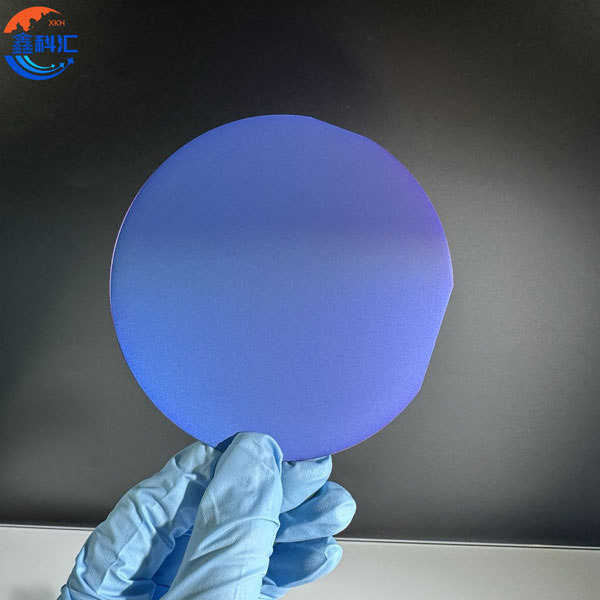

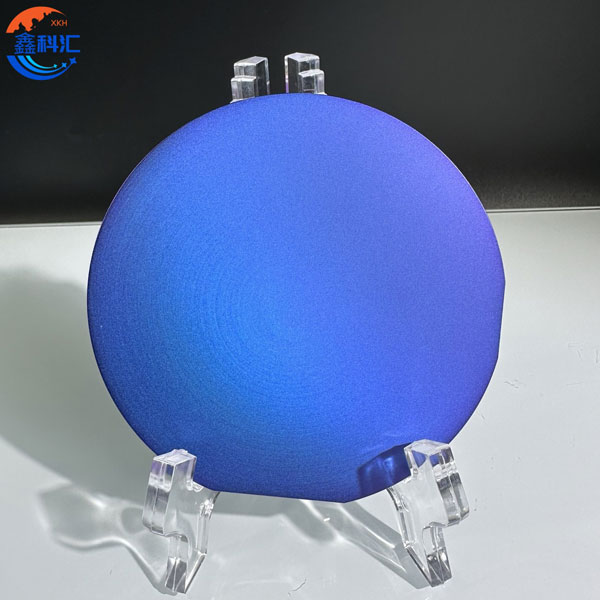

I-Semi-Insulating SiC ku-Si Composite Substrates

| Izinto | Ukucaciswa | Izinto | Ukucaciswa |

| Ububanzi | 150±0.2mm | Ukuqondisa | <111>/<100>/<110> njalo njalo |

| I-Polytype | 4H | Uhlobo | P/N |

| Ukungazweli | ≥1E8ohm·cm | Ukucaba | I-Flat/Notch |

| Dlulisa Ukuqina kwesendlalelo | ≥0.1μm | I-Edge Chip, Scratch, Crack (ukuhlola okubonakalayo) | Lutho |

| Ize | ≤5ea/wafer (2mm>D>0.5mm) | I-TTV | ≤5μm |

| Ubulukhuni bangaphambili | I-Ra≤0.2nm (5μm*5μm) | Ubukhulu | 500/625/675±25μm |

Le nhlanganisela inikeza izinzuzo eziningi ekukhiqizeni izinto zikagesi:

Ukuhambisana: Ukusetshenziswa kwe-silicon substrate kuyenza ihambisane nezindlela ezijwayelekile zokucubungula i-silicon futhi ivumela ukuhlanganiswa nezinqubo zokukhiqiza ezikhona ze-semiconductor.

Ukusebenza okuphezulu kwezinga lokushisa: I-SiC inokuhamba okuhle kakhulu kwe-thermal futhi ingasebenza emazingeni okushisa aphezulu, iyenze ifaneleke amandla aphezulu kanye nezinhlelo zokusebenza ze-elekthronikhi eziyimvamisa ephezulu.

I-High Breakdown Voltage: Izinto ze-SiC zine-voltage ephezulu yokuphuka futhi zingamelana nezinkundla zikagesi eziphakeme ngaphandle kokuphuka kukagesi.

Ukulahleka Kwamandla Okuncishisiwe: Ama-substrates e-SiC avumela ukuguqulwa kwamandla okusebenza kahle kakhudlwana nokuncipha kwamandla kumishini kagesi uma kuqhathaniswa nezinto ezivamile ezisekelwe ku-silicon.

Umkhawulokudonsa obanzi: I-SiC inomkhawulokudonsa obanzi, ovumela ukuthuthukiswa kwezinto zikagesi ezingasebenza emazingeni okushisa aphezulu kanye nokuminyana kwamandla aphezulu.

Ngakho-ke i-Semi-insulating SiC ku-Si composite substrates ihlanganisa ukuhambisana kwe-silicon nezici eziphakeme zikagesi nezishisayo ze-SiC, iyenze ifanelekele izinhlelo zokusebenza ze-elekthronikhi ezisebenza kahle.

Ukupakisha Nokulethwa

1. Sizosebenzisa ipulasitiki evikelayo kanye nebhokisi elenziwe ngezifiso ukupakisha. (Izinto ezilungele imvelo)

2. Singenza ukupakisha ngokwezifiso ngokusho nenani.

3. I-DHL/Fedex/UPS Express ivamise ukuthatha cishe izinsuku ezi-3-7 zokusebenza ukuya endaweni.

Umdwebo onemininingwane