Isisetshenziswa Semiconductor Laser Lift-Off

Umdwebo onemininingwane

Uhlolojikelele Lomkhiqizo Wezinto Zokuphakamisa I-Laser

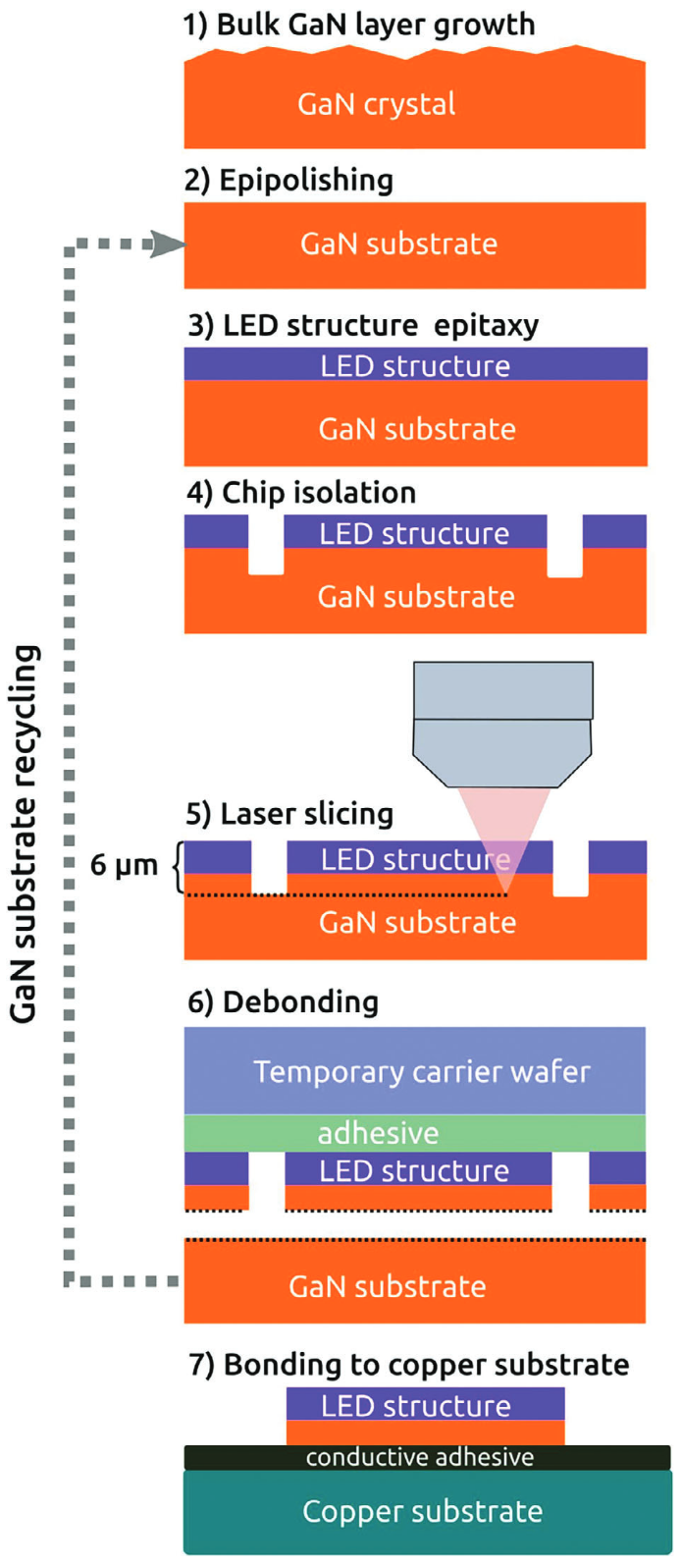

I-Semiconductor Laser Lift-Off Equipment imele isisombululo sesizukulwane esilandelayo sokuncishiswa kwe-ingot okuthuthukisiwe ekucubunguleni impahla ye-semiconductor. Ngokungafani nezindlela ezijwayelekile zokusonta ezithembele ekugayeni okuwumshini, ukusaha izintambo zedayimane, noma i-chemical-mechanical planarization, le nkundla esekelwe nge-laser inikeza enye indlela engenakho ukuthinta, engonakali yokukhipha izendlalelo ezizacile kakhulu kuzingothi eziyinqwaba ze-semiconductor.

Ilungiselelwe izinto zokwakha eziphukayo nezinenani eliphezulu njenge-gallium nitride (GaN), i-silicon carbide (SiC), i-sapphire, ne-gallium arsenide (GaAs), Isisetshenziswa Semiconductor Laser Lift-Off sinika amandla ukusika ngokunemba kwamafilimu esikali se-wafer ngqo kusuka ku-crystal ingot. Lobu buchwepheshe bempumelelo bunciphisa ngokuphawulekayo udoti wezinto ezibonakalayo, buthuthukisa ukuphuma, futhi buthuthukise ubuqotho be-substrate - konke okubalulekile kumadivayisi esizukulwane esilandelayo kugesi wamandla, amasistimu e-RF, izithombe, nezibonisi ezincane.

