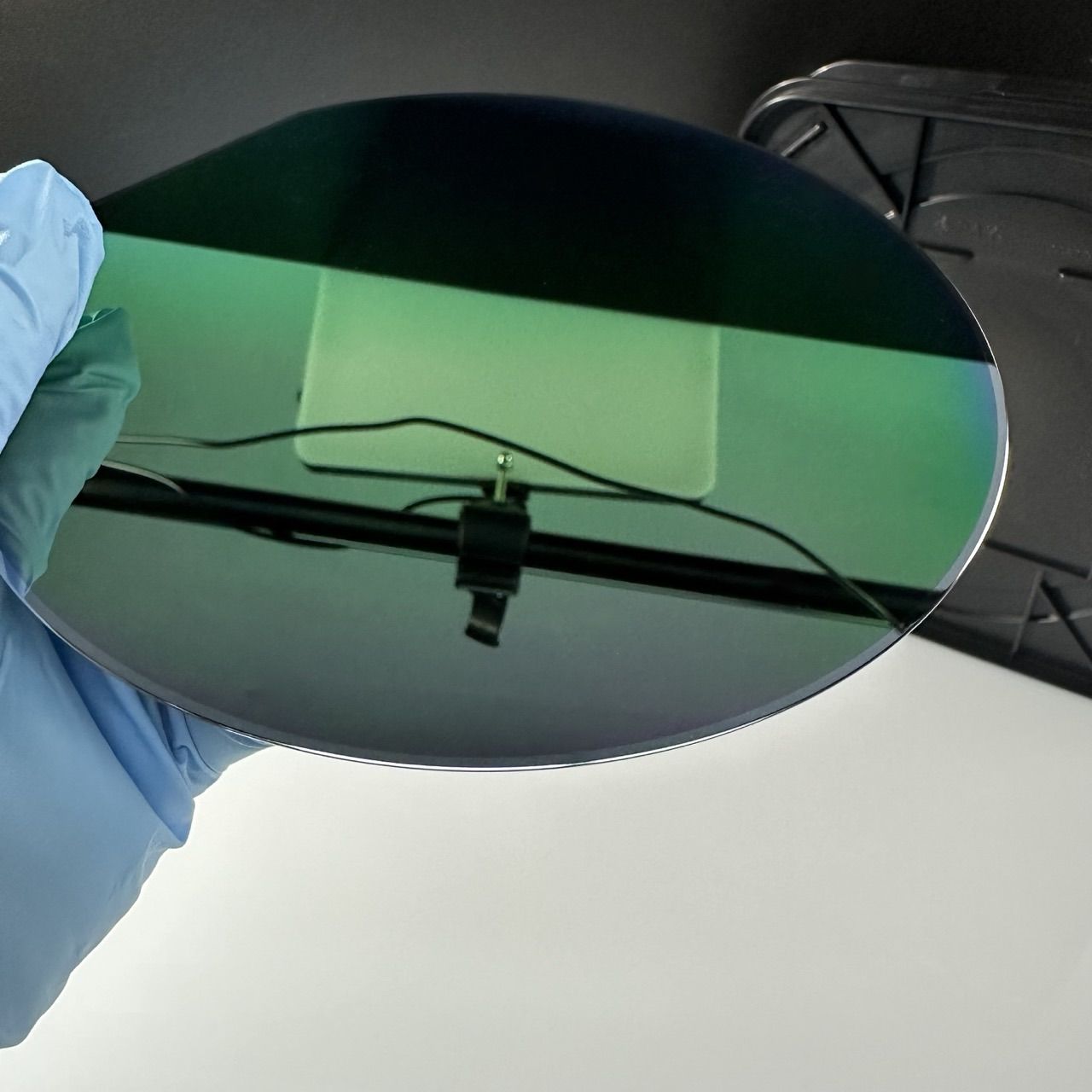

Isithando somlilo se-SiC Ingot Sezindlela Ezinkulu Zobubanzi be-SiC Crystal TSSG/LPE

