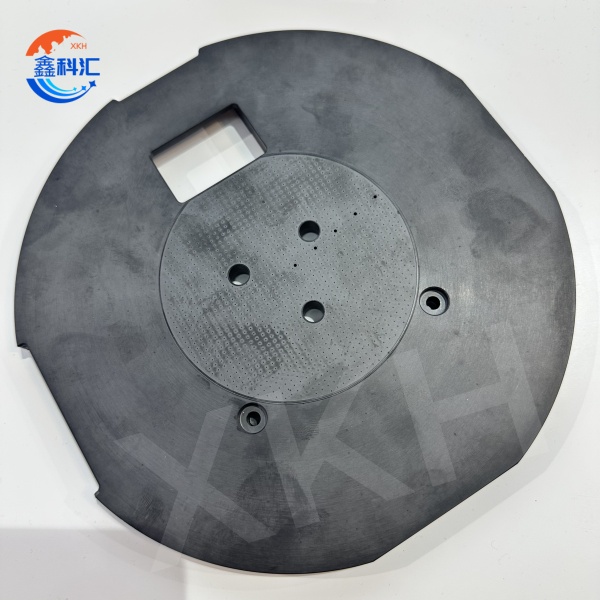

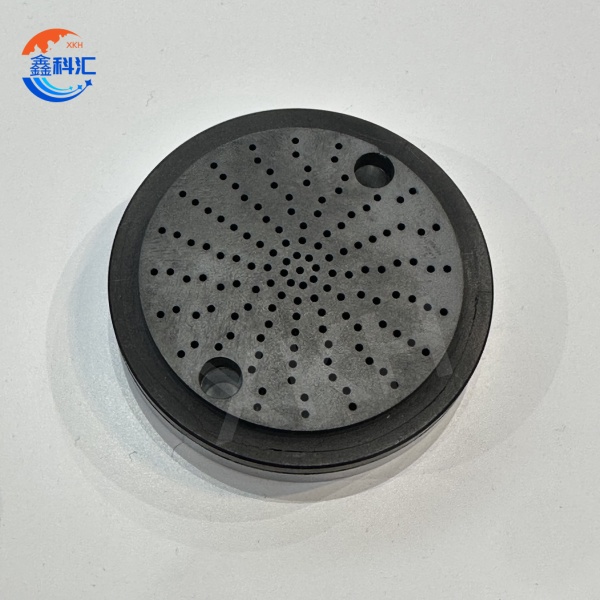

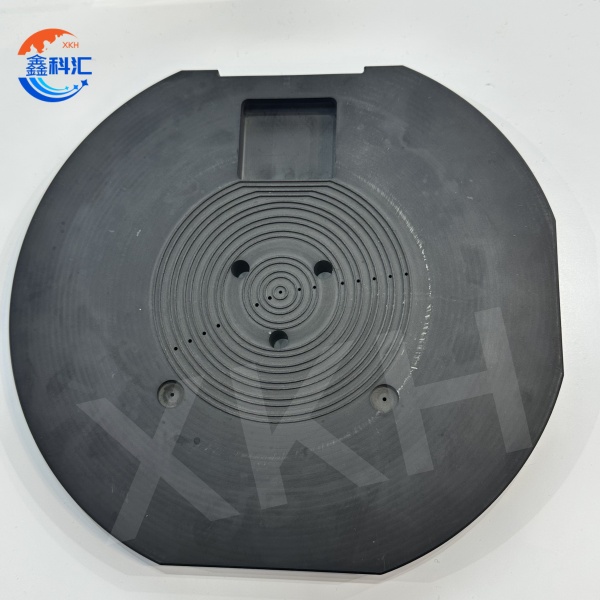

Ithreyi ye-Ceramic chuck ye-Ceramic inkomishi yokumunca ukunemba ukwenziwa ngendlela oyifisayo

Izici zezinto ezibonakalayo:

1.Ukuqina okuphezulu: ubulukhuni be-Mohs be-silicon carbide yi-9.2-9.5, okwesibili kuphela kwedayimane, enokumelana nokugqoka okuqinile.