Ngokugcizelelwa ekulawuleni okuzenzakalelayo, ukubunjwa kwemishayo, nokuhlaziya ukusebenzisana kwe-laser, i-Semiconductor Laser Lift-Off Equipment iklanyelwe ukuhlanganisa ngaphandle komthungo ekugelezeni komsebenzi wokwenziwa kwe-semiconductor kuyilapho isekela ukuguquguquka kwe-R&D kanye nokwanda kokukhiqizwa ngobuningi.

Ubuchwepheshe Nomgomo Wokusebenza Wezisetshenziswa Zokuphakamisa I-Laser

Inqubo eyenziwa yi-Semiconductor Laser Lift-Off Equipment iqala ngokufaka imisebe ingot yomnikezeli ohlangothini olulodwa kusetshenziswa umsebe we-laser we-ultraviolet wamandla aphezulu. Le nsimbi igxile ekujuleni okuthile kwangaphakathi, ngokuvamile eduze kwesixhumi esibonakalayo esinobunjiniyela, lapho ukumuncwa kwamandla kukhuliswa ngenxa yokungafani kokubona, okushisayo, noma kwamakhemikhali.

Kulesi sendlalelo sokumunca amandla, ukushisisa kwendawo kuholela ekuqhumeni okuncane okusheshayo, ukunwetshwa kwegesi, noma ukubola kwesendlalelo esihlangana phakathi kobuso (isb., ifilimu ecindezelayo noma i-sacrificial oxide). Lokhu kuphazamiseka okulawulwa ngokunembile kubangela ungqimba lwekristalu olungaphezulu - olunogqinsi lwamashumi ama-micrometer - lusuke ku-ingot eyisisekelo ngokuhlanzekile.

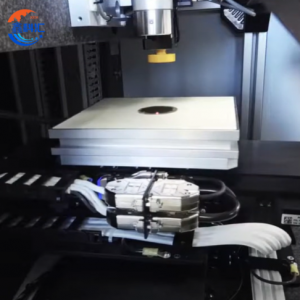

I-Semiconductor Laser Lift-Off Equipment isebenzisa amakhanda okuskena avumelanisiwe anyakazayo, isilawuli se-z-axis esihlelekayo, kanye ne-real-time reflectometry ukuze kuqinisekiswe ukuthi yonke i-pulse iletha amandla endizeni eqondiwe. Okokusebenza kungalungiswa futhi ngemodi yokuqhuma noma amandla e-multi-pulse ukuze kuthuthukiswe ukushelela kwe-detachment futhi kuncishiswe ingcindezi eyinsalela. Okubalulekile, ngenxa yokuthi i-laser beam ayilokothi ixhumane nezinto ezibonakalayo, ingozi yokuqhekeka okuncane, ukukhothama, noma ukuchotshozwa kwendawo iyancipha kakhulu.

Lokhu kwenza indlela yokunciphisa i-laser iguqule igeyimu, ikakhulukazi ezinhlelweni zokusebenza lapho kudingeka khona amawafa ayi-ultra-flat, azacile kakhulu nge-sub-micron TTV (Total Thickness Variation).

Ipharamitha ye-Semiconductor Laser Lift-Off Equipment

| Ubude begagasi | I-IR/SHG/THG/FHG |

|---|---|

| Ububanzi be-Pulse | Nanosecond, Picosecond, Femtosecond |

| Isistimu ye-Optical | Isistimu yokubona elungisiwe noma isistimu ye-Galvano-optical |

| Isiteji se-XY | 500 mm × 500 mm |

| Icubungula Ububanzi | 160 mm |

| Isivinini Sokunyakaza | Ubuningi 1,000 mm/sec |

| Ukuphindaphinda | ±1 μm noma ngaphansi |

| Ukunemba Kwesikhundla Okuphelele: | ±5 μm noma ngaphansi |

| Usayizi we-Wafer | 2–6 amayintshi noma ngokwezifiso |

| Lawula | Windows 10, 11 kanye ne-PLC |

| I-Voltage Yokuhlinzeka Amandla | I-AC 200 V ±20 V, Isigaba esisodwa, 50/60 kHz |

| Ubukhulu bangaphandle | 2400 mm (W) × 1700 mm (D) × 2000 mm (H) |

| Isisindo | 1,000 kg |

Izicelo zezimboni ze-Laser Lift-Off Equipment

I-Semiconductor Laser Lift-Off Equipment ishintsha ngokushesha indlela izinto ezilungiswa ngayo kuzo zonke izizinda zama-semiconductor amaningi:

- Amadivayisi Anamandla e-GaN Amile Wezinto Zokuphakamisa I-Laser

Ukukhishwa kwamafilimu e-GaN-on-GaN azacile kakhulu avela ezingomeni eziyinqwaba kunika amandla ama-architecture okwenziwa aqondile kanye nokusetshenziswa kabusha kwama-substrates abizayo.

