Isisetshenziswa Semiconductor Laser Lift-Off Revolutionize Ingot Thinning

Umdwebo onemininingwane

Ukwethulwa Komkhiqizo Kwezisetshenziswa Zokuphakamisa I-Laser Semiconductor

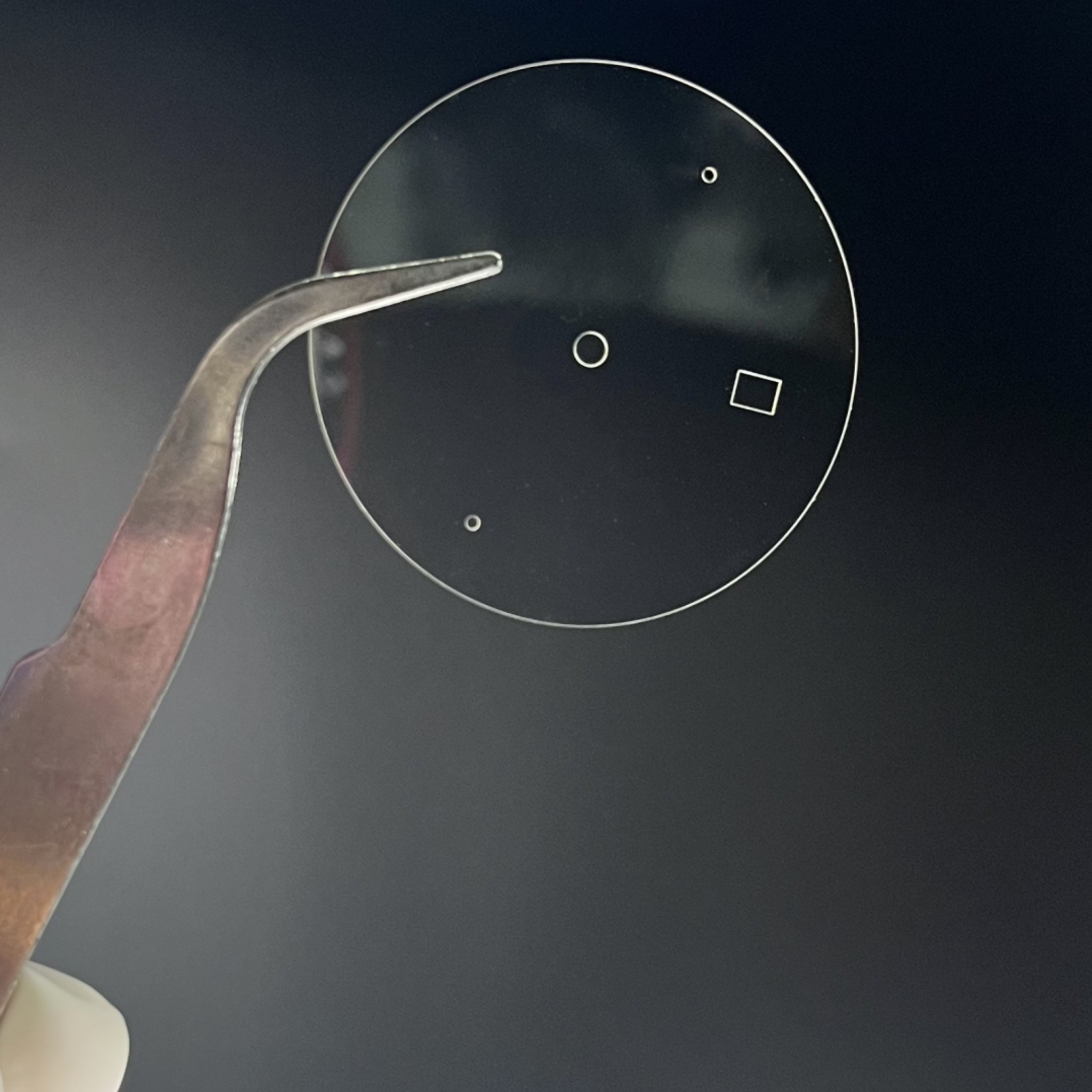

I-Semiconductor Laser Lift-Off Equipment iyisixazululo esikhethekile sezimboni esiklanyelwe ukuncishiswa okunembile nokungathinteki kwama-ingots we-semiconductor kusetshenziswa amasu okuphakamisa okwenziwa nge-laser. Lolu hlelo oluthuthukisiwe ludlala indima ebalulekile ezinqubweni zesimanje zokuphekwa kwe-semiconductor, ikakhulukazi ekwenziweni kwamawafa amancane kakhulu ama-electronics asebenza kahle kakhulu, ama-LED, namadivayisi e-RF. Ngokuvumela ukuhlukaniswa kwezendlalelo ezizacile kusukela kuzingothi eziyinqwaba noma ama-substrates abanikeli, Isisetshenziswa Sokuphakamisa I-Laser Semiconductor sishintsha ukucwenga kwe-ingot ngokuqeda izinyathelo zokusaha, ukugaya, kanye nekhemikhali.

