Ithreyi ye-SiC Ceramic ye-Wafer Carrier Enokumelana Nokushisa Okuphezulu

Ithreyi ye-Silicon Carbide Ceramic (SiC Tray)

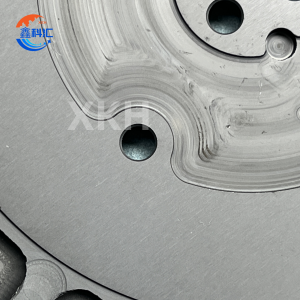

Ingxenye ye-ceramic esebenza kahle kakhulu esekelwe ezintweni ze-silicon carbide (SiC), eyakhelwe izinhlelo zokusebenza ezithuthukisiwe zezimboni ezifana nokukhiqizwa kwe-semiconductor kanye nokukhiqizwa kwe-LED. Imisebenzi yayo eyinhloko ihlanganisa ukusebenza njengesithwali se-wafer, iplathifomu yenqubo ye-etching, noma ukwesekwa kwenqubo yezinga lokushisa eliphezulu, ukusebenzisa amandla okufudumeza okukhethekile, ukumelana nezinga lokushisa eliphezulu, nokuzinza kwamakhemikhali ukuze kuqinisekiswe ukufana kwenqubo kanye nesivuno somkhiqizo.

Izici Ezibalulekile

1. Ukusebenza kwe-Thermal

- I-High Thermal Conductivity: 140–300 W/m·K, idlula ngokuphawulekayo i-graphite evamile (85 W/m·K), evumela ukunqanyulwa kokushisa okusheshayo nokunciphisa ukucindezelwa kokushisa.

- I-Low Thermal Expansion Coefficient: 4.0×10⁻⁶/℃ (25–1000℃), i-silicon esondelene kakhulu (2.6×10⁻⁶/℃), inciphisa izingozi zokuwohloka kokushisa.

2. Izakhiwo zikaMechanical

- Amandla Aphezulu: Amandla e-Flexural ≥320 MPa (20℃), amelana nokucindezelwa nomthelela.

- Ukuqina Okuphezulu: Ukuqina kwe-Mohs 9.5, okwesibili ngemuva kwedayimane, okunikeza ukumelana nokugqoka okuphezulu.

3. Ukuqina Kwamakhemikhali

- I-Corrosion Resistance: Imelana nama-asidi aqinile (isb, i-HF, i-H₂SO₄), ilungele izindawo zenqubo yokushumeka.

- Okungeyona I-Magnetic: I-Intrinsic magnetic susceptibility <1×10⁻⁶ emu/g, ukugwema ukuphazamiseka ngamathuluzi anembayo.

4. Ukubekezelela Imvelo Kakhulu

- Ukuqina Kwezinga Lokushisa Okuphezulu: Ukushisa kokusebenza kwesikhathi eside kufika ku-1600-1900 ℃; ukumelana nesikhathi esifushane kufika ku-2200 ℃ (indawo engenawo umoya-mpilo).

- I-Thermal Shock Resistance: Imelana nokushintsha kwezinga lokushisa okungazelelwe (ΔT >1000℃) ngaphandle kokuqhekeka.

Izinhlelo zokusebenza

| Inkambu yohlelo lokusebenza | Specific Scenario | I-Technical Value |

| I-Semiconductor Manufacturing | I-Wafer etching (ICP), ukufakwa kwefilimu emincane (MOCVD), ukupholishwa kwe-CMP | Ukushisa okuphezulu kwe-thermal kuqinisekisa amasimu okushisa afanayo; ukunwebeka okushisayo okuphansi kunciphisa i-wafer warpage. |

| Ukukhiqizwa kwe-LED | Ukukhula kwe-Epitaxial (isb, i-GaN), i-wafer dicing, ukupakisha | Icindezela ukukhubazeka kwezinhlobo eziningi, ithuthukisa ukusebenza kahle kokukhanya kwe-LED neminyaka yokuphila. |

| Imboni ye-Photovoltaic | I-Silicon wafer sintering furnaces, imishini ye-PECVD isekela | Ukumelana nezinga lokushisa eliphezulu kanye nokushaqeka kwe-thermal kwandisa ubude besikhathi semishini. |

| I-Laser & Optics | Izisekelo zokupholisa ze-laser ezinamandla aphezulu, isistimu yokubona isekela | Ukushisa okuphezulu kwe-thermal kwenza ukuchithwa kokushisa okusheshayo, ukuzinzisa izingxenye ze-optical. |

| Ama-Analytical Instruments | Abanikazi besampula be-TGA/DSC | Umthamo wokushisa ophansi kanye nokuphendula okushisayo okusheshayo kuthuthukisa ukunemba kokulinganisa. |

Izinzuzo Zomkhiqizo

- Ukusebenza Okuphelele: I-thermal conductivity, amandla, nokumelana nokugqwala kudlula kude i-alumina ne-silicon nitride ceramics, ukuhlangabezana nezidingo zokusebenza ngokweqile.

