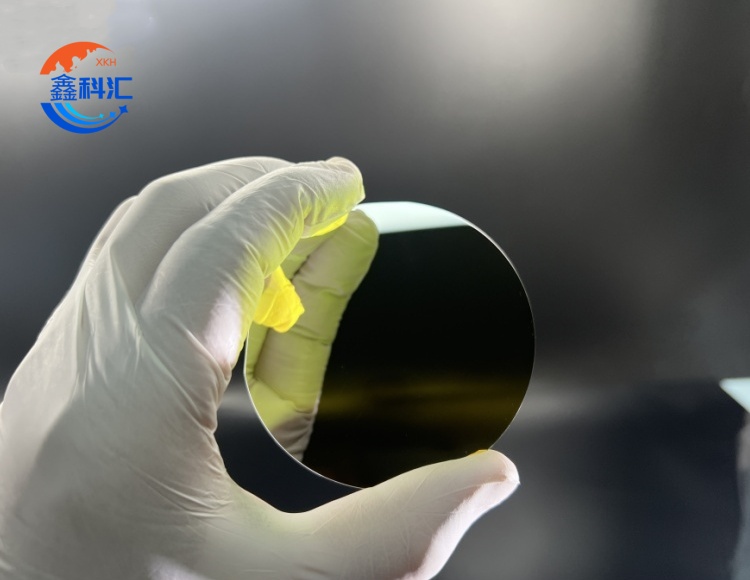

I-Sic Substrate Silicon Carbide Wafer 4H-N Type High Hardness Corrosion Resistance Prime Grade Polishing

Okulandelayo yizici ze-silicon carbide wafer

1. I-thermal conductivity ephakeme: I-thermal conductivity yama-wafers e-SIC iphakeme kakhulu kune-silicon, okusho ukuthi ama-wafers e-SIC angakwazi ukukhipha ukushisa ngokuphumelelayo futhi afanele ukusebenza ezindaweni zokushisa eziphezulu.

2. Ukuhamba kwama-electron aphezulu: Amawafa e-SIC anokunyakaza kwama-electron aphezulu kune-silicon, okuvumela amadivayisi we-SIC ukuthi asebenze ngesivinini esiphezulu.

3. I-voltage ephezulu yokuphuka: I-SIC wafer material ine-voltage yokuphuka ephezulu, okuyenza ifaneleke ukukhiqiza amadivaysi e-semiconductor ane-voltage ephezulu.

4. Ukuzinza kwamakhemikhali okuphezulu: Ama-wafer e-SIC anokumelana nokugqwala kwamakhemikhali okunamandla, okusiza ukuthuthukisa ukuthembeka nokuqina kwedivayisi.

5. Igebe lebhendi elibanzi: Amawafa e-SIC anegebe elibanzi lebhendi kune-silicon, okwenza amadivayisi e-SIC abe ngcono futhi azinze emazingeni okushisa aphezulu.

I-Silicon carbide wafer inezinhlelo zokusebenza eziningana

I-1.Insimu yemishini: amathuluzi okusika kanye nezinto zokugaya; izingxenye ezingagugi kanye nezihlahla; Ama-valve ezimboni kanye nezimpawu; Amabhere namabhola

2.Inkundla yamandla kagesi: amadivaysi e-semiconductor yamandla; High frequency microwave element; High voltage kanye lokushisa eliphezulu amandla electronics; Izinto zokuphatha ezishisayo

3.Imboni yamakhemikhali: i-reactor yamakhemikhali kanye nemishini; amapayipi angaboli kanye namathangi okugcina; Ukwesekwa kwe-Chemical catalyst

4.Umkhakha wamandla: i-turbine yegesi kanye nezingxenye ze-turbocharger; Ingxenye yamandla enuzi kanye nezakhi zezakhi zezinga lokushisa eliphezulu likaphethiloli izingxenye zeseli

5.I-Aerospace: izinhlelo zokuvikela ukushisa ezicitshwayo kanye nezimoto zasemkhathini; Injini ye-jet turbine blades; Inhlanganisela ethuthukile

6.Ezinye izindawo: Izinzwa zokushisa eziphakeme kanye nama-thermopiles; I-Dies kanye namathuluzi wenqubo ye-sintering; Ukugaya nokupholisha nokusika amasimu

I-ZMKJ ingahlinzeka ngekhwalithi ephezulu ye-crystal SiC wafer ( Silicon Carbide ) embonini ye-electronic kanye ne-optoelectronic. I-SiC wafer iyisici sesizukulwane esilandelayo se-semiconductor , enezici zikagesi ezihlukile kanye nezakhiwo ezinhle kakhulu ezishisayo , uma kuqhathaniswa ne-silicon wafer kanye ne-GaAs wafer, i-wafer ye-SiC ifaneleka kakhulu izinga lokushisa eliphezulu kanye nesicelo sedivayisi yamandla aphezulu. I-wafer ye-SiC inganikezwa ngobubanzi obuyiyintshi engu-2-6 , yomibili i-4H ne-6H SiC, uhlobo lwe-N, i-Nitrogen doped, kanye nohlobo lwe-semi-insulating olutholakalayo. Sicela usithinte ukuze uthole ulwazi olwengeziwe lomkhiqizo.

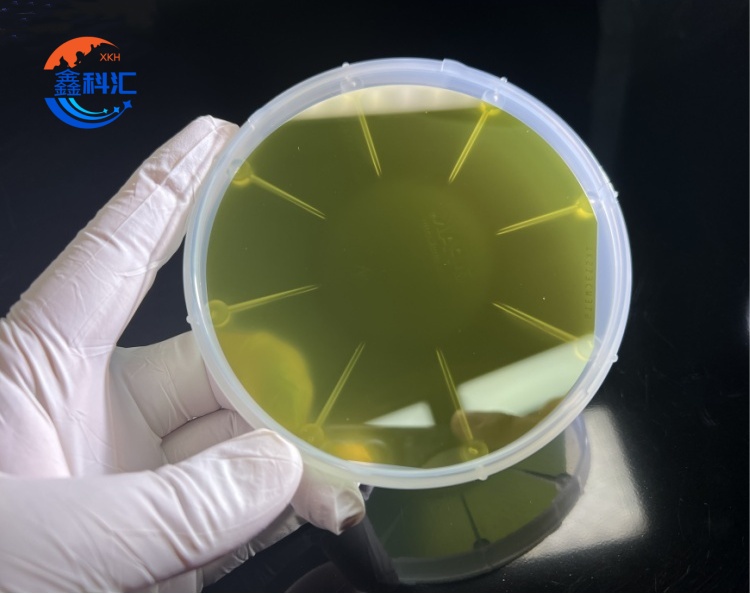

Ifektri yethu inemishini yokukhiqiza ethuthukisiwe nethimba lezobuchwepheshe, elingakwazi ukwenza ngokwezifiso ukucaciswa okuhlukahlukene, ubukhulu kanye nokwakheka kwe-SiC wafer ngokuya ngezidingo eziqondile zamakhasimende.

Umdwebo onemininingwane