Ukunciphisa okuvamile kweziyingo ze-semiconductor, njenge-gallium nitride (GaN), i-silicon carbide (SiC), nesafire, kuvamise ukuba nomsebenzi omkhulu, kumoshe, futhi kujwayele ukonakala noma ukulimala kwendawo. Ngokuphambene, I-Semiconductor Laser Lift-Off Equipment inikezela ngenye indlela engonakali, enembile enciphisa ukulahleka kwezinto ezibonakalayo kanye nengcindezi yendawo ngenkathi ikhulisa umkhiqizo. Isekela izinhlobonhlobo zezinto ezicwebezelayo nezihlanganisiwe futhi ingahlanganiswa ngaphandle komthungo emigqeni yokukhiqiza ye-semiconductor engaphambili noma emaphakathi.

Ngobude begagasi be-laser obulungisekayo, izinhlelo zokugxilisa eziguquguqukayo, nama-wafer chuck ahambisana ne-vacuum, lesi sisetshenziswa sikufanelekela kahle ukusikwa kwe-ingot, ukudalwa kwe-lamella, kanye nokuhlanganisa ifilimu emincane kakhulu yezakhiwo zedivayisi ezime mpo noma ukudluliswa kongqimba lwe-heteroepitaxial.

Ipharamitha ye-Semiconductor Laser Lift-Off Equipment

| Ubude begagasi | I-IR/SHG/THG/FHG |

|---|---|

| Ububanzi be-Pulse | Nanosecond, Picosecond, Femtosecond |

| Isistimu ye-Optical | Isistimu yokubona elungisiwe noma isistimu ye-Galvano-optical |

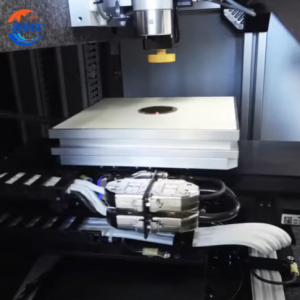

| Isiteji se-XY | 500 mm × 500 mm |

| Icubungula Ububanzi | 160 mm |

| Isivinini Sokunyakaza | Ubuningi 1,000 mm/sec |

| Ukuphindaphinda | ±1 μm noma ngaphansi |

| Ukunemba Kwesikhundla Okuphelele: | ±5 μm noma ngaphansi |

| Usayizi we-Wafer | 2–6 amayintshi noma ngokwezifiso |

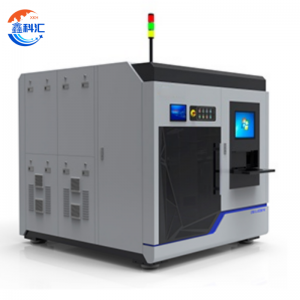

| Lawula | Windows 10, 11 kanye ne-PLC |

| I-Voltage Yokuhlinzeka Amandla | I-AC 200 V ±20 V, Isigaba esisodwa, 50/60 kHz |