2. I-thermal conductivity ephezulu: i-thermal conductivity ye-silicon carbide iphezulu njenge-120-200 W/m·K, engakhipha ukushisa ngokushesha futhi ifanele indawo yokushisa ephezulu.

3. I-coefficient ephansi yokwandisa okushisayo: i-silicon carbide yokwandisa ukushisa kwe-thermal coefficient iphansi (4.0-4.5×10⁻⁶/K), isengagcina ukuqina kobukhulu ezingeni lokushisa eliphezulu.

4. Ukuzinza kwamakhemikhali: i-silicon carbide acid kanye ne-alkali corrosion resistance, ilungele ukusetshenziswa endaweni eyonakalisa amakhemikhali.

5. Amandla aphezulu emishini: I-silicon carbide inamandla okugoba aphezulu namandla acindezelayo, futhi ingamelana nokucindezeleka okukhulu kwemishini.

Izici:

1.Embonini ye-semiconductor, ama-wafer azacile kakhulu adinga ukubekwa enkomishini yokumunca i-vacuum, ukumuncwa kwe-vacuum kusetshenziselwa ukulungisa ama-wafers, futhi inqubo yokuwaxisa, ukucwenga, ukukhanjiswa, ukuhlanza nokusika kwenziwa kumawafa.

I-2.I-Silicon carbide sucker ine-conductivity enhle yokushisa, ingafinyeza ngokuphumelelayo isikhathi se-wax ne-waxing, ithuthukise ukusebenza kahle kokukhiqiza.

3.I-Silicon carbide vacuum sucker nayo ine-asidi enhle ne-alkali ukumelana nokugqwala.

4.Uma kuqhathaniswa nepuleti yenkampani ye-corundum yendabuko, finyeza ukulayisha nokukhipha ukushisa nesikhathi sokupholisa, uthuthukise ukusebenza kahle komsebenzi; Ngesikhathi esifanayo, inganciphisa ukuguga phakathi kwamapuleti angaphezulu naphansi, igcine ukunemba okuhle kwendiza, futhi yandise impilo yesevisi cishe ngama-40%.

I-5.Ingxenye yezinto ezibonakalayo incane, isisindo esincane. Kulula kuma-opharetha ukuthi baphathe ama-pallet, okunciphisa ingozi yokulimala okubangelwa ubunzima bezokuthutha cishe ngama-20%.

6.Usayizi: ububanzi obukhulu 640mm; Ukucaba: 3um noma ngaphansi

Inkambu yohlelo lokusebenza:

1. Ukukhiqizwa kwe-semiconductor

● Ukucutshungulwa kwe-wafer:

Ukulungiswa kwe-wafer ku-photolithography, i-etching, ukufakwa kwefilimu encane nezinye izinqubo, ukuqinisekisa ukunemba okuphezulu kanye nokuvumelana kwenqubo. Izinga layo eliphezulu lokushisa kanye nokumelana nokugqwala kulungele izindawo zokukhiqiza ze-semiconductor ezinokhahlo.

●Ukukhula kwe-Epitaxial:

Ku-SiC noma i-GaN ukukhula kwe-epitaxial, njengesithwali sokushisa nokulungisa ama-wafers, okuqinisekisa ukufana kwezinga lokushisa kanye nekhwalithi yekristalu kumazinga okushisa aphezulu, okuthuthukisa ukusebenza kwedivayisi.

2. Imishini yezithombe zikagesi

● Ukukhiqiza kwe-LED:

Isetshenziselwa ukulungisa isafire noma i-SiC substrate, futhi njengesithwali sokushisa kwinqubo ye-MOCVD, ukuqinisekisa ukufana kokukhula kwe-epitaxial, ukuthuthukisa ukusebenza kahle kwe-LED ekhanyayo nekhwalithi.

● I-Laser diode:

Njengomshini wokunemba okuphezulu, ukulungisa nokushisa i-substrate yokuqinisekisa ukuzinza kwezinga lokushisa, ukuthuthukisa amandla okukhipha kanye nokuthembeka kwe-laser diode.

