I-SiC Ceramic end effector enikeza ingalo yokuthwala i-wafer

I-SiC Ceramic end effector Abstract

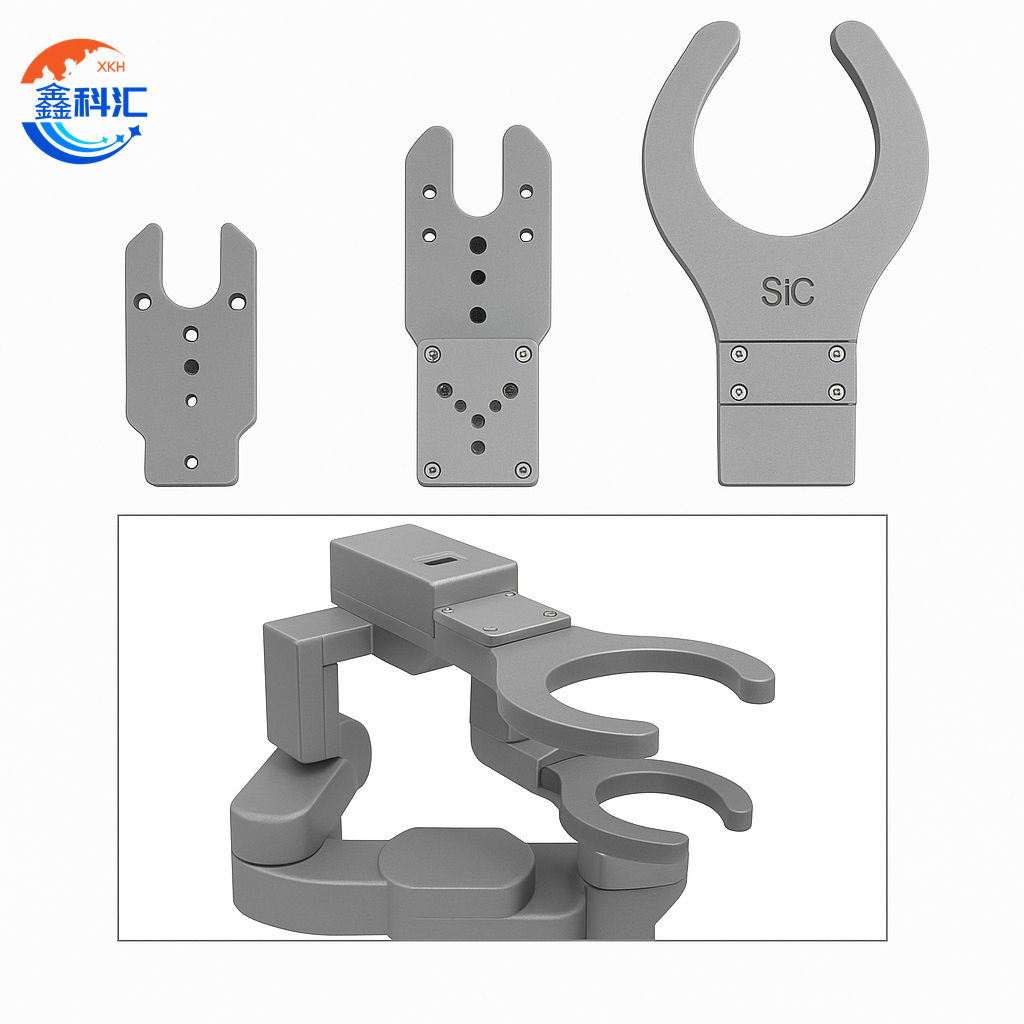

I-SiC (Silicon Carbide) isiphetho se-ceramic siyingxenye ebalulekile ezinhlelweni zokubamba zamawafa anembe kakhulu asetshenziswa ekukhiqizeni ama-semiconductor nasezindaweni ezithuthukisiwe zokwenziwa kwe-microfabrication. Njengoba yakhelwe ukuhlangabezana nezidingo ezidingekayo zendawo ehlanzeke kakhulu, izinga lokushisa eliphezulu, kanye nezimeme kakhulu, lesi siphetho esikhethekile siqinisekisa ukuthuthwa okuthembekile nokungangcoliseki kwamawafa ngesikhathi sezinyathelo zokukhiqiza ezibalulekile ezifana ne-lithography, etching, kanye nokubekwa.

Ukusebenzisa izinto eziphakeme ze-silicon carbide-ezifana nokuhamba okushisayo okuphezulu, ubulukhuni obukhulu kakhulu, ukungabi namakhemikhali okuhle kakhulu, kanye nokwanda okuncane kokushisa-i-SiC Ceramic end-effector inikeza ukuqina kwemishini okungenakuqhathaniswa nokuzinza kwe-dimensional ngisho nangaphansi kokuhamba ngebhayisikili okushisayo noma emakamelweni ezinqubo ezibolayo. Ukukhiqizwa kwayo kwezinhlayiyana eziphansi kanye nezici zokumelana ne-plasma kuyenza ifaneleke ngokukhethekile ukuhlanza igumbi kanye nezinhlelo zokusebenza zokucubungula i-vacuum, lapho ukugcinwa kobuqotho bendawo eyi-wafer nokunciphisa ukungcoliswa kwezinhlayiyana kubaluleke kakhulu.