Isimiso Sokusebenza

Umgomo oyinhloko wokukhula kwe-ingot ye-liquid-phase silicon carbide ingot uhilela ukuncibilikisa izinto zokusetshenziswa ze-SiC ezihlanzeke kakhulu ezinsimbi ezincibilikisiwe (isb, Si, Cr) ku-1800-2100 ° C ukuze kwakheke izixazululo ezigcwele, okulandelwa ukukhula okulawulwayo okulawulwayo kwekristalu elilodwa le-SiC kumakristalu embewu ngokusebenzisa ukuguqulwa kwe-supersaturation regradient enembile. Lobu buchwepheshe bufaneleka ngokukhethekile ukukhiqiza ukuhlanzeka okuphezulu (>99.9995%) amakristalu angawodwa angu-4H/6H-SiC anesici esiphansi sokuminyana (<100/cm²), ahlangabezana nezidingo eziqinile ze-substrate zama-electronics amandla kanye namadivayisi e-RF. Isistimu yokukhula yesigaba se-liquid inika amandla ukulawula okunembile kohlobo lwe-crystal conductivity (uhlobo lwe-N/P) kanye nokumelana nokwakheka kwesixazululo esithuthukisiwe nemingcele yokukhula.

Izingxenye Eziyinhloko

1. I-Special Crucible System: I-high-purity graphite/tantalum composite crucible, ukumelana nezinga lokushisa>2200 ° C, ukumelana nokugqwala kwe-SiC.

2. Uhlelo Lokushisa Lwezindawo Eziningi: Ukumelana okuhlanganisiwe / ukushisa okufakwayo ngokunemba kokulawula izinga lokushisa kwe-± 0.5 ° C (ububanzi be-1800-2100 ° C).

3. I-Precision Motion System: Ukulawula okubili okuvala iluphu lokuzungezisa imbewu (0-50rpm) nokuphakamisa (0.1-10mm/h).

4. Uhlelo Lokulawula Umkhathi: Ukuvikelwa kwe-argon/nitrogen ephezulu, ukucindezela kokusebenza okulungiswayo (0.1-1atm).

5. Uhlelo Lokulawula Okukhaliphile: I-PLC+industrial PC isilawuli esingafuneki ngokuqapha kokukhula kwesikhathi sangempela.

6. Uhlelo Lokupholisa Olusebenzayo: Idizayini yokupholisa amanzi efakwe ngokwezigaba iqinisekisa ukusebenza okuzinzile kwesikhathi eside.

I-TSSG vs. LPE Ukuqhathanisa

| Izici | Indlela ye-TSG | Indlela ye-LPE |

| Ukukhula Temp | 2000-2100°C | 1500-1800°C |

| Izinga Lokukhula | 0.2-1mm/h | 5-50μm/h |

| Usayizi we-Crystal | 4-8 intshi ingots | 50-500μm izingqimba ze-epi |

| Isicelo Esiyinhloko | Ukulungiswa kwe-substrate | Izendlalelo ze-epi zedivayisi yamandla |

| Defect Density | <500/cm² | <100/cm² |

| Ama-Polytypes Afanelekile | 4H/6H-SiC | 4H/3C-SiC |

Izinhlelo zokusebenza ezibalulekile

1. Ama-Electronics Amandla: Ama-substrates angu-6-inch 4H-SiC angu-1200V+ MOSFETs/diode.

2. Amadivayisi e-5G RF: Ama-Semi-insulating SiC substrates we-base station PAs.

3. Izinhlelo zokusebenza ze-EV: Izendlalelo ze-epi eziwugqinsi (>200μm) zamamojula ebanga lezimoto.

4. Iziguquli ze-PV: Ama-substrates anesici esiphansi anika amandla >99% ukusebenza kahle kokuguqulwa.

Izinzuzo Eziyinhloko

1. Ukuphakama Kwezobuchwepheshe

1.1 Idizayini Edidiyelwe Yezindlela Eziningi

Le sistimu yokukhulisa ingot yesigaba soketshezi ye-SiC ihlanganisa ngendlela entsha ubuchwepheshe bokukhula kwekristalu be-TSSG ne-LPE. Uhlelo lwe-TSSG lusebenzisa ukukhula kwesixazululo esinembewu ephezulu ngokuncibilika okunembile kanye nokulawulwa kwe-gradient lokushisa (ΔT≤5℃/cm), okuvumela ukukhula okuzinzile kwama-ingots we-SiC angama-intshi angu-4-8 anobubanzi obungu-15-20kg wezinhlayiya ze-6H/4H-SiC. Uhlelo lwe-LPE lisebenzisa ukwakheka kwe-solvent okuthuthukisiwe (isistimu ye-alloy ye-Si-Cr) kanye nokulawulwa kwe-supersaturation (±1%) ukuze kukhule izendlalelo ze-epitaxial eziwugqinsi ezinobunzima bokuminyana okungu-<100/cm² emazingeni okushisa aphansi kakhulu (1500-1800℃).