| Ubukhulu bangaphandle | 2400 mm (W) × 1700 mm (D) × 2000 mm (H) |

| Isisindo | 1,000 kg |

Isimiso sokuSebenza se-Semiconductor Laser Lift-Off Equipment

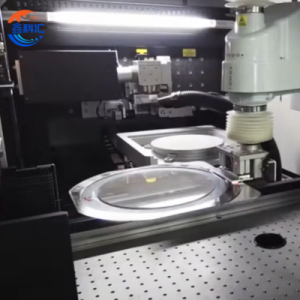

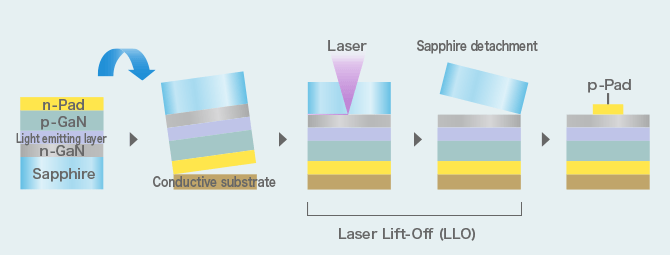

Indlela eyinhloko Yesisetshenziswa Sokuphakamisa I-Laser Semiconductor sincike ekuhlehleni okukhethiwe kwe-photothermal noma ukuphuma kusixhumi esibonakalayo phakathi kwe-ingot yokunikela kanye nesendlalelo se-epitaxial noma esiqondiwe. Ilaser ye-UV enamandla amakhulu (imvamisa i-KrF ku-248 nm noma amalaser e-UV esimo esiqinile azungeze u-355 nm) igxiliswe ngento yomnikeli esobala noma ebonisa ngale, lapho amandla amuncwa ngokukhetha ngokujula okunqunywe kusengaphambili.

Lokhu kumuncwa kwamandla okwenziwa kwasendaweni kudala isigaba segesi esinomfutho ophezulu noma isendlalelo sokunwebeka esishisayo kusixhumi esibonakalayo, esiqala ukuhlukaniswa okuhlanzekile kwe-wafer engaphezulu noma isendlalelo sedivayisi kusukela kusisekelo se-ingot. Inqubo ishunwa kahle ngokulungisa amapharamitha afana nobubanzi be-pulse, i-laser fluence, isivinini sokuskena, kanye nokujula okugxile kwe-z-axis. Umphumela uba ucezu oluzacile kakhulu—ngokuvamile ebangeni elingu-10 kuye ku-50 µm—oluhlukaniswe ngokuhlanzekile nengothi engumzali ngaphandle kokuhuzuka komshini.

Le ndlela yokuphakamisa i-laser ukuze kuncishiswe i-ingot igwema ukulahleka kwe-kerf kanye nokulimala kwendawo okuhlobene nokusaha intambo yedayimane noma ukuxhaphazwa ngomshini. Iphinde igcine ubuqotho bekristalu futhi yehlise izidingo zokupholisha ezansi komfula, okwenza iSemiconductor Laser Lift-Off Equipment ibe ithuluzi elishintsha igeyimu lokukhiqiza i-wafer yesizukulwane esilandelayo.

Izicelo ze-Semiconductor Laser Lift-Off Equipment

I-Semiconductor Laser Lift-Off Equipment ithola ukusebenza okubanzi ekuncipheni kwe-ingot kulo lonke uhla lwezinto ezithuthukisiwe nezinhlobo zedivayisi, okuhlanganisa:

-

I-GaN ne-GaAs Ingot Thinning yamadivayisi Amandla

Inika amandla ukudalwa kwe-wafer emincane ekusebenzeni kahle okuphezulu, ama-transistors amandla amelana kancane nama-diode.

-

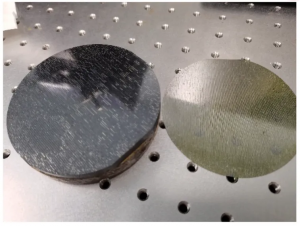

I-SiC Substrate Reclamation kanye ne-Lamella Separation

Ivumela ukuphakanyiswa kwe-wafer-scale kusuka kunqwaba ye-SiC substrates yezakhiwo zedivayisi eziqondile nokusetshenziswa kabusha kwe-wafer.

-

I-Wafer ye-LED Slicing

Ikhuthaza ukukhushulwa kwezendlalelo ze-GaN kusukela kuzingosi eziwugqinsi zesafire ukuze kukhiqizwe ama-substrates e-LED amancane kakhulu.

-

I-RF ne-Microwave Device Fabrication

Isekela i-ultra-thin high-electron-mobility transistor (HEMT) izakhiwo ezidingekayo ku-5G namasistimu e-radar.

-

I-Epitaxial Layer Transfer

Ikhipha ngokunembile izendlalelo ze-epitaxial kusukela kuma-ingots acwebile ukuze ziphinde zisetshenziswe noma zihlanganiswe zibe i-heterostructures.

-

Amangqamuzana eSolar Ancane-Film nama-Photovoltaics

Isetshenziselwa ukuhlukanisa izendlalelo zokumunca ezincane zamaseli elanga aguquguqukayo noma asebenza kahle kakhulu.