I-SiC Ceramic end effector Isicelo

1. Ukuphatha i-Semiconductor Wafer

I-SiC ceramic end effectors isetshenziswa kabanzi embonini ye-semiconductor yokuphatha ama-wafers we-silicon ngesikhathi sokukhiqiza okuzenzakalelayo. Lawa ma-effectants agcina efakwe ezingalweni zerobhothi noma kumasistimu okudlulisa i-vacuum futhi adizayinelwe ukuthwala ama-wafer anosayizi abahlukahlukene njengo-200mm kanye no-300mm. Abalulekile ezinqubweni ezihlanganisa i-Chemical Vapor Deposition (CVD), Physical Vapor Deposition (PVD), i-etching, kanye nokusabalalisa-lapho amazinga okushisa aphezulu, izimo ze-vacuum, namagesi abolayo kuvamile. Ukumelana okushisayo okukhethekile kwe-SiC nokuzinza kwamakhemikhali kuyenza ibe into efanelekile ukumelana nezindawo ezinokhahlo ngaphandle kokonakala.

2. Igumbi lokuhlanza kanye nokuvumelana kweVacuum

Ezilungiselelweni zegumbi lokuhlanza ne-vacuum, lapho ukungcoliswa kwezinhlayiyana kufanele kuncishiswe, izinto zobumba ze-SiC zinikeza izinzuzo ezibalulekile. Indawo eminyene, ebushelelezi bendawo imelana nokukhiqizwa kwezinhlayiyana, okusiza ukugcina ubuqotho be-wafer ngesikhathi sokuthutha. Lokhu kwenza iziphetho ze-SiC zilungele kahle izinqubo ezibucayi ezifana ne-Extreme Ultraviolet Lithography (EUV) kanye ne-Atomic Layer Deposition (ALD), lapho ukuhlanzeka kubalulekile. Ngaphezu kwalokho, ukukhipha umoya okuphansi kwe-SiC kanye nokumelana okuphezulu kwe-plasma kuqinisekisa ukusebenza okuthembekile egunjini le-vacuum, kunweba isikhathi sokuphila kwamathuluzi nokunciphisa imvamisa yokulungisa.

3. High-Precision Positioning Systems

Ukunemba nokuzinza kubalulekile ezinhlelweni zokuphatha eziyisicwecwana esithuthukile, ikakhulukazi ku-metrology, ukuhlola, nokokusebenza kokuqondanisa. I-ceramics ye-SiC ine-coefficient ephansi kakhulu yokwanda okushisayo nokuqina okuphezulu, okuvumela isiphetho sokugcina ukugcina ukunemba kwesakhiwo ngisho nangaphansi kokuhamba ngebhayisikili okushisayo noma umthwalo wemishini. Lokhu kuqinisekisa ukuthi ama-wafer ahlala eqondaniswe ngokunembile ngesikhathi sokuthutha, kunciphisa ubungozi bokuklwebheka okuncane, ukungaqondi kahle, noma amaphutha okulinganisa—izici eziya ngokubucayi kakhulu kuma-sub-5nm process node.

I-SiC Ceramic end effector Properties

1. Amandla Emishini Ephakeme Nokuqina

I-ceramics ye-SiC inamandla akhethekile okusebenza, anamandla okuguquguquka avame ukudlula amavelu okuqina angama-400 MPa kanye nama-Vickers angaphezu kuka-2000 HV. Lokhu kubenza bamelane kakhulu nengcindezi yemishini, umthelela, nokuguga, ngisho nangemva kokusetshenziswa isikhathi eside. Ukuqina okuphezulu kwe-SiC nakho kunciphisa ukuchezuka ngesikhathi sokudluliselwa kwe-wafer enesivinini esikhulu, iqinisekisa ukuma okunembile nokuphindaphindwayo.

2. Excellent Thermal Stability

Esinye sezici ezibaluleke kakhulu ze-ceramics ye-SiC yikhono lazo lokumelana namazinga okushisa aphakeme kakhulu-ngokuvamile afika ku-1600 ° C emkhathini we-inert-ngaphandle kokulahlekelwa ubuqotho bemishini. I-coefficient yabo ephansi yokunwetshwa kwe-thermal (~4.0 x 10⁻⁶ /K) iqinisekisa ukuzinza kwe-dimensional ngaphansi kwamabhayisikili ashisayo, okuwenza afaneleke ezinhlelweni ezifana ne-CVD, PVD, kanye ne-high-temperature annealing.

I-SiC Ceramic end effect Q&A

Q: Yiziphi izinto ezisetshenziswa ku-wafer end effector?

A:Ama-wafer end effectors ajwayelekile enziwa ngezinto ezinikeza amandla aphezulu, ukuqina okushisayo, nokukhiqizwa kwezinhlayiyana eziphansi. Phakathi kwalokhu, i-Silicon Carbide (SiC) ceramic ingenye yezinto eziphambili kakhulu futhi ezithandwayo. Izitsha zobumba ze-SiC ziqine ngokwedlulele, azinze ngokokushisa, azifaki amakhemikhali, futhi azikwazi ukugqokwa, zizenza zilungele ukuphatha amawafa e-silicon athambile endaweni ehlanzekile neyomshini wokuwasha. Uma kuqhathaniswa ne-quartz noma izinsimbi ezimboziwe, i-SiC inikeza ukuzinza okuphakeme okuphezulu ngaphansi kwamazinga okushisa aphezulu futhi ayichithi izinhlayiya, okusiza ukuvimbela ukungcola.