- I-SiC Wafer Thinning ye-Schottky kanye namadivayisi we-MOSFET

Yehlisa ukujiya kwesendlalelo sedivayisi ngenkathi ilondoloza ukuhlukahluka kwe-substrate — ilungele ama-electronics ashintsha ngokushesha.

- I-LED Esuselwa ku-Sapphire kanye Nezisetshenziswa Zokubonisa Zesisetshenziswa Sokuphakamisa I-Laser

Inika amandla ukuhlukaniswa okuphumelelayo kwezendlalelo zedivayisi kusukela kuma-sapphire boules ukuze kusekelwe ukukhiqizwa kwe-micro-LED emincane, elungiselelwe ngokushisa.

- I-III-V Material Engineering Yezisetshenziswa Zokuphakamisa I-Laser

Ihambisa ithimba lezendlalelo ze-GaAs, i-InP, ne-AlGaN ukuze kuhlanganiswe i-optoelectronic ethuthukisiwe.

- I-Thin-Wafer IC kanye Nokwenziwa Kwezinzwa

Ikhiqiza izendlalelo ezisebenzayo ezincanyana zezinzwa zokucindezela, ama-accelerometer, noma ama-photodiode, lapho inqwaba kuwumgoqo wokusebenza.

- I-Flexible and Transparent Electronics

Ilungiselela ama-substrates azacile kakhulu afanele izibonisi eziguquguqukayo, amasekhethi agqokekayo, namawindi ahlakaniphile abonisa ngale.

Kuyo ngayinye yalezi zindawo, Isisetshenziswa Sokuphakamisa I-Laser Semiconductor sidlala indima ebalulekile ekuvumeleni ukwenziwa okuncane, ukusetshenziswa kabusha kwezinto ezibonakalayo, kanye nokwenza lula inqubo.

Imibuzo Evame Ukubuzwa (FAQ) Yezisetshenziswa Zokuphakamisa I-Laser

Q1: Yibuphi ubukhulu obuncane engingabufinyelela ngisebenzisa Isisetshenziswa Sokuphakamisa I-Laser Semiconductor?

A1:Ivamise ukuba phakathi kwama-microns ayi-10–30 kuye ngempahla. Inqubo iyakwazi ukuthola imiphumela emincane ngokusetha okushintshiwe.

Q2: Ingabe lokhu kungasetshenziswa ukusika amawafa amaningi ku-ingot efanayo?

A2:Yebo. Amakhasimende amaningi asebenzisa indlela yokuphakamisa i-laser ukwenza izingcaphuno ze-serial zezendlalelo ezincanyana eziningi ukusuka ku-ingot eyodwa yenqwaba.

Q3: Yiziphi izici zokuphepha ezifakiwe ekusebenzeni kwe-laser enamandla amakhulu?

A3:Izivalo zekilasi 1, amasistimu wokukhiya, ukuvikela imishayo, nokuvalwa okuzenzakalelayo konke kujwayelekile.

Q4: Lolu hlelo luqhathaniswa kanjani namasaha ocingo lwedayimane ngokwezindleko?

A4:Nakuba i-capex yokuqala ingase ibe phezulu, i-laser lift-off kunciphisa kakhulu izindleko ezisetshenziswayo, umonakalo we-substrate, kanye nezinyathelo zokucubungula ngemva kokucubungula — ukwehlisa ingqikithi yezindleko zobunikazi (TCO) isikhathi eside.

I-Q5: Ingabe inqubo ingahle ifinyelele kuma-ingots angu-6-intshi noma angu-8-intshi?

A5:Nakanjani. Iplathifomu isekela ama-substrates afika kwangu-12-intshi ngokusatshalaliswa kwensimbi efanayo kanye nezigaba zokunyakaza zefomethi enkulu.

Mayelana NATHI

I-XKH igxile ekuthuthukisweni kobuchwepheshe obuphezulu, ukukhiqiza, nokudayiswa kwengilazi ekhethekile yokubona nezinto ezintsha zekristalu. Imikhiqizo yethu isebenza ngogesi obonakalayo, ugesi wabathengi, kanye nezempi. Sinikezela ngezinto ezibonakalayo ze-Sapphire, izembozo zamalensi omakhalekhukhwini, i-Ceramics, i-LT, i-Silicon Carbide SIC, i-Quartz, namawafa ekristalu e-semiconductor. Ngobungcweti abanamakhono nemishini esezingeni eliphezulu, sihamba phambili ekucutshungulweni komkhiqizo okungajwayelekile, sihlose ukuba yibhizinisi elihamba phambili le-optoelectronic materials high-tech.