3. Ukunemba kwemishini

●Optical ingxenye yokucubungula:

Isetshenziselwa ukulungisa izingxenye ezinembayo ezifana namalensi optical nezihlungi ukuze kuqinisekiswe ukunemba okuphezulu kanye nokungcola okuphansi ngesikhathi sokucubungula, futhi ifaneleka ekushicileleni okukhulu.

● Ukucutshungulwa kweCeramic:

Njengomshini wokuzinza okuphezulu, ilungele ukunemba kwemishini ye-ceramic ukuze kuqinisekiswe ukunemba kwemishini kanye nokuvumelana ngaphansi kwezinga lokushisa eliphezulu kanye nemvelo ebolayo.

4. Ukuhlolwa kwesayensi

●Ukuhlolwa kwezinga lokushisa eliphezulu:

Njengedivayisi yokulungisa isampula ezindaweni zokushisa okuphezulu, isekela ukuhlolwa kwezinga lokushisa elidlulele ngaphezu kuka-1600°C ukuze kuqinisekiswe ukufana kwezinga lokushisa kanye nokuzinza kwesampula.

● Ukuhlolwa kwe-vacuum:

Njengesampula yokulungisa nesithwali sokushisisa endaweni ye-vacuum, ukuqinisekisa ukunemba nokuphindaphinda kokuhlolwa, okulungele ukumbozwa kwe-vacuum nokwelashwa kokushisa.

Imininingwane yobuchwepheshe:

| (Impahla) | (Iyunithi) | (sic) | |

| (Okuqukethwe kwe-SiC) |

| (Wt)% | >99 |

| (Isilinganiso sikasayizi wokusanhlamvu) |

| micron | 4-10 |

| (Ukuminyana) |

| kg/dm3 | >3.14 |

| (I-porosity ebonakalayo) |

| I-Vo1% | <0.5 |

| (Vickers hardness) | I-HV 0.5 | I-GPa | 28 |

| *(Amandla e-Flexural) | 20ºC | I-MPa | 450 |

| (Amandla acindezelayo) | 20ºC | I-MPa | 3900 |

| (I-Elastic Modulus) | 20ºC | I-GPa | 420 |

| (Ukuphuka kokuqina) |

| MPa/m'% | 3.5 |

| (I-Thermal conductivity) | 20°C | W/(m*K) | 160 |

| (Ukumelana) | 20°C | Ohm.cm | 106-108 |

|

| a(RT**...80ºC) | K-1*10-6 | 4.3 |

|

|

| oºC | 1700 |

Ngokuqoqwa kweminyaka yobuchwepheshe nolwazi lwemboni, i-XKH iyakwazi ukuthunga amapharamitha angukhiye njengosayizi, indlela yokushisisa kanye nedizayini ye-vacuum adsorption ye-chuck ngokuya ngezidingo ezithile zekhasimende, iqinisekisa ukuthi umkhiqizo uvumelana ngokuphelele nenqubo yekhasimende. I-SiC silicon carbide ceramic chucks isiphenduke izakhi ezibalulekile ekucubungulweni kwe-wafer, ukukhula kwe-epitaxial nezinye izinqubo ezibalulekile ngenxa ye-conductivity yabo enhle kakhulu yokushisa, ukuzinza okuphezulu kwezinga lokushisa kanye nokuzinza kwamakhemikhali. Ikakhulukazi ekukhiqizeni izinto ze-semiconductor zesizukulwane sesithathu ezifana ne-SiC ne-GaN, isidingo sama-silicon carbide ceramic chucks siyaqhubeka sikhula. Ngokuzayo, ngokuthuthuka okusheshayo kwe-5G, izimoto zikagesi, ubuhlakani bokwenziwa nobunye ubuchwepheshe, amathemba okusetshenziswa kwe-silicon carbide ceramic chucks embonini ye-semiconductor azoba banzi.

Umdwebo onemininingwane