Esizindeni ngasinye salezi zizinda, Isisetshenziswa Sokuphakamisa I-Laser Semiconductor sinikeza ukulawula okungenakuqhathaniswa kokufana kogqinsi, ikhwalithi yendawo ephezulu, nobuqotho besendlalelo.

Izinzuzo ze-Laser-based Ingot Thinning

-

Ukulahlekelwa Kwezinto Zero-Kerf

Uma kuqhathaniswa nezindlela zendabuko zokusika i-wafer, inqubo ye-laser iholela cishe ekusetshenzisweni kwempahla eyi-100%.

-

Ukucindezeleka Okuncane kanye Ne-Warping

I-lift-off engathinteki iqeda ukudlidliza komshini, kunciphisa umnsalo we-wafer kanye nokwakheka kwe-microcrack.

-

Ukulondolozwa Kwekhwalithi Yobuso

Akukho ukugxusha ngemva kokuncipha noma ukupholishwa okudingekayo ezimweni eziningi, njengoba i-laser lift-off ilondoloza ubuqotho obungaphezulu.

-

I-High Throughput and Automation Ready

Iyakwazi ukucubungula amakhulukhulu ama-substrates shift ngayinye ngokulayisha/ukulayishwa okuzenzakalelayo.

-

Ivumelana nezimo Ezintweni Eziningi

Ihambisana ne-GaN, SiC, sapphire, GaAs, nezinto ezisafufusa ze-III-V.

-

Iphephile Ngokwemvelo

Yehlisa ukusetshenziswa kwama-abrasives namakhemikhali anokhahlo ajwayelekile ezinqubweni zokuncipha ezisuselwe kwi-slurry.

-

Ukusebenzisa kabusha I-substrate

Ama-ingots abanikeli angaphinda asetshenziswe emijikelezweni eminingi yokuphakama, kwehlise kakhulu izindleko zempahla.

Imibuzo Evame Ukubuzwa (FAQ) Yezisetshenziswa Zokuphakamisa I-Laser Semiconductor

-

Q1: Yiluphi uhla lokujiya olungafinyelelwa Isisetshenziswa Semiconductor Laser Lift-Off ngezingcezu zamawafa?

A1:Ubukhulu bocezu obujwayelekile busukela ku-10 µm kuye ku-100 µm kuye ngempahla nokucushwa.I-Q2: Ingabe lo mshini ungasetshenziselwa ama-ingots amancane enziwe ngezinto ezi-opaque njenge-SiC?

A2:Yebo. Ngokulungisa ubude begagasi be-laser nokuthuthukisa ubunjiniyela besixhumi esibonakalayo (isb., izihlanganisi zomhlatshelo), ngisho nezinto ezifiphele kancane zingasetshenzwa.Q3: Ngabe i-substrate yokunikela ihambisana kanjani ngaphambi kokususwa kwe-laser?

A3:Uhlelo lusebenzisa amamojula okuqondanisa asekelwe kumbono we-sub-micron anempendulo evela kumamaki we-fiducial kanye nezikena zokubonakala kwendawo.Q4: Yisiphi isikhathi somjikelezo esilindelekile sokusebenza okukodwa kwe-laser?

A4:Ngokuya ngosayizi we-wafer nokuqina, imijikelezo ejwayelekile ithatha imizuzu emi-2 kuye kweyi-10.Q5: Ingabe inqubo idinga indawo ehlanzekile yegumbi?

A5:Nakuba kungaphoqelekile, ukuhlanganiswa kwegumbi lokuhlanza kuyanconywa ukuze kugcinwe ukuhlanzeka kwe-substrate kanye nesivuno sedivayisi ngesikhathi sokusebenza okunembayo okuphezulu.

Mayelana NATHI

I-XKH igxile ekuthuthukisweni kobuchwepheshe obuphezulu, ukukhiqiza, nokudayiswa kwengilazi ekhethekile yokubona nezinto ezintsha zekristalu. Imikhiqizo yethu isebenza ngogesi obonakalayo, ugesi wabathengi, kanye nezempi. Sinikezela ngezinto ezibonakalayo ze-Sapphire, izembozo zamalensi omakhalekhukhwini, i-Ceramics, i-LT, i-Silicon Carbide SIC, i-Quartz, namawafa ekristalu e-semiconductor. Ngobungcweti abanamakhono nemishini esezingeni eliphezulu, sihamba phambili ekucutshungulweni komkhiqizo okungajwayelekile, sihlose ukuba yibhizinisi elihamba phambili le-optoelectronic materials high-tech.