1.2 Uhlelo Lokulawula Okukhaliphile

Ifakwe ukulawula kokukhula okuhlakaniphile kwesizukulwane sesine esifaka:

• Ukuqapha kwe-multi-spectral in-situ (400-2500nm ububanzi begagasi)

• Ukutholwa kwezinga lokuncibilika okususelwa ku-laser (±0.01mm ukunemba)

• Ukulawulwa kweluphu evalekile esekelwe ku-CCD (<±1mm ukushintshashintsha)

• Ukuthuthukiswa kwepharamitha yokukhula okunamandla e-AI (15% ukonga amandla)

2. Izinzuzo Zokusebenza Kwenqubo

2.1 Amandla Abalulekile we-TSSG Method

• Amandla osayizi omkhulu: Isekela ukukhula kwekristalu okungafika ku-8-inch nge>99.5% yokufana kobubanzi

• Ubucwebe obuphakeme: Ukuminyana kokuhlukaniswa <500/cm², ukuminyana kwe-micropipe <5/cm²

• Ukufana kwe-Doping: <8% i-n-type resistivity variation (4-inch wafers)

• Izinga lokukhula elithuthukisiwe: Okulungisekayo 0.3-1.2mm/h, 3-5× ngokushesha kunezindlela zesigaba somhwamuko

2.2 Indlela ye-LPE Amandla Abalulekile

• I-epitaxy enesici esiphansi kakhulu: Ukuminyana kwesimo sokusebenzisana <1×10¹¹cm⁻²·eV⁻¹

• Ukulawula ukujiya okunembile: 50-500μm ama-epi-layers anokwahluka okungu-<±2%

• Ukusebenza kahle kwezinga lokushisa eliphansi: 300-500℃ ngaphansi kwezinqubo ze-CVD

• Ukukhula kwesakhiwo esiyinkimbinkimbi: Isekela ukuhlangana kwe-pn, ama-superlattice, njll.

3. Ukukhiqiza Ngempumelelo Izinzuzo

3.1 Ukulawulwa Kwezindleko

• 85% ukusetshenziswa kwempahla eluhlaza (vs. 60% evamile)

• 40% ukusetshenziswa kwamandla okuphansi (uma kuqhathaniswa ne-HVPE)

• 90% isikhathi sokuphumula semishini (idizayini yemojuli inciphisa isikhathi sokuphumula)

3.2 Ukuqinisekisa Ikhwalithi

• 6σ isilawuli senqubo (CPK>1.67)

• Ukutholwa kwesici ku-inthanethi (ukulungiswa okungu-0.1μm)

• Ukulandelelwa kwedatha yenqubo egcwele (amapharamitha angu-2000+ wesikhathi sangempela)

3.3 Ukuqina

• Ihambisana ne-4H/6H/3C polytypes

• Ithuthukela kumamojula enqubo angu-12-intshi

• Isekela i-SiC/GaN hetero-integration

4. Izinzuzo Zokusebenza Kwemboni

4.1 Amadivayisi Amandla

• Ama-substrates amelana kancane (0.015-0.025Ω·cm) wamadivayisi angu-1200-3300V

• Ama-substrates afaka i-semi-insulating (>10⁸Ω·cm) wezinhlelo zokusebenza ze-RF

4.2 Emerging Technologies

• Ukuxhumana kwe-Quantum: Ama-substrates omsindo ophansi kakhulu (1/f umsindo<-120dB)

• Izindawo eziyingozi kakhulu: Amakristalu amelana nemisebe (<5% ukuwohloka ngemva kokushiswa kwe-1×10¹⁶n/cm²)

Izinsizakalo ze-XKH

1. Izinto Ezisetshenziswa Ngokwezifiso: Ukucushwa kwesistimu ye-TSSG/LPE eyenziwe ngokwezifiso.

2. Ukuqeqeshwa Kwenqubo: Izinhlelo eziphelele zokuqeqeshwa kwezobuchwepheshe.

3. Ukusekela ngemva kokuthengisa: 24/7 impendulo yobuchwepheshe nokugcinwa.

4. Izixazululo ze-Turnkey: Isevisi ye-spectrum egcwele kusukela ekufakweni kuya ekucubunguleni ukuqinisekiswa.

5. Ukunikezwa Kwempahla: 2-12 inch SiC substrates/epi-wafers etholakalayo.

Izinzuzo ezibalulekile zifaka:

• Amandla okukhula kwekristalu afika ku-8 intshi.

• Ukumelana nokufana <0.5%.

• Isikhathi sokusebenza kwezisetshenziswa >95%.

• 24/7 ukwesekwa kobuchwepheshe.