- Idizayini Elula: Ukuminyana okungu-3.1–3.2 g/cm³ (40% wensimbi), ukunciphisa umthwalo ongenayo kanye nokuthuthukisa ukunemba kokunyakaza.

- Ukuphila Okude Nokuthembeka: Impilo yesevisi idlula iminyaka emi-5 ku-1600 ℃, yehlisa isikhathi sokuphumula futhi yehlise izindleko zokusebenza ngo-30%.

- Ukwenza ngendlela oyifisayo: Isekela amajiyometri ayinkimbinkimbi (isb., izinkomishi zokumunca ezinezimbobo, amathreyi anezendlalelo eziningi) anephutha lokucaba elingu-<15 μm ukuze uthole izinhlelo zokusebenza ezinembayo.

Imininingwane Yezobuchwepheshe

| Isigaba sepharamitha | Inkomba |

| Izakhiwo Zomzimba | |

| Ukuminyana | ≥3.10 g/cm³ |

| Amandla e-Flexural (20 ℃) | 320–410 MPa |

| I-Thermal Conductivity (20℃) | 140–300 W/(m·K) |

| I-Thermal Expansion Coefficient (25–1000℃) | 4.0×10⁻⁶/℃ |

| I-Chemical Properties | |

| Ukumelana ne-Acid (HF/H₂SO₄) | Akukho ukugqwala ngemva kokucwiliswa amahora angu-24 |

| I-Machining Precision | |

| Ukucaba | ≤15 μm (300×300 mm) |

| Ukuqina Kobuso (Ra) | ≤0.4 μm |

Izinkonzo ze-XKH

I-XKH ihlinzeka ngezixazululo ezibanzi zezimboni ezihlanganisa ukuthuthukiswa ngokwezifiso, ukunemba kwemishini, nokulawulwa kwekhwalithi okuqinile. Ekuthuthukisweni kwangokwezifiso, ihlinzeka ngezisombululo zezinto ezibonakalayo zokuhlanzeka okuphezulu (>99.999%) nezimbobo (30–50% porosity), ezibhangqwe nokumodela kwe-3D nokulingisa ukuze kuthuthukiswe amajiyometri ayinkimbinkimbi okusebenza njengama-semiconductors kanye ne-aerospace. Ukucutshungulwa okuqondilekulandela inqubo ehlelekile: ukucubungula impushana → ukucindezela kwe-isostatic/komile → 2200°C sintering → CNC/diamond grinding → ukuhlola, ukuqinisekisa ukupholisha kwezinga le-nanometer kanye nokubekezelela kobukhulu obungu-±0.01 mm. Ukulawulwa kwekhwalithi kuhlanganisa ukuhlolwa kwenqubo ephelele (ukwakheka kwe-XRD, i-SEM microstructure, ukugoba amaphuzu angu-3) nokusekelwa kobuchwepheshe (ukwenziwa ngcono kwenqubo, ukubonisana okungu-24/7, ukulethwa kwesampula kwamahora angu-48), ukuletha izingxenye ezithembekile, ezisebenza kahle kakhulu zezidingo zezimboni ezithuthukile.

Imibuzo Evame Ukubuzwa (FAQ)

1. Q: Yiziphi izimboni ezisebenzisa amathreyi e-silicon carbide ceramic?

A: Isetshenziswa kakhulu ekukhiqizeni i-semiconductor (i-wafer handling), amandla elanga (izinqubo ze-PECVD), imishini yezokwelapha (izingxenye ze-MRI), kanye ne-aerospace (izingxenye ezishisa kakhulu) ngenxa yokumelana nokushisa okukhulu nokuzinza kwamakhemikhali.

2. Q: Isebenza kanjani i-silicon carbide ukudlula amathreyi e-quartz/glass?

A: Ukumelana nokushaqeka okuphakeme okushisayo(kufika ku-1800°C uma kuqhathaniswa no-1100°C we-quartz), ukungabikho kokuphazamiseka kazibuthe, nempilo ende (iminyaka engu-5+ uma iqhathaniswa nezinyanga eziyi-6-12 zequartz).

3. Q: Ingabe amathreyi e-silicon carbide angaphatha izindawo ezine-acidic?

A: Yebo. Ingazweli ku-HF, H2SO4, kanye ne-NaOH—nokugqwala okungu-<0.01mm/ngonyaka, okuyenza ilungele ukushumeka kwamakhemikhali nokuhlanza i-wafer.

4. Q: Ingabe amathreyi e-silicon carbide ayahambisana ne-automation?

A: Yebo. Idizayinelwe i-vacuum pickup kanye nokuphathwa kwerobhothi, enobuso obucaba obungu-<0.01mm ukuvikela ukungcoliswa kwezinhlayiyana ezindwangu ezizenzakalelayo.

5. Q: Iyini ukuqhathaniswa kwezindleko uma kuqhathaniswa nezinto zokwakha zendabuko?

A: Izindleko zangaphambili eziphezulu (3-5x quartz) kodwa i-TCO ephansi ngo-30-50% ngenxa yokuphila okunwetshiwe, isikhathi sokuphumula esincishisiwe, nokonga amandla kusuka ekuphatheni okushisayo okuphakeme.